CONTENT

1APPLICATION......................................................................................................................... 3

2OPERATION CONDITIONS.................................................................................................... 3

3TECHNICAL SPECIFICATIONS ............................................................................................. 3

4DELIVERY SET....................................................................................................................... 4

4.1Standard delivery set..................................................................................................... 4

4.1.1Modification TTR-10AT.......................................................................................... 4

4.1.2Modification TTR-10AK ......................................................................................... 5

4.1.3Modification TTR-10AB ......................................................................................... 5

4.2Optional equipment supplied on request....................................................................... 6

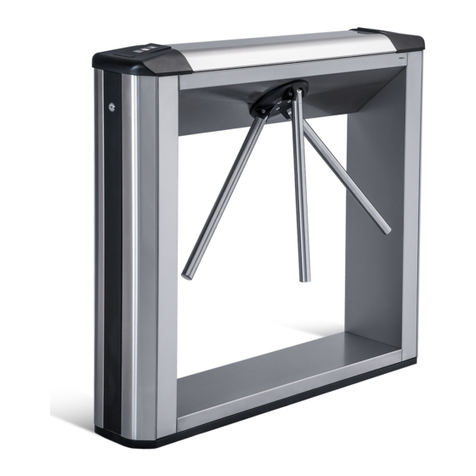

5BRIEF DESCRIPTION............................................................................................................. 6

5.1Main features................................................................................................................. 6

5.2Design........................................................................................................................... 6

5.2.1Turnstile housing and base ................................................................................... 7

5.2.2LED indication unit................................................................................................. 7

5.2.3RC-panel ............................................................................................................... 8

5.2.4Control and interface boards................................................................................. 8

5.2.5Control signals..................................................................................................... 11

5.2.6Turnstile control modes....................................................................................... 12

5.2.7Turnstile mechanism operation algorithm............................................................ 12

5.3Operation devices ....................................................................................................... 13

5.3.1RC-panel connection........................................................................................... 13

5.3.2Emergency unblocking device Fire Alarm........................................................... 14

5.3.3Operation with an ACS controller........................................................................ 14

5.4Additional devices connectable to the turnstile ........................................................... 15

5.4.1Relay outputs....................................................................................................... 15

5.4.2Intrusion detector and siren................................................................................. 16

5.4.3Remote indicators................................................................................................ 16

5.5Operation contingencies and response....................................................................... 17

6MARKING AND PACKAGING............................................................................................... 17

7SAFETY REQUIREMENTS................................................................................................... 18

7.1Installation safety requirements................................................................................... 18

7.2Operation safety requirements.................................................................................... 18

8INSTALLATION INSTRUCTIONS......................................................................................... 18

8.1Installation details........................................................................................................ 18

8.2Installation tools........................................................................................................... 19

8.3Length of cables.......................................................................................................... 20

8.4Installation procedure.................................................................................................. 20

8.5Connection layout........................................................................................................ 24

9OPERATION INSTRUCTIONS.............................................................................................. 26

9.1Power-up..................................................................................................................... 26

9.2Operating modes of the turnstile at pulse control mode.............................................. 26

9.3Operating modes of the turnstile at potential control mode......................................... 27

9.4Actions in emergency.................................................................................................. 28

9.5Troubleshooting........................................................................................................... 28

10MAINTENANCE..................................................................................................................... 29

11TRANSPORTATION AND STORAGE .................................................................................. 30

Appendix 1. Control signal algorithm at pulse control mode.................................................. 30

Appendix 2. Control signal algorithm at potential control mode............................................. 31