Metreel MET-TRACK Installation and operating instructions

TOLL Free Tel:

877-830-9803

Email:

sales@metreel.com

Website:

www.metreel.com

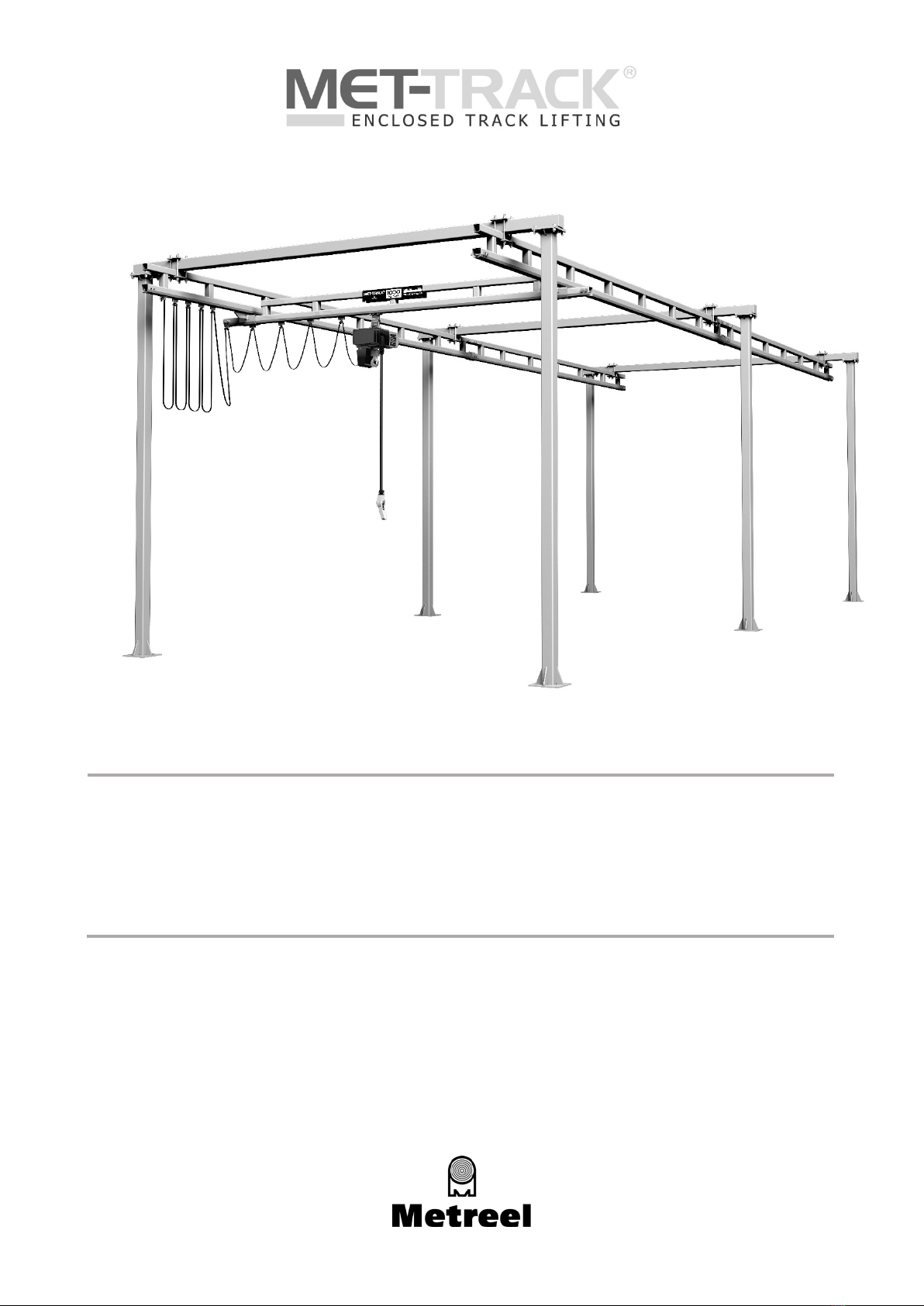

MET-TRACK®Workstation Bridge Cranes

FLOOR MOUNTED

Installation & Maintenance Instructions

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 2of 29

CONTENTS

Introduction............................................................................................................................................ 3

Preparation............................................................................................................................................. 3

Column and Header Installation............................................................................................................4-5

Runway Installation..............................................................................................................................6-8

Bridge & End Truck Options and Parts Breakdown................................................................................ 9-17

Hoist Trolley and Bridge Festoon Installation .......................................................................................... 18

Festoon Storage Extensions (FSE)......................................................................................................19-20

Hoist Trolley Installation........................................................................................................................ 20

Service Connections .............................................................................................................................. 21

Final Steps............................................................................................................................................ 21

Warning, Safety or Capacity Labels ........................................................................................................ 21

Load Testing......................................................................................................................................... 21

Sway Bracing (Optional)........................................................................................................................ 22

Operator Instructions ...................................................................................................................23-24

Inspection and Maintenance Schedule........................................................................................25-28

Warranty Statement ......................................................................................................................... 29

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 3of 29

INTRODUCTION

Thank you for choosing a MET-TRACK® Floor Mounted Workstation Kit Crane from Metreel. We really

appreciate your choice and are confident that, when installed correctly this product will provide you with a

superior materials handling solution. All of our cranes are designed and engineered for a powered hoist

operation, however manual hoists, balancers and any other lifting equipment can be used as long as the

duty is within our standard capacity. If you are unsure about his point then please contact our technical

team on Toll Free 877-830-9803 or email sales@metreel.com

Within our design criteria we have allowed 15% for the weight of the hoist, for example with a 500lb crane,

the hoist unit itself should be no heavier than 75lb. There is also an allowance with the design for normal

impact loading caused by the bridge and hoist movement.

To ensure that you continue to get many years of service from the MET-TRACK® Workstation Crane we

advise that a good inspection / maintenance routine according to our procedures detailed herein must be

adopted.

Dimensions contained in this document and any literature is for guidance only and may differ from the crane

delivered. Please ensure you refer to the General Arrangement Drawing for actual dimensions.

PREPARATION

Before starting the install of this crane it is recommended that you ensure that you have all the materials

required.

We recommend you follow the following steps and confirm you have all items.

1) Confirm all the following documents are present, these will be found in the component box marked

“Contains Documentation”

a) Packing List

b) Installations & Maintenance Manual

c) General Arrangement Drawing

2) Check all items against the packing list

3) Check that you have the correct anchors bolts, refer to Page 2. These are supplied with the crane kit

4) Check that the area in which the crane is to be installed is clean and free of obstructions

5) Check that you have all the required tools and materials needed to assemble the crane, these will

typically include:

a) Torque Wrench

b) General Tools

c) Measure

d) Chalk Line

e) Level

f) Shims

g) Heavy duty drill & bits

h) Steps/Ladders/Man Lifts

i) Lifting equipment for heavier sections

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 4of 29

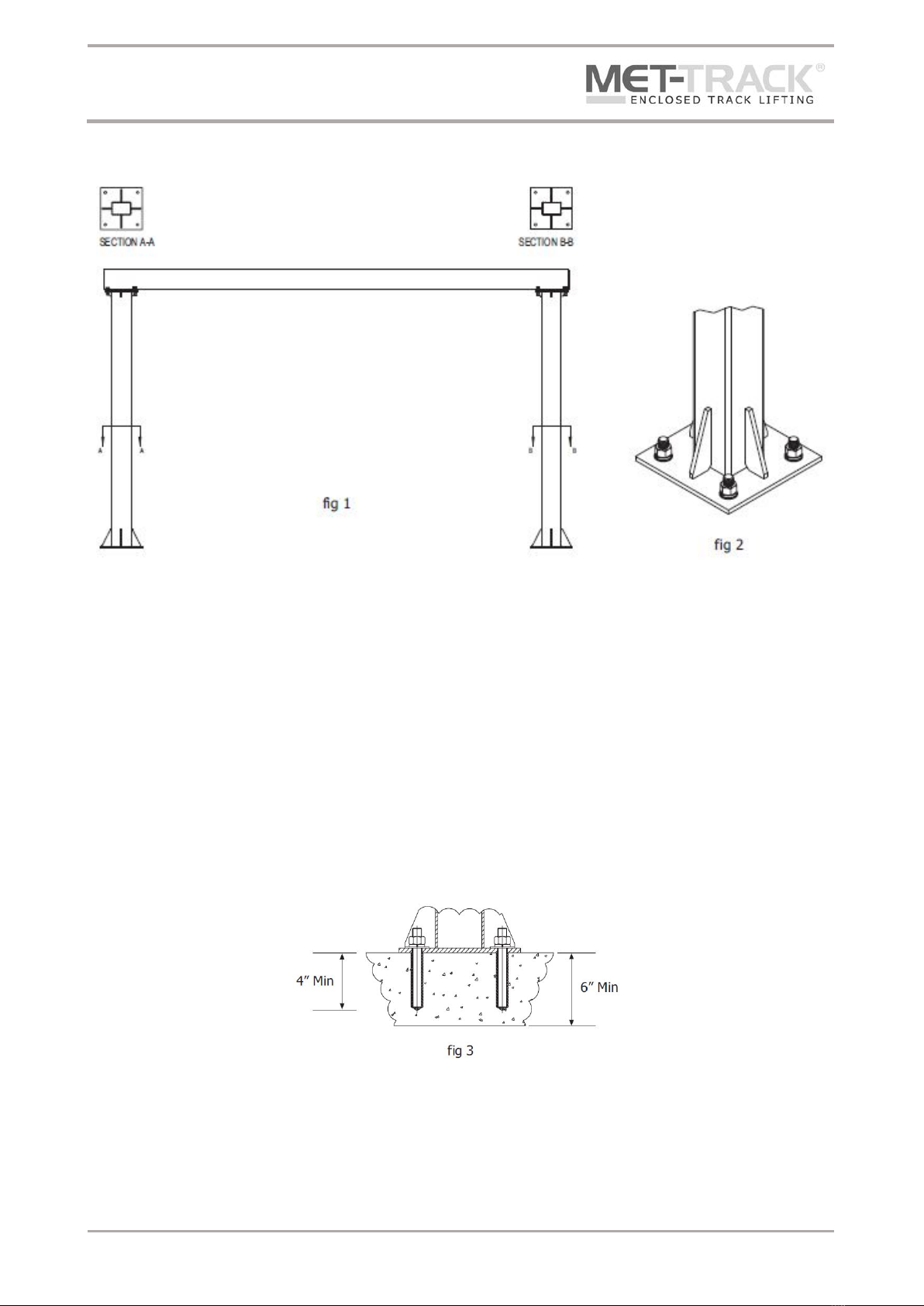

COLUMN & HEADER INSTALLATION

1) Layout and mark the area where the crane is to be installed (refer to the General Arrangement Drawing

for dimensions)

2) Mark out the floor BEFORE drilling using the column bas plate as a template (or refer to the General

Arrangement Drawing for dimensions). Brush away the dust and debris

3) Bolt the first set of columns to the floor, ensuring they are aligned correctly to receive the header (in

case of rectangular columns, ensure the column rotation is as shown in fig1)

a) 4 off ¾” Ø bolts grade 5 or greater MUST be used per column (See fig 2)

b) These MUST be embedded at least 4” into a minimum 6” thick reinforced concrete floor (See fig 3)

c) A minimum of two threads MUST be visible above the nut after tightening

d) Chemical anchor bolts are recommended (not supplied)

4) Check that the column is plumb and level, if not loosen the hardware and place steel shims (not

included) or grout (not included) under base of column until plumb. Once plumb retighten hardware.

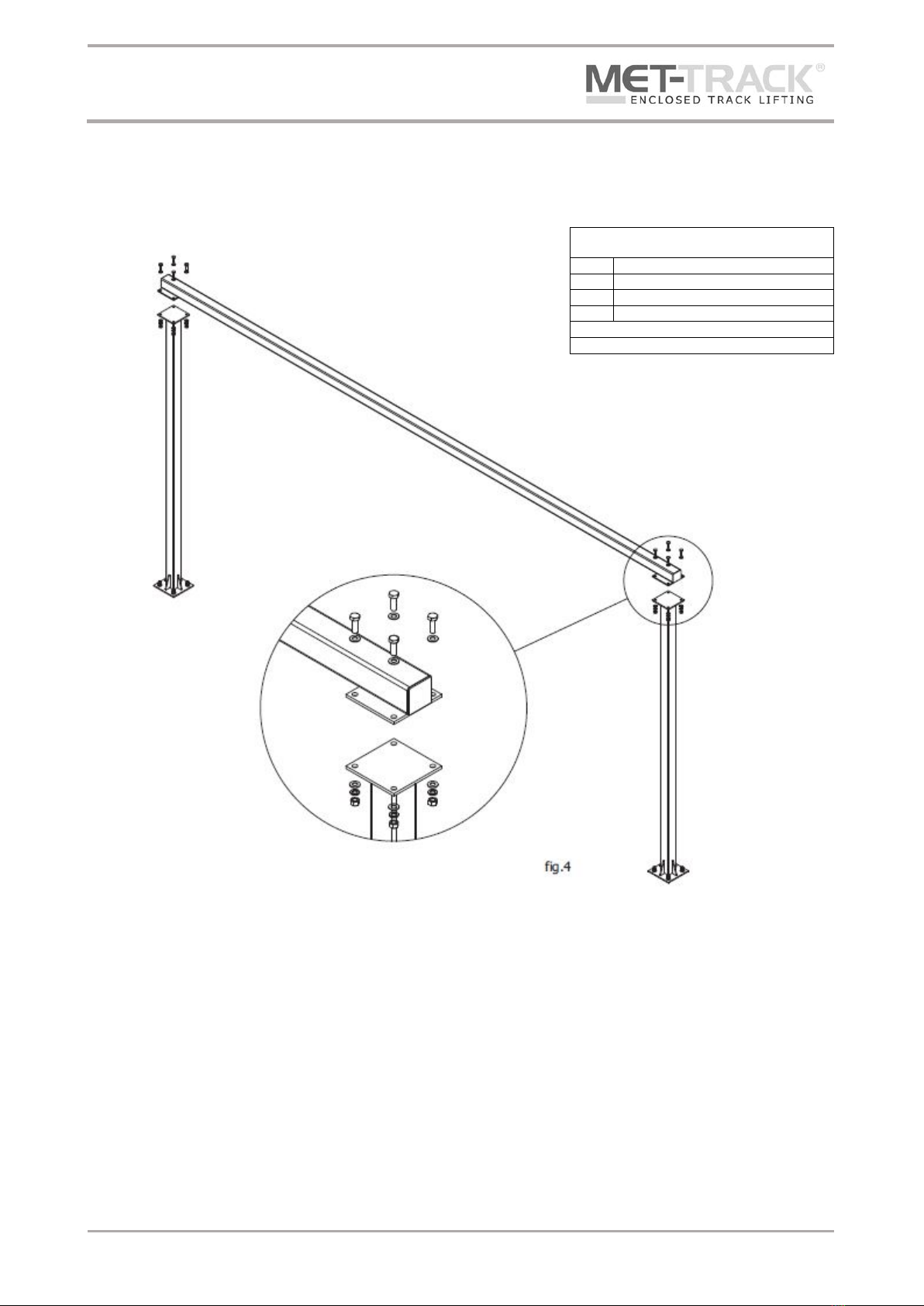

5) Lift and position header using appropriate lifting equipment and fasten the 5/8” x 2” bolt assemblies

supplied (torque to 154ft.-lb) (See fig 4)

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 5of 29

6) Follow the same procedure for the remaining column and header sets

Fixings Parts List

Column to Header Beam (per column)

4 x

5/8” x 2” Bolt

4 x

5/8” Nut

4 x

Type B ‘Narrow’ 5/8” Washer

4 x

Regular 5/8” Spring Washer

All fixings must be UNC

All fixings must be SAE Grade 5

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 6of 29

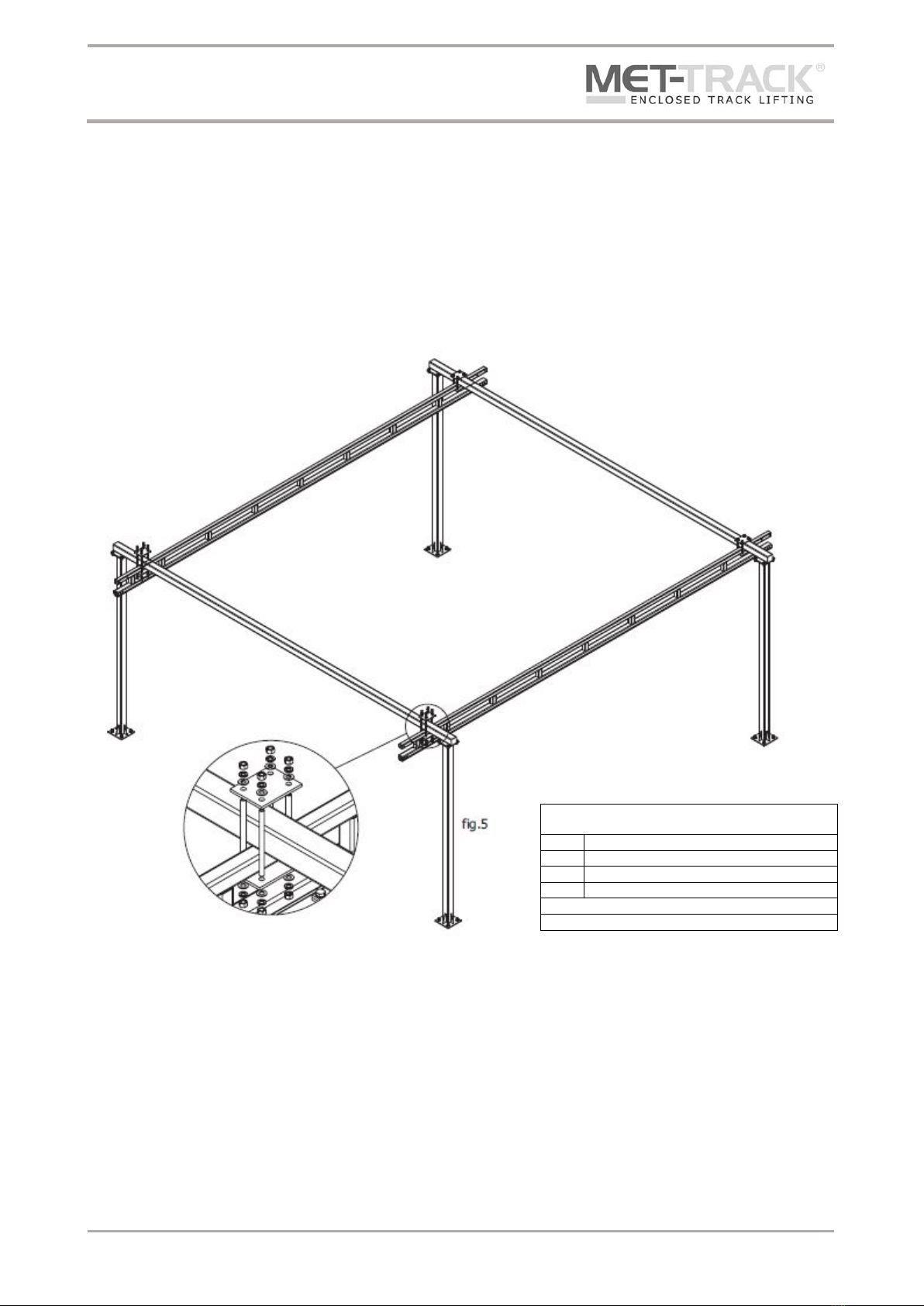

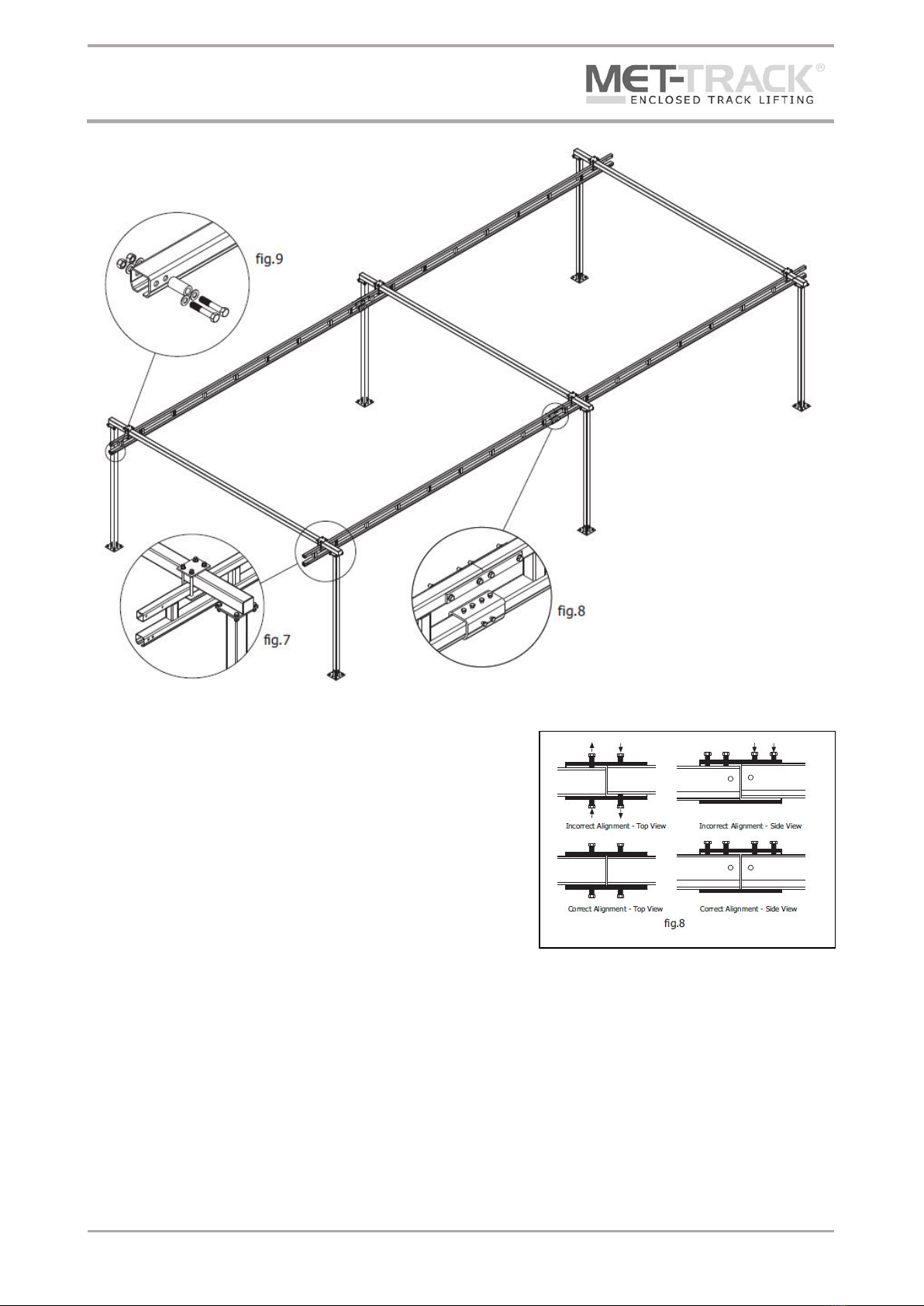

RUNWAY INSTALLATION

1) As the runway sections maybe different depending upon your span selection, check the General

Arrangement Drawing to identify individual gantry sections

2) Being careful not to disturb the columns, lift the first set of runway sections into place (refer to the

General Arrangement Drawing for position and dimension details)

3) Using the runway fixing brackets secure the runway to the header (see fig 5)

4) Do not alter the span (CBS) from that advised in the General Arrangement Drawing and take care to

position the runway centrally or as per the dimensions provided

5) Do not cantilever the end of the runways further than the dimension stated in the General Arrangement

Drawing

6) Check to ensure that the runways are parallel, failure to do so will prevent the bridge from running

smoothly

Fixings Parts List

Runway to Header Fixing Kits (per column)

8 x

5/8” Nut

8 x

Type B ‘Narrow’ 5/8” Washer

8 x

Regular 5/8” Spring Washer

4 x

Studding (length to suit)

All fixings must be UNC

All fixings must be SAE Grade 5

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 7of 29

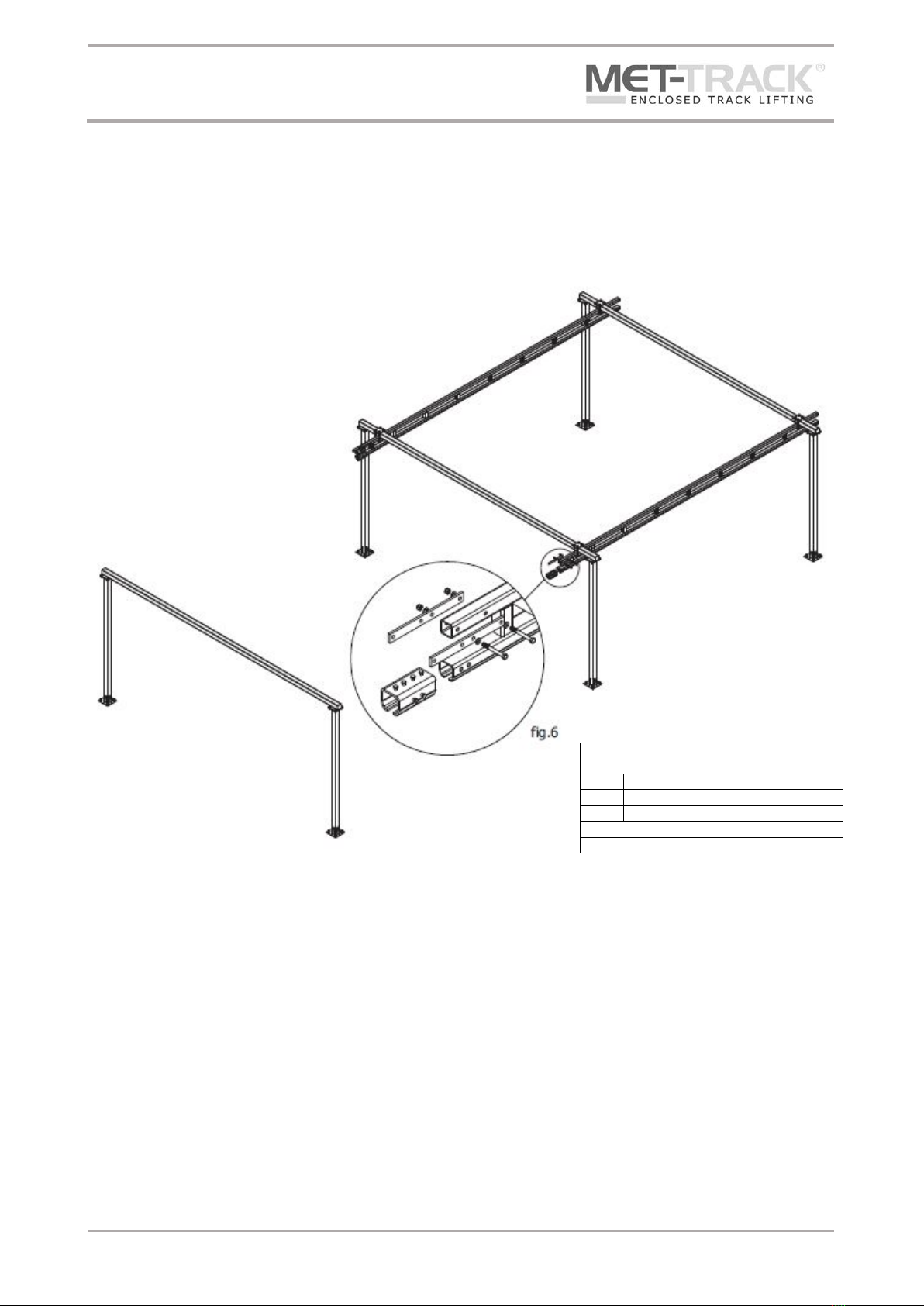

7) Torque fasteners to 75ft.-lb and ensure at least two treads are visible after tightening

8) If you have no more runways to install then skip to step 16

9) Install Joint Kits to previously installed runway (See fig 6)

10) Install the next runway length by lifting and bringing together the runway ends and positioning

according to the General Arrangement Drawing. The gap between the running profile MUST not exceed

1/16”

11) Attach the other end of the runway to the next header using the runway fixing brackets (See fig 7)

Fixings Parts List

Track Joints (per Joints)

4 x

½” (length to suit) Bolt

4 x

½” Type B ‘Narrow’ Flat Washer

4 x

½” Nylon Nut, fixing torque 78ft.-lbs

All fixings must be UNC

All fixings must be SAE Grade 5

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 8of 29

12) Align the runway profile so that the running surfaces are

level

a) To adjust for smooth travel, use the bolts on the top of

the splice joint to force the track down into the base of

the splice joint. Use the bolts on each side to level the

track laterally (see fig 8)

13) Fix final hardware in the splice plates and secure

14) Once secure torque the runway fix bracket fasteners to

170ft.-lb and ensure at least two threads are visible after

tightening

15) For additional runway sections refer to Step 9 through to Step 15 until runway installation is complete

16) Fit runway End Kits at one end of each runway, opposite to where the bridge will be installed (See fig 9)

17) Clean the inside of the runway flanges with a clean, dry cloth to remove grit or debris

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 9of 29

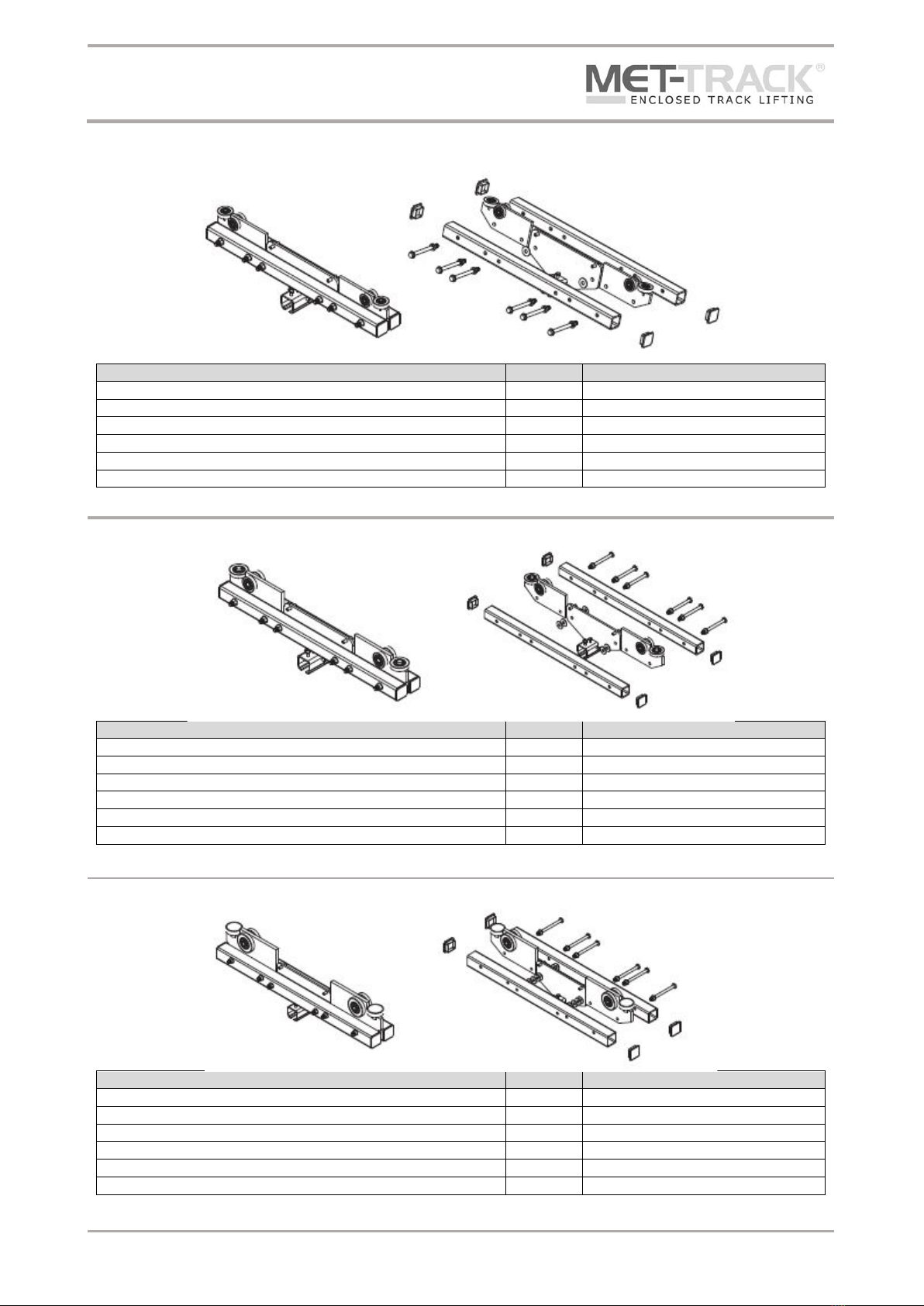

BRIDGE & END TRUCK OPTIONS AND PARTS BREAKDOWN Please ensure you have the correct End Truck

Standard End Truck

Part No.

1454

1554

1654

1754

Cap.(lbs)

250

500

1000

2000

Bridge

Length

Upto 23ft

1454L End Truck

Description

Qty

Part No.

400 Series Splice Plate Weldment

1

23618

SHS for 400 Series Extended Trolley

2

23605

Trolley for 400 Series Extended Truck

2

23622

Plastic End Cap

4

GPN 260 Q 4040 4

End Truck Fixing Kit 2

2

28035

End Truck Fixing Kit 1

4

28034

1554L End Truck

Description

Qty

Part No.

500 Series Splice Plate Weldment

1

23619

SHS for 500 Series Extended Trolley

2

23606

Trolley for 500 Series Extended Truck

2

23623

Plastic End Cap

4

GPN 260 Q 5050 5

End Truck Fixing Kit 3

6

28036

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

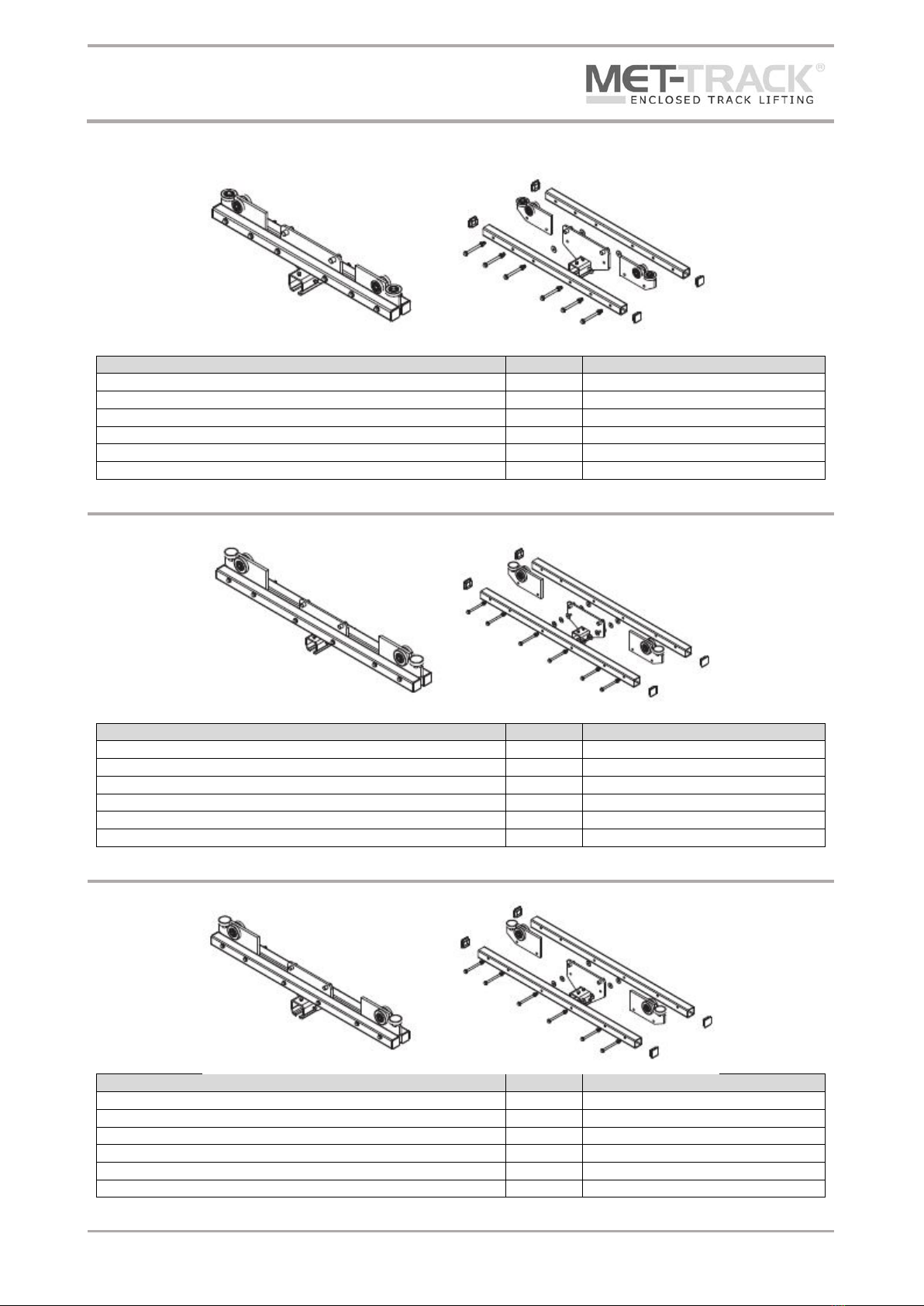

Page 10 of 29

1654L End Truck

Description

Qty

Part No.

600 Series Splice Plate Weldment

1

23620

SHS for 600 Series Extended Trolley

2

23624

Trolley for 600 Series Extended Truck

2

23607

Plastic End Cap

4

GPN 260 Q 5050 5

End Truck Fixing Kit 3

6

28036

1754L End Truck

Description

Qty

Part No.

700/800 Series Splice Plate Weldment

1

23621

SHS for 700 Series Extended Trolley

2

23608

Trolley for 700 Series Extended Truck

2

23625

Plastic End Cap

4

GPN 260 Q 6060 5

End Truck Fixing Kit 4

6

28037

1854L End Truck

Description

Qty

Part No.

700/800 Series Splice Plate Weldment

1

23621

SHS for 800 Series Extended Trolley

2

23609

Trolley for 800 Series Extended Truck

2

23626

Plastic End Cap

4

GPN 260 Q 6060 5

End Truck Fixing Kit 4

6

28037

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 11 of 29

1554-400 End Truck

Description

Qty

Part No.

400 Series Splice Plate Weldment

1

23618

Packer Plates for End Truck Designs

4

23629

Plastic End Cap

4

GPN 260 Q 5050 5

Trolley for 500 Series Extended End Truck

2

23623

SHS for 1554-400 & 1554 End Trucks

2

28024

End Truck Fixing Kit 3

6

28036

1654-400 End Truck

Description

Qty

Part No.

400 Series Splice Plate Weldment

1

23618

Packer Plates for End Truck Designs

8

23629

Plastic End Cap

4

GPN 260 Q 5050 5

600 Series Extended End Truck

2

23624

SHS for 1654-400 & 1654 End Trucks

2

28025

End Truck Fixing Kit 4

6

28036

1754-400 End Truck

Description

Qty

Part No.

Truck Plate Weldment for 1754-400 End Truck

1

28029

Packer Plates for End Truck Designs

16

23629

Trolley for 700 Extended End Truck

2

23625

SHS for 1754-400 End Truck

2

28027

Plastic End Cap

4

GPN 260 Q6060 5

End Truck Fixing Kit 4

6

28037

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 12 of 29

1654-500 End Truck

Description

Qty

Part No.

500 Series Splice Plate Weldment

1

23621

Packer Plates for End Truck Designs

4

23629

Plastic End Cap

4

GPN 260 Q 5050 5

600 Series Extended End Truck

2

23624

SHS for 1654-400 & 1654 End Trucks

2

28025

End Truck Fixing Kit 3

6

28036

1754-500 End Truck

Description

Qty

Part No.

500 Series Splice Plate Weldment

1

23619

Packer Plates for End Truck Designs

12

23629

Plastic End Cap

6

GPN 260 Q 6060 5

Trolley for 700 Extended End Truck

4

23625

SHS for 1754-500 & 1754-600 End Trucks

2

28026

End Truck Fixing Kit 4

6

28037

1754-600 End Truck

Description

Qty

Part No.

600 Series Splice Plate Weldment

1

23620

Packer Plates for End Truck Designs

8

23629

Plastic End Cap

4

GPN 260 Q 6060 5

Trolley for 700 Extended End Truck

2

23625

SHS for 1754-500 & 1754-600 End Trucks

2

28026

End Truck Fixing Kit 4

6

28037

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 13 of 29

1554L-500 End Truck

Description

Qty

Part No.

400 Series Splice Plate Weldment

1

23618

Packer Plates for End Truck Designs

4

23629

Plastic End Cap

4

GPN 260 Q5050 5

Trolley for 600 Series Extended End Truck

2

23623

SHS for 1654-400 & 1654 End Trucks

2

23606

End Truck Fixing Kit 3

6

28036

1654L-400 End Truck

Description

Qty

Part No.

400 Series Splice Plate Weldment

1

23618

Packer Plates for End Truck Designs

4

23629

Plastic End Cap

4

GPN 260 Q 5050 5

Trolley for 500 Extended End Truck

2

23623

SHS for 1554-500 & 1554 End Trucks

2

23624

End Truck Fixing Kit 3

6

28036

1754L-400 End Truck

Description

Qty

Part No.

Truck Plate Weldment for 1754-400 End Truck

1

28029

Packer Plates for End Truck Designs

16

23629

Plastic End Cap

4

GPN 260 Q 6060 5

Trolley for 700 Extended End Truck

2

23625

SHS for 700 Series Extended Trolley

2

23608

End Truck Fixing Kit 4

6

28037

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 14 of 29

1654L-500 End Truck

Description

Qty

Part No.

500 Series Splice Plate Weldment

1

23619

Packer Plates for End Truck Designs

4

23629

Plastic End Cap

4

GPN 260 Q5050 5

600 Series End Truck

2

23624

SHS for 600 Series Extended Trolley

2

23607

End Truck Fixing Kit 3

6

28036

1754L-500 End Truck

Description

Qty

Part No.

500 Series Splice Plate Weldment

1

23619

Packer Plates for End Truck Designs

4

23629

600 Series End Truck

2

23624

SHS for 600 Series Extended Trolley

2

23607

Plastic End Cap

4

GPN 260 Q5050 5

End Truck Fixing Kit 3

6

28036

1754L-600 End Truck

Description

Qty

Part No.

600 Series Splice Plate Weldment

1

236120

Trolley for 700 Series Extended End Truck

2

23625

SHS for 700 Series Extended Trolley

2

23608

Plastic End Cap

4

GPN 260 Q6060 5

Packer Plates for End Truck Designs

8

23629

End Truck Fixing Kit 4

6

28037

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 15 of 29

1854 End Truck

Description

Qty

Part No.

700/850 Series Splice Plate Weldment

1

23621

Trolley for 800 Series Extended End Truck

2

23626

Plastic End Cap

4

GPN 260 Q5050 5

SHS for 1854 End Truck

2

28033

End Truck Fixing Kit 4

6

28037

When building this End Truck, care must be taken to ensure all four pairs of running wheels are

in contact with the runway at all times.

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 16 of 29

1) If a festoon system has been selected for this workstation crane then it may be necessary to put the

appropriate number of festoon trolleys, end clamps and festoon storage extension (FSE) on to one of

the runway’s prior to the bridge being installed. This depends upon where the power source is located,

ideally the end clamp of the festoon should be positioned as close to the power source as possible.

2) Slide the End Trucks over the end of the bridge (Refer to the General Arrangement Drawing for the

positional dimensions).

3) Using the bolts on the top of the sleeve of one of the End Trucks, clamp the bridge (if a conductor

system is being installed this should be the End Truck on the side where the powerfeed will be

positioned).

4) Remove or leave free the bolts on the sleeve of the other End Truck, see fig 10. (This is to allow for the

bridge to float taking up the slight deviation of the installed runways).

5) Install an End Stop to the end of the bridge opposite to the festooning (where appropriate) see fig 11.

Being careful not to allow the free End Truck to slip off, lift up the bridge and insert the end Trucks into

the open ends of the runways. If appropriate make sure the festooning end of the bridge is oriented

with the festoon or conductor system on the runway.

6) Slide End Truck into the runways and immediately install the End Stop Kit in the open ends of the

runway to prevent bridge from falling back out the system.

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 17 of 29

Fixings Parts List

End Stop Kits

All fixings must be UNC

All fixings must be SAE Grade 5

400 Series

500 Series

600 Series

700 / 800 Series

1 x RB45 Sleeve

1 x RB45 Sleeve

1 x RB67 Sleeve

1 x RB67 Sleeve

2 x ½” x 3” Bolt

2 x ½” x 3.5” Bolt

2 x 5/8” x 4.5” Bolt

2 x 5/8” x 5” Bolt

2 x ½” NYLOC Nut

2 x ½” NYLOC Nut

2 x 5/8” NYLOC Nut

2 x 5/8” NYLOC Nut

4 x Type B ‘Narrow’ ½” Washer

4 x Type B ‘Narrow’ ½” Washer

4 x Type B ‘Narrow’ 5/8” Washer

4 x Type B ‘Narrow’ 5/8” Washer

7) Check the position of the bridge, there must be a minimum of 2” between the end of the bridge and the

column upright

8) Clean the inside of the bridge flanges with a clean, dry cloth to remove grit or debris

9) Run the bridge down the complete length of the runway to check for smooth travel. If the bridge

movements is not smooth, check the runways are level and parallel, check that the End Trucks are only

clamped on one side. Make sure the inside running faces of all profiles are clean and all debris has been

removed

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 18 of 29

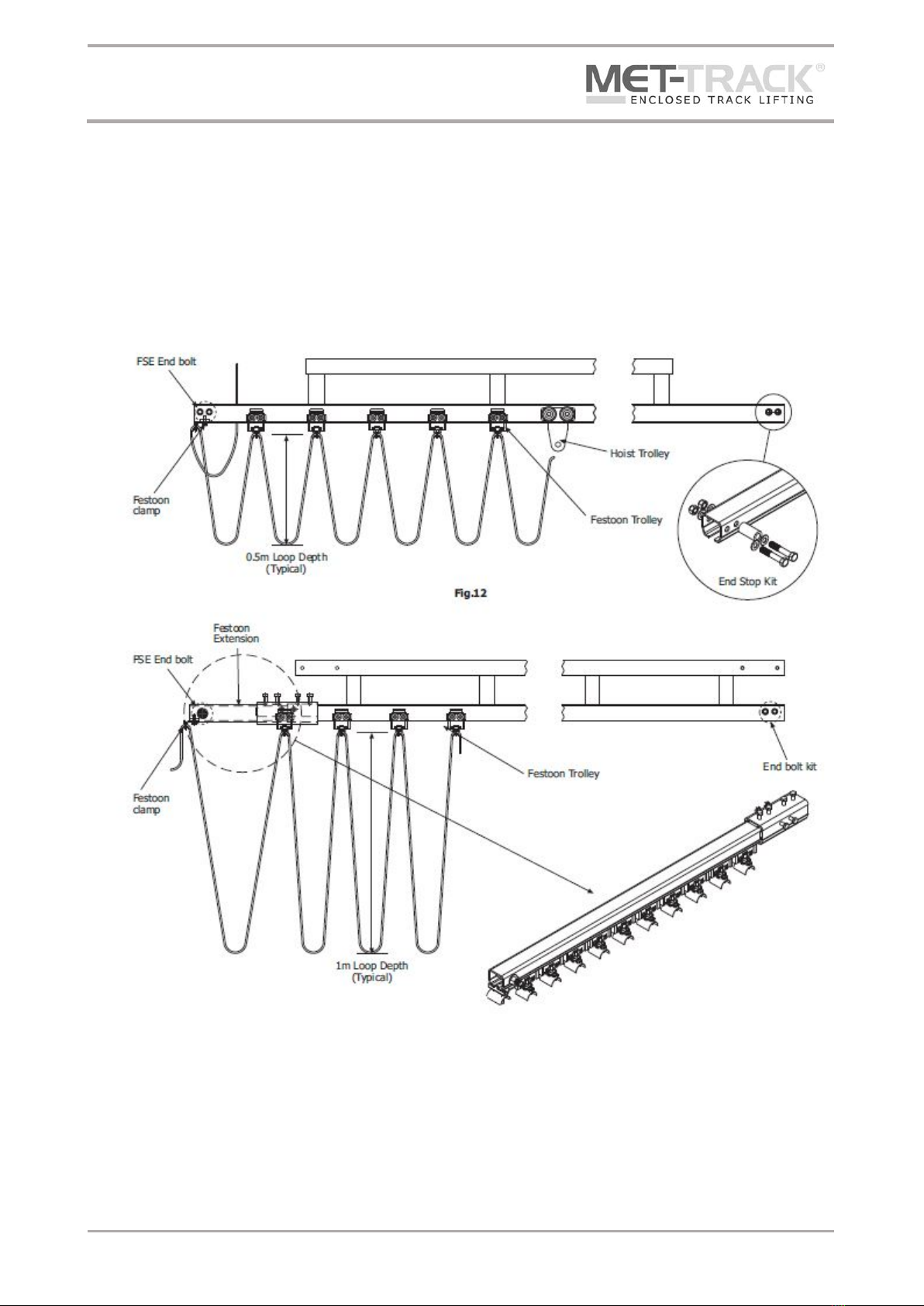

HOIST TROLLEY AND BRIDGE FESTOON INSTALLATION

Install hoist trolley and festoon trolleys on crane bridge track, if applicable, as shown in fig 12. Secure End

Stop bolts and rubber bumpers, also shown in fig 12. Install the festoon cable/hose on the festoon trolleys

at equal spacing, ensure festoon has correct loop depth (refer to the General Arrangement Drawing).

Once installation is completed, the bridge and runways should be levelled. The total system should then be

checked for tightness of all nuts and bolts.

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 19 of 29

FESTOON STORAGE EXTENSIONS (FSE)

400 Series Festoon Extension

(Must be welded to the runway – refer to the General Arrangement Drawing)

500 Series Festoon Extension

600 Series Festoon Extension

Floor Mounted Workstation Bridge Crane

Installation & Maintenance Instructions

Document No. TD002-0618

Last Updated: 14 June 2018

Page 20 of 29

700 & 800 Series Festoon Extension

HOIST AND TROLLEY INSTALLATION

Attach hoist to hoist trolley. Use washers on host mounting pin to centre hoist inside hoist trolley. Reinstall

washer on outside of hoist trolley before installing or reinstalling cotter pin to secure hoist mounting pin.

Replace cotter pin if worn or broken. Bend cotter pin around mounting pin. See fig 13

WARNING: Do not operate hoist or crane if cotter pin is not in place and properly bent over. Check

regularly that the cotter pin is in place and securing the hoist on the hoist trolley.

Part No.

1418

1518

1618

1718

1818

Cap. (lbs)

250

500

1000

2000

4000

Other manuals for MET-TRACK

1

Table of contents

Other Metreel Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Fayat

Fayat Bomag CR 820 T Tier 4 Operating instructions, maintenance instructions

Artic

Artic FUSION SPLICER 5.7 Operation manual

Bomag

Bomag BW 100 AD-5 Operating & maintenance instructions

MULTIQUIP

MULTIQUIP EM120 Operation and parts manual

Altrad

Altrad Belle BGN+ Operator's manual

Draper

Draper EC2000/PRO instructions