Metallkraft MRA 2 User manual

MRA 2

Instruction Manual

MRA 2

MRA - SERIES

Manual Pipe notcher

MRA 3

2 MRA - Series | Version 1.07

Imprint

Product identification

Pipe notcher Item number

MRA 2 3772 2

MRA 3 3772 3

Manufacturer

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D- 6103 Hallstadt

Fax: 004 (0) 51 6555 - 55

E-Mail: [email protected]

Internet: www.metallkraft.de

Original operating instructions

Original operating instructions

Edition: 03.0 .2021

Version: 1.07

Language: English

Author: MS

Indications regarding the copyright

Copyright © 2021 Stürmer Maschinen GmbH, Hallstadt,

Germany.

The contents of these operating instructions are the only

ones property of the company Stürmer Maschinen

GmbH.

Forwarding and copying of this document, utilization and

communication of its contents are prohibited unless ex-

pressly permitted. Infringements oblige you to pay dama-

ges.

Technical changes and errors reserved

Contents

1 Introduction ............................................. 3

1.1 Copyright ............................................................ 3

1.2 Costumer service................................................ 3

1.3 Limitation of liability............................................. 3

2 Safety ....................................................... 3

2.1 Symbol explanation ............................................ 3

2.2 Qualification of the staff ...................................... 4

2.3 Personal protective equipment ........................... 4

2.4 General safety instructions ................................. 5

2.5 Safety signs on the machine............................... 5

3 Intended use ............................................ 5

3.1 Misuse ................................................................ 5

3.2 Residual risks ..................................................... 5

4 echnical Data......................................... 6

4.1 Table................................................................... 6

4.2 Type plate........................................................... 6

5 ransport, Packaging and Storage........ 6

5.1 Delivery............................................................... 6

5.2 Packaging........................................................... 6

5.3 Storage ............................................................... 7

6 Description of the device ....................... 7

7 Set up ....................................................... 7

8 Operation ............................................... 8

8.1 Workflow............................................................. 8

9 Care, Maintenance and Repair............... 8

.1 Cleaning and lubrication of the machine............. 8

.2 Maintenance of the machine...............................

10 Disposal, Recycling of old Equipment 9

10.1 Decommission .................................................

10.2 Disposal of lubricants.......................................

11 Spare parts ............................................ 9

11.1 Ordering spare parts........................................

11.2 Spare part drawing ........................................ 10

12 Explanation.......................................... 11

Introduction

MRA - Series | Version 1.07 3

1 Introduction

With the purchase of the Manual Pipe notcher you have

made a good choice.

horoughly read the operating instructions before

commissioning the Manual Pipe notcher.

It informs you about the proper commissioning, the in-

tended use as well as the safe and efficient operation

and maintenance of your device.

The operating instructions are part of the Manual Pipe

notcher. It must always be stored at the place of use of

the device. In ad-dition, the local accident prevention re-

gulations and ge-neral safety regulations apply to the

area of application of the device.

The illustrations in these operating instructions serve the

general comprehension and may deviate from the actual

type.

1.1 Copyright

The contents of these instructions are copyright. Their

application is admissible in the frame the device utilisa-

tion. An application beyond the described application is

not allowed without written approval of the manufacturer.

For the protection of our products, we shall register tra-

demark, patent and design rights, as this is possible in

individual cases. We strongly oppose any infringement

of our intellectual property.

1.2 Costumer service

Please contact your dealer if you have any questions

about your machine or technical information. There you

will be happy to help with expert advice and information.

Germany:

Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Str. 26

D- 6103 Hallstadt

Repair-Service:

Fax: 004 (0) 51 6555-111

E-Mail: [email protected]

Spare part orders:

Fax: 004 (0) 51 6555-11

E-Mail: [email protected]

We are always interested in valuable experience and

knowledge gained from using the application which then

could be shared and be valuable to develop our products

even further.

1.3 Limitation of liability

All information and notes in these operating instructions

were summarised taking the applicable standards and

rules, the state-of-the-art and our long-term knowledge

and experiences into consideration.

In the following cases the manufacturer is not liable for

damages:

- Non-observance of the operating instructions,

- Inappropriate use,

- Use of untrained staff,

- Unauthorised modifications,

- Technical changes,

- Use of not allowed spare parts.

The actual scope of delivery may deviate from the expla-

nations and presentations described here in case of spe-

cial models, when using additional ordering options or

due to latest technical modifications.

The obligations agreed in the delivery contract, the gen-

eral terms and conditions as well as the delivery conditi-

ons of the manufacturer and the legal regulations at the

time of the conclusion of the contract are applicable.

2 Safety

This paragraph will give you an overview of all important

safety packages for the protection of persons as as well

as for the safe and undisturbed operation. Other taskba-

sed safety notes are included in the individual chapters.

2.1 Symbol explanation

Safety instructions

The safety notes in these operating instructions are high-

lighted by symbols. The safety notes are introduced by

signal words which express the concern of the risk.

DANGER!

This combination of symbol and signal words indi-cate

an imminently dangerous situation which may lead to

death or severe injuries if they are not avoi-ded.

4 MRA - Series | Version 1.07

Safety

ips and recommendations

It is necessary to observe the safety notes quoted in

these operating instructions in order to reduce the risks

for personal injuries and damages to property.

2.2 Qualification of the staff

This manual is intended for:

- the operators,

- the staff for maintenance work.

Only persons who are expected to carry out this work re-

liably are permitted for all work. Persons whose reactivity

z. As influenced by drugs, alcohol or drugs are not allo-

wed.

This manual identifies the qualifications of the persons li-

sted below for the different tasks:

Operator:

The operator has been instructed in a briefing by the

operator about the tasks assigned to him and possible

dangers of improper behavior. The operator may only

carry out tasks that go beyond normal operation if this is

specified in this operating manual and the operator has

expressly entrusted this to him.

Personnel:

Due to their technical training, knowledge and experi-

ence as well as knowledge of the relevant standards and

regulations, qualified personnel are in a position to carry

out the work assigned to them and to recognize potential

dangers independently and to avoid hazards.

Manufacturer:

Certain work may only be carried out by specialist per-

sonnel of the manufacturer. Other personnel are not au-

thorized to carry out this work. To carry out the work,

contact our customer service.

2.3 Personal protective equipment

The personal protective equipment serves to protect per-

sons against impairments of safety and health while wor-

king. The staff has to wear personal protective equip-

ment while performing different works on and with the

device which are indicated in the individual paragraphs

of these instructions.

The personal protective equipment is explained in the

following paragraph:

WARNING!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to death or severe injuries if they are not avoided.

CAU ION!

This combination of symbol and signal words indi-

cate a possibly dangerous situation which may lead

to minor or light injuries if they are not avoided.

NO E!

This combination of symbol and signal words indicate

a possibly dangerous situation which may lead to

property and environmental damages if they are not

avoided.

ips and recommendations

This symbol highlights useful tips and recommenda-

tions as well as information for an efficient and trou-

ble-free operation.

ips and recommendations

All persons involved in operation and maintenance

must

- have the required qualifications.

- Pay close attention to these operating instructions.

Eye protection

The goggles protect the eyes from flying parts and

liquid splashes.

Protective gloves

The protective gloves serve to protect the hands

against sharp components as well as against fric-

tion, abrasions or deep injuries.

Intended use

MRA - Series | Version 1.07 5

2.4 General safety instructions

Please note the following:

-Keep the machine and its working environment always

clean. Ensure adequate lighting.

- In principle, secure your workpiece when working with

suitable clamping devices. Make sure there is sufficient

contact surface.

- The notching machine shall not be modified in its de-

sign and shall not be used for purposes other than

those foreseen by the manufacturer.

- Never work under the influence of concentration-distur-

bing illnesses, fatigue, drugs, alcohol or medicines.

- Keep children and persons unfamiliar with the notching

machine away from their working environment.

- Eliminate disturbances that affect safety immediately.

- Before each use of the notching machine, make sure

that no parts are damaged. Damaged parts must be re-

placed immediately to avoid any danger.

- Do not overload the notching machine! You work better

and safer in the specified performance range.

- Only use original spare parts and accessories to avoid

possible dangers and accident risks.

2.5 Safety signs on the machine

The machine has safety markings and instructions (Fig.

1) which must be observed and followed.

Fig. 1: Safety labels

Damaged or missing safety symbols on the machine can

lead to malfunctions with personal injury and material da-

mage. The safety symbols attached to the machine must

not be removed.

Damaged safety symbols must be re-placed immedi-

ately. From the moment the signs are not immediately

recognizable and comprehensible, the ma-chine must be

taken out of service until the new signs are fitted.

3 Intended use

The notching machine is designed exclusively for un-

latching pipes made of steel, stainless steel, non-ferrous

metals (aluminum, copper, brass) with the diameters

specified in "Technical data" up to a maximum wall thick-

ness of 3 mm (for S235JR steel). The notching takes

place at a fixed angle ( 0 °).

The machine must not be operated in potentially explo-

sive environments.

Proper use also includes compliance with all information

in this manual. Any use beyond the intended use or

otherwise is considered misuse.

For structural and technical changes to the notching ma-

chine, the company Stürmer Maschinen GmbH assumes

no liability.

Claims of any kind due to damage due to improper use

are excluded.

3.1 Misuse

3.2 Residual risks

Even if all safety regulations are observed and the ma-

chine is used correctly, there are still residual risks listed

below:

- There is a risk of injury to the upper limbs (e.g., hands,

fingers).

- Danger from falling workpieces.

1234 5

WARNING!

Danger in case of misuse!

Misuse of the notching machine can lead to dange-

rous situations.

- Only operate the notching machine within the per-

formance range specified in the technical data.

- Never bypass or override the safety devices.

- Only operate the notching machine in a technically

perfect condition.

6 MRA - Series | Version 1.07

echnical Data

4 echnical Data

4.1 able

* Performance data based on material with tensile strength 400 N / mm²;

** for stainless steel (VA): factor 0.67

4.2 ype plate

Fig. 2: Type plate

5 ransport, Packaging and Sto-

rage

5.1 Delivery

Check the notching machine after delivery for visible

transport damage. If the notching machine is damaged, it

must be reported immediately to the transport company

or the dealer..

ransport

Improper transport of individual devices, packaged or

unpacked unsecured devices that are stacked on top of

or next to each other is prone to accidents and can

cause damage or malfunctions for which we do not pro-

vide any liability or guarantee.

Transport the scope of delivery secured against shifting

or tipping with an adequately dimensioned industrial

truck to the installation site.

General hazards during internal transport

The transport may only be carried out by authorized and

qualified persons. Act responsibly when transporting and

always consider the consequences. Refrain from daring

and risky actions.

Inclines and slopes are particularly dangerous (e.g.

driveways, ramps and the like). If it is unavoidable to

drive on such passages, special care is required.

Before starting the transport, check the transport route

for possible hazards, unevenness and imperfections as

well as sufficient strength and load-bearing capacity.

Hazardous areas, bumps and imperfections must be in-

spected prior to transport. The removal of hazardous

areas, bumps and obstructions at the time of transport by

other employees leads to considerable dangers.

Careful planning of internal transport is therefore essen-

tial.

5.2 Packaging

All packaging materials and packaging aids used in the not-

ching machine are recyclable and must always be recy-

cled.

Cardboard packaging components are shredded and sent

to the waste paper collection.

The foils are made of polyethylene (PE) and the upholstery

parts are made of polystyrene (PS). These materials are to

be handed in to a recycling center or to the responsible wa-

ste disposal company.

echnical Data MRA 2 MRA 3

Pipe diameter*

[mm]

28 / 34 / 43 50 / 61

Max. Wall thick-

ness*

construction steel

aluminium

copper

brass

stainless steel**

3 mm

4,5 mm

4 mm

4 mm

2 mm

3 mm

4,5 mm

4 mm

4 mm

2 mm

Notcher dimensi-

ons without lever

LxBxH [mm]

1 5x160x80 205x160x105

Notcher dimensi-

ons with lever

LxBxH [mm]

1060x160x80 10 0x160x105

Weight 8 kg 15 kg

NO E!

Protect the Manual Pipe notcher from moisture.

CAU ION!

Risk of injury from devices fall over and falling down-

from forklifts, pallet trucks or transport vehicles.

Only use means of transport and load attachment

means that can take the total weight.

CAU ION: RISK OF OPPING OVER

The device may not be lifted more than 2cm unsecu-

red.

Employees must be outside the danger zone, the

reach of the load.

Warn employees and make employees aware of the

risk.

Description of the device

MRA - Series | Version 1.07 7

5.3 Storage

Store the notching machine thoroughly cleaned in a dry,

clean and frost-free environment.

Apply protective oil to the tool to prevent it from rusting.

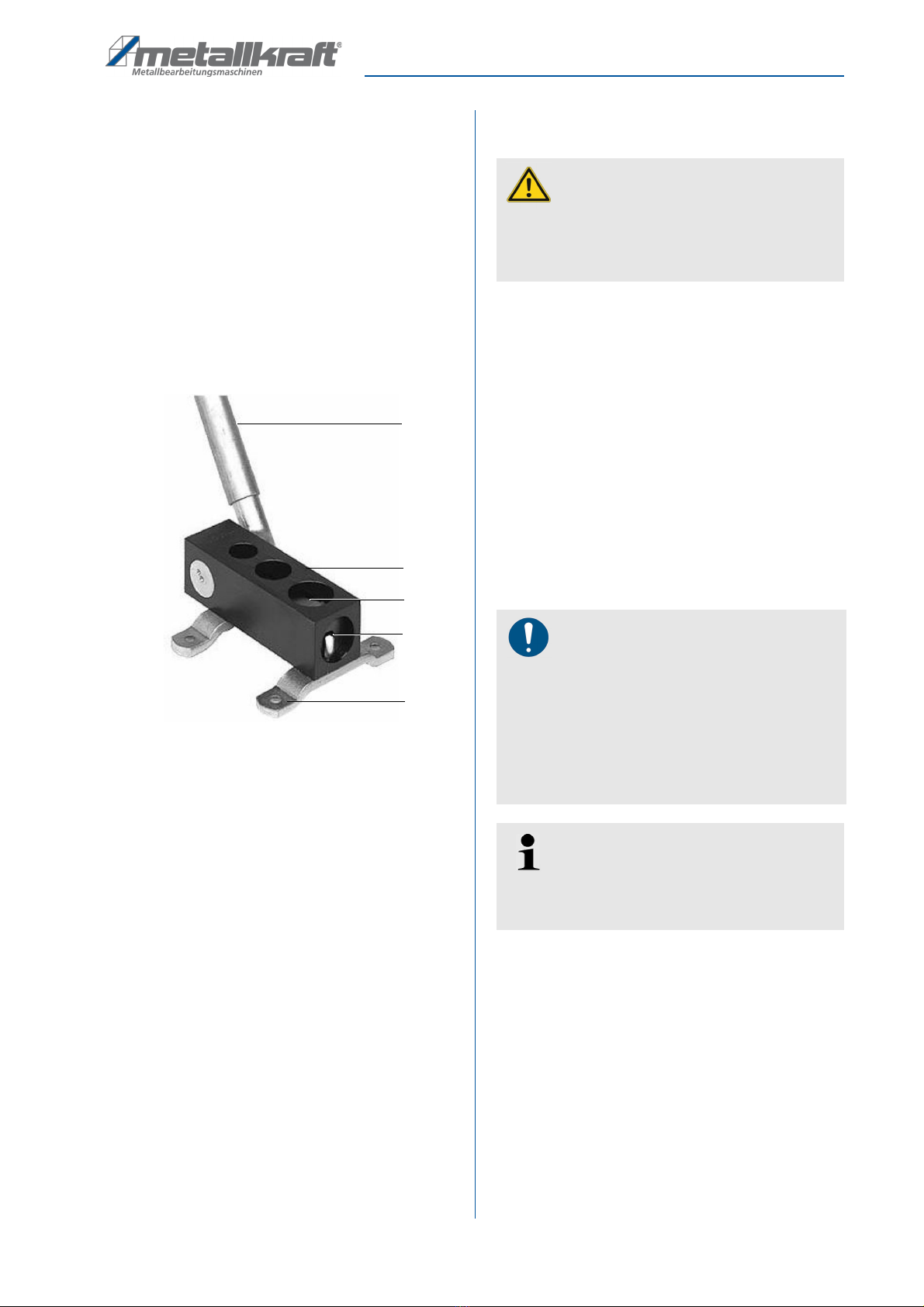

6 Description of the device

Illustrations in this operating manual serve the gene-

ral understanding and may deviate from the actual

design.

Fig. 3: Description of the device MRA 2

1 Release lever

2 Housings

3 Notch opening for 43 mm diameter pipes

4 Notching knives

5 Mounting hole

7 Set up

In order to achieve a good function of the notching ma-

chine and a long service life, the site should meet the

following criteria.

- The notching machine may only be set up and ope-

rated in dry and freezing conditions.

- The substrate must be suitable for the work. Pay

attention to carrying capacity and evenness of the

subsoil.

- Protruding parts, such as support tables, etc., are

to be secured if necessary by on-site measures so

that persons are not endangered.

- Provide enough space for operators and material

handling.

- Ensure adequate lighting (minimum value: 300 lux)

1

2

4

5

3

DANGER!

Before setting up the machine, check the load-bea-

ring capacity of the substrate. The installation space

must be able to bear the weight of the machine, the

workpieces and the processing pressure.

NO E!

Clean the notching machine before first use

- For this purpose use conventional solvents, for. B.

Petroleum.

- No water, no nitrolic solvents or similar use!

After the notching machine has been cleaned, all

bare parts must be lightly oiled. For this only resin u.

use acid-free machine oil!

ips and recommendations

For a secure footing, it is advisable to fasten the not-

ching machine on a firm, stable and level surface

through the holes in the machine base.

8 MRA - Series | Version 1.07

Operation

8 Operation

8.1 Workflow

Step 1: Fix the notching machine horizontally or vertically

on a suitable work table using the holes.

Step 2: Open the tool with the release lever and insert

the pipe end into the appropriate opening.

Step 3: Make the cut by operating the release lever and

remove the workpiece.

9 Care, Maintenance and Repair

9.1 Cleaning and lubrication of the ma-

chine

The notching machine should always be cleaned after

each use.

Sweep or wipe all open machine parts with a broom or

cloth at regular intervals.

Treat bare metallic work surfaces with anti-rust spray.

Lubricate all moving parts and bearings daily before star-

ting work.

WARNING!

Risk of injury!

There is a risk of injury to the operator and other per-

sons if they do not adhere to the following rules.

- The operator may not work while under the influ-

ence of alcohol, drugs or medication.

- The operator must not work when he is tired or suf-

fering from concentration-impairing illnesses.

- The notching machine may only be operated by one

person. Other persons must keep away from the

work area during operation.

DANGER!

Risk of injury!

When working on the notching machine,

- is to wear tight-fitting clothing.

- no jewelry may be worn.

- Do not wear scarves, ties or similar.

- For long hair, a hairnet must be worn.

Wear safety glasses!

Wear safety gloves

A EN ION!

Risk of crushing!

When working with the notching machine can cause

bruising of the upper limbs.

DANGER!

Always only one pipe, never work on several pipes at

the same time.

Before starting work, check that the knives of the not-

ching machine are sharp and there are no chips in

the tool.

ips and recommendations

Do some test cuts before you start production!

ips and recommendations

To ensure that the notching machine is always in

good working condition, regular care and main-

tenance work must be carried out.

WARNING!

Danger due to insufficient qualifica-

tion of persons!

Insufficiently qualified persons can not assess the

risks involved in repairing the notching machine and

expose themselves and others to the risk of serious

injury.

All maintenance work should only be carried out by

qualified persons.

DANGER!

Never use solvents to clean plastic parts or painted

surfaces. A surface release and consequential

damage may occur.

Wearing safety gloves!

Disposal, Recycling of old equipment

MRA - Series | Version 1.07

9.2 Maintenance of the machine

If the notching machine does not work properly, contact

a dealer or our customer service. The contact details can

be found in chapter 1.2 Customer Service.

10 Disposal, Recycling of old

equipment

In the interests of the environment, care must be taken to

ensure that all components of the machine are disposed

of in the proper and approved way.

10.1 Decommission

Disused devices must be taken out of service immedi-

ately in order to prevent later misuse and endangering

the environment or people.

- If necessary, disassemble the machine into manage-

able and usable components and components.

- Feed the machine components to the appropriate dis-

posal channels.

10.2 Disposal of lubricants

The disposal instructions for the lubricants used are pro-

vided by the lubricant manufacturer. If necessary, ask for

the productspecific data sheets.

11 Spare parts

11.1 Ordering spare parts

The spare parts can be obtained from the dealer or di-

rectly from the manufacturer. The contact details are in

chapter 1.2 Customer Service.

Specify the following key data when ordering spare

parts:

- Device type

- Serial number

- Lot

- Description

- Desired shipping method (post, freight, sea, air, ex-

press)

- Delivery address

Spare parts orders without above given information can

not be considered. If the shipping method is missing,

shipping will be at the discretion of the supplier.

Information on the device type, article number and year

of manufacture can be found on the type plate, which is

attached to the device.

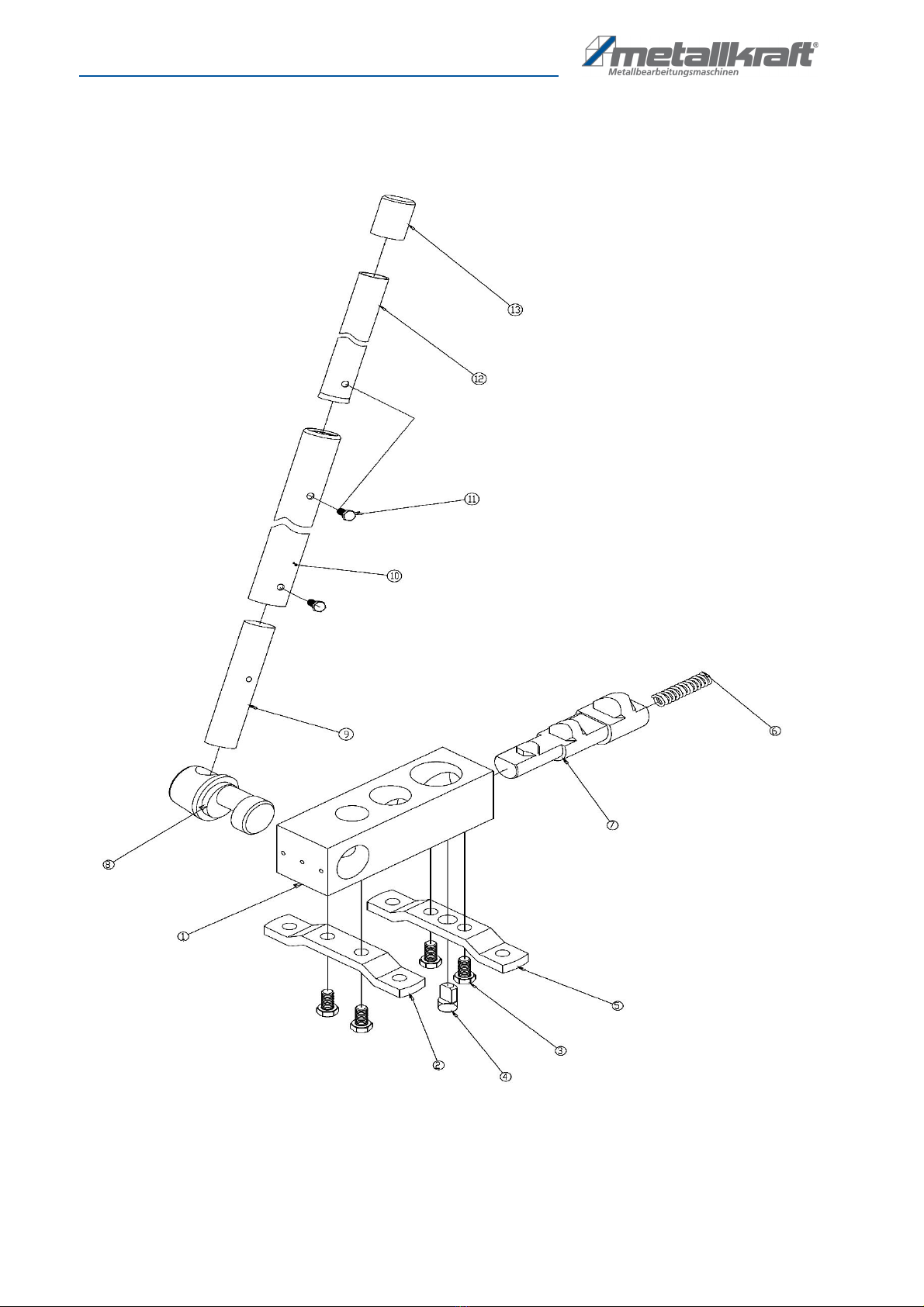

Example

The eccentric for the Pipe notcher MRA 2 must be or-

dered. The eccentric has the number 8 in the spare parts

drawing 1.

By ordering spare parts, send a copy of the spare parts

drawing (1) with the marked part (eccentric) and marked

positon number (8) to the dealer or spare parts depart-

ment and provide the following information:

- Type of device:

Pipe notcher MRA 2

- Item number:

3772992

- Drawing number:

- Position number:

8

DANGER!

- Maintenance and repair work may only be carried

out by qualified personnel.

- Only use original spare parts.

NO E!

Using non-approved spare parts voids the manufactu-

rer's warranty

DANGER!

Risk of injury due to incorrect spare

parts!

The use of incorrect or faulty replacement parts can

be dangerous to the operator and cause damage and

malfunction.

- Only use original spare parts from the manufacturer

or replacement parts approved by the manufacturer.

- In case of doubt, always contact the manufacturer.

10 MRA - Series | Version 1.07

Spare parts

11.2 Spare part drawing

Abb. 4:

Fig. 4

FIG. 4 Spare part drawing MRA 2 / MRA 3

Explanation

MRA - Series | Version 1.07 11

Manufacturer/distributor: Stürmer Maschinen GmbH

Dr.-Robert-Pfleger-Starße 26

D- 6103 Hallstadt

We hereby declare that the machine described below, due to its design and construction as well as in the version we

have placed on the market, complies with the relevant basic health and safety requirements.

A declaration of conformity according to Machinery Directive 2006/42 / EC Annex 1 does not require this machine. In the

event of a modification of the machine not agreed with us, this declaration shall lose its validity.

Product group: Metallkraft® Metal working machines

ype of machine: Manuelle Pipe notcher

Designation of the machine *: MRA 2

MRA 3

Item number *: 3772 2

3772 3

Serial number *: ____________________

Year of construction *: 20____

* please fill in according to the information on the type plate

Responsible for documentation: Kilian Stürmer, Stürmer Maschinen GmbH,

Dr.-Robert-Pfleger-Str. 26, D- 6103 Hallstadt

Hallstadt, 1 .12.2014

______________________

Kilian Stürmer

Manager

12 Explanation

www.metallkraft.de

This manual suits for next models

3

Table of contents

Other Metallkraft Cutter manuals