5

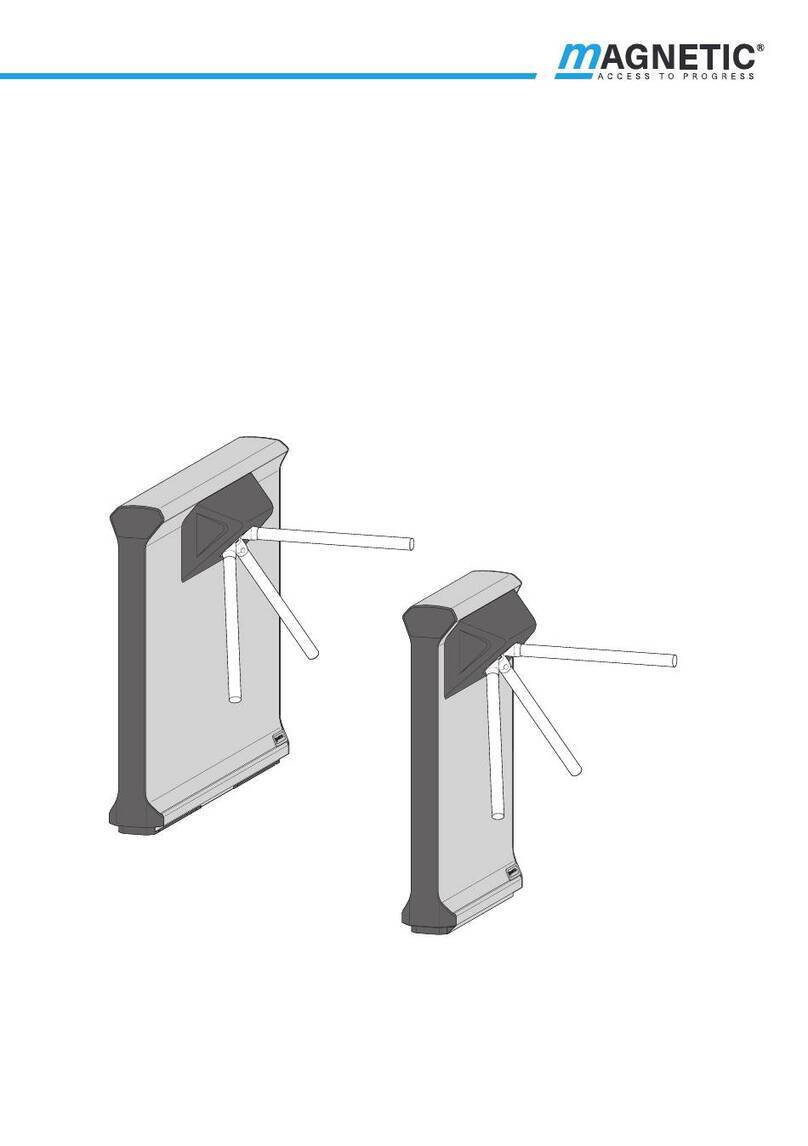

MPT-333 and MPT-353

Contents

8.3 Required steps 60

8.4 Specifying the installaon posion 60

8.5 Seng up foundaon and placing empty conduits 60

8.5.1 Requirements foundaon 60

8.5.2 Requirements empty conduits 61

8.5.3 Seng up foundaon and placing empty conduits 62

8.5.4 Foundaon and empty conduit plan

for base frame FURA T5 63

8.5.5 Foundaon and empty conduit plan for direct mounng 65

8.6 Mounng the base frame 67

8.7 Preliminary work for installaon directly on the foundaon 69

8.8 Mounng the MPT-353 69

8.8.1 Mounng the cage halves 70

8.8.2 Mounng the support beam 71

8.8.3 Mounng the connecng rods and the centre pillars 73

8.8.4 Mounng the locking combs 80

8.8.5 Closing the cover of the support beam 81

8.9 Checking the assembly 82

9 Mounng the oponal mounng pillar for access-control devices 83

10 Electrical connecon 91

10.1 Safety during electrical connecon 91

10.2 Installing electrical protecve devices 92

10.3 Open and close cover or service door 93

10.3.1 Opening and closing the cover 94

10.3.2 Opening and closing the service door 94

10.4 Connecng the mains cable 95

10.5 Connecng customer control lines 97

10.6 Connecng emergency opening contacts 97

10.7 Installing and connecng customer access-control devices 97

10.8 Checking the electrical connecons 98

11 Commissioning 99

11.1 Safety during commissioning 99

11.2 Pung the pedestrian gate into operaon 99

11.3 Switching the pedestrian gate on and o 100

11.4 Parameterising the pedestrian gate 101