Metkon FORCIPOL Series Administrator Guide

1

metkon.com

OPERATION & INSTRUCTION MANUAL

MODULAR GRINDING AND POLISHING SYSTEM

2

EC Declaration of Conformity

Manufacturer : Metkon Instruments Inc.

Address : Demirtas Dumlupinar Organize Sanayi Bolgesi

Ali Osman Sonmez Cd. No: 14 Bursa / TURKEY

Model No : FORCIPOL 102/202

Herewith declares that;

Metallographic Grinding & Polishing Machine

is in conformity with the provisions of the Machinery Directive (directive 2006/42/EEC), as amended, and with national

implementing legislation;

is in conformity with the provisions of the Low Voltage Directive (directive 2014/35/EU), as amended, and with national

implementing legislation;

is in conformity with the provisions of the EMC Directive (directive 2014/30/EU), as amended, and with national

implementing legislation;

And furthermore declares that

the following (parts/clauses of) standards have been applied

EN ISO 12100:2010, TS EN 60204-1, TS EN IEC 61000-6-2, TS EN 61000-6-4

Authorized Person: ERCIN SENAY

Position: Manager of Research and Development Department

Year: 2019

Bursa / Turkey

3

Index

DESCRIPTION ............................................................................................................................ 6

Design .....................................................................................................................................................................................6

Technical Data ........................................................................................................................................................................7

Warranty .................................................................................................................................................................................8

Safety Precautions ..................................................................................................................................................................8

INSTALLATION & SET UP........................................................................................................... 9

Unpacking & Checking Contents of Package ...........................................................................................................................9

Step by Step Unpacking...........................................................................................................................................................9

Installation and Set-Up ...........................................................................................................................................................9

Electrical Installation ........................................................................................................................................................................ 10

Water & Cable Connections................................................................................................................................................................ 11

Assembling FORCIMAT 52/102 Automatic Head.................................................................................................................................12

Air Connection...................................................................................................................................................................................13

Assembling Sample Holders.............................................................................................................................................................. 14

Adjusting the Height of FORCIMAT 52/102 Head............................................................................................................................... 14

Fixing and Releasing the Automatic Head ..........................................................................................................................................15

LEVOMAT Specimen Loading Fixture................................................................................................................................................ 16

DOSIMAT Peristaltic Fluid Dispenser..................................................................................................................................................17

Installation of DOSIMAT 12/52/102 ....................................................................................................................................................17

To Make DOSIMAT Ready for Operation............................................................................................................................................ 18

Cleaning DOSIMAT Hoses...................................................................................................................................................................19

Platen Installation..............................................................................................................................................................................19

Using Different Diameter Discs ..........................................................................................................................................................19

Optional Recirculating Cooling System (ENVIRO) ...............................................................................................................................19

Noise Level ........................................................................................................................................................................................19

CONTROL PANEL (FORCIPOL Control Unit)............................................................................. 20

Control Button Functions ......................................................................................................................................................20

CONTROL PANEL (FORCIMAT 52) ........................................................................................... 20

Control Button Functions ......................................................................................................................................................20

CONTROL PANEL (DOSIMAT 12)...............................................................................................21

Control Button Functions ...................................................................................................................................................... 21

CONTROL PANEL (DOSIMAT 52) ..............................................................................................21

Control Button Functions ...................................................................................................................................................... 21

CONTROL PANEL (DOSIMAT 102) ........................................................................................... 22

TOUCH SCREEN CONTROL PANEL (FORCIMAT 102) ............................................................... 22

Control Button Functions ......................................................................................................................................................22

Password List........................................................................................................................................................................23

Operation Parameter Ranges ................................................................................................................................................23

OPERATION (FORCIPOL Control Unit)..................................................................................... 24

4

Setting Parameters ................................................................................................................. 24

Setting Disc Speed ............................................................................................................................................................................ 24

Setting Disc Turning Direction .......................................................................................................................................................... 24

Setting Operation Time ..................................................................................................................................................................... 24

Cooling Water ................................................................................................................................................................................... 24

Cooling Water Activation Modes....................................................................................................................................................... 24

Disc Cleaning and Drying Function ................................................................................................................................................... 24

Changing Parameters of Disc Cleaning and Drying Function............................................................................................................. 24

Start and Stop ................................................................................................................................................................................... 24

OPERATION (FORCIMAT 52).................................................................................................... 25

Setting Parameters ................................................................................................................. 25

Setting Disc Speed ............................................................................................................................................................................ 25

Setting Head Speed........................................................................................................................................................................... 25

Opposite Rotation Direction.............................................................................................................................................................. 25

Setting Operation Time ..................................................................................................................................................................... 25

Cooling Water ................................................................................................................................................................................... 25

Cooling Water Activation Modes....................................................................................................................................................... 25

Disc Cleaning and Drying Function ................................................................................................................................................... 25

Changing Parameters of Disc Cleaning and Drying Function............................................................................................................. 25

Manual Operation............................................................................................................................................................................. 26

Pistons Up/Down.............................................................................................................................................................................. 26

Start and Stop ................................................................................................................................................................................... 26

OPERATION (DOSIMAT 12) ...................................................................................................... 26

Setting Parameters ................................................................................................................. 26

Setting Dosing Period ....................................................................................................................................................................... 26

Setting Dosing Time.......................................................................................................................................................................... 26

Purge .......................................................................................................................................................................................... 26

Retratch .......................................................................................................................................................................................... 26

Turning off/on the DOSIMAT 12 ........................................................................................................................................................ 26

OPERATION (DOSIMAT 52)...................................................................................................... 27

Setting Parameters ................................................................................................................. 27

Selecting / Deselecting the Bottles ................................................................................................................................................... 27

Setting Dosing Period and Dosing Time............................................................................................................................................. 27

Purge .......................................................................................................................................................................................... 27

Retratch .......................................................................................................................................................................................... 27

Turning off/on the DOSIMAT 52........................................................................................................................................................ 27

OPERATION (FORCIMAT 102).................................................................................................. 28

Mounting of Sample Holder.................................................................................................... 28

Switch on the Equipment ....................................................................................................... 28

Manual Operation .................................................................................................................................................................29

Individual / Central Force Operation .....................................................................................................................................29

Generating a New Program ................................................................................................................................................... 31

Saving/Loading Program .......................................................................................................................................................32

5

Saving Program................................................................................................................................................................................. 32

Loading Program .............................................................................................................................................................................. 32

SERVICE AND MAINTENANCE ................................................................................................. 33

Maintenance .........................................................................................................................................................................33

Daily Maintenance............................................................................................................................................................................ 33

Weekly Maintenance ........................................................................................................................................................................ 33

Monthly Maintenance....................................................................................................................................................................... 34

Yearly Maintenance.......................................................................................................................................................................... 34

Troubleshooting....................................................................................................................................................................35

ACCESSORIES AND CONSUMABLES........................................................................................ 36

Sample Holders and Accessories...........................................................................................................................................36

Consumables.........................................................................................................................................................................39

SiC Grinding Papers .......................................................................................................................................................................... 39

MAGNETO Diamond Grinding Discs................................................................................................................................................... 43

MAGNETO-S Silicon Carbide Grinding Discs...................................................................................................................................... 45

Polishing Cloths................................................................................................................................................................................46

Diamond Products ............................................................................................................................................................................48

Alumina & Colloidal Silica Products...................................................................................................................................................49

TECHNICAL DOCUMENTATION ............................................................................................... 50

Pneumatic Wiring Diagram (FORCIMAT 52)...........................................................................................................................50

Pneumatic Wiring Diagram (FORCIMAT 102).........................................................................................................................50

Customer Service .................................................................................................................................................................. 51

6

DESCRIPTION

Design

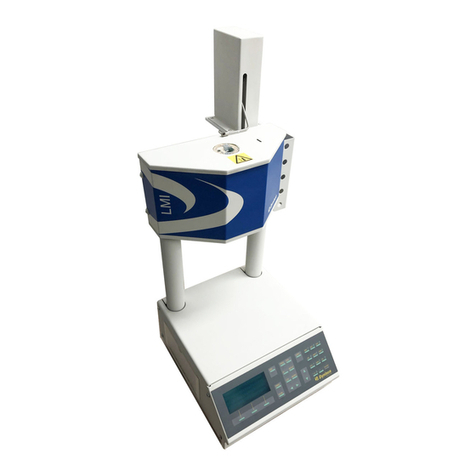

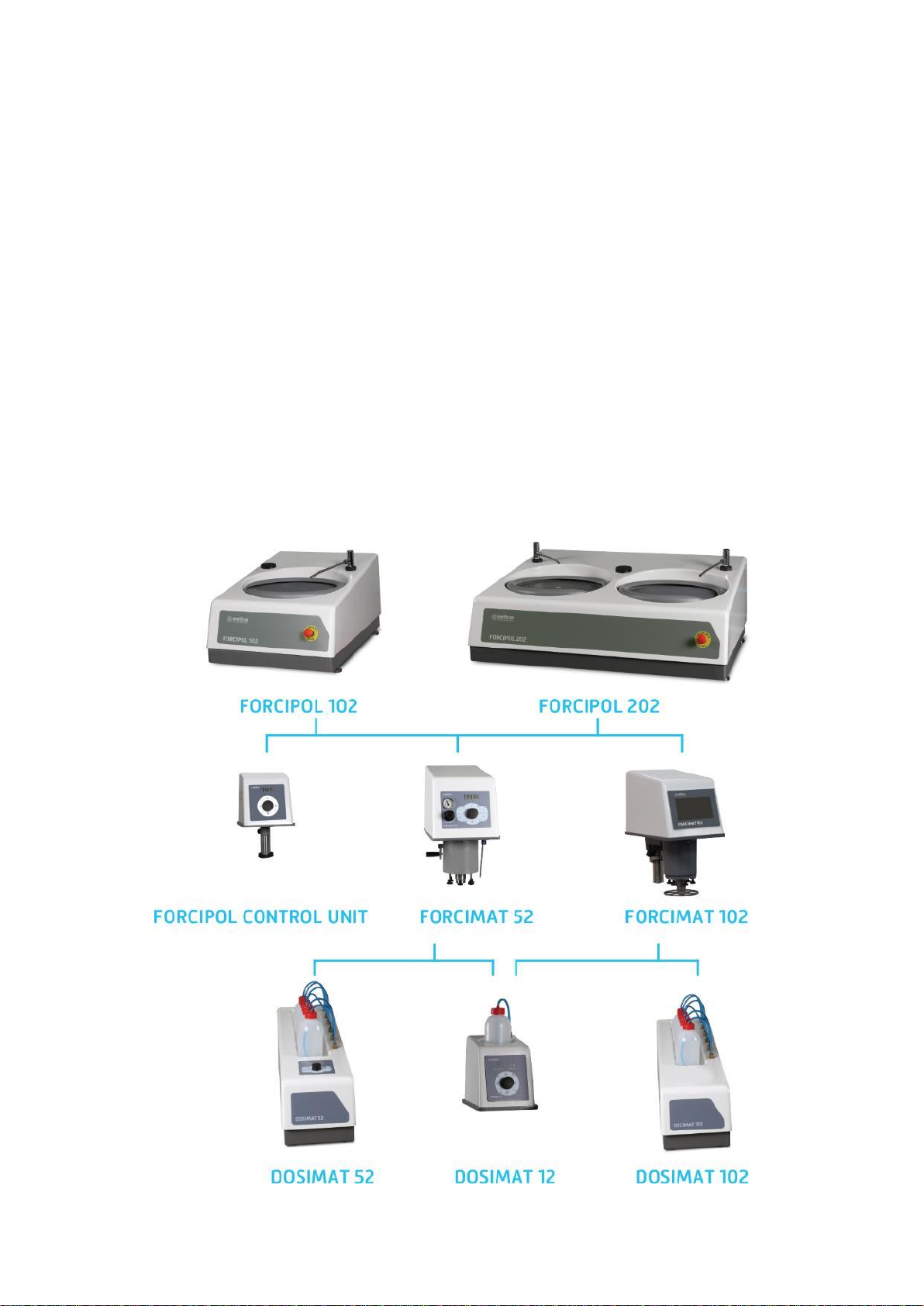

All materials testing laboratories in the industry, research or

educational field have a demand for sample preparation.

Whether your requirements call for individual components or

basic sample preparation, FORCIPOL family of instruments

will meet your needs. FORCIPOL Series of instruments are

available as Single wheel (FORCIPOL 102) and Dual wheel

(FORCIPOL 202) Units.

Both single and double wheel versions are suitable with

Ø200, Ø250 and Ø300 mm wheels. The working wheel is

powered by a high torque 1.0 HP electric motor with both

clockwise and counterclockwise wheel rotation possibility.

The state of the art frequency converter allows smooth speed

variation (50-600 rpm) of the grinding wheel with soft start

and soft stop. This allows the setting of the optimum speed

for each individual preparation process. It is perfect choice for

laboratories preparing a wide range of different materials

from very small to very large.

FORCIPOL instruments are designed to modular configuration

for manual, semi-automatic and programmable automatic

equipment. When only manual preparation is required,

FORCIPOL Control Unit can be fitted on the FORCIPOL grinder

/ polisher. If automatic operation is required in the future, one

of the FORCIMAT automatic heads can be installed at any

time.

When the number of specimens to be prepared increases,

FORCIPOL instruments can be fitted with one of FORCIMAT

automatic heads (FORCIMAT 52 or FORCIMAT 102) for

automation. FORCIMAT automatic heads provide high rate

sample preparation and frees the operator from the grinding

and polishing procedures. FORCIMAT series of Automatic

Heads are available as two types:

FORCIMAT 52 and FORCIMAT 102

7

Technical Data

Model

Order No

FORCIPOL 102

36 21-200/250/300

FORCIPOL 202

36 22-200/250/300

Number of Wheels

1

2

Wheel Diameter

Ø200/250/300 mm

Ø200/250/300 mm

Base Motor Power

1 HP

1 HP

Wheel Speed

50-600 RPM

50-600 RPM

Wheel Rotation Direction

CW/CCW

CW/CCW

Dimensions, WxDxH, (cm)

45 x 74 x 34

87 x 74 x 34

Weight, kgs

50

55

Model

Order No

FORCIPOL Control Unit

30 11

FORCIMAT 52

30 12

FORCIMAT 102

30 14

Operation

Manual

Semi Automatic

Programmable

Automatic

Application of Force

-

Individual

Individual + Central

Control Panel

Touch Pad Controls

Touch Pad Controls

7" HMI Touch Screen

Program Memory

Last Parameters

Retained in Memory

Last Parameters

Retained in Memory

30 Programs

Head Motor Power

-

100 W

100 W

Sample Holder Rotation Direction

-

CW

CW

Sample Holder Speed

-

50-150 RPM

50-150 RPM

Individual Force

-

5-60 N

5-60 N

Central Force

-

-

30-500 N

Grinding Depth Measurement

-

-

Optional

(10 µm Accuracy)

Disc Cleaning & Drying Feature

Yes

Yes

Yes

Smart Water Saving Feature

Yes

Yes

Yes

Compatible Instruments

FORCIPOL 102/202

FORCIPOL 102/202

FORCIPOL 102/202

Compressed Air Requirement

-

6 Bars

6 Bars

Dimensions, WxDxH, (cm)

20 x 20x 39

(above FORCIPOL disc)

26 x 46 x 54

(above FORCIPOL disc)

26 x 46 x 54

(above FORCIPOL disc)

Weight, kgs

5

16

16

Model

Order No

DOSIMAT 12

40 06

DOSIMAT 52

40 07

DOSIMAT 102

40 08

Number of Pumps (Bottles)

1

6

6

Control Panel

Touch Pad Controls

Touch Pad Controls

Controllable from LCD

Screen of FORCIMAT 102

Program Memory

Last Parameters

Retained in Memory

Last Parameters

Retained in Memory

30 Programs

Pre-Dosing Function

No

No

Yes

Compatible Instruments

FORCIMAT 52/102

FORCIMAT 52

FORCIMAT 102

Dimensions, WxDxH, (cm)

14 x 21x 16

20 x 74 x 30

20 x 74 x 30

Weight, kgs

5

15

15

8

Warranty

The FORCIPOL Series of instruments are guaranteed against

defective material or workmanship defects for a period of 12

months from the date of receipt by the customer or latest 18

months after the shipping date. The warranty is not valid if

inspection shows evidence of misuse or unauthorized repair.

Warranty covers only replacement of defective materials. If

this unit need to be returned to our factory for service, please

contact your distributor for authorization and include the

following details: Serial Number of the unit, Invoice number

and date. Transport costs belong to the customer.

NOTE

The equipment is designed to be used with

METKON accessories and consumables. In case of

misuse of equipment, improper installation,

alteration, use of different source parts, improper

repair, METKON will accept NO responsibility for any

damages to the operator or the equipment. Disassembling of

any part should always be performed by a qualified

technician

Safety Precautions

Read the below instructions carefully before use.

Place the machine on a sturdy and safe platform.

The equipment must be installed in compliance with

local safety regulations.

Only use approved METKON accessories and

consumables to achieve maximum safety and lifetime.

Follow the instructions and safety regulations when

lifting and carrying the equipment.

Be sure that the water connections are assembled

properly without any water leakage.

Be sure that the water outlet hose is safely assembled to

the outlet connection.

Make sure that the grinding and polishing discs are

correctly assembled and the pins on the faceplate are

engaged with the grinding disc.

While grinding manually, be careful not to touch the

grinding disc and do not put your hand close to head.

Do not try to collect a specimen from the working area

while the disc is turning.

Disconnect the electrical connection before servicing the

equipment.

Do not put your hand under the sample holder while

moving the head up and down.

Follow the periodically maintenance.

NOTE

METKON Instruments Inc. can make any changes

without notice on the equipment, accessories,

consumables and miscellaneous products.

Consequently; visual or written information on

the instruction manuals, technical materials, catalogues,

website, product videos and other marketing materials may

show inconsistencies and may be different from the product.

9

INSTALLATION & SET UP

Unpacking & Checking Contents of Package

Carefully unpack and check contents of the package. If any

components are missing or damaged, save the packing list

and materials and advise your distributor and the carrier of

the discrepancy.

Carefully unpack and check that the following items have

been received:

Power Cable, 1.8 mt, 1 piece

Drain Hose, 1.5 mt, 1 piece

Water Inlet Hose, 1.5 mt, 1 piece

Pneumatic Fitting, 8 mm to ¼”, 1 piece

Brass adapter, ¼”to ½”, 1 piece

Hose Clamp, Ø22 to Ø36 mm, 1 piece

Air Hose, 1.5 mt, 1 piece (If FORCIMAT 52/102 is ordered)

Hex Key, 1.5 mt, 1 piece (If FORCIMAT 52/102 is ordered)

WARNING

Please consider the weight of equipment and

be sure that there are enough people (at least

2) or lifting equipment to lift safely for

transportation. It is recommended to wear

safety shoes during transportation.

ATTENTION

FORCIPOL 102/202 is bolted to a wood base for

protection during shipping. Remove the bolt

securing the unit to the wood base.

Step by Step Unpacking

Carefully remove the outer stretch wrap, cut the strips

and remove the cover.

Place the upper box on the ground.

Open that box and remove the consumables.

10

Open the other box and remove the equipment from the

box by holding wooden base at the bottom. Be careful

not to damage ABS cover when lifting. Please consider

weight of equipment when lifting it. Lift the equipment

by considering the center of gravity.

Equipment is fixed on the wooden base with bolts.

Carefully remove these bolts.

Carefully remove the protective bubble wrap. Be carefull

not to damage equipment while using a knife.

Installation and Set-Up

CAUTION

Follow approved procedures and take all

necessary preventive safety measures when

lifting and installing this equipment. Improper

lifting can result equipment damage.

FORCIPOL 102/202 is available as bench top.

FORCIPOL 102/202 should be placed on a sturdy and safe

platform. Please be sure that the platform is large enough

and can stand its weight.

In order to work with equipment comfortably, it is

recommended to leave at least 30 cm space from all side

of the equipment.

You can see the dimensions and weight of FORCIPOL

102/202 together with FORCIPOL Control Unit as below:

FORCIPOL 102 + FORCIPOL Control Unit

Dimensions

W

D

H

45 cm

74 cm

39 cm

Weight

Approx. 55 kgs

FORCIPOL 202 + FORCIPOL Control Unit

Dimensions

W

D

H

87 cm

74 cm

39 cm

Weight

Approx. 60 kgs

Electrical Installation

Before making electrical connections, check that the voltage

and frequency stated on the specification plate correspond to

the local voltage and frequency. Check that the values for

mono-phase voltage if it is compatible with the intended

electrical supply before installation.

ATTENTION

Connect the unit to the grounded mains

voltage.

WARNING

Electrical Shock Hazard. A qualified electrical

technician should perform all hard wiring and

electrical maintenance.

11

Disconnect the power supply before making any

electrical adjustments.

Make sure that the supply voltage and frequency is

correct. Check the values from the machine identification

plate located at the rear of the machine:

Voltage / Frequency

Operational

Power Range

Fuse Rating

230 V, 50/60 Hz. 1 ph.

200 - 250 V

10A (C Type)

115 V, 50/60 Hz. 1 ph.

100 - 125 V

10A (C Type)

Identification Plate

Connect the equipment to the grounded mains voltage.

Power cord will be supplied with the equipment.

Lenght of power cable is 1.8 meters.

Power Cable

You can see suitable power sockets as below. If you have

not suitable power socket, in this case you should supply

a suitable power cord.

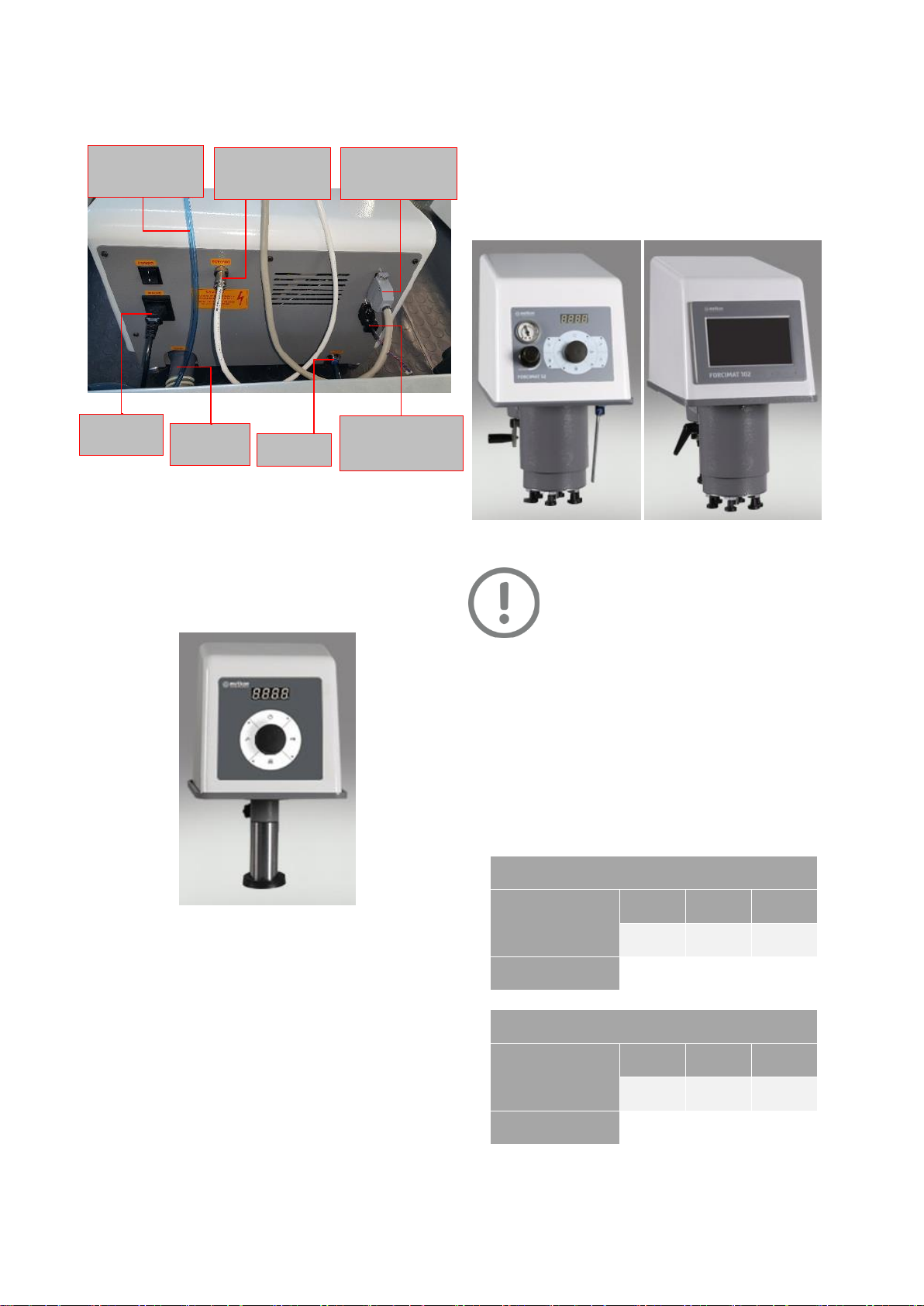

Water & Cable Connections

FORCIPOL 102/202 requires water supply with a

minimum of 2 liters/min flow rate.

Maximum water pressure must not exceed 3 bars. Well

water or hard water must not be used.

If the equipment used with well water, hydrophore or

very hard water; a water filtering and pressure regulator

system must be used. Please contact Metkon Service

representative if you need water filtering and pressure

regulator system.

Water Filtering and Pressure Regulator System

ATTENTION

A Hydrophore generates much higher water

pressure than city water. This causes input

hose to blow out and solenoid valve to be

damaged. Maximum water pressure must not exceed 3 bars.

ATTENTION

Well water or hard water causes solenoid valve

to be clogged up and broke down due to dirt

and lime.

Water inlet and drain hoses will be sent together with the

equipment. (See: Installation Kit)

See diameters of hoses as below:

Drain Hose:

Input diameter: 29 mm

Outer diameter: 33 mm

Water Hose:

Input diameter: 5 mm

Outer diameter: 8 mm (5/16”)

Please be sure that there are enough space or holes for

hoses at the backside of the equipment.

12

Connect the line water to the unit with the plastic tube.

Fix the Drain Water Hose to the drain.

Connections

Assembling FORCIMAT 52/102 Automatic Head

FORCIPOL instruments are designed to modular configuration

for manual, semi-automatic and programmable automatic

equipment. When only manual preparation is required,

FORCIPOL Control Unit can be fitted on the FORCIPOL.

FORCIPOL Control Unit

When the number of specimens to be prepared increases,

FORCIPOL instruments can be fitted with one of FORCIMAT

automatic heads (FORCIMAT 52 or FORCIMAT 102) for

automation. FORCIMAT automatic heads provide high rate

sample preparation and frees the operator from the grinding

and polishing procedures.

FORCIMAT series of Automatic Heads are available as two

types: FORCIMAT 52 and FORCIMAT 102.

FORCIMAT 52 provides single force semi automatic

application. It has touch pad controls with turn knob.

FORCIMAT 102 provides single force and central force

application. It has programmable 7” HMI touch screen.

FORCIMAT 52 FORCIMAT 102

CAUTION

Follow approved procedures and take all

necessary preventive safety measures when

lifting and installing this equipment. Improper

lifting can result equipment damage.

Both FORCIPOL Control Unit, FORCIMAT 52 and FORCIMAT

102 are mounted on FORCIPOL base same way. Follow below

steps to step by step mount:

Please be sure that the platform is large enough and can

stand its weight.

You can see the total dimensions and total weight of

FORCIPOL 102/202 together with FORCIMAT 52/102 as

below:

FORCIPOL 102 + FORCIMAT 52/102

Dimensions

W

D

H

45 cm

74 cm

54 cm

Weight

Approx. 66 kgs

FORCIPOL 202 + FORCIMAT 52/102

Dimensions

W

D

H

87 cm

74 cm

54 cm

Weight

Approx. 71 kgs

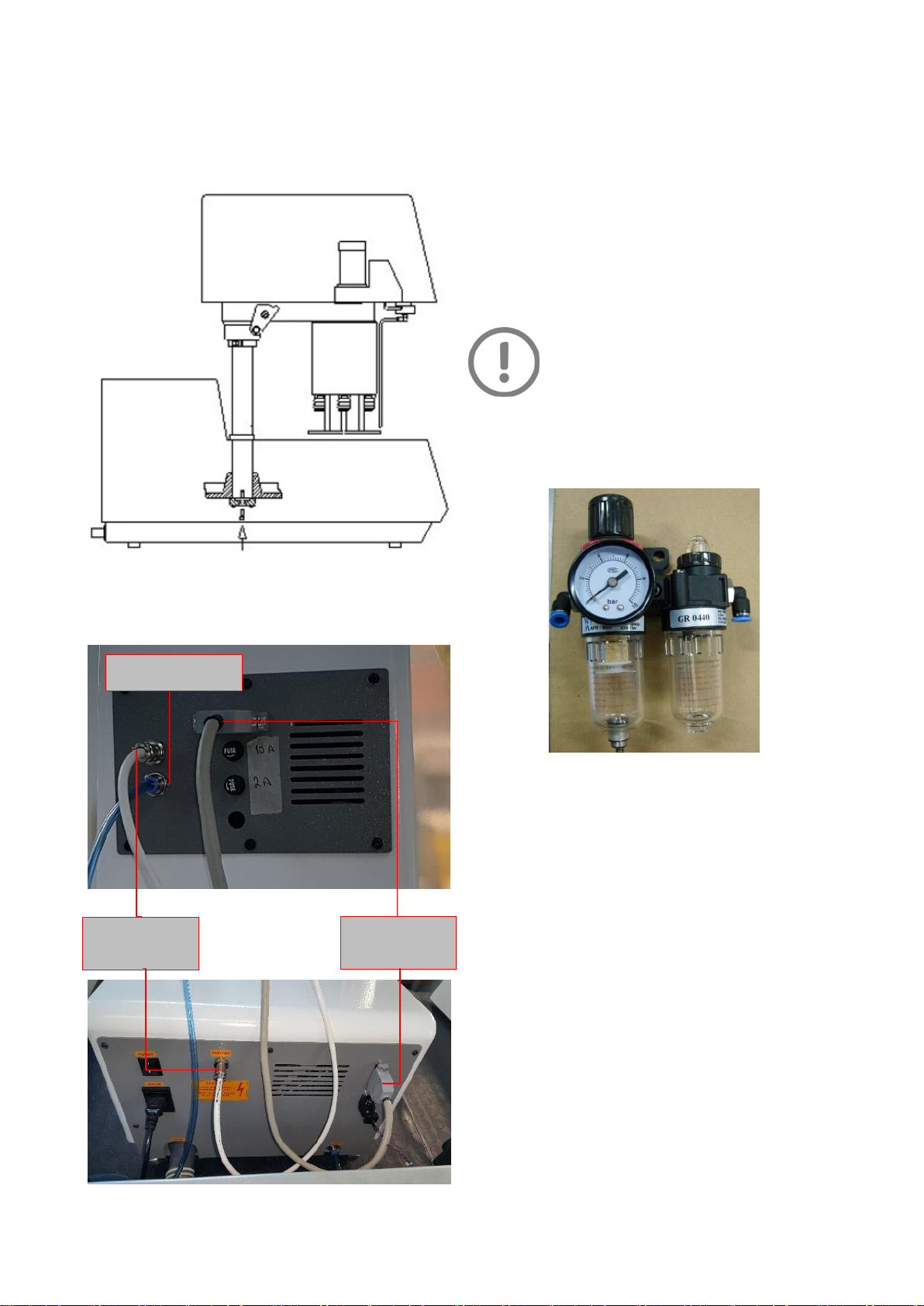

Air Source

Connection to

FORCIMAT 52/102

Drain Water

Outlet

Water Inlet

Power Cable for

Head Unit

Communication

Cable for Head Unit

Communication and

Power Cable for

Dosing Unit

Mains Power

Cable

13

Pull off the plastic plug on the surface of FORCIPOL.

Place FORCIMAT with its column in the FORCIPOL and fix

it from the bottom with the M8 screw. Be sure that the

screw is tighten correctly. (FORCIPOL Control Unit is also

mounted in same way)

Fixing FORCIMAT with M8 Screw at the bottom of FORCIPOL

Make power and communication cable connections as

below: (Same for FORCIPOL Control Unit)

FORCIMAT 52/102 Connections

FORCIPOL 102/202 Connections

Air Connection

If FORCIPOL 102/202 is equipped with one of FORCIMAT

52/102 automatic head, it requires air supply with 6 bars

pressure. (FORCIPOL Control Unit does not require air

connection)

A compressor, which can generate more than 6 bars and

has 50 liters capacity, is enough for only one equipment.

If you have more equipment that use air supply, please

consult your local compressor dealer to choose correct

compressor.

ATTENTION

If there is a doubt about the quality of the air

supply, make certain that a filter and regulator

unit for compressed air, which is connected in

the airline before FORCIMAT 52/102.

METKON can supply GR 0440 Air Filtering and

Lubricating Unit, which regulates air pressure to 6 bars.

Air Filtering and Lubricating Unit

A pneumatic air hose with 8 mm outer diameter will be

supplied with the equipment. (See: Installation Kit)

Please be sure that you have suitable connection fittings

to connect hose to the airline.

Power Cable for

FORCIMAT 52/102

Communication

Cable for

FORCIMAT 52/102

Air Source Connection

to FORCIMAT 52/102

14

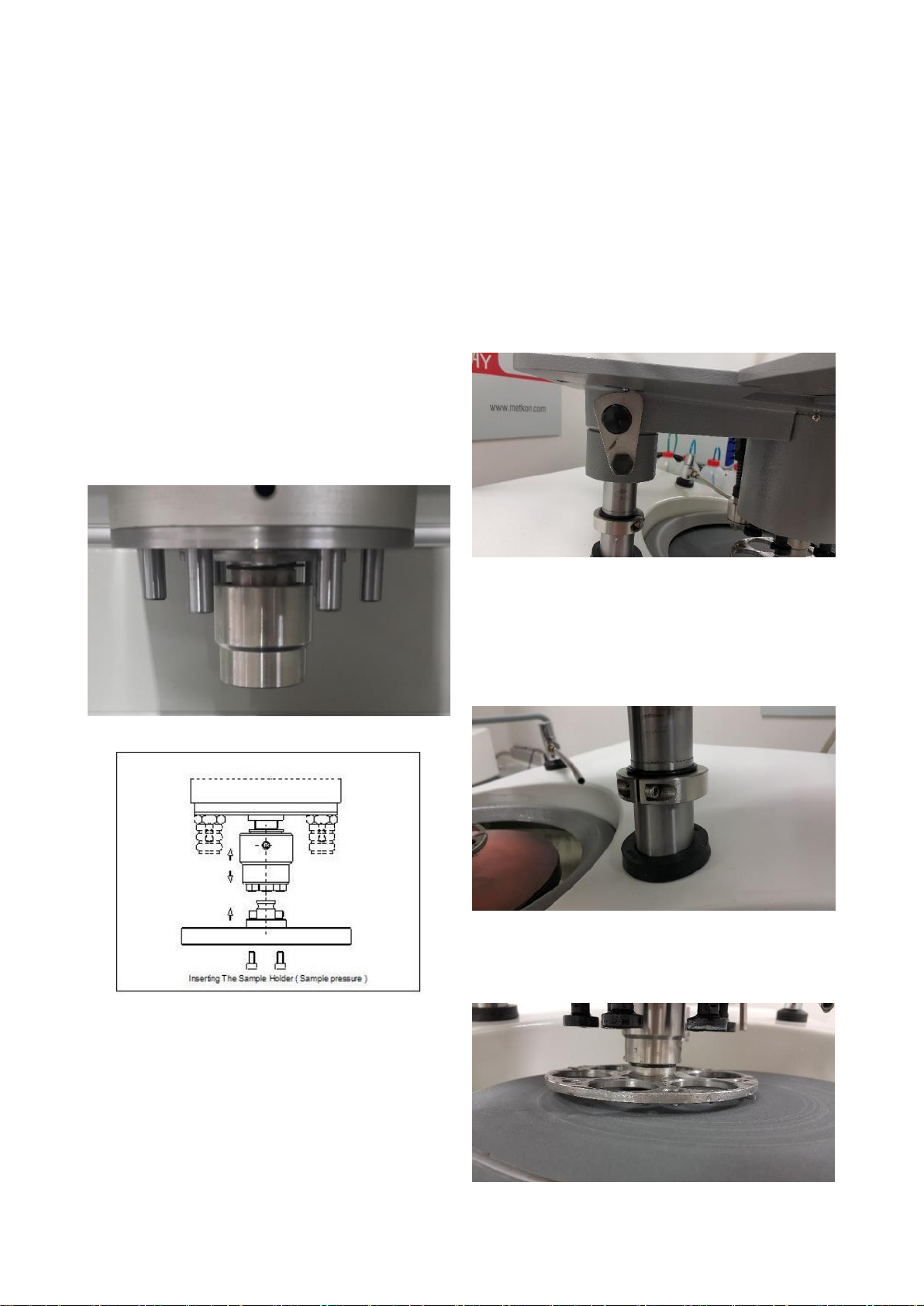

Assembling Sample Holders

The FORCIMAT 52 is designed for only Single Force

applications; the FORCIMAT 102 is designed for both Single

Force and Central Force applications. Six Single Force pistons

prepare one to six samples at the same time. The piston feet

are engineered to provide optimally flat sample preparation.

Use Central Force for multiple simultaneous sample

preparation. A soft start and soft stop motor function helps

prevent sample damage. The mechanical vertical drive

provides downforce without the need for compressed air in

Central Force operation.

Single and central sample holders are mounted in same way.

Insert the “central or individual force sample holder

adapter”on the automatic head.

Move the chuck upwards by hand.

Insert the sample holder and release the chuck.

Connection Chuck

Mounting Specimen Holder

Adjusting the Height of FORCIMAT 52/102 Head

When you place the FORCIMAT on the FORCIPOL we strongly

advise you to check the distance between the single force

sample holder and the disc when the sample holder is at the

bottom position. It should be 5 mm. If it is longer or shorter

you need to adjust the height. Height of FORCIMAT 52 and

FORCIMAT 102 are adjusted similarly but there is a little

difference.

Follow below steps to adjust height of FORCIMAT 52:

Move the head position handle up. The FORCIMAT 52 will

go up by pneumatic force.

Head Position Handle

Loosen the setscrew of the adjusting collar. If the lenght

you measured at the beginning is shorter than 5 mm,

move the collar upwards and tighten the setscrew again.

If it was longer than 5 mm at the beginning, than you

have to move the collar downwards and tighten

setscrew.

Adjusting Collar

After that check the distance again when the sample

holder is at the bottom position. If the distance is not OK

again you have to do the steps one more time.

Distance Between Sample Holder and Disc Should be 5 mm

15

Follow below steps to adjust height of FORCIMAT 102:

FORCIMAT 102 cannot go up by pneumatic force like

FORCIMAT 52. For this reason, there are two collars to

prevent head from falling down. Do not loosen both of

them at the same time.

If the lenght you measured at the beginning is shorter

than 5 mm, you should move the collar upwards. To do

this;

oLoosen the upper collar.

oLift the head up by the help of another person.

oMove the collar up and tighten.

oLoosen and move up another collar and tighten it.

If it was longer than 5 mm at the beginning, than you

have to move the collars downwards. To do this;

oLoosen the bottom collar.

oMove the collars down and tighten it.

oLoosen another collar and move it down, then

tighten it.

Head Position Handle and Collars

Fixing and Releasing the Automatic Head

Before starting grinding & polishing operation, the automatic

head should be fixed. Both FORCIMAT 52 and FORCIMAT 102

is fixed similar way with head positioning handle.

FORCIMAT 52:

If you turn the handle up, the head will go up by pneumatic

force and will be able to move right and left. You can easily

replace sample holder or disc at this position.

If you turn the handle down, the head will go down. If you

keep it turning more, the head will be fixed and cannot be

moved right and left.

Loose Position Fixing Position

FORCIMAT 102:

If you turn the handle up, the head will be loosen. You can

easily position the head.

If you turn the handle down, the head will be fixed and

cannot be moved right and left.

Loose Position Fixing Position

ATTENTION

Before moving down the automatic head, make

sure that the water tube is not under the

sample holder. Otherwise, the sample holder

may put pressure on the water tube and may

damage it. The damages caused by operator mistake are out

of warranty.

16

LEVOMAT Specimen Loading Fixture

All specimens on the central sample holder should be at the

same level to obtain same result for all samples. Therefore,

you should adjust level of samples before the operation.

LEVOMAT Specimen Loading Fixture is designed for this

purpose as an optional accessory. You adjust the level of the

entire specimen very quickly and easily.

Please see below step by step how to fix samples at the same

level using LEVOMAT:

Put the Specimen Loading Plate on the LEVOMAT.

Diameter of Specimen Loading Plate should be chosen

according to sample holder's diameter.

Place Central Sample Holder on to the Specimen Loading

Plate.

Push the arm downwards to fix sample holder properly.

Place your specimens into the Sample Holder.

Tight each the screws properly using an Allen key.

Pull it upwards to release sample holder. The Sample

Holder is Ready to use with DIGIPREP

17

DOSIMAT Peristaltic Fluid Dispenser

DOSIMAT Peristaltic Dispenser is an optional accessory for the

FORCIMAT 52 and FORCIMAT 102 systems. It is an automatic

fluid dispensing instrument used in combination to obtain

consistent specimens and to save time and consumables.

DOSIMAT can feed both diamond suspensions / lubricants and

aluminium oxide suspensions. Automatic dosing of

consumables is applied precisely for perfect sample surfaces.

Efficiency is further increased with high quality peristaltic

pumps that guarantee exactly the same dosing every time for

automation and control of consumable consumption. The

liquid is dosed exactly to where the operator wants it on the

polishing cloth. No vaporization or spray mist occurs.

It is possible to clean all the tubes with a single button at the

end of preparation steps to eliminate the risk of clogged

tubes.

Three different DOSIMAT Peristaltic Fluid Dispensers are

available for FORCIMAT 52 and FORCIMAT 102:

DOSIMAT 12 (With 1 Peristaltic Pump)

DOSIMAT 12 has one peristaltic and non-misting pump for

diamond suspensions, alumina suspensions, lubricant or 2 in

1 suspensions and can be matched with Forcimat 52 and

Forcimat 102 Automatic Heads. Modern touch pad controls

with ergonomic turn knob allows fast and easy setting of

dispensing parameters like; frequency, dosing time, etc.

parameters and increases productivity. The last parameter

settings are always retained in the memory.

DOSIMAT 52 (With 6 Peristaltic Pump)

DOSIMAT 52 has 5 peristaltic pumps for diamond suspensions

/ lubricant and 1 pump for aluminium oxide suspension or 2

in 1 suspensions and can be matched with Forcimat 52

Automatic Head. Modern touch pad controls with ergonomic

turn knob allows fast and easy setting of dispensing

parameters like; frequency, dosing time, etc. parameters and

increases productivity. The last parameter settings are always

retained in the memory.

DOSIMAT 102 (With 6 Peristaltic Pump)

DOSIMAT 102 has 5 peristaltic pumps for diamond

suspensions / lubricant and 1 pump for aluminium oxide

suspension or 2 in 1 suspensions and can be matched with

Forcimat 102 Automatic Head. Dispensing parameters like;

frequency, dosing time, fluid selection etc. are controlled

through the LCD screen of the FORCIMAT 102 Automatic Head

and can be stored in memory.

DOSIMAT 12/52/102

DOSIMAT bottles are named with numbers on FORCIMAT

102’s software from 1 to 6.

Number 1 bottle has dedicated for alumina suspensions. Do

not put alumina suspensions on the other bottles. These

pumps cannot drip suspension due to density of alumina

suspension. Moreover, they can be clogged up quickly.

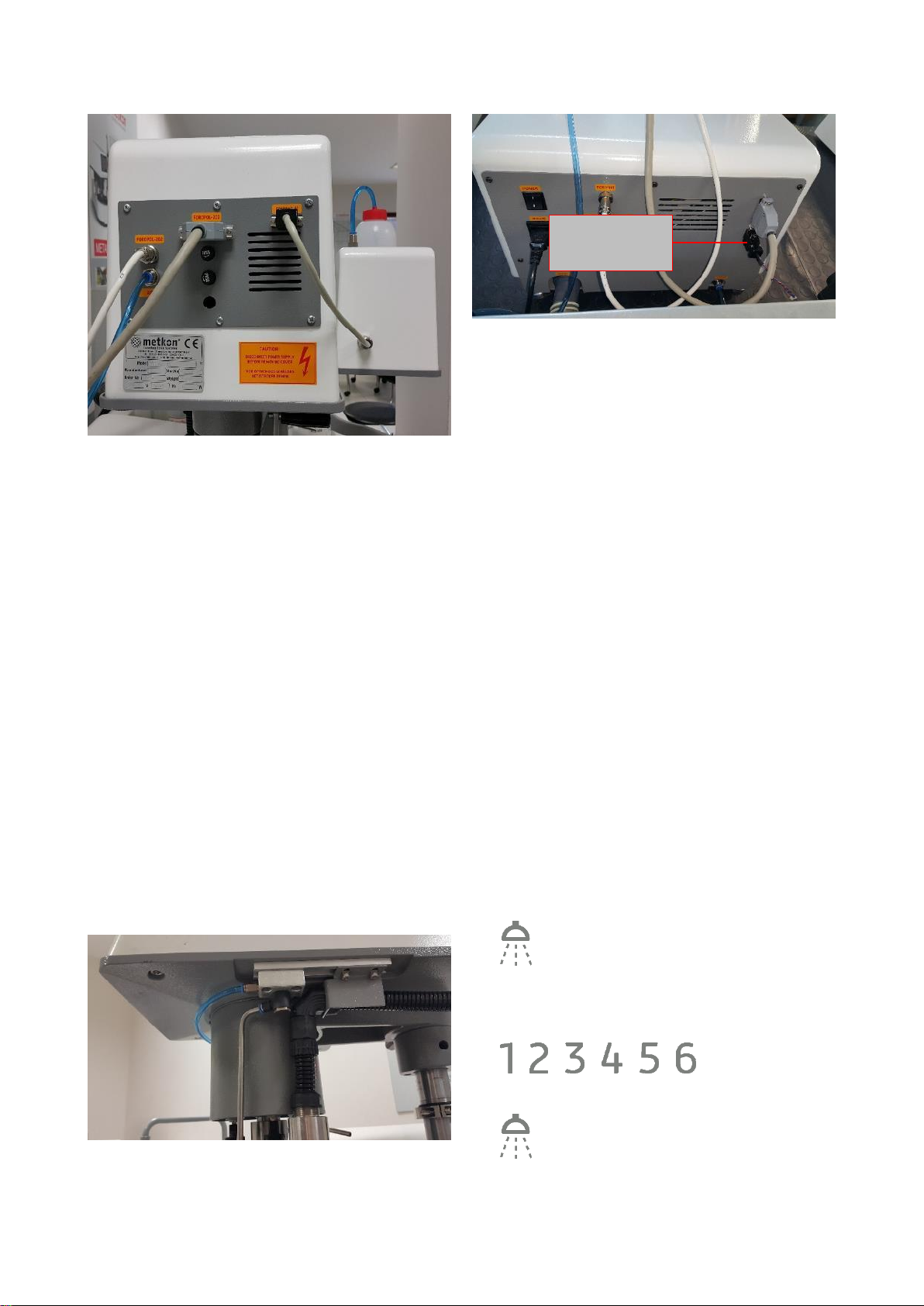

Installation of DOSIMAT 12/52/102

DOSIMAT 12

DOSIMAT 12 can be used together with FORCIMAT 52 or

FORCIMAT 102. Follow below steps to install DOSIMAT 12:

Place the mounting bracket of DOSIMAT 12 to the left

hand side of FORCIMAT’s base.

Tighten the screws and fix it properly.

Mount the dosing pipe to the right hand side of

FORCIMAT.

18

Make cable connection.

Activate the DOSIMAT 12 from the FORCIMAT 52 or

FORCIMAT 102.

If you have FORCIMAT 52; follow below steps to activate

DOSIMAT 12:

oKeep pressing the turn-knob until it enter

factors settings menu.

oChoose “P3” by turning the turn-knob, then

press on turn-knob.

oChoose “1” and press turn-knob again. (0: None,

1: DOSIMAT 12, 2: DOSIMAT 52, 3: Both)

oPress disc speed button to exit.

If you have FORCIMAT 102; follow below steps to activate

DOSIMAT 12:

oEnter the SETTINGS >>> METKON SERVICE

menu.

oSet DOSIMAT 12 to “ACTIVATE”

oExit

DOSIMAT 52

DOSIMAT 52 can be used together with FORCIMAT 52. Follow

below steps to install DOSIMAT 52:

Place the DOSIMAT 52 to right or left hand side of

FORCIPOL.

Mount the dosing pipe to the right hand side of

FORCIMAT 52.

Make cable connection.

Activate the DOSIMAT 52 from the FORCIMAT 52.

Follow below steps to activate DOSIMAT 52:

oKeep pressing the turn-knob until it enter

factors setting menu.

oChoose “P3” by turning the turn-knob, then

press on turn-knob.

oChoose “2” and press turn-knob again.

(0: None, 1: DOSIMAT 12, 2: DOSIMAT 52,

3: Both)

oPress disc speed button to exit.

DOSIMAT 102

DOSIMAT 102 can be used together with FORCIMAT 102.

Installation of DOSIMAT 102 is same as DOSIMAT 52. The only

difference is activation. Follow below steps to activate

DOSIMAT 102:

oEnter the SETTINGS >>> METKON SERVICE

menu.

oSet DOSIMAT 102 to “6”

oExit

To Make DOSIMAT Ready for Operation

Fluids are conveyed from bottles to polishing cloth via plastic

hoses. So, the pumps should be run until fluids drip from steel

pipes before the first operation.

Follow below steps to run the pumps:

DOSIMAT 12

Keep pressing the purge button until fluid starts dripping

from the steel pipe.

DOSIMAT 52

Press the number of bottles that you want to use during

operation.

Keep pressing the purge button until fluids start dripping

from the steel pipes.

Communication and

Power Cable for

DOSIMAT 52/102

19

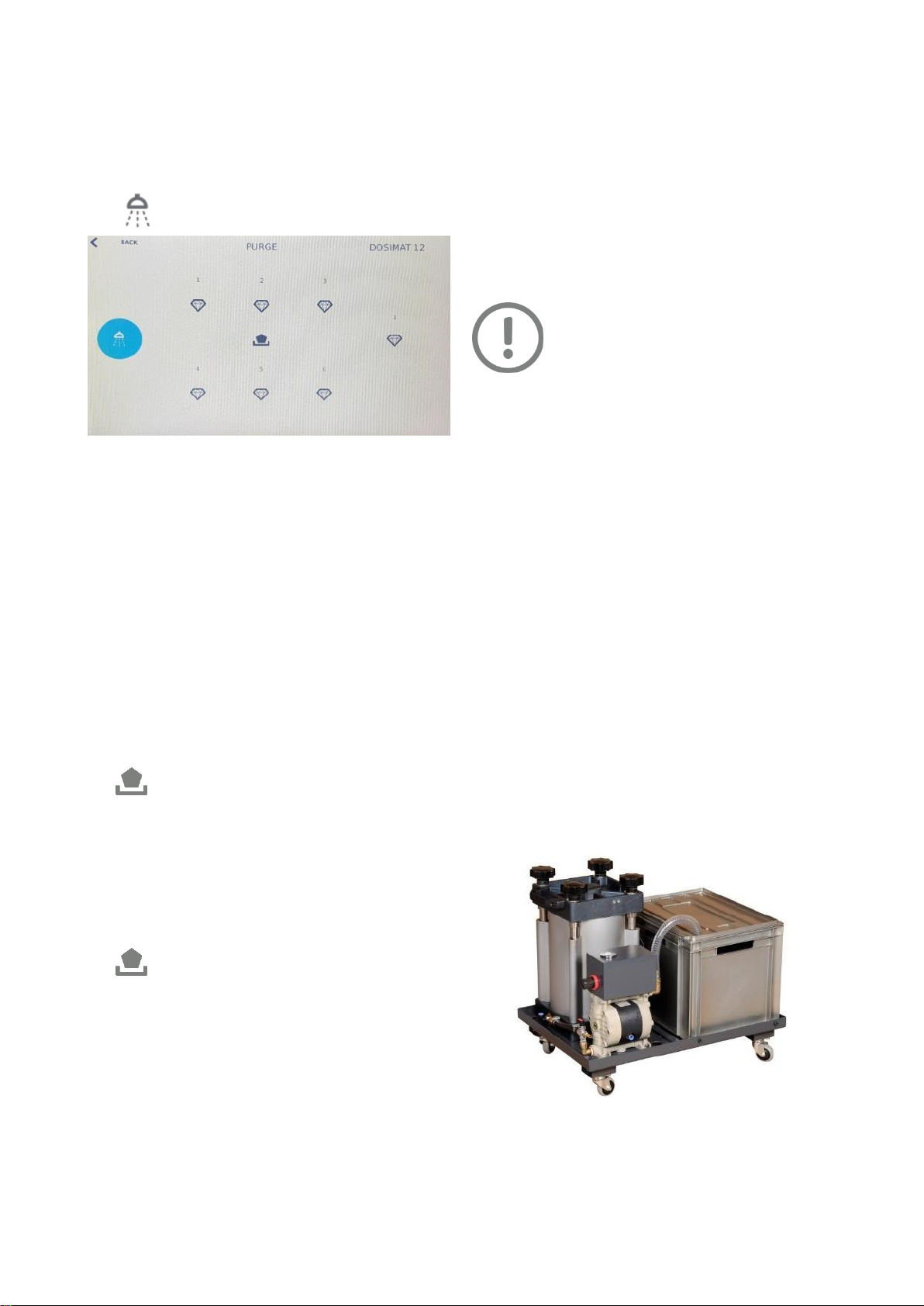

DOSIMAT 102

Enter Manual, Single or Central Operation menu from the

FORCIMAT 102.

Press manual DOSIMAT button from operation menu.

DOSIMAT menu will appear.

Manual DOSIMAT Menu

Activate the pump by pressing bottle icon that you want

to use during polishing operation.

Deactivate the pump by pressing same bottle icon when

it starts to drip.

Cleaning DOSIMAT Hoses

If you do not use the equipment for long time (such as end of

working shift), you should clean the tubes of dosing unit by

using “Retract” function. Otherwise, the tubes can be clogged

and dosing hoses may blow up. Warranty does not cover this

kind of damages. Follow below steps to clean the hoses:

DOSIMAT 12/52

Keep pressing “Retract” button until all fluids come back

to bottles.

DOSIMAT 102

Enter Manual, Single or Central Operation menu from the

FORCIMAT 102.

Press manual DOSIMAT button from operation menu.

DOSIMAT menu will appear.

Keep pressing “Retract” button until all fluids come back

to bottles.

Platen Installation

Align the holes under the platen (polishing wheel) with

the pins on the faceplate.

Place the platen on the base plate with the pins inserted

in the platen.

Press down on the platen to produce a secure fit and

check that the platen does not wobble.

Position and install the splash ring.

ATTENTION

Always use the splash ring to prevent a messy

over-spray. Before use, make sure the platen

surface is clean and free of residue from

previous operations. Adhesive residues may

be removed with an approved solvent.

Using Different Diameter Discs

Both FORCIPOL 102 and FORCIPOL 202 are suitable for Ø200,

Ø230, Ø250 and Ø300 mm working wheels.

For switching between Ø250 and Ø300 mm discs, you

only need to change PVC or Aluminum wheels.

For switching Ø200 mm, you need to change the base

plate (faceplate) first. Then, you can use Ø200 mm PVC

or aluminum wheels.

Please see the order codes and suitable wheel diameters of

base plates:

YM 6505: Base plate for Ø250 mm and Ø300 mm wheels.

YM 0269: Base plate for Ø200 mm and Ø230 mm wheels.

If you need one of these base plates in the future, please

contact with Metkon to order it.

Optional Recirculating Cooling System (ENVIRO)

Enviro Filter Unit is a closed loop recirculating filter system,

which is optionally available. It has a 20-lt reservoir capacity

with 1-micron filter entering the grinder / polisher intake.

Enviro can also be coupled with line water and 80-micron

filtering system for disposal.

ENVIRO Filter Unit

Noise Level

Approx. 60 dB is measured at idle running at a distance of 1 m

from the machine.

20

CONTROL PANEL (FORCIPOL

Control Unit)

FORCIPOL Control Unit has a modern looking and easy to use

operator panel with buttons and knob. It has specially

designed to increase operator comfort and maximize

productivity. All grinding and polishing parameters can be set

easily and quickly. A multipurpose digital display allows you to

observe all parameters.

FORCIPOL Control Unit

Control Button Functions

Time

Disc Speed

Water

Start/Stop

CONTROL PANEL (FORCIMAT 52)

FORCIMAT 52 has a modern looking and easy to use operator

panel with buttons and knob. It has specially designed to

increase operator comfort and maximize productivity. All

grinding and polishing parameters can be set easily and

quickly. A multipurpose digital display allows you to observe

all parameters.

FORCIMAT 52 Control Panel

Control Button Functions

Head Speed

Disc Speed

Time

Opposite Direction

Manual Operation

Water

Pistons Up/Down

Start/Stop

Other manuals for FORCIPOL Series

1

This manual suits for next models

2

Table of contents

Other Metkon Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Daihan Scientific

Daihan Scientific MSH-20D user manual

ThermoFisher Scientific

ThermoFisher Scientific ARL EQUINOX Series Instruction Notice

Phcbi

Phcbi MCO-170MP operating instructions

NoiseKen

NoiseKen EPS-02Hv2 instruction manual

Hettich

Hettich ROTO SILENTA 630 RS operating instructions

Tencor

Tencor AlphaStep 200 manual