Metkon FORCIMAT User manual

OPERATINGandINSTRUCTIONSMANUAL

FORCIMAT

AUTOMATICSPECIMENMOVER

3

EC DECLARATION OF CONFORMITY

Manufacturer : Metkon Instruments Inc.

Address : Demirtas Dumlupinar Organize Sanayi Bolgesi

Ali Osman Sonmez Cd. No:14 Bursa / TURKEY

Herewith declares that;

Automatic Specimen Mover, Model: FORCIMAT

-is in conformity with the provisions of the Machinery Directive (directive 2006/42/EEC), as

amended, and with national implementing legislation;

-is in conformity with the provisions of the Low Voltage Directive (directive 2006/95/EEC), as

amended, and with national implementing legislation;

-is in conformity with the provisions of the EMC Directive (directive 2004/108/EEC), as

amended, and with national implementing legislation;

and furthermore declares that

-the following (parts/clauses of) standards have been applied

EN ISO 12100:2010, TS EN 60204-1, TS EN 61000-6-2, TS EN 61000-6-4

......................................................................................................................................................................

Authorized Person: Ercin Senay

Position: Manager of Research and Development Department

Year: 2014

4

INDEX

A. DESCRIPTION ................................................................................................................................................ 5

1. DESİGN ............................................................................................................................................................... 5

2. TECHNİCAL DATA .................................................................................................................................................. 6

3. WARRANTY ......................................................................................................................................................... 6

4. SAFETY PRECAUTİONS ............................................................................................................................................ 6

B. INSTALLATION & SET UP ............................................................................................................................... 7

1. UNPACKİNG &CHECKİNG CONTENTS OF PACKAGE ...................................................................................................... 7

2. INSTALLATİON AND SET-UP..................................................................................................................................... 8

2.1 Mounting of Automatic Head.................................................................................................................. 9

2.2 Connections ............................................................................................................................................. 9

2.3 Electrical Installation ............................................................................................................................. 11

2.4 Adjusting the Height of the Forcimat Head........................................................................................... 12

2.5 Mounting Sample Holder ...................................................................................................................... 13

2.6 Noise Level............................................................................................................................................. 14

C. CONTROL PANEL ..........................................................................................................................................14

1. CONTROL BUTTON FUNCTİONS.............................................................................................................................. 14

D. OPERATION..................................................................................................................................................15

1. MANUAL MODE ................................................................................................................................................. 15

2. AUTO MODE .................................................................................................................................................... 15

E. SERVICE AND MAINTENANCE.......................................................................................................................16

1. MAİNTENANCE ................................................................................................................................................... 16

2. TROUBLESHOOTİNG............................................................................................................................................. 16

F. ACCESSORIES AND CONSUMABLES ..............................................................................................................16

1. ACCESSORİES...................................................................................................................................................... 16

G. TECHNICAL DOCUMENTATION.....................................................................................................................17

1. RECOMMENDED SPARE PART LİST .......................................................................................................................... 17

2. PNEUMATİC WİRİNG DİAGRAM ............................................................................................................................. 17

3. CUSTOMER SERVİCE ............................................................................................................................................ 18

4. ELECTRİCAL WİRİNG DİAGRAMS............................................................................................................................. 18

5

A. DESCRIPTION

1. Design

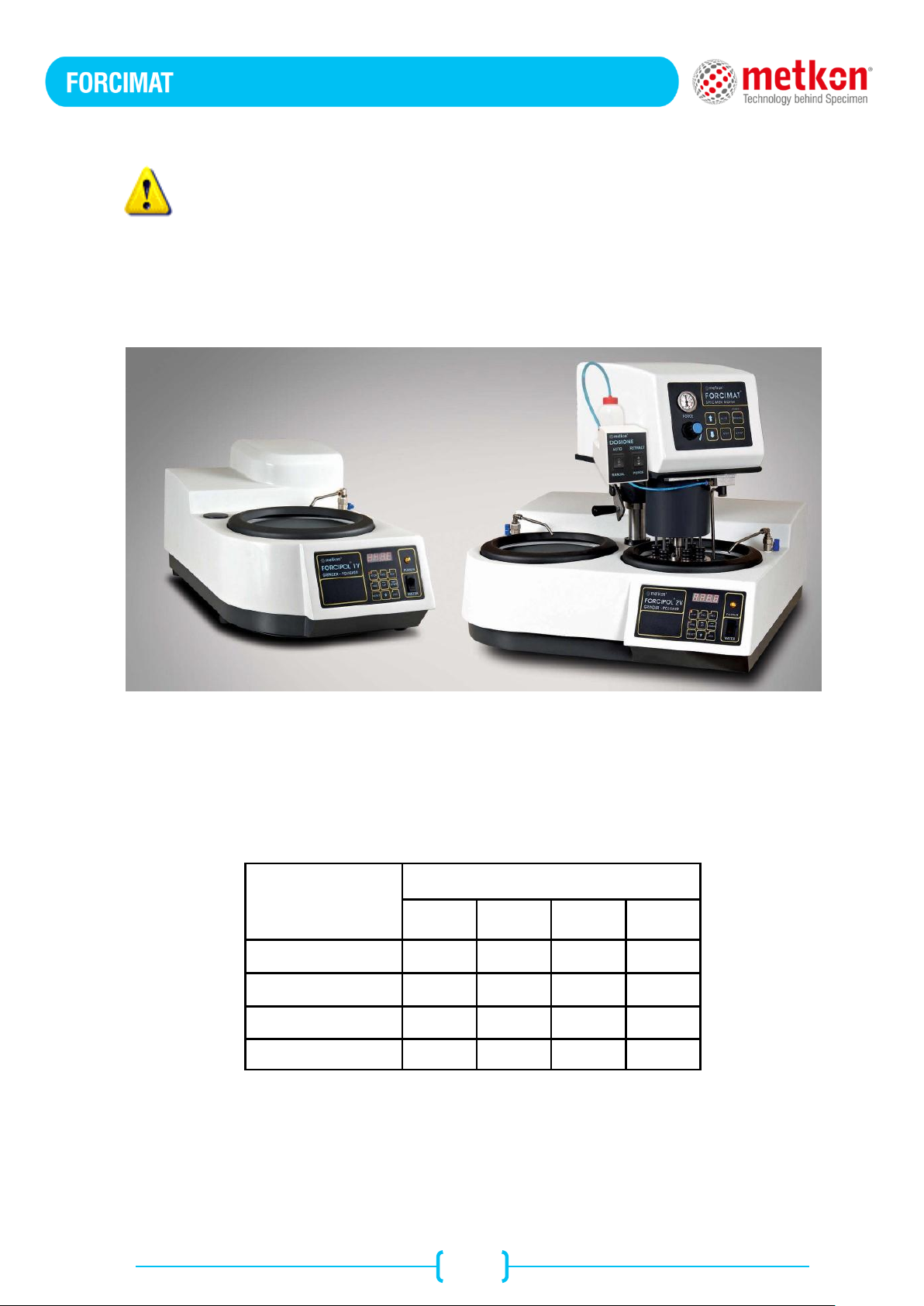

The FORCIMAT Automatic Head is mounted on a rigid, hardened column of which the other end is fixed

to the base casting of the FORCIPOL grinder/polisher. FORCIMAT can be integrated to all FORCIPOL

model grinder/polishers and is rapidly positioned via its quick-locking clamping mechanism.

The specimen holder is driven by a 100 Watt DC motor at 50-150 rpm. The force is set individually which

is pneumatically adjustable between 5N and 60N from the front panel and can be seen on a direct

reading gage. The system is enclosed in an ABS housing with touch-pad front panel.

An adjustable and exchangable drip lubricator is a standard integrated part of FORCIMAT. The dosing

level is adjusted by a flow valve for optimal use of lubricant to obtain consistent results.

A complete series of easily exchangable specimen holders (6 specimens) from 25 to 40mm and from 1”

to 1 ½” is available to be used with FORCIMAT.

DOSIONE is an optional lubricating accessory of FORCIMAT. Please press ( I ) button on tha front pannel

of DOSIONE, when you put water and lubricant into the DOSIONE to first start. Please adjust the flow

rate of lubricant to required rate by rotating the flow rate button.

When you are replacing the bottle of DOSIONE please pay special attention to mount the bottle to its

place properly. If it does not fix properly, it can not perform the lubriacation.

The specimens are (1 to 6) easily placed in the specimen holder. The dosing level of the drip lubricator is

adjusted. The individual sample force is set from the front panel of the FORCIMAT. The cycle time, disc

speed and disc rotational direction are set from the front panel of FORCIPOL grinder/polisher and Start

button is depressed. Both instruments, FORCIMAT and FORCIPOL start operating simultaneously. Upon

completion of the cycle, both instruments stop and an audio signal informs the operator.

Fig. 1 FORCIPOL 2V with FORCIMAT

6

2. Technical Data

EQUIPMENT

Forcimat

Forcimat TS

Application of Force

Individual

Individual

Force, (N)

5 - 60

5-60

Head Speed, (rpm)

50 - 150

35

Rotation Direction

CW / CCW

CW

Display

DP

DP

Automatic Drip Lubricator

Standard

Standard

Dimensions, WxDxH, (cm)

23x43x25

23x43x25

Weight, (kgs)

16

16

Motor Power, (W)

100 W

100W

Needed air supply

6 Bar

6 Bar

3. Warranty

The FORCIMAT is guaranteed against defective material or workmanship for a period of 12 months from

the date of receipt by the customer or latest 18 months after the shipping date. Warranty is not valid if

inspection shows evidence of misuse or unauthorized repair. Warranty covers only replacement of

defective materials. In case this unit must be returned to our factory for warranty service please ask for

prior authorization and include the following details: Serial Number of the unit, Invoice number and

date. Transport costs belong to the customer.

4. Safety Precautions

Read the below instructions carefully before use.

Place the machine on a sturdy and safe table.

The equipment must be installed in compliance with local safety regulations.

Only use approved METKON accessories and consumables to achieve max. safety and

lifetime.

Follow the instructions and safety regulations when lifting and carrying the equipment.

Keep your hands away from the specimen holder and the automatic head when lowering the

Forcimat.

Do not touch the rotating parts during operation.

Use appropriate safety clothing. Long clothings, accessories and/or hair can be caught by

rotating parts.

If the Forcimat with Forcipol has to be moved to a new location, diassemble the Forcimat

from the Forcipol.

Disconnect the electrical connection before servicing the equipment.

Follow the periodically maintenance.

The equipment is designed to be used with METKON accessories and consumables. In

case of misuse of equipment, improper installation, alteration, use of different source

parts, improper repair, METKON will accept NO responsibility for any damages to the

operator or the equipment. Disassembling of any part should always be performed by

a qualified technician.

7

B. INSTALLATION & SET UP

1. Unpacking & Checking Contents of Package

Carefully unpack and check contents of the package. If any components are missing or damaged,

save the packing list and materials and advise the carrier and Metkon Instruments Inc. of the

discrepancy.

Carefully unpack and check that the following items have been received:

oPower Cable, 1.8 mt, 1 piece

oAir Hose, 1.5 mt, 1 piece

oHex Key, 1.5 mt, 1 piece

WARNING! The FORCIMAT weighs from 16 kgs. please be sure that there are enough people

(at least 2) to safely lift the unit from the shipping carton. It is recommended to wear safety

shoes during transportation.

Carefully remove outer packing material. Refer to the packing documents for a list of items supplied.

8

2. Installation and Set-Up

CAUTION! Follow approved procedures and take all necessary preventive safety measures

when lifting and installing this equipment. Improper lifting can result equipment damage.

FORCIMAT is an optional accessory of FORCIPOL series of Grinding & Polishing Machine.

FORCIMAT is mounted on FORCIPOL. Please be sure that the platform is large enough and can

stand it’s weight.

In order to work with equipment comfortably, it is recommended to leave at least 30 cm space

from all side of the equipment.

You can see the dimensions and weight of FORCIMAT and FORCIPOL as below:

Equipment

Dimensions

W

D

H

Weight

FORCIMAT

230 mm

430 mm

250 mm

16 kgs

FORCIPOL 1V

380 mm

690 mm

340 mm

30 kgs

FORCIPOL 300-1V

380 mm

690 mm

340 mm

30 kgs

FORCIPOL 2V

700 mm

690 mm

340 mm

40 kgs

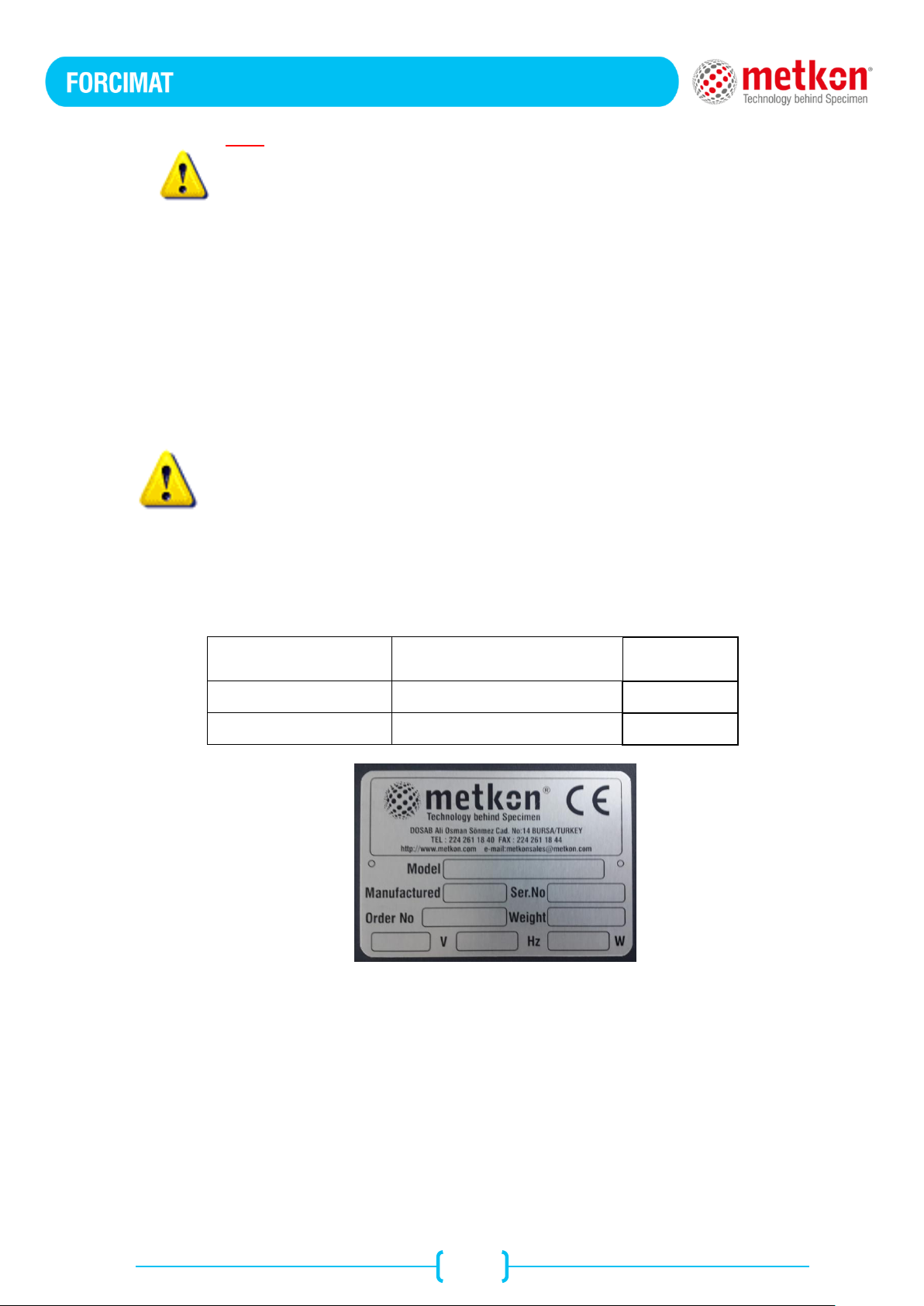

Place the FORCIMAT on FORCIPOL with convenient access to a 1-phase grounded power source, water

supply and water drain. Make the connections of the air hose and the data cable between FORCIMAT

Head and the FORCIPOL.

9

2.1 Mounting of Automatic Head

FORCIMAT Automatic Specimen Mover is used in combination with FORCIPOL Grinder and Polishers.

Please follow up the following steps to combine FORCIMAT to FORCIPOL’s.

1. Pull off the plastic plug on the surface of FORCIPOL.

2. Place FORCIMAT with its column in the FORCIPOL and fix it from the bottom with the M8

screw. Be sure that the screw is tighten correctly.

2.2 Connections

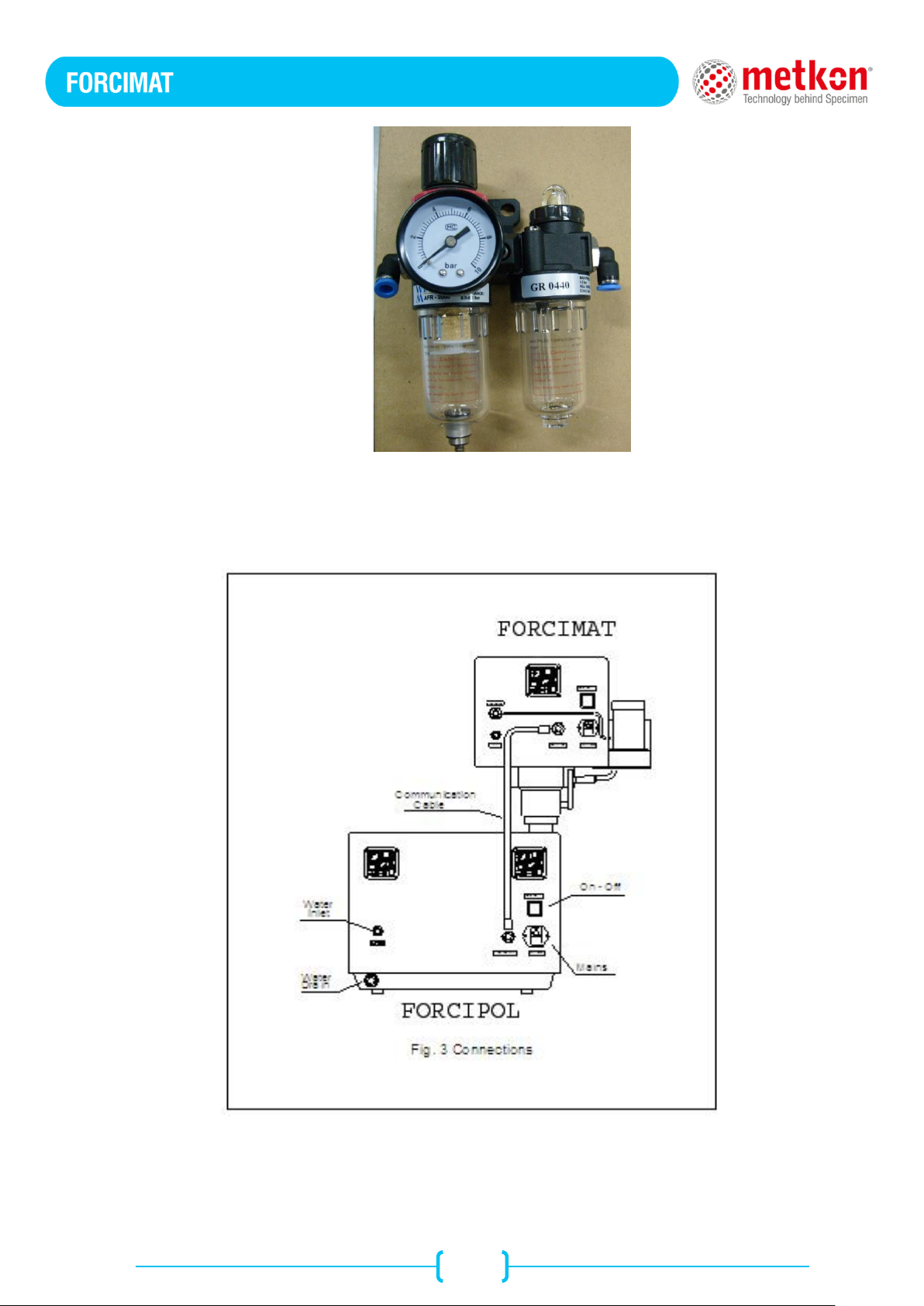

FORCIMAT requires air supply with 6 bars pressure.

A compressor which can generate more than 6 bars and has 50 liters capacity is enough for only

1 equipment. If you have more equipment that use air supply, please consult your local

compressor dealer to choose correct compressor.

If there is a doubt about the quality and pressure of the air supply, make certain that a filtering

and regulator unit for compressed air is connected to the air line before FORCIMAT.

METKON can supply GR 0440 Air Filtering and Lubricating Unit which regulates air pressure to 6

bars.

10

A pneumatic air hose with 6 mm outer diameter will be supplied with the equipment. (See:

Installation Kit)

Please be sure that you have suitable connection fittings to connect hose to the air line.

1. Connect the mains cable between FORCIMAT and mains.

2. Connect the supplied “Communication Cable” between FORCIMAT and FORCIPOL.

3. Connect the compressed air hose (supplied) to the air socket on the back of the instrument.

4. Connect the other end to the compressed air source which has to be 6 bars.

11

Note:

If there is a doubt about the quality of the air supply, make certain that a filter and

regulator unit for compressed air is connected in the air line before FORCIMAT.

5. Please do not use teflon bant to the elbow and nipel connections.

6. Please connect the Lubomat connection cable to the back side socket of FORCIMAT GRP

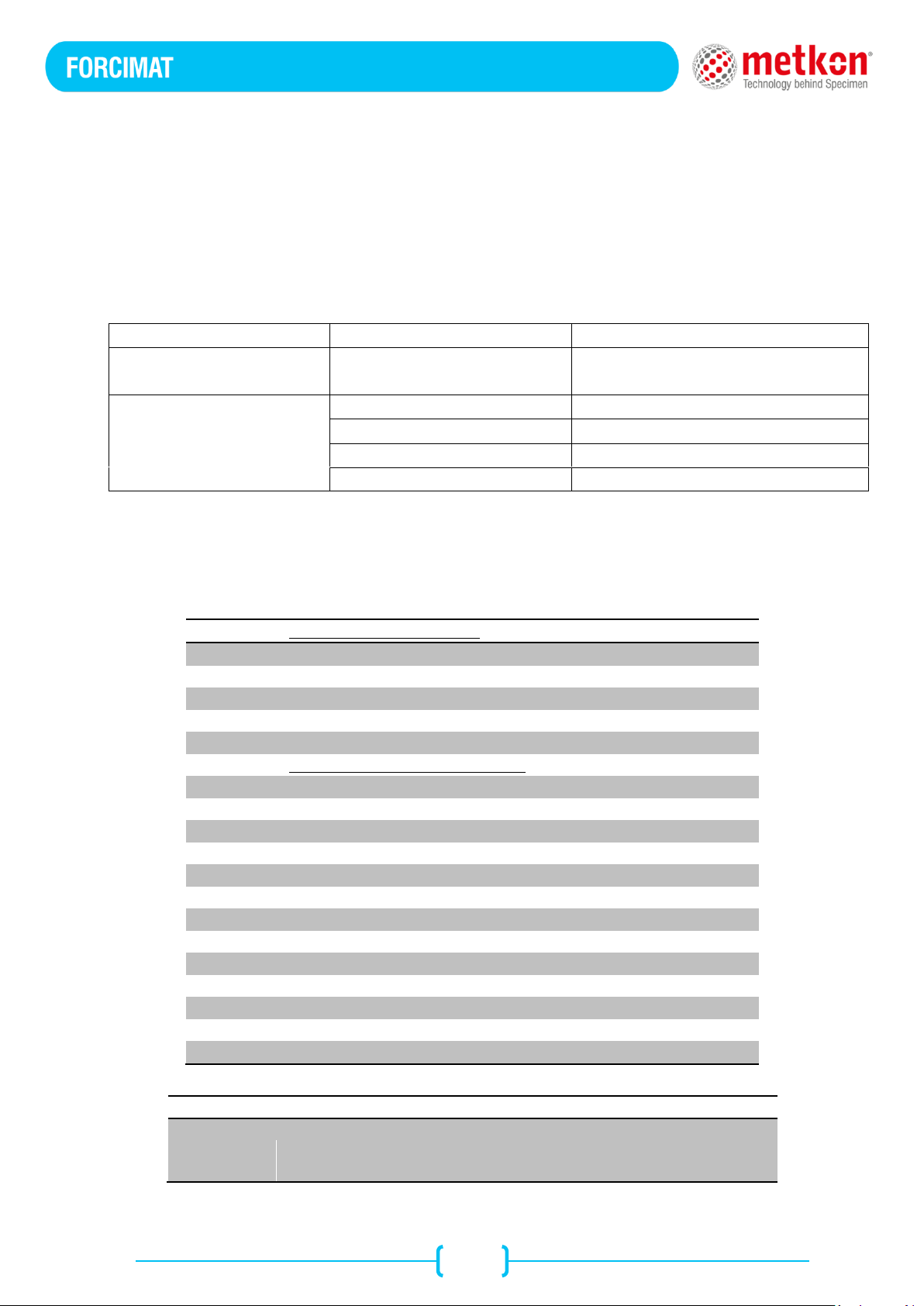

2.3 Electrical Installation

Before making electrical connections, check that the voltage and frequency stated on the specification

plate correspond to the local voltage and frequency. Check that the values for three-phase voltage, is

compatible with the intended electrical supply before installation.

ATTENTION! Connect the unit to the grounded mains voltage.

WARNING! Electrical Shock Hazard. A qualified electrical technician should perform

optional hard wiring and electrical maintenance.

Disconnect the power supply before making any electrical adjustments.

Make sure that the supply voltage and frequency is correct. Check the values from the back thin

metal plate.

Voltage / Frequency

Operational Power Range

Fuse Rating

230 V, 50/60 Hz. 1 ph.

220 - 240 V

6 A (C Type)

115 V, 50/60 Hz. 1 ph.

110 - 120 V

6 A (C Type)

Connect the equipment to the grounded mains voltage. Power cord will be supplied with the

equipment.

Lenght of power cable is 1.8 meters.

12

You can see suitable power sockets as below. If you have not suitable power socket, in this case

you should supply a suitable power cord.

2.4 Adjusting the Height of the Forcimat Head

When you place the Forcimat on the FORCIPOL we strongly advise you to check the distance between

the sample holder and the disk when the sample holder is at the bottom position. It should be 5

mm.(Fig.4.) If it is longer or shorter you need to adjust the height. For adjusting the lenght first hold the

head up by using the handle (Fig.5.) and please loosen the set-screw of the adjusting collar. (Fig.6.)

If the lenght you measured at the beginning is shorter than 5 mm, please hold the collar upside and

tighten the set-screw again. If it was longer than 5 mm. at the beginning, than you have to move the

collar downwards and tighten the collar(Fig.7.). Than check the distance again when the sample holder

is at the bottom position. If the distance is not OK again you have to do the steps one more time.

13

Fig.4. Distance between sample holder and disk Fig.5. Head Position Handle

Fig.6 Fig.8

2.5 Mounting Sample Holder

Place your sample holder on the spindle of the Forcimat.

Tighten the 3 setscrews indicated on the below photo.

To take the sample holder out, loosen the 3 setscrews and take out the sample holder.

14

2.6 Noise Level

Approx. 60 dBa is measured at idle running at a distance of 1m. from the machine

C. CONTROL PANEL

Fig.3. FORCIMAT CONTROL PANEL and BACK VIEW

1. Control Button Functions

Direct reading force gage: shows the individual force being applied on each sample. By using the

regulator, the amount of force required is set.

RPM: Adjust the rotation speed of the Forcimat Head

STOP: Stop button is used to stop the unit when it is in operation.

START: This button is used to start the motor in clockwise direction.

UP & DOWN (↑ ↓): buttons activate the single force pistons on each sample.

“Auto” mode: FORCIMAT is activated from FORCIPOL grinder/polisher. When FORCIPOL starts, so

does the FORCIMAT.

“Manual” mode: FORCIMAT can be operated independent of FORCIPOL.

HEAD (CCW-CW): Selection of the head rotation in Clock Wise or Counter Clock Wise.

PERIOD: Total time of dispencing

FREQUENCY: Standby time for dispencing

15

D. OPERATION

Turn ON/OFF switch is at the rear side of the equipment. FORCIMAT units have quite simple

operation.

1. Manual Mode

Depress “MANUAL”

Turn the handle down to lower the unit. And turn the handle downwords to lock the head in its

position.

Place the specimens and depress

Select rotation direction from the rear side of the automatic head

Adjust the Drip Lubricator, in manual or automatic mode. In Manual mode you have to press

purge or retract button manually. In automatic mode the DOSIONE will also start automatically.

Adjust frequency & period for DOSIONE Dispencing Unit

Depress “START” from FORCIMAT Head as well as FORCIPOL.

When the preparation is finished, depress “STOP”

Depress to take the specimens.

Turn the handle up to raise the unit in case the working wheel needs to be changed.

2. AUTO Mode

Depress “AUTO”

Turn the handle down to lower the unit.

Place the specimens and depress

Select rotation direction from the rear side of the automatic head

Adjust the Drip Lubricator, in manual or automatic mode. In Manual mode you have to press

purge or retract button manually. In automatic mode the DOSIONE will also start automatically.

Adjust frequency & period for DOSIONE Dispencing Unit

Set the speed of FORCIPOL-V grinder/polisher.

Set the cycle time from FORCIPOL-V.

Adjust the Drip Lubricator.

Start the FORCIPOL-V by depressing FWD or REV. (depending on the rotational direction you

want)

At the same time FORCIMAT will also be activated.

At the end on the cycle time, FORCIPOL-V and FORCIMAT will stop automatically and the buzzer

will start beeping.

Depress to take the specimens.

Turn the handle up to raise the unit to move to the next step.

16

E. SERVICE and MAINTENANCE

1. Maintenance

FORCIMAT Automatic head does not require periodic maintenance. In case of service required, do not

disassemble or try to repair by unqualified personnel. Please contact your local representative.

2. Troubleshooting

Fault

Cause

Action

Automatic head moves during

operation

The head is not locked

Lock Forcimat from the lock unit on the

spindle.

Power lamp is not on

The main switch is OFF

Turn on the main switch.

The fuses at the back are blown

Change the blown fuses

The pistons does not activate

No air connection

Check the air hose connections

The air hose squeezed

Straighten the hose

F. ACCESSORIES and CONSUMABLES

1. Accessories

Accessories for FORCIMAT:

31 82

Special Splash Guard, 200 mm., to be used with automatic heads

31 83

Special Splash Guard, 250 mm., to be used with automatic heads

31 93

Special Splash Guard, 300 mm., to be used with automatic heads

GR 0440

Air filtering and lubricating unit

Specimen Holders for FORCIMAT:

33 01

Specimen holder, 6 x Ø40 mm specimen

33 02

Set of insert rings for 30 mm

33 03

Set of insert rings for 25 mm

33 04

Set of rings for 1 1/4"

33 05

Set of rings for 1 1/2"

33 06

Specimen holder, Blank

33 07

Specimen holder, 3 x Ø50 mm; 3 x Ø30

45 51

Specimen holder, 6 x ø 25mm

45 54

Specimen holder, ø 145mm, 6xØ 1"

45 52

Specimen holder, 6 x ø 30mm specimen.

45 55

Specimen holder, 6 x 1 1/4 inch specimen.

45 56

Specimen holder, 6 x 1 1/2 inch specimen.

45 58

Specimen holder, 3 x 2 inch specimen.

DOSIONE Peristaltic Fluid Dispenser

GR 0874

Microprocessor controlled, with peristaltic and non-misting pump for

diamond suspensions, lubricant or 2 in 1 suspensions, with interface

to be connected to FORCIMAT/DIGIPREP’s Automatic Head.

17

G. TECHNICAL DOCUMENTATION

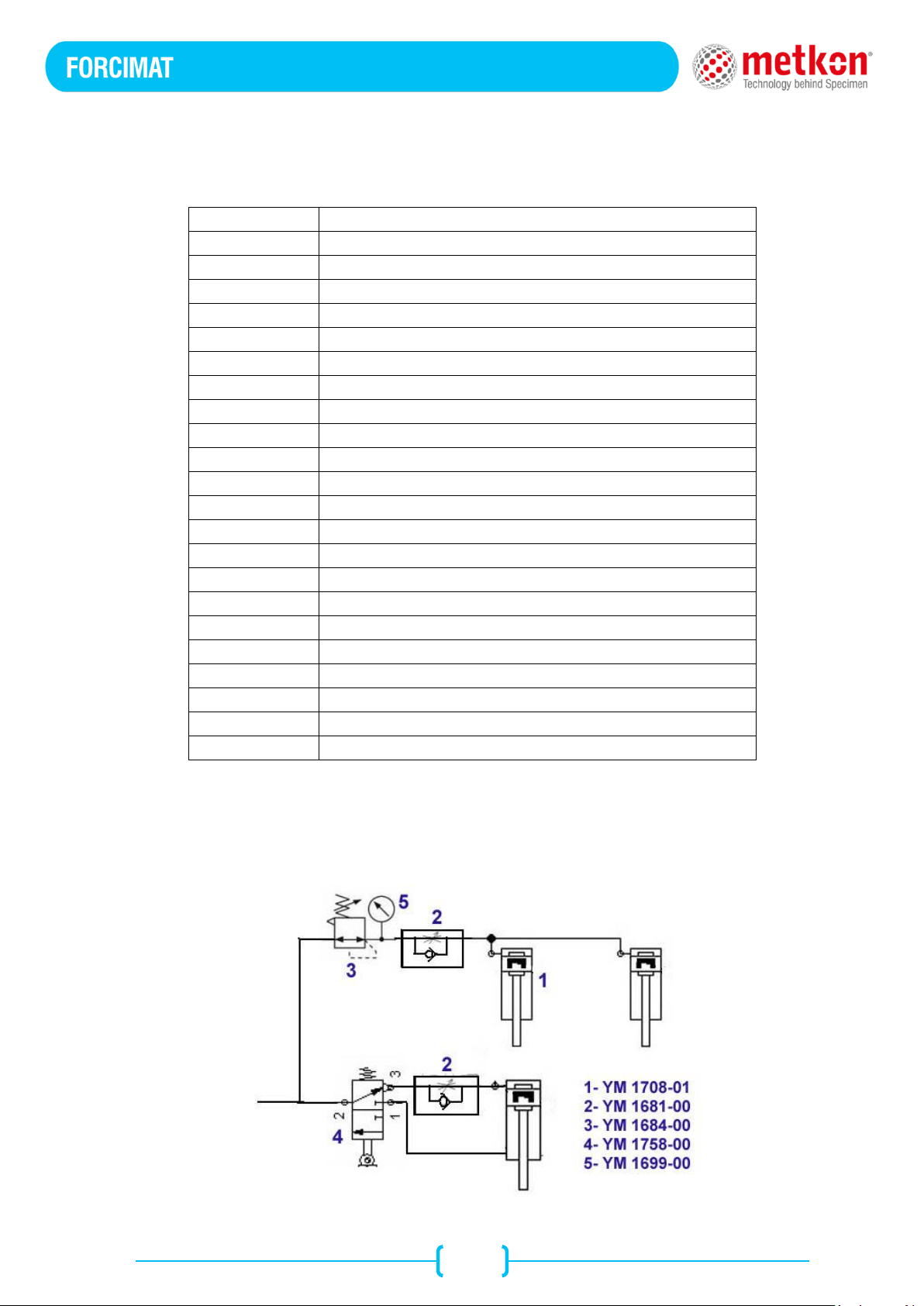

1. Recommended Spare Part List

ORDER CODE

DESCRIPTION

YM 0440-01

Cable TTR 2X0.75, White

YM 0746-00

Ventilator 80X80X25 220V, Cooling

YM 1188-01

Motor 24VDC 90W 210RPM

YM 5480-00

Loading foot, FRC

YM 1653-00

TIHGTENING BUSHING, FORCIMAT

YM 1659-00

ROTATING CONNECTOR 1/4 WITH BEARING KSL06-02S

YM 1661-00

Mechanical valve YMV 320

YM 1665-00

Bearing 51106 URB

YM 5721-00

power supply,SP 240-24V 10A

YM 5419-00

Belt 3PJ 432

YM 1684-01

Pneumatic governor 01-R-2001/4, Shako

YM 1691-01

Control board+Display Keyboard, FRC

YM 1696-00

Connector MIC 225-2-M

YM 1697-00

Connector MIC 25-2-F

YM 1699-00

Manometer 40, 0-6 BAR

YM 1708-01

SINGLE ACTING CYLNDER, USC 12 X 40-P

YM 1721-00

Pneumatic elbow PL04-M5C

YM 1758-01

Valve NV 5321 24V DC, Single

YM 1763-00

Potentiometer, Relay, Forcimat

YM 1764-00

Potentiometer Switch, Forcimat

YM 3751-00

BEARING 6006

YM 3779-01

Pump, 24V SR 10/30 RETSCHLE, Forcimat

2. Pneumatic Wiring Diagram

18

3. Customer Service

Our factory-trained assembly personal are at your disposal for customer service.

Please contact one of the following addresses:

METKON OFFICE ADDRESSES

Head Quarter

Metkon Instruments Inc.

Demirtas Dumlupinar Organize Sanayi Sitesi

Ali Osman Sonmez Cad. No:14 Bursa/TURKEY

Tel: +90 (224) 261 1840

Fax: +90 (224) 261 1844

E-Mail: metkonsales@metkon.com

Web: www.metkon.com

Metkon Americas

100 S. Saunders Rd. Lake Forest, IL 60045

Tel: 1 (847) 574-6317

Fax: 1 (847) 572-0886

E-Mail: metkonsales@metkon.com

Web: www.metkon.com

4. Electrical Wiring Diagrams

Table of contents

Other Metkon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Daihan Scientific

Daihan Scientific MSH-20D user manual

ThermoFisher Scientific

ThermoFisher Scientific ARL EQUINOX Series Instruction Notice

Phcbi

Phcbi MCO-170MP operating instructions

NoiseKen

NoiseKen EPS-02Hv2 instruction manual

Hettich

Hettich ROTO SILENTA 630 RS operating instructions

Tencor

Tencor AlphaStep 200 manual