8695 4985

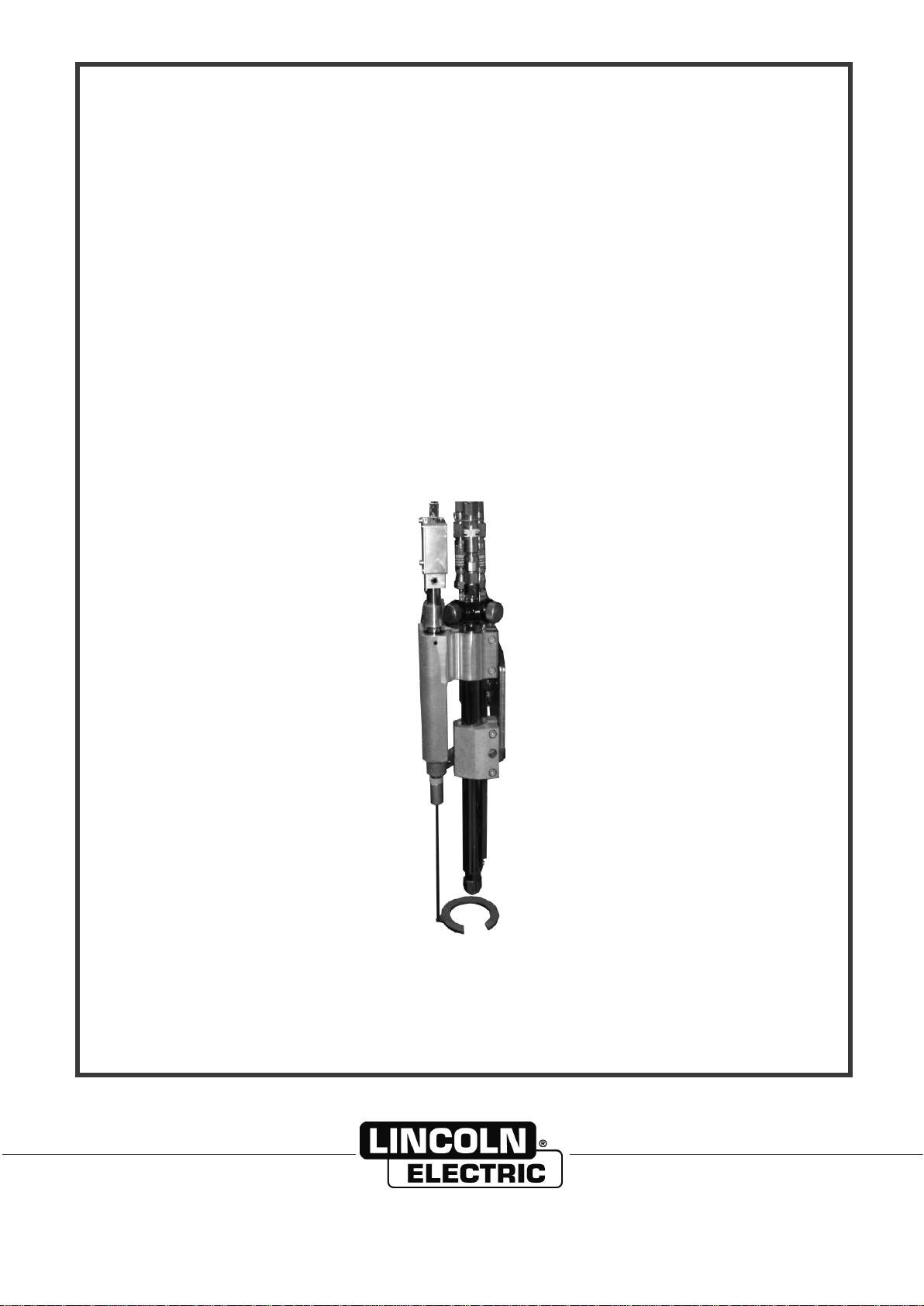

ESSENTIAL OXYCUTTING I

CONTENTS

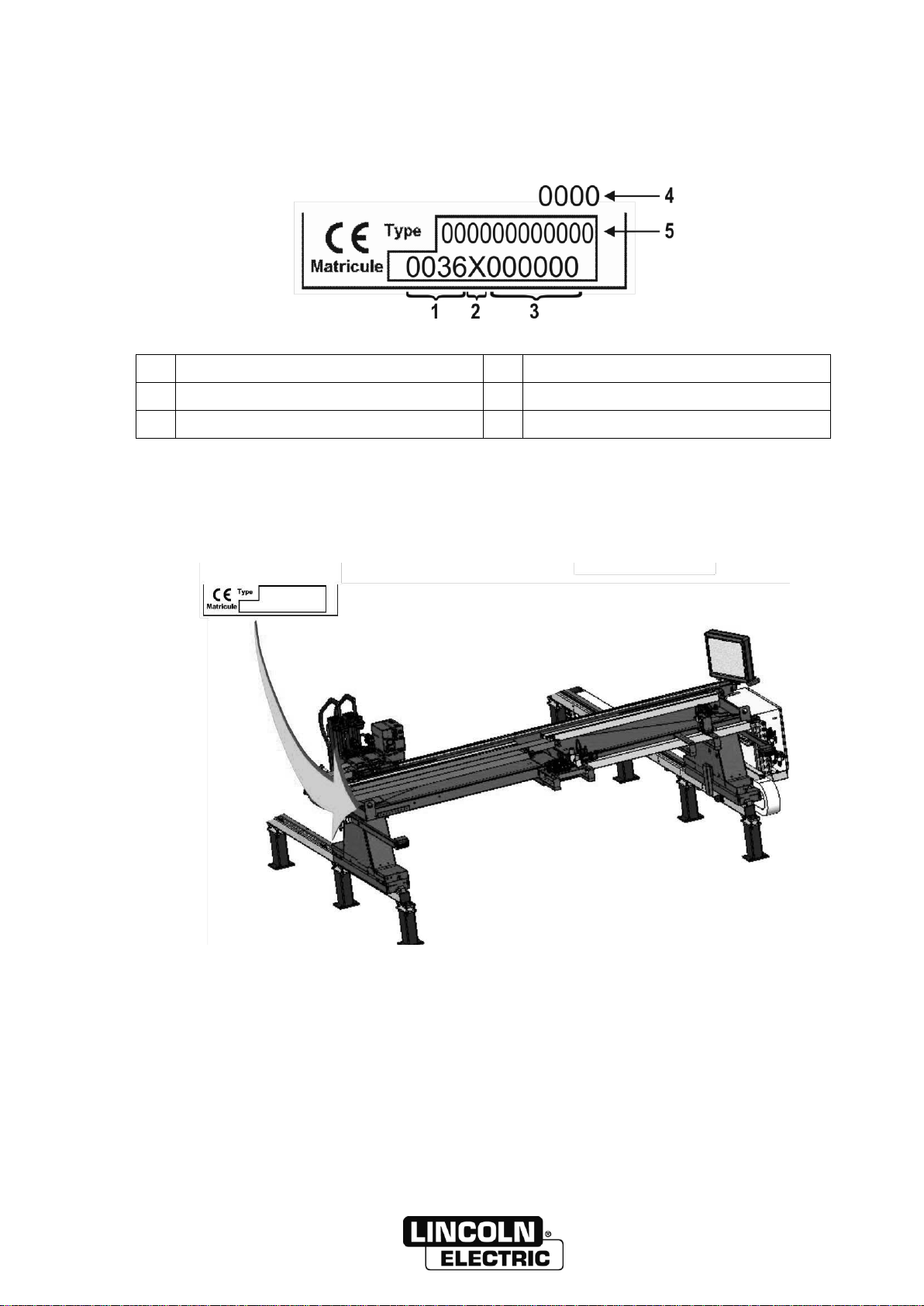

A - IDENTIFICATION.........................................................................................................................1

B - SAFETY INSTRUCTIONS............................................................................................................3

1 - GENERAL SAFETY INSTRUCTIONS................................................................................3

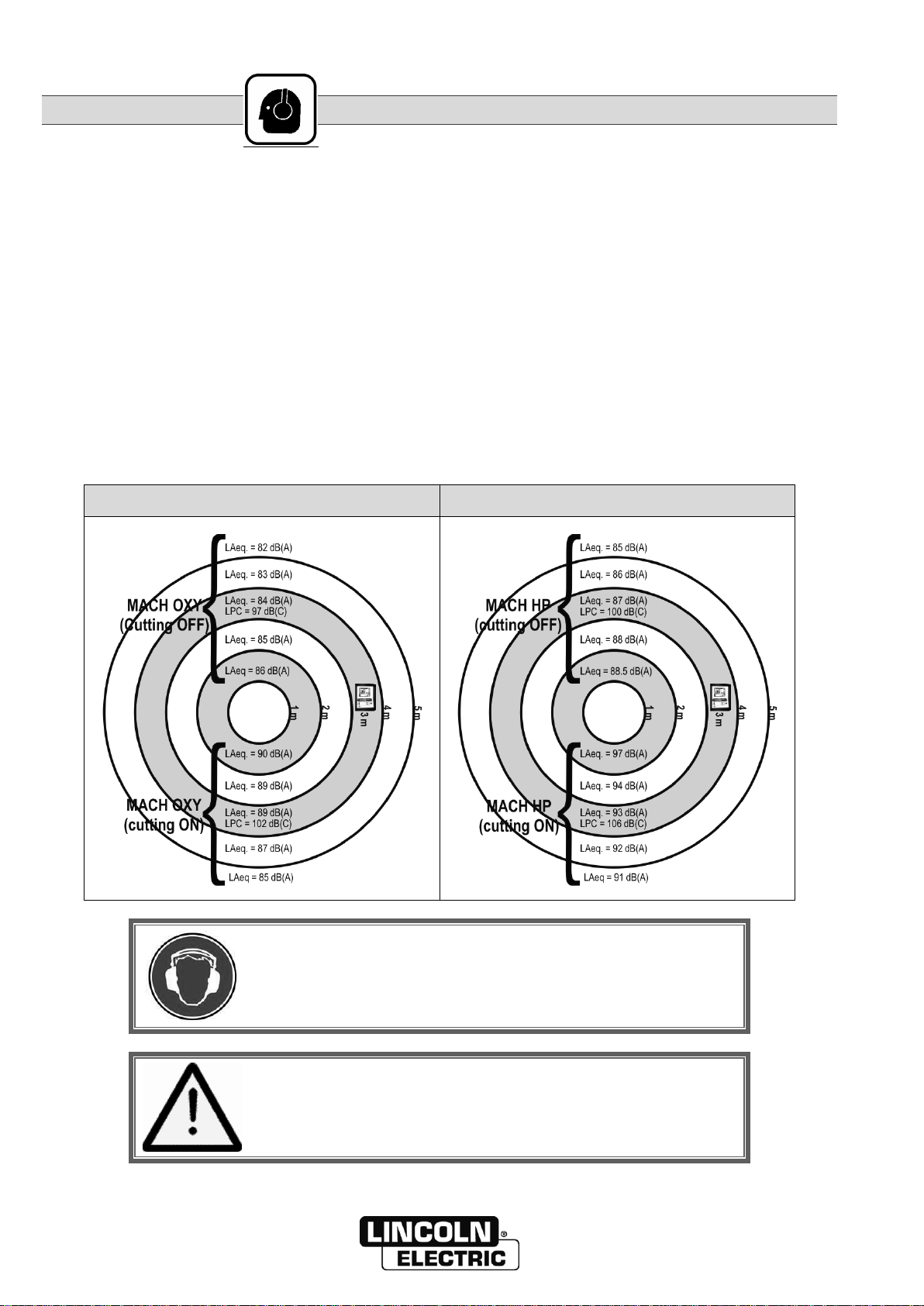

2 - AIRBORNE NOISE .............................................................................................................4

3 - ELECTRICAL SAFETY.......................................................................................................5

4 - USE OF PERSONAL PROTECTIVE EQUIPMENT............................................................5

5 - INSTRUCTIONS FOR THE USE OF GAS .........................................................................5

6 - CONDITIONS FOR USE.....................................................................................................6

7 - RISK OF HEATING.............................................................................................................7

C - DESCRIPTION .............................................................................................................................9

1 - POSSIBILITIES OF THE ESSENTIAL OXYCUTTING INSTALLATION............................9

2 - INSTALLATION ON LINCOLN ELECTRIC MACHINE.......................................................10

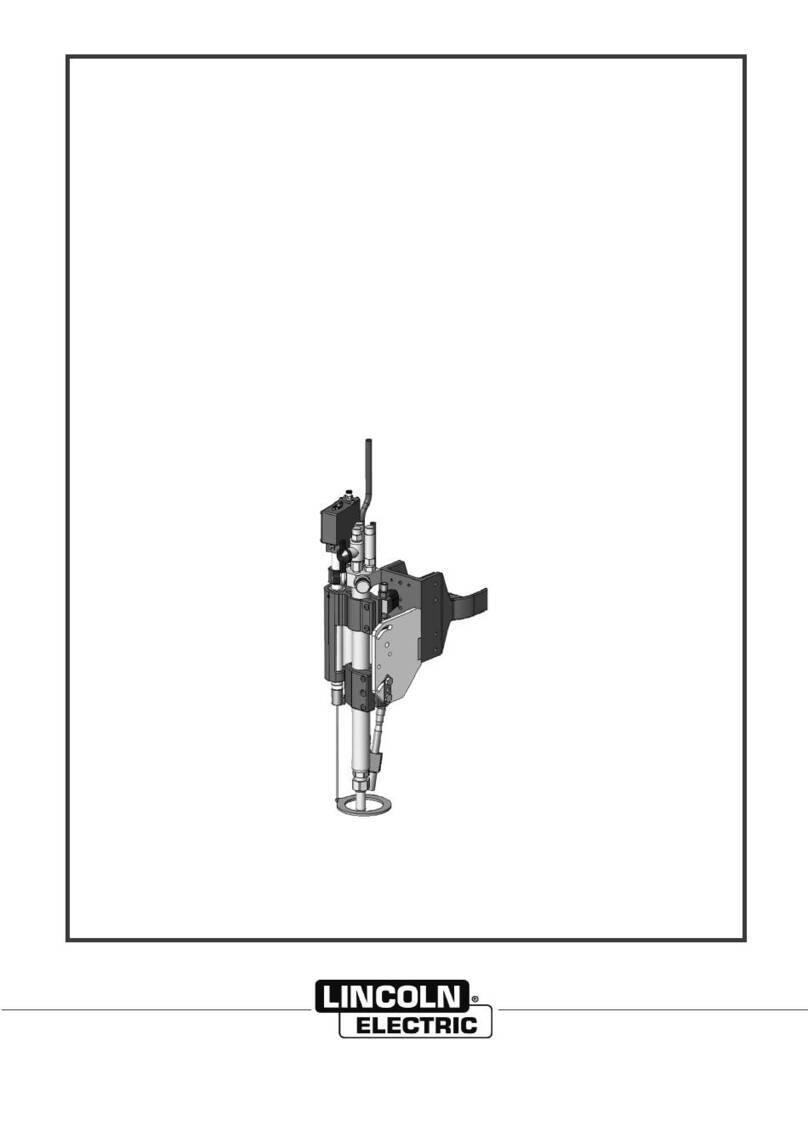

3 - ESSENTIAL OXY CUTTING GAS ASSEMBLY (REF. A)...................................................12

4 - CYCLE FUNCTION ASSEMBLY........................................................................................13

5 - ESSENTIAL OXYCUTTING SOLENOID VALVE ASSEMBLY (REF. B)............................13

6 - LONGITUDINAL BUNDLES (FL)........................................................................................14

7 - TRANSVERSE BUNDLES (FT)..........................................................................................14

8 - TOOL HOLDER (REFERENCE P) .....................................................................................14

9 - TORCH OPTION (REFERENCE OC).................................................................................15

10 - FUEL GAS REGULATION KIT .........................................................................................15

D - MONTAGE INSTALLATION........................................................................................................17

1 - CONDITIONS OF INSTALLATION.....................................................................................17

2 - CONNECTION....................................................................................................................19

E - OPERATOR MANUAL.................................................................................................................21

1 - OPERATOR CONTROLS...................................................................................................21

2 - ADJUSTMENTS..................................................................................................................22

3 - GAS SUPPLY CHANGE.....................................................................................................22

4 - CYCLE ................................................................................................................................23

F - MAINTENANCE............................................................................................................................25

1 - SERVICING.........................................................................................................................25

2 - TROUBLESHOOTING........................................................................................................27

3 - SPARE PARTS...................................................................................................................31

PERSONAL NOTES ..........................................................................................................................38