METRON QA-IDS Troubleshooting guide

1

Q A - I D S

U s e r & S e r v i c e M a n u a l

Q A - I D S I n f u s i o n P u m p T e s t e r

Copyright 1998 by METRON. All rights reserved.

METRON:

USA _ FRANCE NORWAY

1345 Mo roe NW, Suite 255A 30, rue Paul Claudel Travba eveie 1

Gra d Rapids, MI 49505 91000 Evry, Fra ce N-7044 Tro dheim, Norway

Pho e: (+1) 888 863-8766 Pho e: (+33) 1 6078 8899 Pho e: (+47) 7382 8500

Fax: (+1) 616 454-3350 Fax: (+33) 1 6078 6839 Fax: (+47) 7391 7009

E-mail: metronus@aol.com E-mail: metronfrance@infonie.fr E-mail: support@metron.no

Disclaimer

METRON provides this publicatio as is without warra ty of a y ki d, either express or implied, i cludi g

but ot limited to the implied warra ties of mercha tability or fit ess for a y particular purpose. Further,

METRON reserves the right to revise this publicatio a d to make cha ges from time to time to the co te t

hereof, without obligatio to METRON or its local represe tatives to otify a y perso of such revisio or

cha ges. Some jurisdictio s do ot allow disclaimers of expressed or implied warra ties i certai tra sactio s;

therefore, this stateme t may ot apply to you.

Limited Warranty

METRON warra ts that the QA-IDS I fusio Pump Tester will substa tially co form to published specifica-

tio s a d to the docume tatio , provided that it is used for the purpose for which it was desig ed. METRON will,

for a period of twelve (12) mo ths from date of purchase, replace or repair a y defective a alyzer, if the fault is

due to a ma ufacturi g defect. I o eve t will METRON or its local represe tatives be liable for direct, i di-

rect, special, i cide tal, or co seque tial damages arisi g out of the use of or i ability to use the QA-IDS I fu-

sio Pump Tester, eve if advised of the possibility of such damages. METRON or its local represe tatives are

ot respo sible for a y costs, loss of profits, loss of data, or claims by third parties due to use of, or i ability to

use the QA-IDS I fusio Pump Tester. Neither METRON or its local represe tatives will accept, or be bou d

by a y other form of guara tee co cer i g the QA-IDS I fusio Pump Tester other tha this guara tee. Some ju-

risdictio s do ot allow disclaimers of expressed or implied warra ties i certai tra sactio s; therefore, this

stateme t may ot apply to you.

Trademarks

IBM is a registered trademark, a d PC/XT is a trademark of IBM Corporatio . Ce tro ix is a registered trade-

mark of Ce tro ix Corporatio . Microsoft is a registered trademark a d Wi dows is a trademark of Microsoft

Corporatio .

2

Table of Contents

MANUAL REVISION RECORD............................................................................................5

1. INTRODUCTION..................................................................................................................7

1.1 QA-IDS Features .........................................................................................................................7

1.2 Specificatio s................................................................................................................................7

1.3 Ge eral I formatio ......................................................................................................................8

2. INSTALLATION...................................................................................................................9

2.1 Receipt, I spectio a d Retur .....................................................................................................9

2.2 Setup............................................................................................................................................10

2.3 Power ..........................................................................................................................................10

2.4 PRO-Soft QA-IDS.......................................................................................................................10

3. OPERATING QA-IDS........................................................................................................13

3.1 Co trol Switches a d Co ectio s.............................................................................................13

3.2 Key Pad Fu ctio s.....................................................................................................................14

3.3 Me u a d Fu ctio Keys............................................................................................................14

3.4 Display Me us a d Messages ...................................................................................................15

3.5 Pri ti g Test Reports.................................................................................................................20

3.6 Operator Mai te a ce................................................................................................................22

4. INFUSION PUMP TESTING.............................................................................................23

4.1 I troductio ................................................................................................................................23

4.2 Test Preparatio ..........................................................................................................................23

4.3 Occlusio Pressure/ Bolus Volume Testi g ..............................................................................25

4.4 I fusio Flow Rate a d Volume Testi g....................................................................................26

5. CONTROL AND CALI RATION....................................................................................29

5.1 Required Test Equipme t...........................................................................................................29

5.2 Adjusti g the Display Co trast ..................................................................................................29

5.3 Testi g Power Supply to IDS.....................................................................................................29

5.4 Testi g Pressure Gauge Accuracy..............................................................................................30

5.5 Testi g Flow Rate Accuracy.....................................................................................................30

5.6 Checki g the Battery Backup.....................................................................................................31

6. COMPONENT FUNCTIONS AND PARTS....................................................................33

6.1 Theory of Operatio ....................................................................................................................33

6.2 Power Supply..............................................................................................................................33

6.3 Pri ter Output..............................................................................................................................33

6.4 Serial Port...................................................................................................................................34

6.5 Microprocessor............................................................................................................................34

6.6 Pressure Gauge............................................................................................................................34

6.7 Pump............................................................................................................................................34

6.8 Stepper Motor/Drivers................................................................................................................34

6.9 Co trol Pa el...............................................................................................................................35

6.10 Compo e t Parts......................................................................................................................35

3

APPENDIX A: DIAGRAMS......................................................................................39

Processor board Compo e t Locatio ...........................................................................................41

6.10.1 Processor board Schematic Diagram 1 ...............................................................................42

6.10.2 Processor board Schematic Diagram 2 (Digital Part) .......................................................43

6.10.3 Processor board Schematic Diagram 3 (CPU) ..................................................................44

6.10.4 Processor board Schematic Diagram 4 (Memory) ............................................................45

6.10.5 Processor board Schematic Diagram 5 (RS232C a d Pri ter) .........................................46

6.10.6 Processor board Schematic Diagram 6 (Digital Outputs) .................................................47

6.10.7 Processor board Schematic Diagram 7 (Digital I puts) ....................................................48

6.10.8 Processor board Schematic Diagram 8 (A/D) ...................................................................49

6.10.9 Processor board Schematic Diagram 9 (Stepper Motor a d Drivers) ..............................50

6.10.10 Processor board Schematic Diagram 10 (Pressure Se sor a d Temperature) ................51

6.10.11 Processor board Schematic Diagram 11 (Mai Part) ......................................................58

6.10.12 Processor board Schematic Diagram 12 (Keyboard, Pressure Se sor a d Pump I dex)

..........................................................................................................................................................59

APPENDIX : ERROR REPORT FORM, QA-IDS.........................................................62

APPENDIX C: SUGGESTION FORM, QA-IDS...............................................................65

4

Manual Revision Record

This record page is for recordi g revisio s to your QA-IDS User and Service Manual that have

bee published by METRON or its authorized represe tatives. We recomme d that o ly the ma -

ageme t or facility represe tative authorized to process cha ges a d revisio s to publicatio s:

•make the pe cha ges or i sert the revised pages;

•e sure that obsolete pages are withdraw a d either disposed of immediately, or marked as

superseded a d placed i a superseded docume t file, a d;

•e ter the i formatio below reflecti g that the revisio s have bee e tered.

Rev No Date Entered Reason Signature of Person Entering Change

0 - Initial Release

5

This page intentionally left blank.

6

1. Introduction

This chapter describes the Metro ’s QA-IDS I fusio Pump Tester’s

features a d specificatio s.

1.1 QA-IDS Features

METRON’s QA-IDS I fusio Pump Tester is a precisio i stru-

me t, desig ed for use by trai ed service tech icia s, for testi g all

types of i fusio pumps accordi g to I ter atio al Electrotech ical

Commissio (IEC) Draft Sta dard 62.D (IEC 601.2.24). Tests i -

clude:

•volumetric tests

•bolus tests

•occlusio alarm tests

QA-IDS is capable of detecti g a mi imum volume variatio of o e

microliter i a ra ge of 0.10 milliliter per hour (ml/hr) to 1000.0

ml/hr. Flow measureme ts are take every 30 seco ds, so that the

measureme ts are i depe de t of the i fusio pump’s flow rate.

Test results, show i the QA-IDS's LCD display, ca be pri ted out

directly, or tra sferred to a PC via the PRO-Soft QA-IDS test auto-

matio software. PRO-Soft lets you desig test protocols, remotely

co trol the QA-IDS, a d store the test results.

1.2 Spe ifi ations

1. Flow Rate

Flow Range 0.10 ml/hr - 1000.0 ml/hr

Min. volume detection 0.72 µl

Dis lay resolution 0.01 ml/hr

2. Time Interval to A hieve ± % A ura y of Reading

1000 ml/hr 100 ml/hr 10 ml/hr

0.5% 0.6 sec 0.5% 6 sec 0.5% 52 sec

1.0% 0.3 sec 1.0% 3 sec 1.0% 26 sec

1.5% 0.2 sec 1.5% 2 sec 1.5% 18 sec

3. Pressure Generation

Range: - 200 to + 600 mmHg

Accuracy:

- 200 to + 200 mmHg: ± 10 mmHg

+ 201 to + 600 mmHg: ± 20 mmHg

4. O lusion Alarm Test

Measurement Range: - 400 to +1500 mmHg.

7

Accuracy:

- 400 to + 500 mmHg: ± 10 mmHg

+ 501 to + 1500 mmHg: ± 2% of reading

Maximum In ut Pressure: 2500 mmHg

5. Bolus Test

Accuracy: ± 20 µl

1.3 General Information

Temperature Requirements

+15°C to +35°C when o erating

0°C to +50°C in storage

Display

Ty e LCD gra hic dis lay

Al hanumeric format 4 lines, 40 characters

Dis lay control 7 function keys and a key ad

Data Input/ Output (2) Parallel rinter ort (1); Bi-directional RS

-232C (1) for Com uter control

Power From 110 VAC to 240 VAC, 47 / 63 Hz.

Me hani al Spe ifi ations

Housing Metal case

Height 13.5 cm / 5.31 in.

Width 23.5 cm / 9.25 in.

De th 24.5 cm / 9.65 in.

Weight 4.30 kg / 9.48 lbs.

Printer Port Centronics Interface

Standard A essories

User and Service Manual QA-IDS (P/N 15035)

Additional A essories

Carrying case (P/N 15100)

Carrying case, ext. rinter (P/N 10500)

PRO-Soft QA-IDS software (P/N 15200)

PRO-Soft QA-IDS DEMO (P/N 15201)

User Manual PRO-Soft QA-IDS (P/N 15205)

Storage

Store in the carrying case in dry surroundings within the tem era-

ture range s ecified. There are no other storage requirements.

Periodi Inspe tion

The unit should be calibrated every 12 months.

8

2. Installation

This chapter explai s u packi g, receipt i spectio a d claims, a d

the ge eral procedures for QA-IDS setup.

2.1 Re eipt, Inspe tion

and Return

1. I spect the outer box for damage.

2. Carefully u pack all items from the box a d check to see

that you have the followi g items:

•QA-IDS I fusio Pump Tester (P/N 15000)

•User a d Service Ma ual QA-IDS (P/N 15035)

3. If you ote physical damage, or if the u it fails to fu ctio

accordi g to specificatio , i form the supplier immedi-

ately. Whe METRON AS or the compa y’s represe ta-

tive, is i formed, measures will be take to either repair the

u it or dispatch a replaceme t. The customer will ot have

to wait for a claim to be i vestigated by the supplier. The

customer should place a ew purchase order to e sure de-

livery.

4. Whe retur i g a i strume t to METRON AS, or the

compa y represe tative, fill out the address label, describe

what is wro g with the i strume t, a d provide the model

a d serial umbers. If possible, use the origi al packagi g

material for retur shippi g. Otherwise, repack the u it us-

i g :

•a rei forced cardboard box, stro g e ough to carry the

weight of the u it.

•at least 5 cm of shock-absorbi g material arou d the u it.

•o abrasive dust-free material for the other parts.

Repack the u it i a ma er to e sure that it ca ot shift i the

box duri g shipme t.

METRON’s product warra ty is o page ii of this ma ual. The

warra ty does ot cover freight charges. C.O.D. will ot be ac-

cepted without authorizatio from METRON A.S or its represe -

tative.

9

2.2 Setup

1. Equipme t co ectio is as show i the typical setup be-

low.

2. If PRO-Soft QA-IDS is bei g used, attach a RS-232 ( ull

modem/data tra sfer co figured) cable to the 9-pi D-sub

outlet port located at the rear of the QA-IDS. Do ot attach

the pri ter cable to the QA-IDS. See below. However, if

you are ot usi g PRO-Soft QA-IDS, a d are se di g di-

rectly to a pri ter for pri touts, attach the pri ter cable to

the 25-pi outlet port .

2.3 Power

Main On/Off Switch. QA-IDS should remai off for at least 5 sec-

o ds before switchi g o agai , i order to allow the test circuits to

discharge fully.

2.4 PRO-Soft QA-IDS

PRO-Soft QA-IDS is a fro t-e d test automatio a d prese tatio

tool for METRON's QA-IDS I fusio Pump Tester. It allows you to

co duct the same tests, but by remote co trol via a IBM-com-

patilbe PC/XT with MS Wi dows (Versio 3.1 or later).

10

NOTE

Some RS-232C cables are

missing the connection be-

tween the seventh and the

eighth wires in the cable.

The cable may still be called

NULL-modem, but it will not

work with the QA-IDS. Refer

to the PRO-Soft QA-IDS

Users Manual for more in-

formation.

Each of the QA-IDS tests ca be ru i depe de tly from PRO-Soft

i the “Ma ual” test mode. Results are show o the PC scree dur-

i g testi g, a d the user is prompted to set the tested equipme t ac-

cordi gly. At the co clusio of tests, the user may pri t a report,

store the test a d results o disk, or both. Combi atio s of tests ca

be created a d stored as “Test Seque ces.” The program mai tai s a

library of these seque ces. I this way you ca store a d retrieve se-

que ces that are appropriate for each i fusio device bei g tested at

your facility.

Seque ces ca the be used i depe de tly, or ca be attached to a

checklist, writte procedure, a d equipme t data i the form of a

test “Protocol.” The equipme t data ca be e tered ma ually i to

the protocol, or it may be retrieved by PRO-Soft from the QA-MAP

program or other equipme t files. Protocols ca be created easily for

each i fusio pump i your i ve tory, a d stored for use. Test pro-

tocols with results ca be pri ted, or stored o disk, a d the results

of testi g ca be se t back to the equipme t database to close a

work order a d update the service history.

11

NOTE

PRO-Soft QA-IDS has its

own user manual which

contains all the information

concerning the rogram. If

you order a demonstration

version of the rogram you

also receive the manual.

This page intentionally left blank.

12

. Operating QA-IDS

This chapter explai s the operati g co trols, switches a d me us of

the QA-IDS, details how to use them i testi g, a d provides i -

structio s for pri ti g reports, a d operator mai te a ce.

3.1 Control Swit hes and

Conne tions

Front Panel

1. Key Pad 11 al hanumeric keys, used to enter information.

2. Fun tion Keys F1-F4 are used to select the functions shown in the

menu bar at the bottom of the dis lay, i.e., for se-

lecting the function that is directly above the key.

F5-F7 are used to select the function, or enter in-

formation in the message field in the same line.

3 LCD Display Shows messages, test results and function menus.

4 Inlet Inlet connection for infusion set.

5. Drain Connection for drainage tube.

6. Upgrade Keys S ecial function keys for firmware u grade.

13

Rear Panel

7. Power Swit h Turns ower ON and OFF.

8. Mains QA-IDS Mains connection for test instrument.

9. Printer Outlet Port 25 in D-sub. Centronic out ut.

10. RS-232 Serial Port 9- in D-sub

3.2 Key Pad Fun -

tions

The alpha umeric keys comprise both umbers a d letters. Hold the

key i a d it moves automatically from character to character.

3.3 Menu and Fun tion

Keys

The QA-IDS uses displays, fu ctio keys a d a keypad to provide

flexibility a d co trol over operatio s. The top three li es i the dis-

play are used for messages, status a d results. The me u bar is

show at the bottom of the display. Fu ctio keys are umbered

from F1 to F7.

A fu ctio /me u is selected by pressi g that key which is directly

below/to the right of the me u u it show i the display.

14

3.4 Display Menus and

Messages

1. Startup Screen. The followi g scree s will be displayed

i seque ce for the first two seco ds after the QA-90 has

bee switched ON.

2. Main Menu

This wi dow offers the followi g fu ctio s:

•Press Occlusion Test (F5) to go to the Occlusio Test

Setup Scree . See paragraph .4.5 below.

•Press Flow Measurement (F6) to go to the Flow Measure-

me t Test Setup Scree . See paragraph .4.6 below.

•Press Equipment Code (F7) to record the code or ame of

the device u der test. Press Enter (↵ ) to store.

3. PRIME (F1). Whe PRIME (F1) is pressed, the follow-

i g display will appear:

•Press GO ACK (F2) to retur to the mai me u.

4. SETUP (F3)

This fu ctio is used for e teri g ge eral i formatio i co -

ectio with the test. Three mai displays are show below.

•Press Operator (F6) to record the operator’s ame or i i-

tials.

15

•Press Establishment (F5) to record the establishme t.

•Press MAIN MENU (F4) to retur to the mai me u.

•Press MORE (F1) a d the followi g display will appear:

•Press Serial no (F7) to record the serial umber of the QA-

IDS bei g used.

•Press Reference Unit (F6) to select the refere ce u it, as

follows:

mmHg mBar kg/cm2inH2O

cmH2O kPa inHg PSI

•Press Alarm After Test (F5) a d select Yes or No.

•Press GO ACK (F2) to retur to the previous display.

•Press MAIN MENU (F4) to retur to the mai me u.

•Press MORE (F1) a d the followi g display will appear:

•Press Language (F7) to select the la guage used for the

testi g.

•Press Date (F6) to set the day/mo th/year.

•Press Time (F5) to set the hour/mi ute/seco d.

•Press GO ACK (F2) to retur to the previous display.

•Press MAIN MENU (F4) to retur to the mai me u.

5. Occlusion Test (F5)

The Occlusio Alarm Test is used to protect the patie t. A Oc-

clusio Pressure Alarm will be activated if the pressure i side

the admi istratio set exte ds preset levels. The three mai test

displays are show below.

16

•Press Flow Set (F7) to set the preset value of the i fusio

pump.

•Press Alarm Prsr (F6) to set the preset pump value.

•Press START (F2) to start the Occlusio Test, a d the fol-

lowi g display will appear:

The followi g parameters are displayed:

Prsr: The ressure in the connction tube. Measurement results

dis lay: max. value > instantaneous measured value >

mean value in mmHg.

Time: The time from test start until alarm activation. Measure-

ment results dis lay: max. time > ela sed time > mean

time in minutes/seconds.

Bolus: The volume ex ansion within the tube when the infusion

um alarm activates. Measurement results dis lay: max.

bolus > last executed calculation after STOP is ressed >

mean bolus in milliliters.

•Press GO ACK (F4) to retur to the previous me u.

•Press STOP (F2) to stop the test.

•Press START (F2) to retur to the previous me u.

•Press GO ACK (F4) to retur to the previous display.

6. Flow Measurement (F6)

This fu ctio is used for e teri g flow i formatio i co ec-

tio with the test. There are four mai displays, show below:

17

The followi g parameters are displayed:

Flow Set: This value is the reset value of the infusion um . All er-

ror calculations of the flow measurement are related to

this value. If the Flow Set value is not entered correctly,

this may cause a oor resentation with incorrect overall

errors.

Press Set: This function enables you to enter + ( ositive) or - (nega-

tive) back ressure into the system. O eration range is

from -200 to +600 mmHg.

dT: Interrogation time, or time between two measurements.

Average value during the test interval is dis layed. Rec-

ommended dT from IEC is 30 sec, and this is the mini-

mum value to be selected on the QA-IDS. Maximum dT is

600 sec. or 10 minutes. Default value is 30 sec.

•Press Flow Set (F7) to set the preset value of the i fusio

pump.

•Press Press Set (F6) to set the releva t + or - backpressure

i to the system.

•Press dT (F5) to set the i terrogatio time, or time betwee

two measureme ts.

•Press PR HDR (F3) to pri t a header.

•Press MAIN MENU (F4) to retur to the Mai Me u.

•Press MORE (F1) a d the followi g scree will appear:

The followi g parameters are displayed:

Test Time: This is the reset time for a test. Maximum testing time

is 24 hours. Default value is 1 hour.

Delay Time: This is the delay before the first measuring.

•Press Test Time (F7) to set the actual time of the test.

•Press Delay Time (F6) to set the delay before the first mea-

sureme t.

•Press MORE (F5) to retur to the previous display.

•Press PR HDR (F3) to pri t a header.

18

•Press MAIN MENU (F4) to retur to the Mai Me u.

•Press START (F2) to start flow measureme t, a d the

Flow Measurement 1 display will appear:

The followi g parameters are displayed:

Mean Flow: The flow of the liquid volume in infusion um every

second dis layed in ml/h and %.

Cum. Volume: The cumulative volume from start of the test.

Time Left: The remaining time before the test is finish.

•Press STOP (F2) to retur to the Flow measureme t setup.

•Press MORE (F1) a d the Flow Measurement 2 display

will appear.

The followi g parameters are displayed:

Inst. Flow: Instantaneous Flow shows: max. value > mean value

> minimum value in %.

Inst. Flow: Instantaneous Flow shows: max. value > mean value

> minimum value in ml/h.

Prsr: The ressure in the connection tube.

•Press STOP (F2) to retur to the previous display.

•Press MORE (F1) to retur to the Flow Measurement

Setup.

19

3.5 Printing Test Re-

ports

Hard copy pri touts of test results ca be made if a pri ter is co -

ected to the QA-IDS. See paragraph 2.2 for connecting the printer.

To obtai a pri tout of the test, select PR HDR (F3) at the comple-

tio of the test. As ca be see by the followi g examples, the pri t-

outs co tai :

•QA-IDS u it, operator a d establishme t ide tificatio .

•Tested equipme t ide tificatio

•Test setup data, a d detailed reselts.

•Test summary

•Comme ts

1. Example Pri tout of a Flow Measureme t Test.

METRON QA-IDS I fusio pump tester Ver.

1.17

Serial o.:

Operator : Establishme t :

- - EQUIPMENT INFORMATION - -

Equipme t Code : ___________________________________________

Serial o. : ___________________________________________

Status : ___________________________________________

Group : ___________________________________________

Ma ufacturer

:

___________________________________________

Type : ___________________________________________

Model : ___________________________________________

Locatio : ___________________________________________

- - SETUP DATA FLOW MEASUREMENT TEST - -

Flow set : ml/h Test Time : s

Press Set : mmHg Delay Time : s

dT

:

s

dT

No.

Pressure

(mmHg)

Cum. Volume

(ml)

I st. Flow

(ml/h) (%)

Mea Flow

(ml/h) (%)

*****************************************************************

*********

- - TEST SUMMARY - -

Mea Flow : ml/h

Max. Peak Flow : ml/h

Mi . Peak Flow : ml/h

Cum. Volume : ml

Measureme t Time : s

Comme ts : ___________________________________________

___________________________________________

Date-Time/Sig ature ______________________________

20

Table of contents

Other METRON Test Equipment manuals

Popular Test Equipment manuals by other brands

Flextest

Flextest FL2005.1 instruction manual

Aegis

Aegis OSC-9200 user manual

norbar

norbar 80026 Operator's manual

ITD Food Safety Inc.

ITD Food Safety Inc. Temp-Taker 3 Subway Edition Getting started

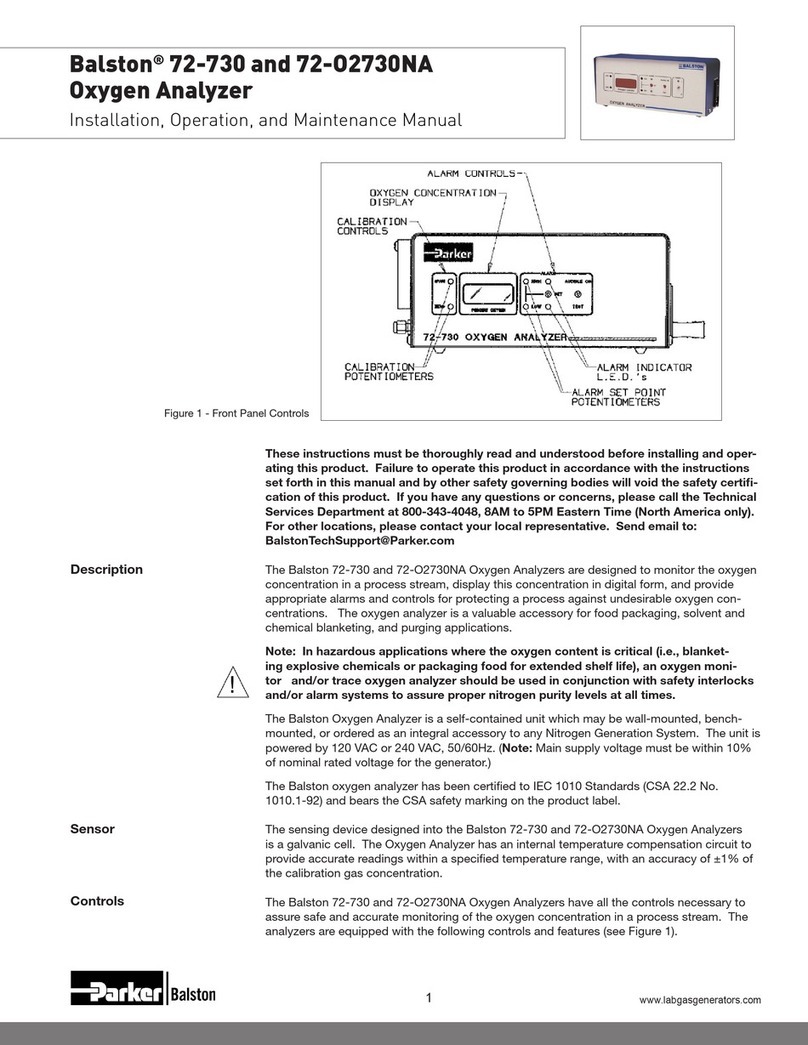

Parker

Parker Balston 72-730 Installation, operation and maintenance manual

Atec

Atec ROD-L M25 Operation & service manual