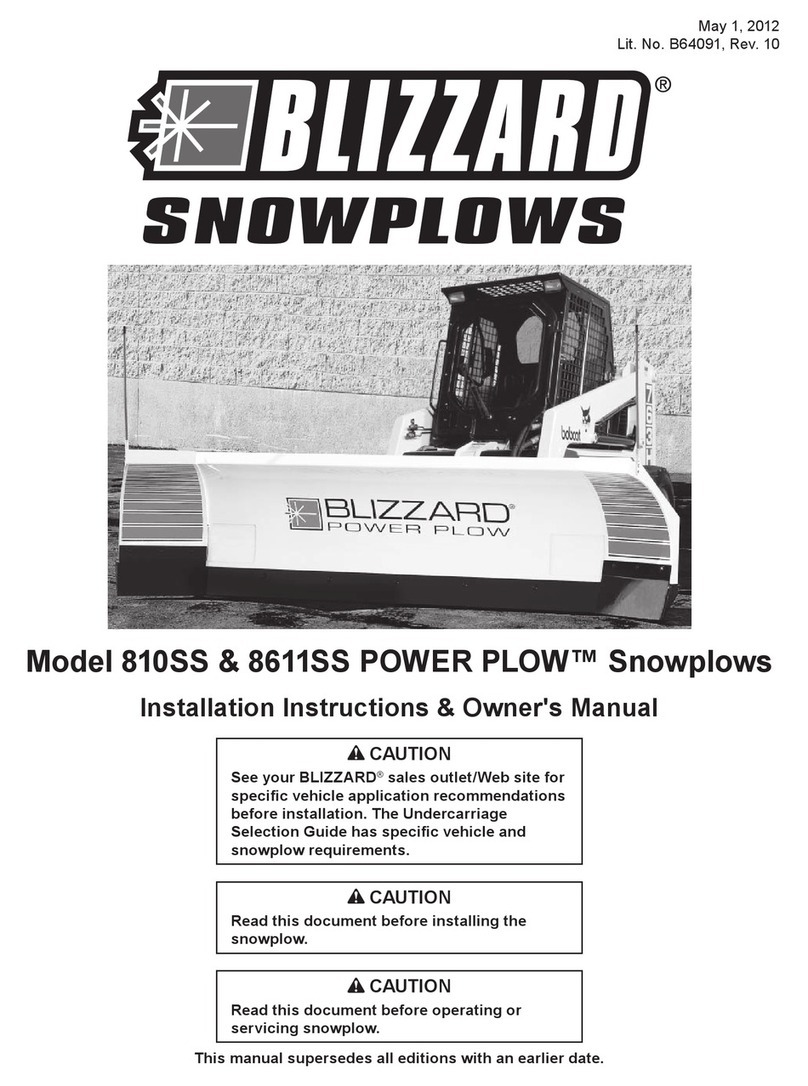

CRANKSTAND STORAGE

To store Crankstand on the Lift Frame slide the tube that is attached to the

side of the Crankstand over the receiver tube on the driver’s side of the Lift

Frame. Insert the chain locking pin through the vertical holes on both the

tubes. Note: Crankstand should always be fully retracted (up) and be

pinned in the vertical transport position when not in use. Receiver Tube

Cap may be placed over the driver side transport tube while the Crankstand

is in use on the A-Frame. The Receiver Tube Cap may also be switched over

to the Adjustment Tube of the A-Frame when the Crankstand is mounted to

the Lift Frame.

Storage of the Crankstand is the responsibility of the operator. The

stand can be stored on the lift frame in the retracted position to the

driver’s side transport tube or inside the vehicle cab.

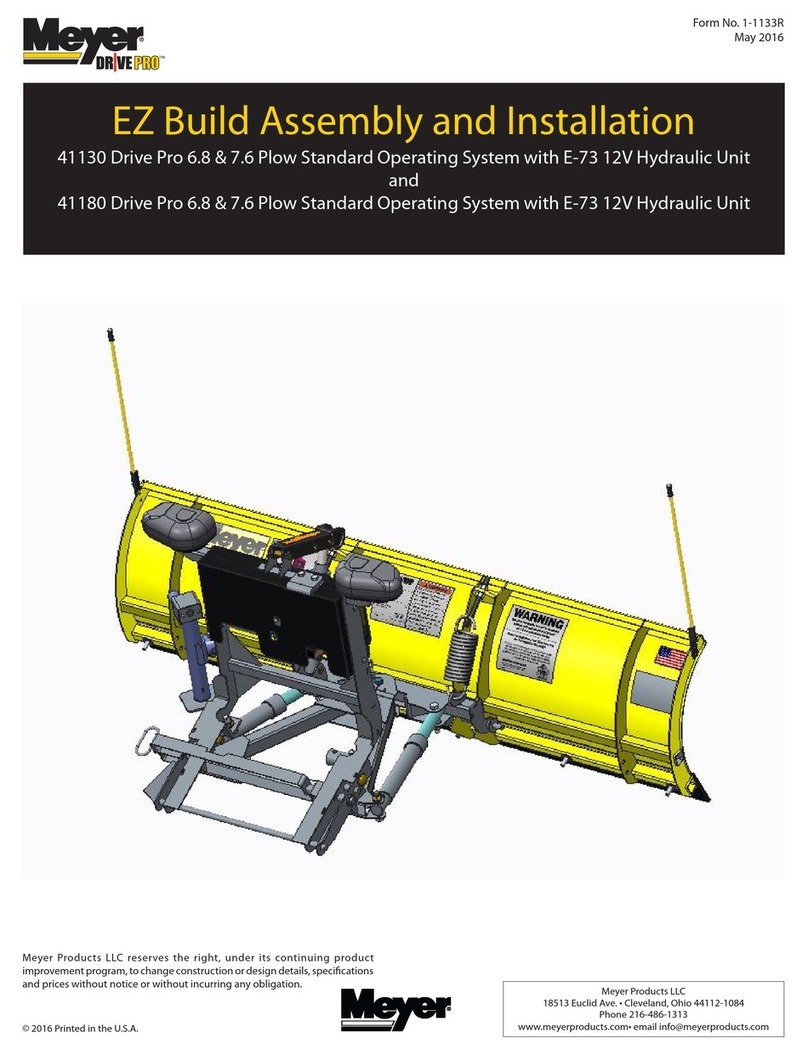

HYDRAULIC COVER

Install Black Hydraulic Cover before installing the Lift Assembly to the Lift

Frame. Begin by sliding the Hydraulic Cover down over the Lift Ram. Slide

the side covering the motor carefully over the motor, do not force or stretch

the Hydraulic Cover it will fit comfortably over all parts of the Hydraulic Unit.

Feed the three coil wires (red, green and black) through the hole located on

backside of cover. Route coupler weather plugs through holes in cover where

power angling hoses enter. Snap Cover together. Caution: Care should be

taken with the installation and or removal of the Hydraulic Cover, including

partial removal when repairs are performed on the Hydraulic Lift Unit. Tearing

of the Hydraulic Cover for any reason will not be covered under the Meyer

Warranty.

ATTACHING MOLDBOARD ASSEMBLY ONLY

Attach A-Frame to Lift Frame by connecting Crankstand to the adjustment

tube in the center of the A-Frame Frame. Insert the chained locking pin all

the way through the vertical holes on both the tubes. Crank up A-Frame until

the holes on the back ears of the A-Frame are about 12" off the ground. Pull

out the Yellow Handle Pins on both sides of the Lift Frame. Twist handle

slightly to the right or left disengaging the pin. Pull truck up to the A-Frame/

Moldboard assembly aligning the A-Frame ears between the two lift frame

plates until contact is made with the Clevis Frame. Once you feel contact,

push the moldboard assembly a few inches forward, this insures proper

alignment so that the A-Frame is square to the Clevis Frame. Adjust the

Crankstand up until the front of the truck raises slightly. Rotate the Yellow

Handled Pins so that the small leg realigns with the slot, engaging the pin.

The spring loaded pin should snap into place locking the A- frame to the lift

frame. Note: If pins do not properly engage move the truck slightly forward

a few more inches and/or adjust (raise or lower) the Crankstand until pins

lock into place. If only one pin should engage, retract the stand to the full

upright position. Remove the Crankstand from the A-frame by removing the

chained locking pin. Reattach the Crankstand to the transport tube on the

driver’s side of the Lift Frame in the vertical transport position. Attach the

Lift Chain to the Lift Arm through the two hooks on the lift arm. Adjust the lift

chain at the lift arm so that there are 2-3 links of slack. This ensures that the

plow blade will lift fully and be able to follow the ground contour while plowing.

Raise the plow with the hydraulics and swing the moldboard slightly left or

right until the pin engages.

4