DD-75-181 R(2) Y.T.13.07.17

8

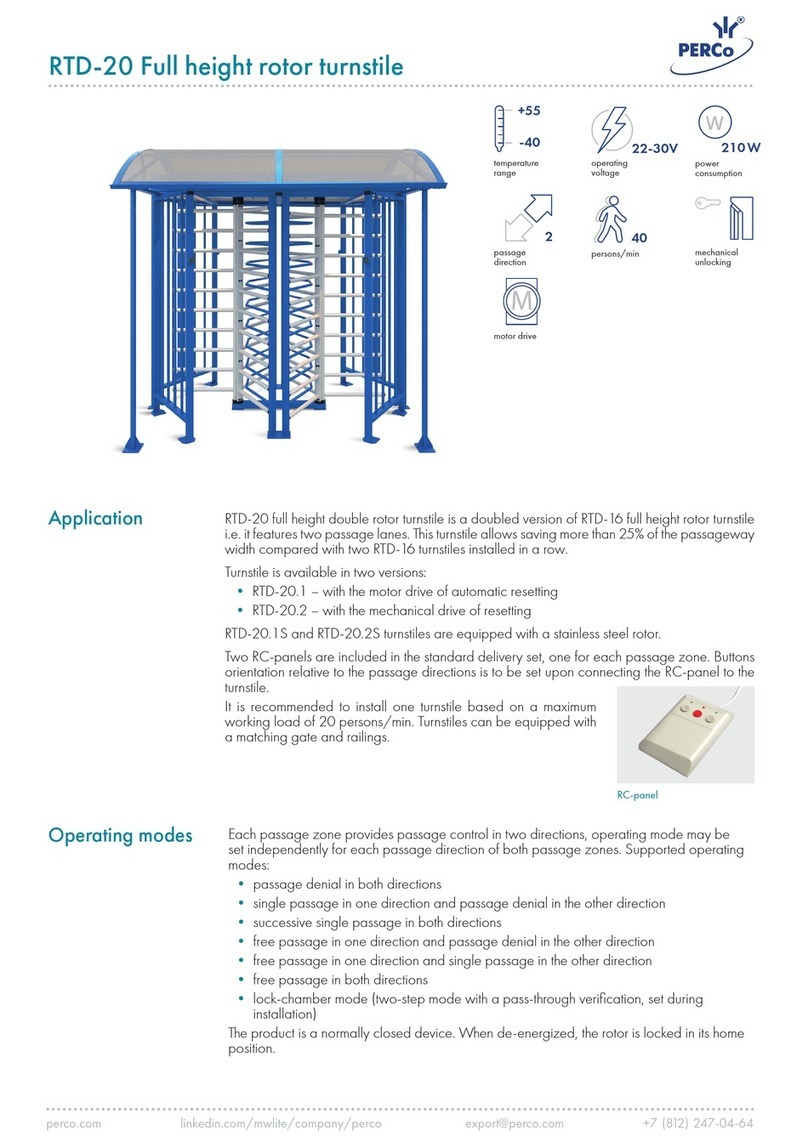

4.2 Full- Height Turnstile System Specications (Standard)

1. System is designed for bi-directional operation. In standard models, when power is cut off, arms freewheel to allow

freepassageinbothdirections;optionallythesystemcanbesetuptolock(fail-lock)whenpoweriscutoff.

2. Mechanical parts of the turnstiles are made of stainless steel and galvanized metal. All locking mechanism

components are made of stainless steel.

3. Once passage is permitted and arms rotate 30 degrees, arms will not return, and another passage is not allowed by

the system until the completion of the movement.

4. After each complete passage the manual system returns to standby position smoothly and quietly by means of a

hydraulic shock absorber. Motor driven versions complete rotation by a light push following authorization.

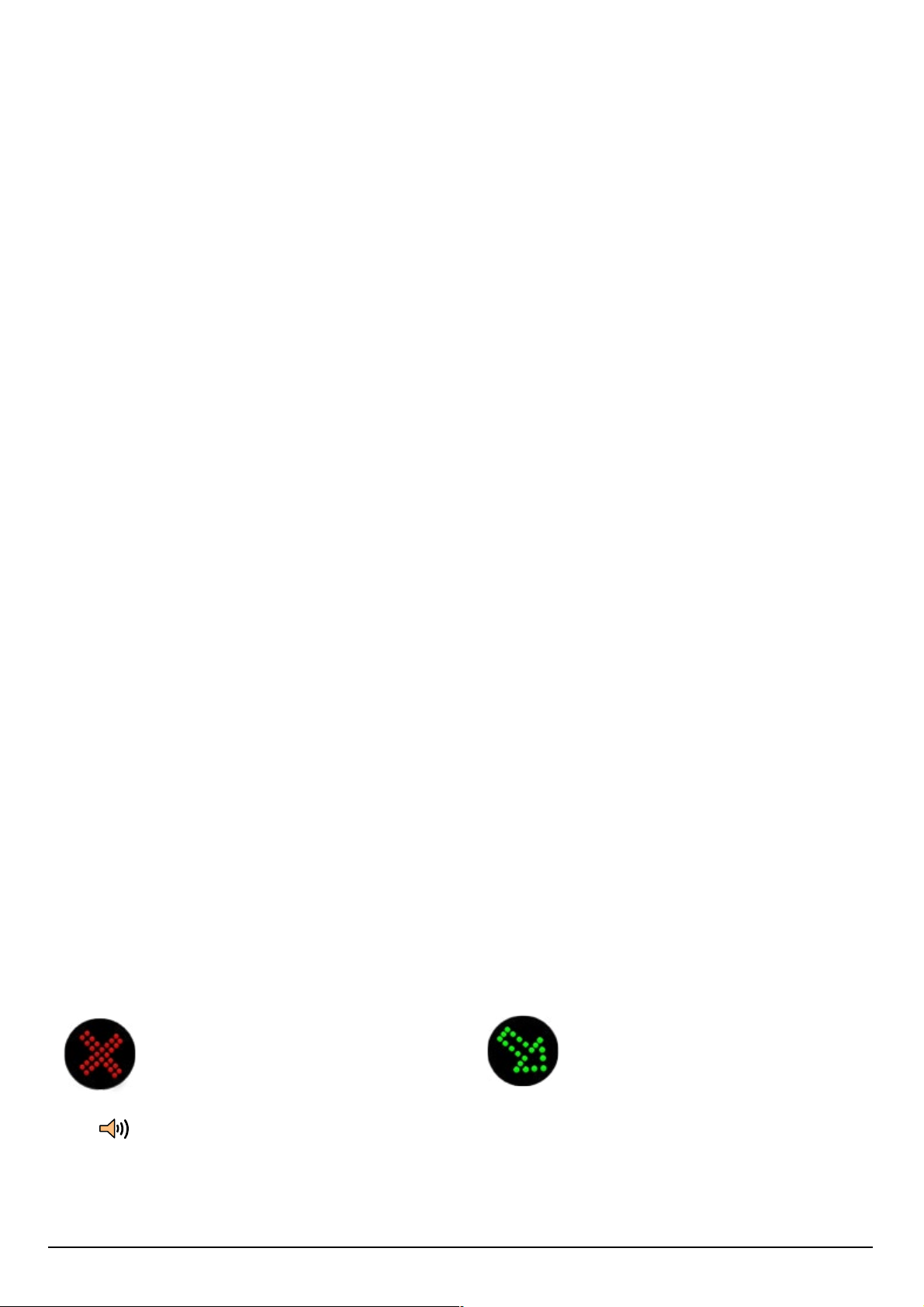

5. Signalizationisprovidedwithdirectionindicatorsplacedonbothsidesoftheupperbodyoftheturnstile(While

greenarrowindicatesactivepassagedirection,redbarshowstheinhibitedpassagedirection).Inadditiontothevisual

signalizationwithgreen/redindicators,anaudiobuzzersignalisprovidedduringpassage.

6. SolenoidsusedwithinthesystemaredrivenbyPWMforreliability,optimalenergyefciencyandlessheat.Theydo

not warm up to more than 10 degrees above the ambient temperature.

7. Electronicboardcontrollingthesystemis“coatedinsidethehole’type”andthereforenotaffectedbyvibration.

8. The micro-processor based electronic control system used in the turnstiles can be programmed for various

functions and operating modes by a simple dip switch selection.

9. All inputs and outputs are isolated by opto-coupler and relay components for increased reliability.

10. Turnstilepassagedirectionscanbeinhibited(closed),setupforonewaytrafcornormalbi-directionaloperation

byenable/disableterminallocatedonthecontrolboard.

11. Thepowersupplyissupportedby“switching-mode”technologyforbettervoltageregulationandenergyefciency.

12. Turnstile only allows passages of authorized people. If a person does not pass within a pre-set time limit following

authorizationcontact(selectablefor6,12,18orinniteseconds),thesystemautomaticallylocksandreturnsto

standby.

13. After each complete passage, the system provides dry contact relay output for each direction. An optional counter

can be used.

14. Electroniccontrolunitoftheturnstileisprotectedagainstwaterforoutdoorinstallations.

15. Turnstiles can work in sync with door-type metal detectors; In security applications, even passage of a person with

authorization can be blocked automatically upon receiving contact from a metal detector. The system can be returned

to normal operation by the operator.

16. Incasesofemergencytheturnstilecanbeswitchedinto“emergencymode”withanormallyclosedmanualbutton

orrelayfromrealarmsystem.Inemergencymodearmsrotatefreelyinbothdirectionsallowingfreepassage.

17. Turnstilepassagedirectionscanbearrangedindifferentcombinationsbyadipswitchonthecontrolboard.(For

example:onedirectioncontrolledotherdirectionfree;bothdirectionscontrolledbyseparatereaders,singlereaderfor

bothdirections.)

18. Turnstiles allow passage of only one person at a time for each authorization contact into the control board.

19. Card readers or similar access control systems can be integrated into the turnstiles separately or jointly for

controllingbothsidesdependingontheneedsandspecicrequirements.

20. Onceapassageiscompleted,anentranceorexitdirectiondata(drycontact)isprovidedtothedatacollection

terminal.

4.3 Full Height Motorized Turnstile System Specications

1. Microprocessorcontrolledbi-directionalsytemincorporatesanefcientPWMdrivenDCmotor.

2. Upon passage authorization received by the control board, system activates the motor following a light push on

the rotor and completes the rotation of 90° or 120° depending on the model. The rotor stops and tries to continue its

rotation once more if it meets an obstacle during its movement. If the obstacle is still present the rotor stops an alarm

is activated.

4. Followingacompletepassage(90°or120°rotation)turnstilelocksandbecomesreadyforthenextpassage.

5. Emergency mode: Controlled by a normally closed (NC)buttonorrealarmsystemcontact.Turnstilewillrotate

free in both directions as long as the emg contact remains open. Upon re-establishment of emg contact, turnstile

returns to normal operation mode.

REDX:Passagewayclosed(see5.2’) GREENARROW:Passagewayopen.

Buzzer is heard when a passage is authorized.

In alarm mode the indicators alternately blink in red and green and buzzer is heard.

4.4 Indicators

The system features status indicators on both sides and a buzzer for user guidance.