CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

7 – 8 with a multimeter.

3) Input: Check that the input signal is within 0 – 100% of

the full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications shown below.

OUTPUT LOAD REQUIREMENTS

Open collector 50V DC @50mA max.

Relay contact 120V AC @200mA max. (cosø=1)

24V DC @200mA max. (resistive load)

5V pulse 600 Ω min.

24V pulse 800 Ω min.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

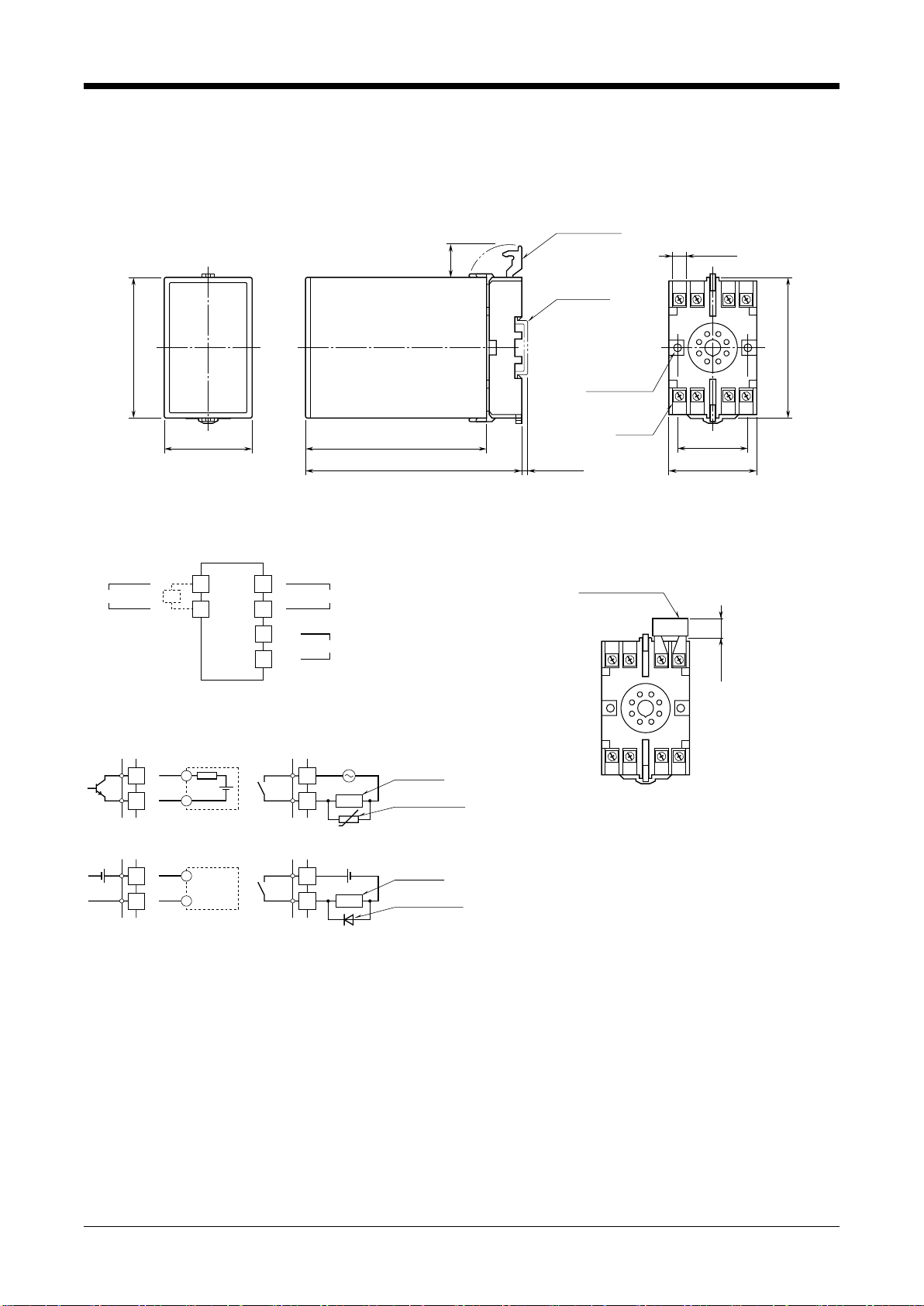

■HOW TO CALIBRATE THE OUTPUT SIGNAL

Connect a signal generator to the input terminal and a fre-

quency counter to the output terminal.

Zero Adj.

Span Adj.

Low-End Cutout

Monitor LED

Range Selector

Low-End Cutout

Adjustment Pulse Width Adj.

• Output Range Adjustment (coarse range)

1) Select an appropriate coarse range in the table to the

right, and set the front accessed Range Selector.

• Zero/Span Adjustments

1) First nullify Low-end Cutout Adj. to 0%.

2) ZERO (fine range): Apply 5% input and adjust output to

5%.

2) SPAN (fine range): Apply full-scale (100%) input and ad-

just output to 100%.

3) Check ZERO adjustment again with 5% input.

4) When ZERO value is changed, repeat the above proce-

dure 1) – 3).

Note: The output frequency is precisely doubled by turning

Range Selector by 1 division to the counterclockwise

direction. In order to quickly make low frequency range

adjustments, conduct fine adjustment first with a higher

coarse range, and then change coarse range to the actual

one.

• Low-end Cutout Adjustment

1) Apply the desired input to be eliminated.

2) Turn the Low-end Cutout Adj. clockwise until the Cutout

LED is turned on.

3) Turn it slowly counterclockwise to the exact position

where the Cutout LED is still on but will be turned off if

it turned further counterclockwise.

• Output Pulse Width Adjustment

The pulse width is adjusted at the factory until the duty

ratio becomes 50% of the maximum frequency. If this value

lies outside of the adjustable range, either maximum or

minimum selectable value will be used.

If the pulse width needs to be changed, go through the fol-

lowing procedures.

1) Turn the Pulse Width Adj. fully counterclockwise.

2) Apply 100% input and turn it slowly clockwise until the

output device (e.g. counter) operates.

■FREQUENCY RANGES

• Open Collector, 5V Pulse

SW No. SPAN RANGE

MIN. (50%) MAX. (100%)

0 0 – 5 kHz 0 – 10 kHz

1 0 – 2.5 kHz 0 – 5 kHz

2 0 – 1.25 kHz 0 – 2.5 kHz

3 0 – 625 Hz 0 – 1.25 kHz

4 0 – 312 Hz 0 – 625 Hz

5 0 – 156 Hz 0 – 312 Hz

6 0 – 78 Hz 0 – 156 Hz

7 0 – 39 Hz 0 – 78 Hz

8 0 – 20 Hz 0 – 39 Hz

9 0 – 10 Hz 0 – 20 Hz

A 0 – 5 Hz 0 – 10 Hz

B 0 – 2.5 Hz 0 – 5 Hz

C 0 – 1.25 Hz 0 – 2.5 Hz

D 0 – 36 pulses/min. 0 – 1.25 Hz

E 0 – 18 pulses/min. 0 – 36 pulses/min.

F 0 – 9 pulses/min. 0 – 18 pulses/min.

• Middle Range Frequency Open Collector & 5V Pulse

SW No. SPAN RANGE

MIN. (50%) MAX. (100%)

0 Not Used Not Used

1 Not Used Not Used

2 Not Used Not Used

3 Not Used Not Used

4 Not Used Not Used

5 0 – 156 Hz 0 – 312 Hz

6 0 – 78 Hz 0 – 156 Hz

7 0 – 39 Hz 0 – 78 Hz

8 0 – 20 Hz 0 – 39 Hz

9 0 – 10 Hz 0 – 20 Hz

A 0 – 5 Hz 0 – 10 Hz

B 0 – 2.5 Hz 0 – 5 Hz

C 0 – 1.25 Hz 0 – 2.5 Hz

D 0 – 36 pulses/min. 0 – 1.25 Hz

E 0 – 18 pulses/min. 0 – 36 pulses/min.

F 0 – 9 pulses/min. 0 – 18 pulses/min.

KAPU

EM-3582 Rev.11 P. 3 / 4

MG CO., LTD. www.mgco.jp

5-2-55 Minamitsumori, Nishinari-ku, Osaka 557-0063 JAPAN