Page 2English Manual 1019622-C

Table of Contents + Safety

OPERATE SAFELY

Read Before Using:

Pesticides can cause personal injury and harm the envir-

onment when used improperly. Be sure to follow label

recommendations concerning safety and disposal.

SET-UP PROCEDURE

The SPYDSB-9G was pressure tested prior to shipment.

Some components were disassembled for packaging and

shipment. The basic set-up procedure is as follows:

• Remove the spray wand from inside the tank.

• Remove all contents from the box.

• Cut the plastic ties holding the boom sections together.

• Report any missing or damaged items to your dealer

immediately.

NOTE: The pink liquid residue in the tank is RV antifreeze.

Flush out the tank before use.

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . 2

Parts . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Assembly . . . . . . . . . . . . . . . . . . 9 - 11

Use and Care

Operation & Maintenance . . . . . . 12

Initial Start-Up & Pressure . . . . . 12

Battery Recharging . . . . . . . . . . . 13

Spray Nozzle Settings . . . . . . . . . 13

Calibration . . . . . . . . . . . . . . . . . 14

Troubleshooting . . . . . . . . . . . . . 15

Accessories . . . . . . . . . . . . . . . . . 16

Warranty . . . . . . . . . . . . . . . . . . . . . 18

Observe all safety precautions including

wearing of protective clothing and equipment.

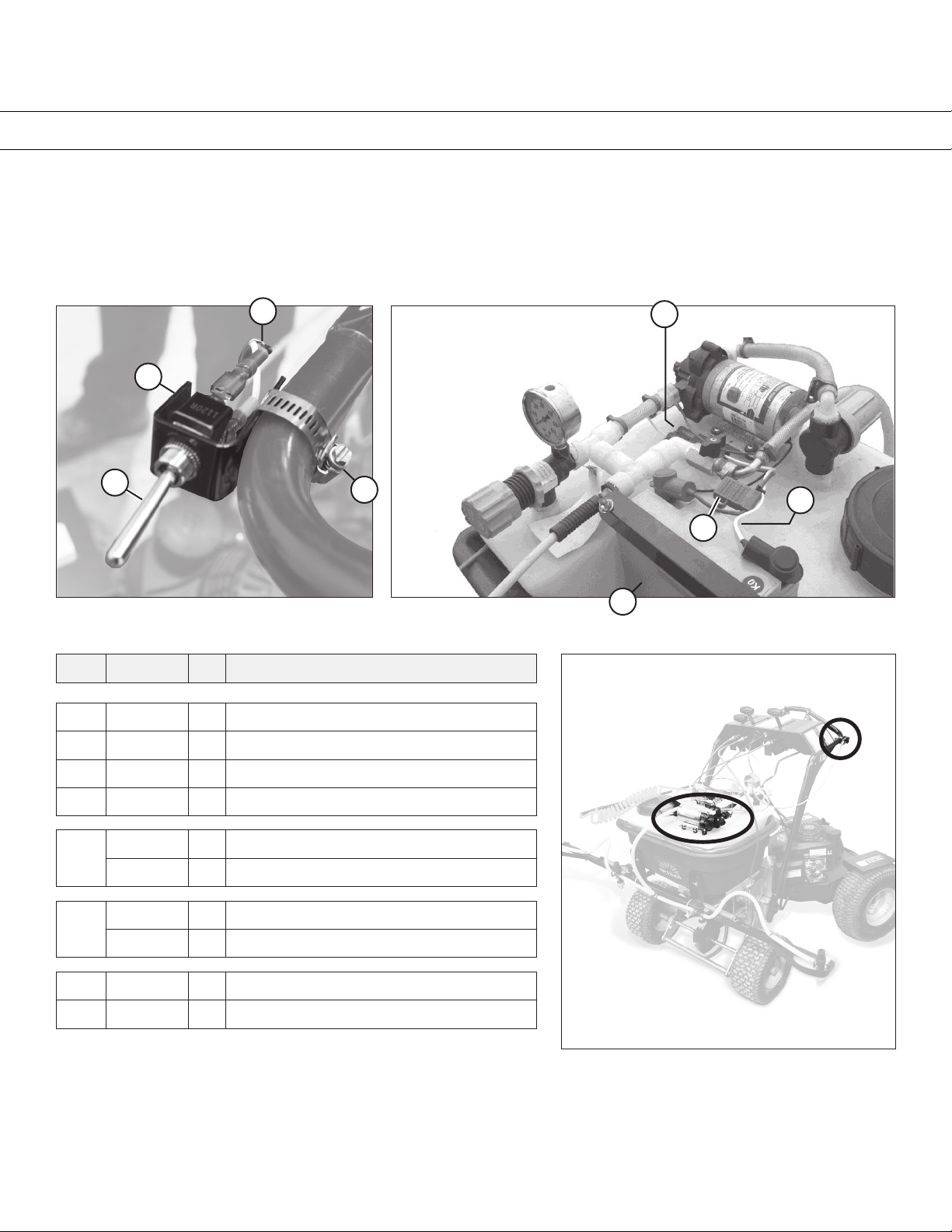

COMPATIBILITY

The SPYDSB-9G is designed to fit the

following spreaders:

SPYKER • S10 0 -12011

LESCO • 101186

• 105821

• HPS Chariot