MetriCorr Slimline ICL-C User manual

Toerringvej 7 Roedovre 2610 Denmark - Tel. +45 9244 8080 info@metricorr.com

Slimline series

ICL-C & MasterLink

Operation Manual

Document: 102272-00

Release date: June 2021

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 2 | 54

Contents

1Scope................................................................................................................ 4

2ICL-C & MasterLink Unit.................................................................................... 5

2.1 MasterLink module connectors & control ............................................................................6

2.2 ICL-C module connectors ......................................................................................................7

3Configuration ................................................................................................... 8

3.1 Switch on & Initial Communication.......................................................................................8

3.2 WebService - general ............................................................................................................9

3.2.1 Setup of ICL-C & MasterLink........................................................................................................ 11

3.2.2 Communication interval.............................................................................................................. 13

3.2.3 Sample interval & Start time ....................................................................................................... 14

3.2.4 Intensive measurements ............................................................................................................. 15

3.2.5 Assigning probes/sensors/components to the ICL-C .................................................................. 16

3.2.6 Linking ER probes to your account.............................................................................................. 17

4Line Current Sensor ........................................................................................ 18

4.1 LC input voltage range.........................................................................................................18

4.2 Connections to steel pipe or other structure......................................................................19

4.3 DC resistance (LC input) ......................................................................................................19

4.4 AC measurements for a steel pipe (LC input) .....................................................................20

4.5 WebService - Line Current Sensor (LCS)..............................................................................21

4.5.1 Create Line Current Sensor.......................................................................................................... 21

4.5.2 Defined Specific Resistivity Table ................................................................................................ 24

4.5.3 Data display –Line Current Sensor (LC Sensor)........................................................................... 25

5Installation ..................................................................................................... 28

5.1 Solar Junction Box Installation ............................................................................................28

5.2 Big Fink Installation .............................................................................................................33

5.3 Big Fink Solar Solution.........................................................................................................38

5.4 Battery Hat Solution............................................................................................................39

6Your Data –Simple WEBservice Instructions................................................... 40

6.1 View & Download Logged Data...........................................................................................40

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 3 | 54

6.2 Unit Pipeline & Location Assignment..................................................................................41

6.3 Alerts ...................................................................................................................................42

6.4 Reports ................................................................................................................................43

7Satellite –communication .............................................................................. 44

7.1 Satellite modem & placement ............................................................................................45

7.2 Power & LED indicators.......................................................................................................45

7.3 Webservice Subscription.....................................................................................................46

7.4 Setup in Webservice............................................................................................................47

7.4.1 Example: 25h interval measurement campaign.......................................................................... 48

7.4.2 Example: 24h interval measurement campaign.......................................................................... 49

7.5 App & Data for satellite connected MasterLinks ................................................................49

Appendix 1: Junction Box Mounting Guide........................................................... 50

Appendix 2: Solar Charger Instructions ................................................................ 51

Revision

Date

Comments

Prepared

Review

Approval

001

2021-06-02

Review Section 7. Satellite –communication

RCH

LBT

LBT

Draft R001

2021-01-08

Operation Guide ICL-C & MasterLink.

Already reviewed by LBT and FGa.

This version is based on the previous ICL &

MasterLink operation guide by FrB, 2018-11-14.

RCH

LBT

FGa

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 4 | 54

1Scope

This document is a guideline for setup and operation of the datalogger model “ICL-C & MasterLink”from

MetriCorr’s Slimline series of remote monitoring equipment. Hereafter referred to as “unit”.

The MetriCorr remote monitoring system uses an online WebService, where all the data from site are

uploaded and stored. The unit consists of a MasterLink module and an ICL-C module, where both modules

are configured and controlled from WebService.

Before you start:

•If you want to link your new unit to an existing MetriCorr WebService account, please email

-Account Name (existing or new) you wish the unit(s) to be assigned to.

-User email address (for new users to log in to existing or new accounts)

-MasterLink Serial Number(s) you wish to link to the account

•If you are a new customer or setting up a NEW account, please also provide details of a Primary

contact person for data & administration communication with MetriCorr.

1. Name & title / position

2. Email address

3. Telephone number

Once you have confirmation that the units have been assigned to the account as requested (together with

login details if you have requested a new account or user), you are ready to start.

IMPORTANT: Do not disassemble the unit. If the unit is malfunctioning, please contact MetriCorr.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 5 | 54

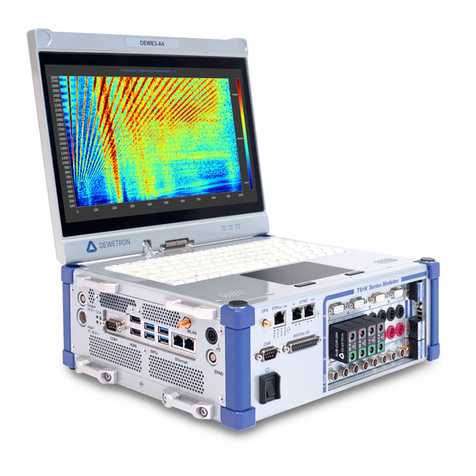

2ICL-C & MasterLink Unit

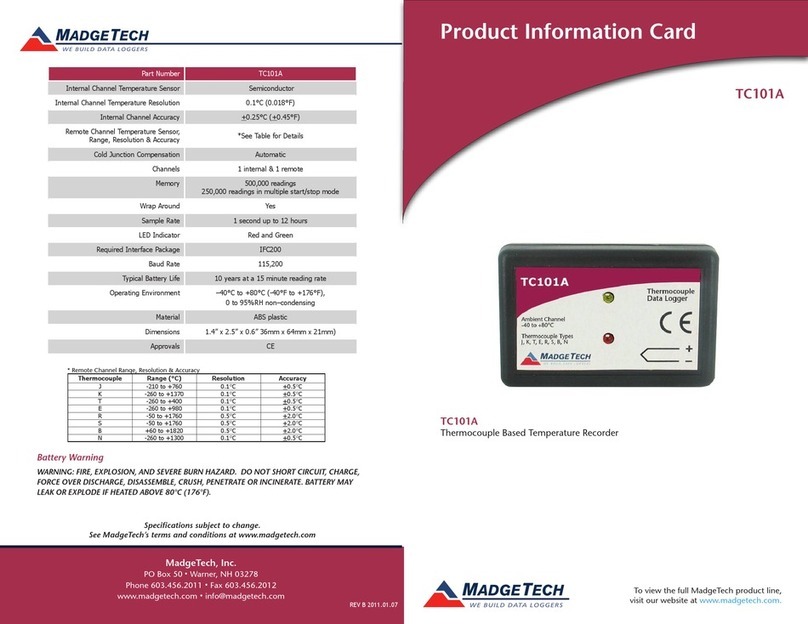

The Slimline ICL-C

measurement module

is paired with a

MasterLink control and

communications

module. They are

shipped preassembled

as shown:

Figure 1. ICL-C & MasterLink as shipped

Standard accessories:

-Antenna LTE with 1m wire and adhesive pad

-Protective caps for connectors

-Power cable with DC connector

-Yellow wire 1m, 4mm banana connectors

-Black wire 1m, 4mm banana connectors

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 6 | 54

2.1 MasterLink module connectors & control

The MasterLink module comes with a Status/control button, antenna, and Power supply connectors as

standard. Optional interface connectors are available on-demand.

Figure 2. MasterLink module connectors & control

Table 1. MasterLink - Specifications

MasterLink –Specifications

Battery Lifetime

+3 years @ 1h logging intervals and

weekly transmissions

Casing

IP65

Humidity

0-100% RH condensing conditions

Operating conditions

-40 °C to +85 °C

Storage capacity

+200 000 readings

Logging intervals

(Normal mode)

10 min → ∞, recommended 1 hour

Logging interval

(Campaign mode)

1 sec in pre-defined time intervals

A: Antenna connection

B: Status/control button & LED indicator

C: Power supply connector

(with protective cap)

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 7 | 54

2.2 ICL-C module connectors

The ICL-C module's endplate consists of five connectors for the ER probe connection, Line Current Sensor,

and Reference electrode to Pipe/structure measurement.

ER channel (1)

Resistance Range

150 mΩ

Repeatability

0.2 µΩ

Precision

0.4 µΩ

Line Current channel (2)

Input voltage range DC

(Before clip)

± 1.2 V

Input voltage range AC

(Before clip)

845 mVRMS

Target input range for

DC measurements

-20 mV →+20 mV

Resolution

0.2 µV

DC accuracy

± 1 µV

AC accuracy

± 4 µV

Input resistance

33 kΩ

Terminal "Pipe" –Pipe/structure connection

Terminal "Ref." –Reference Electrode connection

The voltage measurement between

"Pipe" and "Ref." is performed by both

channel 1 and channel 2.

Voltage measurement (both channels)

Input range (voltage)

± 100 V

Resolution (voltage)

1 mV

DC accuracy (voltage)

± 1 mV ± 0.3% reading

AC accuracy (voltage)

± 2 mV ± 1% reading

ER Probe Current measurement (channel 1)

Current range

± 300 mA

Resolution (current)

0.1 µA

AC accuracy (current)

± 4 µA ± 1% reading

DC accuracy (current)

± 1 µA ± 1% reading

Figure 3. ICL-C module

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 8 | 54

3Configuration

3.1 Switch on & Initial Communication

Once connected to the antenna and battery, push the 'Status/Control' button ('E' in Figure 3) and release

(<0.5s). This will indicate the unit's current status/mode with a series of flashes on the LED built into the

button. Please refer to the LED flash patterns below.

*The device is Off. 5 short (0.5 milliseconds) flashes per second for 5

seconds. This signal is triggered by a short (<0.5s) push on the push-

button.

Figure 4. LED flash indication

Mode / status

Description

Waiting

The device is active and waiting for the next measurement to be performed.

Short (50 milliseconds) flash every 8 seconds

Measuring

The device is performing a measurement.

Longer flash (0.5 seconds) repeated every second.

Searching

The device is searching for a network.

1 short (0.5 milliseconds) flash repeated every second.

Transmitting

The device is transmitting data to the WebService.

3 short (0.5 milliseconds) consecutive flashes repeated every second.

Off

The device is Off.

5 short (0.5 milliseconds) flashes per second for 5 seconds.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 9 | 54

3.2 WebService - general

Log on to https://data-metricorr.com using the username and password sent to you as per Section 1. For

data safety, it is recommended that your assigned password should be changed on your first login. This can

be done in the 'Profile' menu. You should also 'Logout' when you have completed your session.

The landing page is the "ICL ER probe" page and looks like this:

Click "DATA" -> "I LCS" to show the "Line Current Section":

Click "RMU" -> "MASTERLINKS" to show the page "Your defined MasterLinks":

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 10 | 54

Figure 5." Your defined Masterlinks" page

"Your Defined MasterLinks" can be any

of the following types: ICL, VL100 or ICL_C

An overview of the columns in the" Your defined Masterlink" table above is described in Table 2 below:

Table 2. Your defined MasterLinks –parameter description

Parameter

Data (example)

Comment

MobileID

AL02840252

MasterLink Serial number

SW version

1.3.145,1.3.145,1.3.145

Software version (MasterLink, Bluetooth, ICL-C module)

Battery

/

Not fitted with battery

Net info

3G/Fair,-81dBm

Network connection and signal strength

Received Time (UTC)

13-Jan-2021 11:51:21

UTC time stamp of LAST communication/data transfer

Next wakeup (UTC)

13-Jan-2021 12:50:32

UTC time stamp of NEXT communication attempt

Status

OK, 348 logger lines

received

" OK" indicates that communication went well.

" 348 logger lines received" inform amount of data received since

last communication session.

Longitude

12.430468

Geographic coordinate [degrees]

Lattitude

55.695079

Geographic coordinate [degrees]

Time

11:38:57

UTC time stamp for geographic coordinate

Connected Device

ICL-C

Indicate type of logger, in example: ICL, VL-100 or ICL-C

Serial number

AT0239770

Serial number of ICL-C module

Channel 1 SN

PI20304415

Serial number of connected ER probe

Channel 2 SN

Pipesection 08

Serial number of Line Current Component, i.e. a pipe section.

Options

Setup

Link to the Setup page

History

Link to the History page

S/N (ICL_C module)

Line Current (component)

ER probe (component)

Setup link

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 11 | 54

The 'Received Time' should be approximately that of when the unit was powered up. Status should be 'OK.'

After the unit has started communication (refer to" Figure 4. LED flash indication" flash pattern, 3rd row), it

could take a few moments for the WebService to update. Refresh your browser page if it does not appear

within 1 minute.

Should the unit not display on the MasterLink page, restart the unit to force new communication.

3.2.1 Setup of ICL-C & MasterLink

On the setup page in WEBService, the user shall specify the interval between measurements or a schedule

for a weekly" Intensive mode" campaign.

On the" Your defined Masterlink" page, see

Figure 5, you can access the setup page for the current ICL-C & MasterLink:

Click' Setup' in the column to the right:

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 12 | 54

Now the Setup page will be shown:

In the following sections, the setup page will be described in detail.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 13 | 54

3.2.2 Communication interval

Two parameters set the interval between MasterLink communication (wake up) with WebService:

1. Sleep(OK) hours. As long as communication is successful, the MasterLink goes to sleep for example,

168 hours before the next wake-up, where communication and data transfer are established again.

2. Sleep(Fail) hours. If communication fails, the MasterLink try to establish communication with a

different interval. (I.e. 4 hours)

For battery operation, it is recommended to set the unit for a 4h sleep interval in case of a communication

error (Sleep (FAIL) hours), and a 24h (once daily) for normal operation (Sleep (OK) hours) in order to

preserve battery life.

The existing settings are shown under 'Latest Registration'. For a new unit this will be blank.

Installation mode.

After initial power-up, 'Installation mode' will be activated. Communication frequency will be forced

automatic to 1h. This stated will automatically be disabled after three days and returned to recommended

normal operation.

Communication frequency can configurated as desired. It is recommended to specify a 4h sleep time, in

case of a communication error (Sleep (FAIL)) and a 24h (once daily) for normal operation (Sleep (OK)) to

preserve battery life.

Latitude & Longitude coordinates.

You can also request the unit's position (estimated latitude, longitude by GNSS) by checking the 'Get

Position' box. The retrieved data will be displayed in the 'MasterLink' table on next scheduled 'wake up'.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 14 | 54

3.2.3 Sample interval & Start time

The time between each measurement of ER probe, Line Current Sensor and Pipe-Ref voltage are specified

as Sample interval, which can be set by the user according to the part of the Setup page shown below:

Start time, HH:MM (UTC) sets the time of the first sample to be measured.

Sample interval (min) sets the interval for the next sample to be measured. The unit will continue to

perform measurements with this interval until the user stops it.

The 'Latest Registration' text shows when the next measurement is currently due to occur. All

updates will be performed at this time. This can be 'forced' by physically restarting the MasterLink.

Remember to 'Save request' beforehand.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 15 | 54

3.2.4 Intensive measurements

There are seven individual periods available. Each of the periods specifies a measurement there will be

repeated on weekly basics; all setup is in UTC Time.

For example, three periods are enabled in the weekly schedule.

1. Every Monday, starting at 10:15 AM, for a period of 2 hours

2. Every Wednesday, starting 8:45 PM, for a period of 4 hours

3. Every Thursday, starting 3:00 AM, for a period of 30 min

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 16 | 54

3.2.5 Assigning probes/sensors/components to the ICL-C

The ICL-C has two channels: Channel 1 (ER probes) and Channel 2 (Line Current Sensor).

At the bottom of the setup page, you can assign ER probes to Channel 1 (Probe 1) and a LCS component to

Channel 2 (LCS Sensor) using the drop-down list of probes you have linked to your account, see the

following section "4.5.1 Create Line Current Sensor".

ER probes for ICL-C will always be" Connected". Only Channel 2 on an ICL-MasterLink (a different product in the Slimline series) can

be configured as" Native" via a hardware jumper inside the unit. "Connected" means that the ER probe is connected to the "Pipe"

terminal. "Native" means that the ER probe is NOT connected to the "Pipe" terminal, which is used for corrosion measurements in

free air.

As shown below, probes/sensors can be 'Disabled' from the drop-down list for both channels. Assigning a

probe/sensor/component to a channel allows the ICL-C to take readings on that channel.

Probe 1 (ER probe)

Suppose an ERv2 probe is connected to the ICL-C. In that case, the unit will automatically detect the probe

serial number and the probe certificate data, which does not need any further action once the probe serial

number is displayed.

LCS sensor (LCS component)

Before you can assign an LCS sensor, you must create an LCS sensor certificate, a data-set typed in on the

webpage described in section "4.5.1 Create Line Current Sensor".

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 17 | 54

3.2.6 Linking ER probes to your account

The slimline ICL automatically recognizes the new ERv2 generation probes, and the data are stored

automatically. However, previous-generation probes must be configured manually:

Manual ER probe configuration

Click “Component” -> “ICL ER Probe”

The landing page will now show "Your Probe Certificate data":

Click "Create Sensor"

The landing page is displayed to the right, where a

new sensor/probe can be created by manually

typing in the certificate data for the ER probe.

The certificate is provided with each probe. If you

do not have the certificate for the probe you want

to upload, please email the serial number to

copy as soon as possible.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 18 | 54

4Line Current Sensor

The Line Current (LC) input on the ICL-C is designed to monitor the current flowing in a steel pipe (or other

structure), hereafter referred to as "pipe", by measuring the voltage drop across a certain span of the pipe.

However, it is possible to measure any voltage source connected to the LC input within the maximum limits

of ± 1.2 Vdc. Data for both DC and AC voltages are accessible in WebService.

The DC current in the pipe is calculated by a user-defined DC

resistance and displayed in WebService as a graph.

The AC current in the pipe depends on many fluctuating factors such

as soil moisture level and is therefore not calculated in WebService.

The LC input consists of the two terminals LC+ and LC-,

which are galvanically isolated from all other terminals.

4.1 LC input voltage range

The LC input is designed to monitor signals in the µV and mV range with a maximum target DC voltage of 20

mV. However, the maximum allowable input voltage range is ± 1.2 Vdc to allow a much higher AC voltage

signal without clipping the signal as illustrated in the graph below:

If the LC input voltage exceeds 1.2 V, the A/D converter will clip the signal and an error message will be

shown.

Time

0s 5ms 10ms 15ms 20ms 25ms 30ms 35ms 40ms

V(V1:+)

-1.2V

-0.8V

-0.4V

-0.0V

0.4V

0.8V

1.2V

20 mV

DC amplitude: 20 mV

AC amplitude: 1.18 V

Freq: 50 Hz

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 19 | 54

4.2 Connections to steel pipe or other structure

A steel pipe is used for this illustration, where the ICL-C MasterLink is placed in the center between the two

line current measuring points:

The current "I" with an arrow indicates the positive current direction.

4.3 DC resistance (LC input)

DC current in a buried steel pipe only depends on the DC resistance of a given length of the steel pipe,

which is a fixed value. (Does not change with soil moisture level, etc.). Since the DC resistance of a given

length of steel pipe (span) is much smaller than the AC impedance, it is recommended to select the pipe

span long enough to achieve a DC voltage measurement high enough to give accurate readings.

The recommended DC target voltage is 20 mV, which gives a good resolution in the µV range while keeping

a good headroom for superimposed AC voltages before clip (± 1.2 Vdc), 60 times higher than 20 mV.

MetriCorr

Slimline series –ICL-C & MasterLink Operation Manual 20 | 54

Example: 12.75" steel pipe, 100-meter span

This example indicates the measured voltage range of a steel pipe with the given data:

Data for steel pipe

Outer diameter

12.75”

324 mm

Wall thickness

0.5"

12.7 mm

DC resistance

23.3 mΩ/mi

14.5 µΩ/m

DC resistance for 100 m pipe:

Voltage measurement per ampere:

The pipe current that results in a measured voltage of 20 mVdc across the span of the pipe (100m) is given

by:

Maximum peak current before clip:

4.4 AC measurements for a steel pipe (LC input)

The LC input offers an AC voltage measurement to be displayed in Webservice.

Determining the AC current in a buried steel pipe requires advanced models to predict the AC impedance,

which depends on many factors:

-Steel pipe inductance (Relative permeability of the steel type used for the pipe)

-Pipe dimensions

-Capacitance to surrounding soil (coating)

-Specific earth resistance (depends on location and soil moisture level)

Note that the AC impedance will change according to the moisture content of the surrounding soil.

This manual suits for next models

1

Table of contents

Other MetriCorr Data Logger manuals