Metallkraft UB 10 User manual

UB 10

Instruction Manual

UB 10

Universal bending machine

UB 10

2 UB 10 | Version 2.01

Imprint

Product identification

Universal bending machine Item number

UB 10 3776010

Manufacturer

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt/Bamberg

Fax: 0049 (0) 951 96555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Indications regarding the operating instructions

Original instructions

Edition: 28.01.2019

Version: 2.01

Language: English

Author: FL

Indications regarding the copyright

Copyright © 2019 St rmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the sole

property of the company St rmer.

Passing on as well as copying of this document, the use

and distribution of its content are prohibited if not explic-

itly permitted. Contraventions are liable to compensa-

tion.

Subject to technical modifications and error.

Contents

1 Introduction ............................................. 3

1.1 Coypright ............................................................ 3

1.2 Customer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Requirements to staff.......................................... 4

2.3 Personal protective equipment ........................... 4

2.4 General safety instructions ................................. 5

3 Intended Use............................................ 5

3.1 Misuse ................................................................ 6

3.2 Residual risks ..................................................... 6

3.3 Technical condition............................................. 6

4 Technical Data.........................................

5 Transport, packaging, storage............... 7

5.1 Delivery and Transport ....................................... 7

5.2 Packaging........................................................... 7

5.3 Storage ............................................................... 7

Description of the device ....................... 7

7 Assembly ................................................. 7

7.1 Set up ................................................................. 8

8 Work and operation ................................ 8

8.1 Application of the eccentric counter-holder......... 8

8.2 The production of U-shaped tabs ..................... 10

8.3 Production of handles....................................... 11

8.4 The production of pipe supports ....................... 12

8.5

The production of U-shaped tabs and mounting

brackets............................................................. 14

9 Special accessories .............................. 15

9.1 Bending segment for spirals ............................. 15

9.2 Heating pipe bending roll set ............................ 16

9.3 Clamp ............................................................... 16

9.4 Adjustable stop 10-200..................................... 16

10 Care, maintenance and repair............ 1

10.1 Maintenance ................................................... 17

10.2 Repair ............................................................ 17

11

Disposal, recycling of used devices

.... 17

11.1 Decommissioning ........................................... 17

11.2 Disposal of new equipment packaging ........... 17

12 Spare parts .......................................... 18

12.1 Ordering spare parts....................................... 18

13 Spare parts drawing............................ 19

14 Declaration........................................... 20

15 Notes .................................................... 21

Introduction

UB 10 | Version 2.01 3

1 Introduction

You have made a good choice by purchasing the ME-

TALLKRAFT Bending machine.

Read the operating manual thoroughly before com-

missioning the machine.

It gives you information about the proper commissioning,

intended use and safe and efficient operation and main-

tenance of your bending machine.

The operating manual is part of the bending machine

package. Always keep this operating manual in the loca-

tion where your bending machine is being operated. All

local accident prevention regulations and general safety

instructions for the operating range of your bending ma-

chine must also be complied with.

1.1 Coypright

The contents of these instructions are copyright. They

may be used in conjunction with the operation of the de-

vice. Any application beyond those described is not per-

mitted without the written approval of St rmer GmbH.

For the protection of our products, we shall register tra-

demark, patent and design rights, as this is possible in

individual cases. We strongly oppose any infringement

of our intellectual property.

1.2 Customer service

Please contact your dealer if you have questions con-

cerning your Bead bending machine or if you need tech-

nical advice. They will help you with specialist informa-

tion and expert advice.

Germany:

St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

Repair service:

Fax: 0049 (0) 951 96555-111

E-Mail: [email protected]

Internet: www.metallkraft.de

Spare part orders:

Fax: 0049 (0) 951 96555-119

E-Mail: [email protected]

We are always interested in valuable experience and

knowledge gained from using the application-which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised while taking applicable standards and

rules, the state-of-the-art technology and our long-term

knowledge and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use

- Use of untrained staff,

- Unauthorised modifications

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery condi-ti-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This section provides an overview of all major safety

pac-kages for personal protection and safe and trouble-

free operation. Further task-related safety instructions

are contained in the individual chapters.The term "ma-

chine" below replaces the usual trade name of the object

to which these operating instructions refer (see cover

sheet).

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-

cates an imminently dangerous situation which may

lead to death or severe injury if not avoided.

WARNING!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to death or severe injury if not avoided.

4 UB 10 | Version 2.01

Safety

Tips and recommendations

It is necessary to observe the safety notes written in

these operating instructions in order to reduce the risk of

personal injuries and damages to property.

2.2 Requirements to staff

The different tasks described in this manual represent

different requirements to the qualification of the persons

entrusted with these tasks.

Only persons reliable working procedures can be ex-

pected from, are allowed to perform all works. Persons

the responsiveness of which is affected by e. g. drugs,

alcohol or medication, are not allowed to work with the

machine.

The qualifications of the personnel for the different tasks

are mentioned below:

Operator

The operator is instructed by the operating company

about the assigned tasks and possible risks in case of

improper behaviour. Any tasks which need to be per-for-

med beyond the operation in the standard mode must

only be performed by the operator if it is indicated in

these instructions and if the operating company expres-

sively commissioned the operator.

Qualified personnel

Due to their professional training, knowledge and experi-

ence as well as their knowledge of relevant regulations

the specialist staff is able to perform the assigned tasks

and to recognise and avoid any possible dangers them-

selves.

Manufacturer

Certain works may only be performed by specialist per-

sonnel of the manufacturer. Other personnel is not au-

thorized to perform these works. Please contact our cus-

tomer service for the execution of all arising work.

2.3 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff member has to wear personal protec-tive

equipment while performing different tasks on and with

the machine which are indicated in the individual para-

graphs of these instructions.

The personal protective equipment is explained in the

following paragraph:

CAUTION!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to slight or minor injury if not avoided.

NOTE!

This combination of symbol and signal words indi-

cates a potentially dangerous situation which may

lead to material or environmental damage if not avoi-

ded.

Tips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

WARNING!

Danger in case of insufficient quali-

fication of the staff!!

Insufficiently qualified persons cannot estimate the

risks while using the vacuum cleaner and expose

themselves and others to the danger of severe or let-

hal injuries.

- Have all works only performed by qualified persons.

- Keep insufficiently qualified persons out of the work-

ing area.

Eye protection

The goggles protect the eyes from flying parts and

liquid splashes.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Safety boots

Safety boots protect the feet from being crushed, fall-

ing parts and slipping over on slippery ground.

Protective clothes

Protective clothes are made of a tightly fitted fabric

without the protruding parts of low tear strength.

Intended Use

UB 10 | Version 2.01 5

2.4 General safety instructions

Please note the following:

- Use the guards and secure them securely. Never work

without guards and get them working.

- Always keep the machine and its working environment

clean. Ensure adequate lighting.

- The universal bending machine must not be modified in

design and should not be used for purposes other than

those foreseen by the manufacturer.

- Never work under the influence of concentration-distur-

bing illnesses, fatigue, drugs, alcohol or medicines.

- Keep children and persons not familiar with the Univer-

sal Bending Machine away from their work environ-

ment.

- Eliminate disturbances that affect safety immediately.

- Protect the universal bending machine from moisture.

- Before each use of the Universal Bending Machine,

make sure that no parts are damaged. Damaged parts

must be replaced immediately to avoid any danger.

- Do not overload the universal bending machine! You

work better and safer in the specified performance

range. Use the right tool! Make sure the tools are not

dull or damaged

- Only use original spare parts and accessories to avoid

possible dangers and accident risks.

- To avoid injury from crushing, pay attention to the shea-

ring edges during transport, cleaning and when using

the machine.

- Always make sure that you never get any body parts

into the bending area when using the machine.

- Avoid unnatural posture and maintain balance at all

times. Wear work shoes to increase their stability.

- If you pass on this bending machine, you must hand

over all the tools and documents supplied with the ben-

ding machine.

- Due to the forces occurring during the forming process,

the machine must be firmly connected to the ground to

absorb the reaction forces.

- Before and during work, check the work area so that

there are no unauthorized persons in it. Do not allow

the bending machine to be touched by other persons,

especially children.

- Maintain the machine with care. Keep the bending ma-

chine clean in order to be able to work well and safely in

the long term. Follow the instructions for maintenance.

- Remove oil and grease residues from the handle and

keep it dry.

- Observe the maximum dimensions of the workpieces

given in the technical data

- Before starting the bending machine work, find out

about the type of material to be processed.

- Do not overload the bending machine. It works better

and safer in the specified field of application.

- Check the stability of the machine and, if necessary,

the secure screw connection with the foundation.

- Please note that the use of other tools and other acces-

sories may result in injury to you.

- Always work on only one workpiece.

- Damaged machine parts must be replaced or repaired

as intended by a recognized specialist workshop.

- Make sure that only original spare parts are used du-

ring repairs. Otherwise, the operator is at risk of acci-

dents.

3 Intended Use

The universal bending machine is suitable for bending

flat, rectangular and round sections and for heating pi-

pes. A rational way to bend usual shapes and curves.

The machine is light enough and can be carried to diffe-

rent workplaces.

The compact dimensions of the Universal Bending Ma-

chine UB 10 ensure easy handling. It is suitable for both

private and commercial use.

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or

otherwise is considered misuse.

WARNING!

The improper use of this device as well as the disre-

gard of the safety instructions or operating instructi-

ons in the operating instructions exclude any liability

of the manufacturer for resulting damage to persons

or objects.

WARNING!

Danger in case of misuse!!

Misuse of the universal bending machine can lead to

dangerous situations.

- Only operate the Universal Bending Machine in the

performance range specified in the technical data.

- Never bypass or override the safety devices.

- Only operate the Universal Bending Machine in a

technically perfect condition.

6 UB 10 | Version 2.01

Technical Data

3.1 Misuse

If the intended use is observed, no reasonably foresee-

able misuse is possible, which could lead to dangerous

situations with personal injury.

3.2 Residual risks

Even if all safety regulations are observed and the ma-

chine is used correctly, there are still residual risks listed

below:

- There is a risk of injury to the upper limbs (e.g., hands, fin-

gers).

- Danger from falling workpieces

- Danger of pulling in clothes and objects.

- During set-up and set-up work, it may be necessary to dis-

mantle on-site protective equipment. This creates various

residual risks and potential dangers that every operator

must be aware of.

3.3 Technical condition

The Universal Bending Machine UB 10 complies with the

current state of the art in design and execution and is

built according to the recognized safety rules.

Please note the following:

- Before each use, the machine should be checked

for externally visible damage.

- During each use, the operating behavior is obser-

ved.

- In the event of safety-relevant deviations from the

delivery condition, the machine must be inspected by

an authorized specialist and, if necessary, repaired.

- From the point in time when the machine no longer

meets the normal operating conditions, the bending

machine must be taken out of service until repaired.

3.3.1 Machine operation

The bending machine can be dangerous if it is not used

in accordance with the chess and intended purpose.

In addition to the health and safety instructions in this

operating manual, the generally applicable safety and

accident prevention regulations for protection against the

risk of injury must be observed and adhered to.The work

instructions in the individual chapters of the operating in-

structions must be followed. The safety instructions must

be observed under all circumstances. Despite observing

all working instructions, safety and accident prevention

regulations, there remains a residual risk when handling

the machine. Through concentrated and forward-looking

work and action, you can reduce the residual risk.

4 Technical Data

Scope of delivery:

- Bending rollers: 2 x Ø 24/30/37/43/49/62/75 mm

Optional accessories:

- Heating pipe bending roller set

Item number: 3790001

- Bending roller set 10-180

Item number: 3790002

- Adjustable stop 10-200

Item number: 3790003

- Clamping plate

Item number: 3790004

- Conversion kit for UB 10 to RB 30

Item number:3790006

- Helical bending element UB 11

Item number:3790011

-

Separate holding handle for helical bending element UB 11

Item number: 3790280

DANGER!

The machine may only be operated in a technically

perfect condition. Any faults must be eliminated im-

mediately.

DANGER!

Unauthorized modifications or changes, especially

those that affect the safety of the machine operator,

are generally prohibited. Technical changes, conver-

sions and extensions made by the user on the ma-

chine may void the machine's operating license and

are the responsibility of the operator.

ATTENTION!

In the interest of further technical development or

changing regulations, the manufacturer reserves the

right to make changes to the characteristics of the

product at any time without prior notice.

Technical Data UB 10

Pipes G 3/4 "

Weight 32 kg

Flat steel: plate rolling 10 x 50 mm

Flat steel: acute bending 6 x 50 mm

Round materials Steel/Aluminium/Copper

16 mm

Round materials stainless steel

14 mm

Square materials Steel/Aluminium/Copper

16 x 16 mm

Square materials stainless steel 14 x 14 mm

Transport, packaging, storage

UB 10 | Version 2.01 7

5 Transport, packaging, storage

5.1 Delivery and Transport

Delivery

Check the Machine on delivery for any visi-ble transpor-

tation damage. If you notice any damage to the device

please report this immediately to the carrier or dealer.

Transport

Remove the factory-prepared antirust agent with thinner

or paint remover before installing the device. Then lubri-

cate with machine oil. Make sure that the device is not

set up or put into operation in a damp or wet environ-

ment. The humidity should not exceed 60% and the

measured room temperature should be between max. 0

° C and 40 ° C amount. .

5.2 Packaging

All used packaging materials and packaging aids are re-

cyclable and should be taken to a materials recycling de-

pot to be disposed of.

The delivery packaging is made of cardboard, so please

dispose carefully by having it chopped up and given to

the recycling collection

The film is made of polyethylene (PE) and the cushioned

parts of polystyrene (PS). Deliver these substances to a

collection point for recyclable materials or to the waste

disposal company which looks after your region.

5.3 Storage

Thoroughly clean the Universal Bending Machine in a

dry, clean and frost-free environment.

The universal bending machine must not be parked in a

room with chemicals.

If the machine is stored for a long time, all bare metal

parts must be greased against rusting.

6 Description of the device

Illustrations in this operating manual serve the gene-

ral understanding and may deviate from the actual

design.

Fig. 1: Description of the device

7 Assembly

Please note the following:

- Make sure that all bolts are inserted correctly and

in the proper place.

Fig. 2: Assembly

NOTE!

For a safe stand, it is recommended to attach the de-

vice to a stable and stable surface using the holes pro-

vided on the bottom of the device.

Adjusting pin

Bending

arm

Eccentric counterholder

Bending

unit

bending

rollers for

round

material

Frame

Bending rollers for flat

material

8 UB 10 | Version 2.01

Work and operation

1 screw

2 screw

3 Nut

4 spacer tube

5 spacer ring

7.1 Set up

Mount the machine firmly on the ground at a suitable

location.

Note the following:

• Make sure you have enough space around the ma-

chine (see Fig. 3).

• Make sure that the bending machine is firmly screwed

to the floor.

Fig. 3: Set up example

8 Work and operation

Information about the use of the machine

• Do not bend other steels than standard structural steel.

(8 x 50 mm and round steel up to Ø16 mm, rectangular

steel up to a size of 14 x 14 mm and heating pipes up to

a size of G3 / 4˝!

• Do not bend materials thicker than 6 mm around the

center pin. Always use the Ø24 mm rollers to prevent the

bolt from bending.

• Do not use additional lever extension.

• Do not use the right-angle bending accessory to bend

wooden blocks.

• When using the right angle bend accessory, bend only

standard steel up to 6 x 50 mm or 7 x 30 mm.

• Keep the work area around the machine clean to avoid

unnecessary accidents.

• Preventing the bending roller from dropping suddenly

could cause serious injury.

• When shearing, edging and bending, you can mount a

rip fence. To do this, screw the guide pins of the rip fence

to the frame.

8.1 Application of the eccentric counter-holder

This counterholder in the bending arm ensures that the

material is firmly clamped during the bending process.

Fig. 4: Counter-holder

The eccentric anvil offers four positions. Always use the

proper position to bring the anvil as close as possible to

the center pin or roller, but make sure that a small gap is

left for the material.

To reach two of the four positions, the anvil must rotate

from side to side. If the hole is to the left of the center, the

backstop will slip and thus the material will. If you are

using a large bending roller, insert the counterholder and

stop into the corresponding hole so that the material is

firmly attached. Place the anvil as close to the central

bolt or to the bending roller as possible and turn the anvil

into one of the four positions. You can adjust the stop on

the support plate by one hole forward or backward to

achieve the required clearance.

Too large a distance between the central bolt or the ben-

ding roller and the stop causes the slipping of the mate-

rial and thus an inaccurate bending radius.

If a very accurate bend radius is desired, it is prudent to

secure the material with a retainer clip against the anvil

to prevent the material from slipping.

Wall

Work and operation

UB 10 | Version 2.01 9

Fig. 5: Centering the counter-holder

In most cases it is not necessary to use a retaining clip

when using an anvil. However, you can use a holder

clamp, if you want to make special curvatures.

Fig. 6: Right Position of the counterholder

Examples of the eccentric counterhold for each "correct"

position:

Position 1

Bender for flat material or round material of mm: Ø

37 m

Fig. 7: Example Position 1

Position 2

Bender for flat material or round material of mm: Ø

75 mm

Fig. 8: Example Position 2

Position 3

Flat or round material of mm: use central bolt

Fig. 9: Example Position 3

10 UB 10 | Version 2.01

Work and operation

Position 4

Rectangular or round steel of 1 mm: Use Ø 30 mm

bending roller

Fig. 10: Example Position 4

Application of right-angle bending accessory

Fig. 11: Application of the bending accessory

If you want to bend a right angle, mark the location of the

sheet with chalk. When inserting the material into the

bending machine, make sure that the marked area is still

partially visible. The bending edge of the right-angle ben-

ding accessory covers the other side of the marked loca-

tion.

If two right angles are to be bent on the same flat mate-

rial (eg 5 x 25 mm), the marked points must be separa-

ted by 3 mm more than the required inner dimension. If

the material thickness is different, the corresponding

bending allowances must be taken into account

If very precise work is needed, first bend a specimen be-

fore bending a large amount. So you can find out if you

need to move the spot or if you need to lengthen or shor-

ten the material.

This instruction manual specifies the bending measure,

but if you are unsure about the dimensions, it is better to

use a narrower material than the required thick material,

which would be more expensive. If you are sure about

the bending and bending degree, make a note of it for

further use.

Fig. 12: Application of the bending accessory

The adjustable stop is used for equal curvatures. Make

sure that the screw is tight and that the stopper is tight.

Fig. 13: Chalk mark

This image shows the exact position of the chalk mark against

the bending edge of the right-angle bending accessory.

8.2 The production of U-shaped tabs

Preparing the material - The length of the material for U-

shaped tabs must be cut according to the size of the

bending element.

The holes in the carrier plate

The number of the hole in which the ex-centric counter-

holder is placed.

Fig. 14: Holes of the carrier plate

Work and operation

UB 10 | Version 2.01 11

The position of the eccentric counter-holder

The correct position of the counter-holder, according to

the thickness of the material to form U-shaped tabs.

Fig. 15: Position of the counter-holder

The distance to the eccentric counterholder

Before bending the material, measure the distance from

the eccentric anvil.

Fig. 16: Distance to the anvil

Bending roller

It is used in the bending fork.

The holes in the bending arm

The various holes in the bend of the bend arm show

where the bolt is placed to hold the bend roll.

Fig. 17: Holes in the bending arm

8.3 Production of handles

Round material

With the bending machine you can produce handles with

different shapes and sizes. Each of the three illustrated

handles has been bent by Ø 15 mm and a length of 230

mm steel. After bending the bends, drill a Ø 15 mm hole

in the tab. Then insert the handle into the tab and weld it

tight. Sand the rest off the tab to get a flat surface.

The correct position of the eccentric counter-holder is gi-

ven by the diameter of the material (see picture on the

right). After you have made the first bend, you must turn

the material 90 ° and bend the other end 90 °.

Fig. 18: Production of handles

Flat material

Chalk the workpiece as shown in the picture. The mar-

kings on the ends must be on one side of the material,

the inside on the other side.

The dimensions in the illustration can be replaced by

others. Depending on the user's idea of the universal

bending machine.

Fig. 19: Production of handles with flat material

1. Curvature

Insert a flat material up to the mark (1) and bend it by 90

°. Check the angle before proceeding. Attach the eccent-

ric counterhold so that the respective angles are 90 °.

Distance

NOTE!

When using a different diameter material for the hand-

le, the diameter of the hole in the tab must be identical

to the diameter of the handle.

12 UB 10 | Version 2.01

Work and operation

Fig. 20: Curvature 1

2. Curvature

Turn the material and insert it to the mark 2. Again, turn a

90 ° angle here.

Fig. 21: Curvature 2

3. Curvature

Turn over the half-finished product and place it in the de-

vice up to mark 3. Bend another 90 ° angle.

Fig. 22: Curvature 3

4. Curvature

Turn the half finished product over and repeat step 3.

Fig. 23: Curvature 4

8.4 The production of pipe supports

Fig. 24: Manufacturing pipe clamp

1.Curvature

Put the eccentric anvil in position Then insert the mate-

rial into the bending machine as in the picture. Use the

manual lever to bend the material until the bender roller

reaches the material end.

Fig. 25: Curvature 1

Pipe clamp

Work and operation

UB 10 | Version 2.01 13

2. Curvature

Insert the right angle accessory. Insert the product so

that the curvature lies on the bolt. Insert the stop into

hole 6 (clockwise). Now bend the material with the lever,

so that the lever is about 3 mm from the bolt.

Fig. 26: Curvature 2

Attach the retaining clip to the end of the stopper to pre-

vent the material from slipping.

You can also make many other types of clamps. Write

down the work steps for the different types of clamps.

This will help you later if you want to make it again.

Fig. 27: Production double pipe clamp

1. Curvature

Insert the material into the bender as shown in the

picture. Use the lever to bend it until the bender roller re-

aches the end of the material.

Fig. 28: Curvature 1

2. Curvature

Turn over the half-finished product and place it in the

bending device. (See image). Now take the lever and

bend the material until the bending roller reaches the end

of the material.

Fig. 29: Curvature 2

3. Curvature

Attach the right angle attachment. Now insert the mate-

rial as far as possible into the bending device, so that it

leans against the central bolt. (You must take out the

central bolt). Insert the stop in hole 6 clockwise. Move

the bending lever so far that it is approx. 3 mm away

from the stop.

Fig. 30: Curvature 3

4. Curvature

Turn the half-finished product over to the other end. Now

insert the material as far as possible into the bending de-

vice, so that it leans against the central bolt. (You must

take out the central bolt again). Now bend the material.

The lever must be 3 mm away from the stop.

Fig. 31: Curvature 4

Pipe clamp

14 UB 10 | Version 2.01

Work and operation

8.5 The production of U-shaped tabs and

mounting brackets

Before you start making U-shaped tabs, try bending a

pattern first. Check all sizes and make the necessary

changes.

Fig. 32: Finishing U-shaped tabs

Always move the eccentric anvil so that it is as close to

the bolt or bender as possible to prevent the material

from slipping.

If you want to extend the U-shaped tab, you will first find

out how much material you need for it. Now you have to

add twice the amount.

Example: If you want to extend the tab by 25 mm, you

must add 50 mm over the total length. The distance from

the eccentric anvil to the material end will only increase

by 25 mm. The other 25 mm are for the other end. The

bending machine has bending rolls of different sizes.

This allows you to bend different U-shaped tabs. Always

use rollers on the center bolt when working with a mate-

rial thicker than 9 mm. Otherwise you could accidentally

bend the bolt. The material is stretched during the ben-

ding process. This stretch is different for each material.

For this reason, we recommend that you test the stretch

even if you use this manual.

Make a note of the diameters of the bending rolls and the

dimensional deviation of the elongation. So you can save

time in a repeated production.

Fig. 33: Correct arrangement

Example 1

For a 9 mm screw with a length of 310 mm, the distance

from the eccentric anvil to the stop is 2.15 mm.

Fig. 34: Example 1

Example 2

For a screw with a length of 310 mm and a thickness of

12 mm, the distance from the eccentric counter-holder to

the stop is 1.15 mm.

Fig. 35: Example 2

Special accessories

UB 10 | Version 2.01 15

Example 3

For screws with a length of 315 mm and a thickness of

15 mm, the distance from the eccentric anvil is 6 mm.

Fig. 36: Example 3

The sizes given here are suitable for making 250 mm

long screws. However, you can always vary the length

by simply shortening or lengthening the length. You can

also change the length of the material after curvature by

reducing or extending the length of the eccentric anvil.

Make sure that a sufficient length of material leans

against the counterholder.

9 Special accessories

9.1 Bending segment for spirals

The bending segment is supplied as a separate acces-

sory and can bend a hot rolled material of 5 x 25 mm.

The edge of the segment bends the material in a spiral. If

you want to make several spirals of the same shape,

mark the top of the bend segment where the first spiral

stops. If you bend the other spirals up to this mark, the si-

zes of the spirals will all be the same.

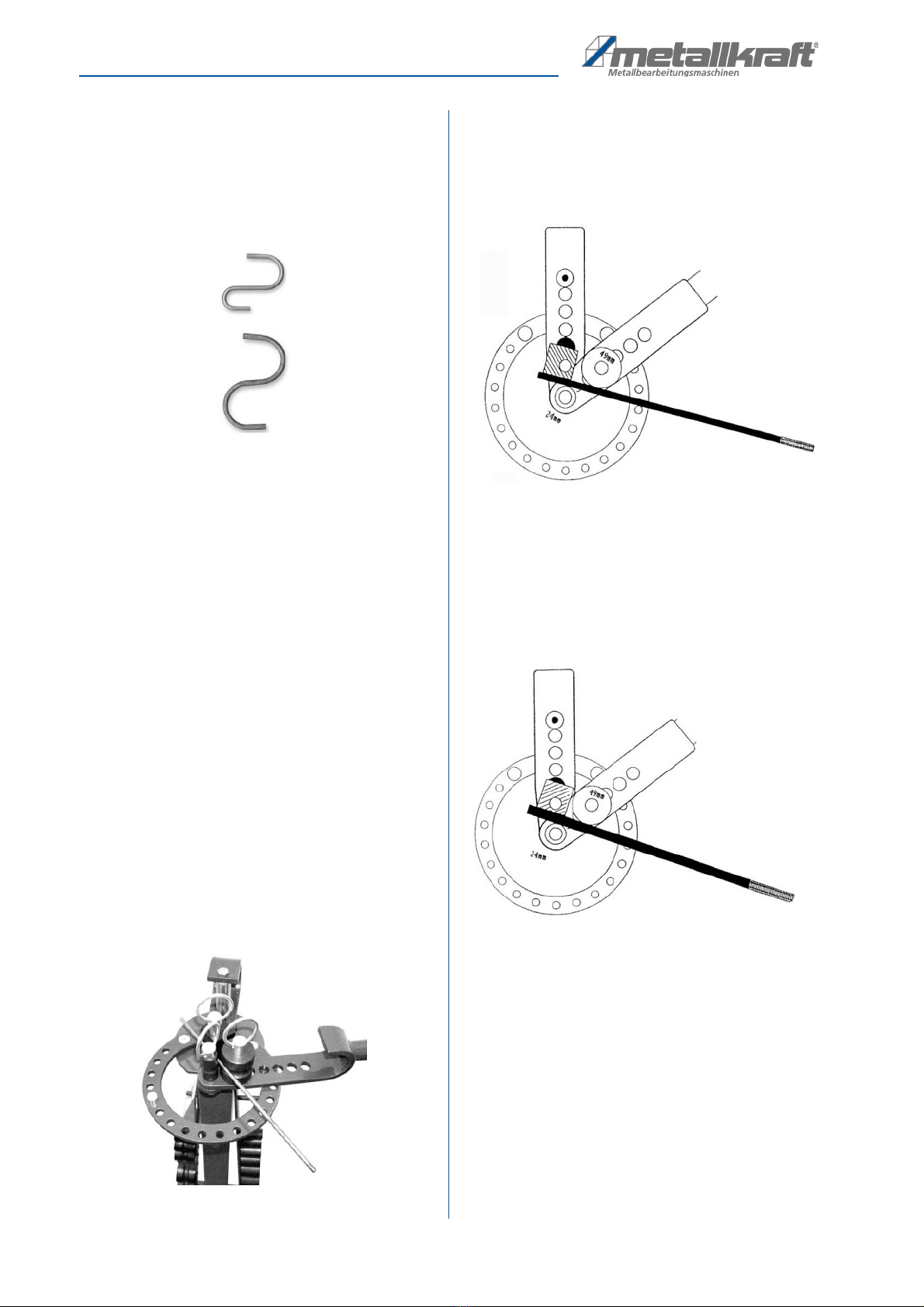

Fig. 37: Bending segments for spirals

By bending large and small spirals, you must first insert

the fence and the bend segment into hole 2.

Fig. 38: Insert stop

If you would like to produce a large spiral after the first

phase of bending, remove the stop of the bending seg-

ment from hole 2 and insert them into hole 5 (at the very

end).

Fig. 39: Making a big spiral

Do not bend a large spiral when the fence and bend seg-

ment are in hole 5. You need to start with it when in hole

2, otherwise the spiral will not be formed properly.

Fig. 40: Produce a big spiral

16 UB 10 | Version 2.01

Care, maintenance and repair

Turn the spiral around as long as the bending segment

allows it. Take out the stop and the segment and place

them in the hole for the second bend and finish the spiral.

9.2 Heating pipe bending roll set

For cold bending of heating pipes of size G3 / 8 ", G1 /

2", G3 / 4 ". For a curvature of a heating pipe, a heating

pipe bending roll set is required (larger and smaller rolls).

The large roll is used as the middle and the material is

bent with it. The procedure is similar to the normal ben-

ding rollers.

Fig. 41: Heating tube bending rolls set

9.3 Clamp

It is used for mounting the dismantled bending unit of the

UB 10. For this you need three screws. The clamping

plate must be firmly mounted to an anchored workbench.

Fig. 42: Clamp

9.4 Adjustable stop 10-200

It is a universal, adjustable stop to produce material of the

same length for a series of bends. Use a screw and a nut

to secure the fence in the second or third hole.

Then turn the stopper so that the curved material is per-

pendicular to the outer side of the stopper. Fix the stopper

so that the material is parallel to the underside of the stop-

per. The adjustable stop can be fixed from both sides.

Fig. 43: Adjustable stop

10 Care, maintenance and repair

NOTE!

The pipe must not be bent more than 180 °, other-

wise it will jam in the bending roller.

Tips and recommendations

To ensure that the bending machine is always in

good operating condition, regular care and main-

tenance work must be carried out.

DANGER!

Danger due to insufficient qualifica-

tion of persons!!

Insufficiently qualified persons can not assess the

risks involved in maintenance work on the machine

and expose themselves and others to the risk of

serious injury.

- All maintenance work should only be carried out by

qualified persons.

NOTE!

Before servicing and maintenance the Universal

Bending Machine, the maintenance instructions must

be carefully read. The handling of the Universal Ben-

ding Machine is only permitted to persons who are

familiar with the Universal Bending Machine.

DANGER!

After servicing, maintenance and repair, check that all

panels and guards are properly installed on the machine

and that there is no more tool inside or in the working

area of the universal bending machine. Damaged safety

devices and equipment must be repaired or replaced by

the customer service.

Disposal, recycling of used devices

UB 10 | Version 2.01 17

10.1 Maintenance

General informations:

- Check the universal bending machine for damage

before and after each use.

- All moving parts must be lubricated at regular inter-

vals. Use only acid-free lubricants.

- Do not clean the universal bending machine with

aggressive chemicals, but only with a dry cloth.

- Do not store the universal bending machine outs-

ide and protect it from high humidity, cold or heat.

- The machine clean and the warehouse seats and

work surfaces of the work.

10.2 Repair

If the bending machine does not work properly, contact a

dealer or our customer service. The contact details can

be found in chapter 1.2 Customer Service.

11 Disposal, recycling of used devices

Please take care in your own interest and in the interest

of the environment that all component parts of the ma-

chine are only disposed of in the intended and permitted

way.

11.1 Decommissioning

Disused equipment must be taken out of service immedi-

ately in order to avoid later misuse and endangering the

environment or people.

- Dispose of all environmentally hazardous fluids from

the old device.

- If necessary, disassemble the machine into manage-

able and usable assemblies and components.

- Supply the machine components and operating materi-

als to the appropriate disposal channels.

11.2 Disposal of new equipment packaging

All packaging materials and packaging aids used in the

machine are recyclable and must always be recycled.

The packaging wood can be sent for disposal or recy-

cling.

Packaging components made of cardboard can be crus-

hed for waste paper collection.

The films are made of polyethylene (PE) or upholstery

parts made of polystyrene (PS). These substances can

be reused after reprocessing if they are forwarded to a

recycling center or to the disposal company responsible

for them.

Only pass on the packaging material sorted, so that it

can be directly recycled.

ATTENTION!

To avoid injuries caused by crushing, pay attention

by shearing edges during transport, cleaning and

when using the device.

NOTE!

Oil and grease cleaning agents are hazardous to the

environment and must not be disposed of in waste-

water or normal household waste. Dispose of these

funds in an environmentally friendly way. The

cleaning cloths soaked in oil, grease or detergent are

easily combustible. Collect them in a suitable, closed

container and dispose of them in an environmentally

friendly way - Do not throw in the trash!

DANGER!

Repair work may only be carried out by qualified per-

sonnel.

18 UB 10 | Version 2.01

Spare parts

12 Spare parts

12.1 Ordering spare parts

The spare parts can be obtained from the dealer or directly

from the manufacturer. The contact details are in chapter

1.2 Customer Service. Specify the following key data when

inquiring or ordering spare parts:

- Type of device

- Item No.

- Position No.

- Year of construction:

- Quantity

- Required mode of dispatch (mail, freight, sea, air,

express)

- Address of dispatch

Spare part orders which do not include the above indica-

tions may not be taken into consideration. If the indica-ti-

ons regarding the mode of dispatch are missing, the pro-

duct is dispatched at the discretion of the supplier.

You will find information regarding the device type, item

No. and year of manufacture on the type plate fixed to

the Machine.

Example

The bending additive for the universal bending machine

UB 10 has to be ordered. This is indicated in the spare

parts drawing with the item number 010-070.

- Type of device: Universal bending machine

- Item number: 377 010

- Position number: 010-070

Your order number is: 0-377 010-010-070

The order number consists of the item number, the posi-

tion number and one digit in front of the item number (0).

- Place the digit 0 in front of the item No.

- Also place the digit 0 in front of the position No. 1

trough 9.

DANGER!

Risk of injury due to incorrect spare

parts!

The use of incorrect or faulty replacement parts may

cause danger to the operator and cause damage and

malfunction.

- Only original spare parts from the manufacturer or re-

placement parts approved by the manufacturer must be

used.

- In case of doubt, always contact the manufacturer.

NOTE!

Using non-approved spare parts voids the manu-

facturer's warranty

Spare parts drawing

UB 10 | Version 2.01 19

13 Spare parts drawing

In case of service, the following drawing shall help to identify the necessary spare parts. If necessary, send a copy of the

parts drawing with the marked components to your authorised dealer.

Fig. 44: Spare parts drawing UB 10

20 UB 10 | Version 2.01

Declaration

Manufacturer / distributor: St rmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D-96103 Hallstadt

The universal bending machine is a hand-operated machine and is not subject to harmonized standards in

the sense of the regulations for CE certification. Therefore, the creation of a CE declaration and a

corresponding marking are not necessary.

Product group: Metallkraft® Metal working machines

Designation of the machine: UB 10

Machine type: Universal bending machine

Item number: 3776010

Serial number: ___________________

Year of manufacture: 20____

The designated product complies with the following regulations:

Applied national standards and technical specifications:

the regulations valid until now in Germany directory index machines October 92 to the GSG

e.g. VDI 2854, VBG 1, VBG 5

Responsible for documentation: Kilian St rmer, Dr.-Robert-Pfleger-Str. 26, D-96103 Hallstadt

Hallstadt, 06.05.2007

______________________

Kilian St rmer

General Manager

14 Declaration

Table of contents

Other Metallkraft Cutter manuals

Popular Cutter manuals by other brands

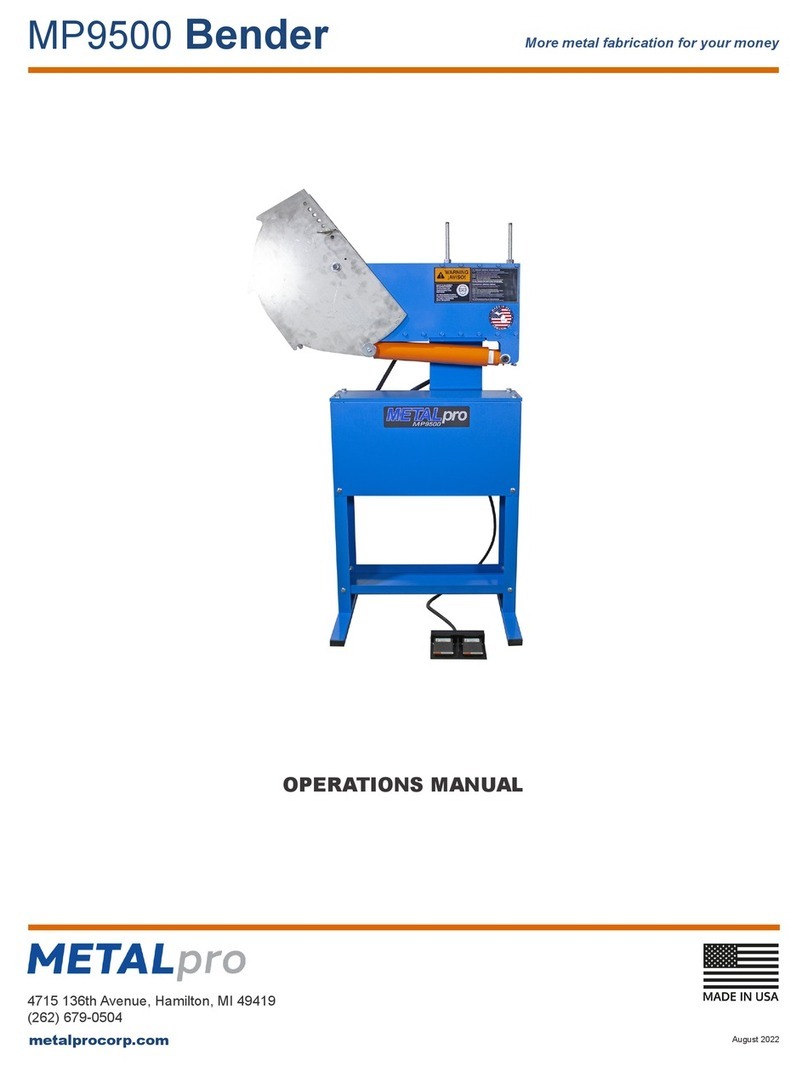

METALpro

METALpro MP9500 Operation manual

Cricut Expression

Cricut Expression 24" Personal Electronic Cutter user manual

REMA

REMA KS 100 INSTRUCTIONS MANUAL AND SERVICE INSTRUCTIONS

Globe

Globe GFP500 instruction manual

Jula

Jula Meec tools B-850 operating instructions

practyl

practyl 450ETC1-18031.1 instruction manual