Bulletin TI-72730J Installation, Operation and Maintenance Manual

72-730 and 72-O730NA Oxygen Analyzer

www.labgasgenerators.com

3

1-800-343-4048

The galvanic cell is not installed into the analyzer prior to shipment. It is shipped in the bag

which contains the documentation for the product. The tools required to install the oxygen sensor

are a small at head or Phillips screwdriver and wire strippers. Install the sensor as follows:

1 Remove sensor cover on left side of unit.

2 Strip sensor connecting wires to 1/4" to 3/8" (6mm to 9mm) using wire strippers. Install the

sensor into the sensor holder on the left side panel of the analyzer (see Figure 3) by pushing

rmly into place.

3 Insert small screwdriver into the hole adjacent to the wire connection point (see Figure 3) and

press to open connector.

4 Slide the stripped wire end into the appropriate (red or black) connection port until it “bottoms

out”. The red wire goes to the “+” connector, and the black wire goes to the “-” connector.

5 Remove the screwdriver to clamp the wire into the connection port. Pull the wire gently to test

integrity of the connection. Repeat this procedure from step 2 if the wires release easily.

6Replace sensor cover before powering up unit.

The 72-730 and 72-O2730NA Oxygen Analyzers are preset at the factory for operation at 120

VAC. (Note: Main supply line voltage must be within 10% of the nominal rated voltage for the

generator.) The voltage setting for the analyzer is shown through a small window on the power

entry module on the right side of the analyzer (see Figure 5). Check the voltage selector set-

ting prior to energizing the analyzer. The selector setting should match the voltage of the local

power supply. (Note: The "NA" version of the oxygen analyzer will only operate at 120 VAC.) Plug

the provided power cord into the power entry receptacle of the analyzer, and plug the opposite

end into a wall outlet with earth ground protection. The North American cordset is rated for 125V,

10 amperes, 18 AWG, SJT, with ferrite bead. Do not replace it with an inadequately rated cordset.

The analyzer is powered on by plugging into electrical supply. There is no power switch on

this product.

If the voltage selector displays an input power voltage different from the local power supply, it may

be changed using only a small screwdriver (check voltage rating of analyzer on product label on

the bottom panel to ensure compatibility with local electrical supply). First, use the screwdriver

to release the cover of the power entry module on the right side of the analyzer (see Figure 5).

Next, rotate the voltage selector until the desired input voltage is displayed in the window. Finally,

replace the power entry module cover.

Galvanic Cell

Voltage Selector

The 72-730 and 72-O2730NA are calibrated prior to shipment; however, Parker strongly recom-

mends re-calibrating the units prior to initial start-up. After the initial start-up, the unit should be

calibrated on a bi-weekly basis until a suitable schedule is determined, based upon the level of

accuracy required by the application.

There are two methods of calibrating the 72-730 and 72-O2730NA Oxygen Analyzer: the two

point method and the single point method. In the two point method, the rst point in the

calibration range is set to zero using a zero gas (zero percent oxygen), and the second point in

the range is set to a known percentage of oxygen using a span gas (known quantity of oxygen,

per gas supplier) or compressed air (20.9% oxygen). In the single point method, only one point

in the calibration range is set, using either span gas or compressed air. Maximum accuracy in

oxygen concentration monitoring will be achieved if the oxygen concentration in the span gas is

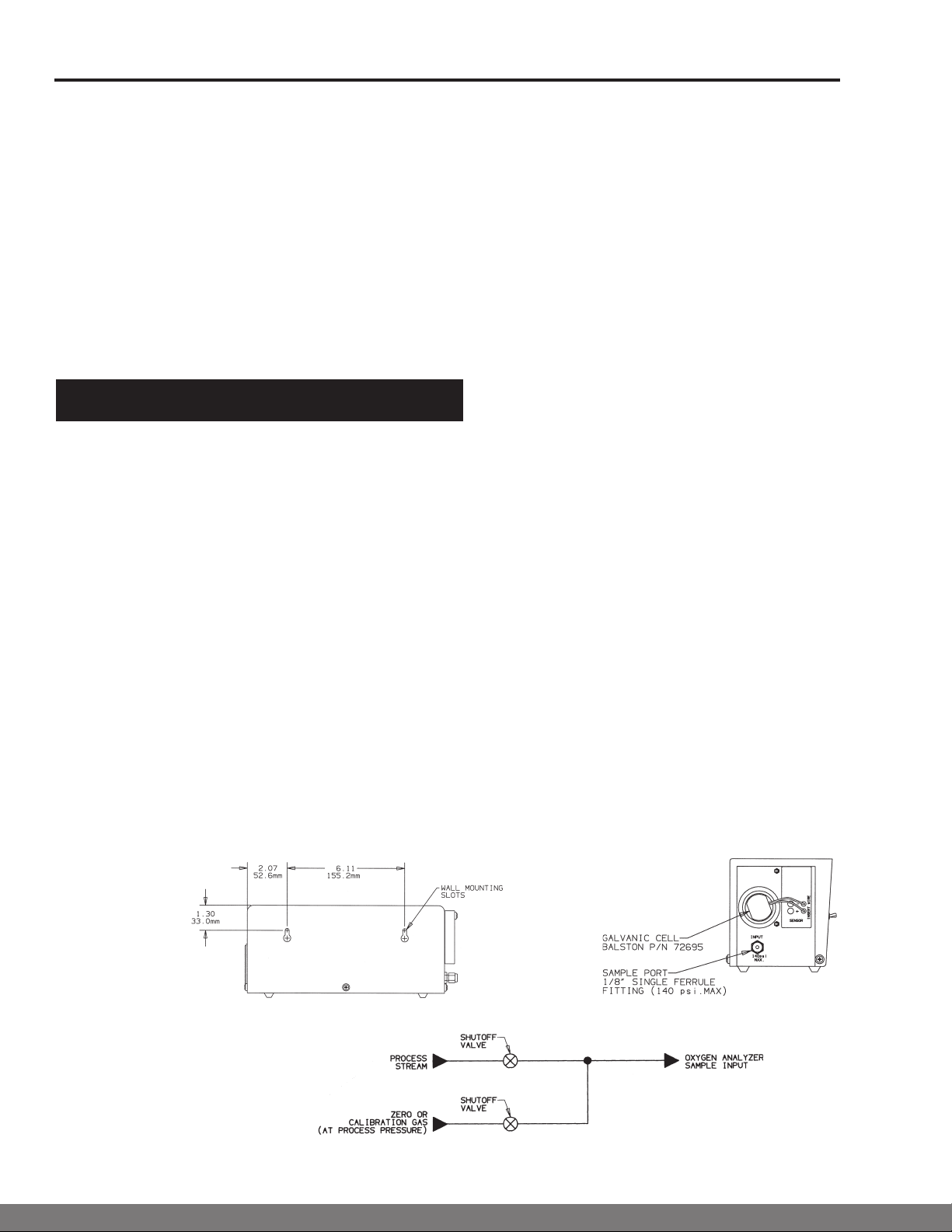

within the range of the expected oxygen concentration in the process stream. See Figure 1 for

calibration controls and Figure 4 for recommended calibration gas valving.

Calibration

Operation

Figure 5 - Right Side View