MGM TMM V7 HBC Series User manual

HBC-series - page 1 / 72

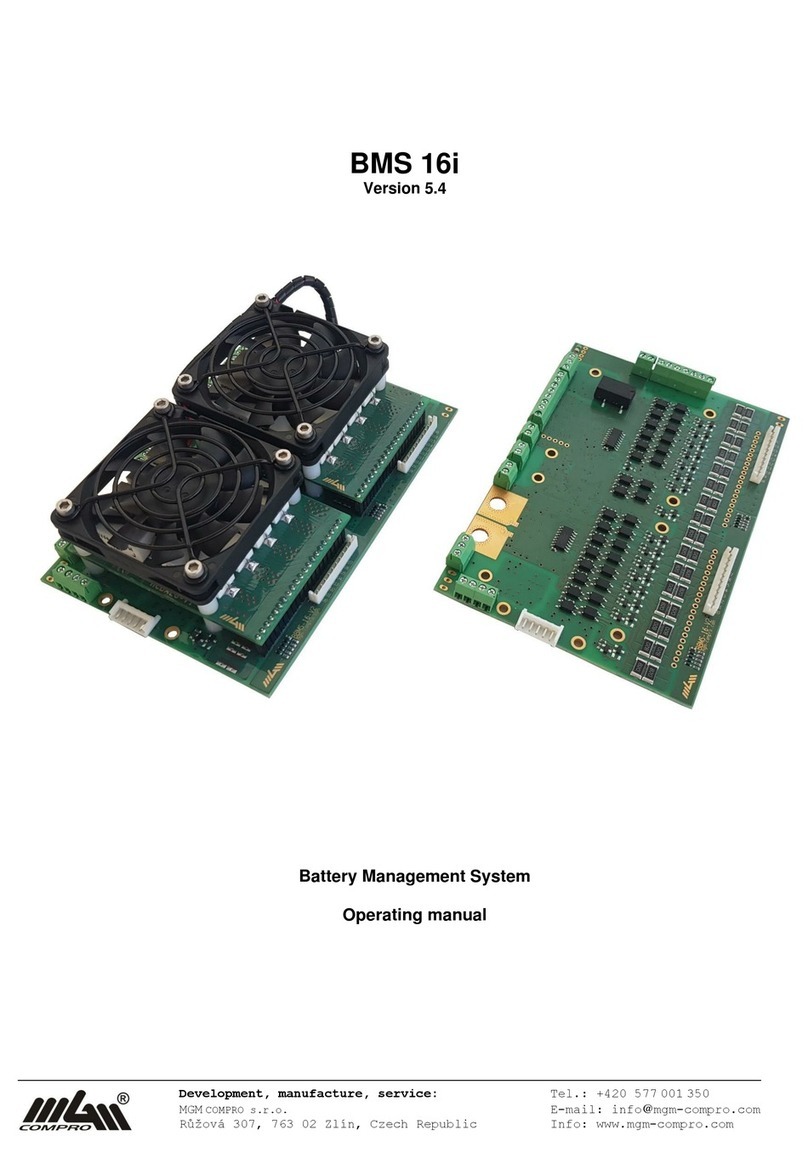

HBC - SERIES V7

18063-3 / 25063-3 / 100120-3 / 140120-3

Low Voltage (63V) + Medium Voltage (120V)

Programmable brushless controllers for industry using

Operating Manual –firmware version 3.8 or higher

Development, manufacture, service:Tel.: +420 577 001 350

MGM COMPRO, Ing. G. Dvorský E-mail: mgm@mgm-compro.cz

Sv. Čecha 593, 760 01 Zlín, Czech Republic Info: www.mgm-compro.com

2 / 72 HBC-series V7 LV+MV

Programmable brushless controllers for industry using

TMM®xxxxxx –3 HBC-series V7

These motor speed controllers provide very quality, smooth motor controls for electric cars, karts, bikes, scooters, boats,

aircrafts, gliders, UAV, paraglides etc.. Great application is located in many industrial drives for pumps, winches, robots,

production lines, ….

Possibility of safety disconnects the battery for running engine (Emergency STOP).

Controller uses the best available power MOSFETs or IGBT modules for higher voltage and synchronous PWM for achieve very high

efficiency.

They feature very advanced (state-of-the-art) algorithms of moor control as well as safety of operation. Controller concept is based on

a long experience with control of both sensorless and sensor BLDC (resp. PMSM) motors in very heavy and demanding operating

conditions. For driving are used very powerful 32-bit ARM microcontrollers.

To enable our customers to exploit the newest developments and satisfy new requirements, SW update of the PC programs as well

as the firmware update of the controller can be carried out by the customer himself/herself though the internet at any time. Thanks to

this are easily accessible customer-specific modifications and adjustments FW.

Basic Features:

Working range controllers Low Voltage: up to 63V, up to 250A continuous power up to 15 kW

Working range controllers Medium Voltage: up to 120V, up to 140A continuous power up to 15 kW

Working range controllers LV + MV: 16 63/500A or 16 120V/280A continuous power up to 33 kW (another manual)

Working range controllers High Voltage: 120 –400V, up to 300A continuous power up to 60 kW (another manual)

Small dimension and weight, many modification

Controlled by powerful 32-bit processor ARM Cortex

Very clear and easy parameters settings by PC with operating system Windows (XP, Vista, 7)

Firmware update via internet

Data transfer to PC (or other equipment) and displaying in real time (Monitoring)

Internal Data logging (BlackBox, record of voltage, rpm, currents, temperatures, …) record 12 minutes in length, with the external

extension of up to several weeks

Very clear indication of controller states and error codes using 4 LED

Synchronous rectification, very high efficiency 98 99%

Motor PWM in range 8 32 kHz

Suitable for inrunners as well as outrunners

Very high rpm limit 250.000 rpm for 2 poles motor (standard version)

Suitable for motors without pole limiting

Sensor motors as well as sensorless motors supported

Automatic settings and optimization of sensor position

Cruise Control function supported with external module CC1

Support regenerative braking and battery charging under braking

Support many working modes (PWM, constant rpm, constant torque / car mode, boat mode, plain mode)

Very smooth step of throttle 2048 values

Possibility to connect brake lights or flashing beacon, indication and outputs

Auxiliary switching DC/DC converter with output voltage 5V or 12V, currents up to 1A (only Low voltage types)

Electronic reversing

Monitoring all phases and bus

Configurable current limits forward / backward

HW support of the voltage, current and temperature fuses

Brake configurable in main control channel or in auxiliary control channel

Controlling by PWM, voltage, potentiometer, data (CAN, RS-485, RS-232 TTL), logic signal

Support BMS (Battery Management System MGM compro for Lithium batteries)

Support measuring (monitoring) of each battery cell

Unmatched protection and management of Lithium batteries

Conversion (recalculation) to internal battery voltage (independence of the processes of internal resistance and currents)

Support any type of the battery (NiCd, NiMH, A123, Lipol, Li-Ion, LiFePo4, Pb, …) or power supply

Support of safety disconnects the battery for running engine (Emergency STOP) for some type of the controllers

Support external display units (display current, rpm, voltage, temperature, energy (fuel meter), ….)

Monitoring controller temperature, motor temperature, battery temperature

Monitoring internal voltages and temperatures

Electronics feeding from traction voltage (available for Low voltage types up to 63V only) or from external supply 14 35V

Dropout of driving signal protection (cut-off potentiometer, etc.)

Current multiplication: take less current from battery, output more current to motor

Compact dimensions

Cooling by airflow, by fan or by water

Support of customer modification of firmware and HW

Support of customer configuration of HW

HBC-series V7 LV+MV profi low power

Table of content:

Table of content:........................................................................................................................................... 3

WARNING..................................................................................................................................................... 3

First steps ..................................................................................................................................................... 4

Basic Recommendations.............................................................................................................................. 4

Technical data (valid for 25°C environment temperature)............................................................................ 5

Switching DC/DC converter.......................................................................................................................... 5

Accessories and options, available combination of HBC controllers............................................................ 7

Available versions of HBC-series TMM xxxxx-3 V7 controllers and basic dimension................................. 8

Basic description of the controllers............................................................................................................. 12

Summary of possible inputs / outputs......................................................................................................... 13

Basic controller connection......................................................................................................................... 18

Emergency disconnection circuit / posibility of automatic traction connecting........................................... 19

Connecting controller to the traction supply and turning on ....................................................................... 22

Control signals specification ....................................................................................................................... 24

Control by data transfer / data communication........................................................................................... 25

Control and additional control by logic signals ........................................................................................... 28

Control signal –correct limits and emergency conditions .......................................................................... 29

Reverse data transfer from the controller, telemetry.................................................................................. 31

External display connecting........................................................................................................................ 32

Sensor motors and controllers.................................................................................................................... 33

Automatic sensor setting procedure........................................................................................................... 33

Optimal and allowed motor sensor position................................................................................................ 34

Basic operating modes - mode choice and basic type of behavior ............................................................ 35

Memory select............................................................................................................................................. 36

Programmable parameters......................................................................................................................... 37

Description of all parameters...................................................................................................................... 39

Parameters setting / Data reading from controller...................................................................................... 50

Locks of parameters ................................................................................................................................... 51

Internal Black Box (flying recorder) –data logger ...................................................................................... 53

Monitoring (display data in real time).......................................................................................................... 57

Throttle limits settings (range of joystick, range of control signals)............................................................ 58

Start with Automatic throttle limits............................................................................................................... 60

Start with programmed throttle limits.......................................................................................................... 61

Maximal revolution of the output shaft Settings.......................................................................................... 62

Maximal revolution of the motor Settings ................................................................................................... 62

Update SW inside the controller (firmware)................................................................................................ 63

Installation and run program Controller 2 ................................................................................................... 65

Update of program Controller 2 .................................................................................................................. 65

Controller states indication, Error messages (firmware 3.8x and higher)................................................ 66

Sparking prevent when connect higher voltage.......................................................................................... 67

Additional information ................................................................................................................................. 68

Some of Protective and Safety mechanisms of TMM®controllers............................................................. 69

Accessories................................................................................................................................................. 70

Content of delivery...................................................................................................................................... 72

Product Warranty........................................................................................................................................ 72

Service and Technical Support................................................................................................................... 72

Note:

Content…………….. all items are available quickly by CTRL+ left mouse button.

blue underlined ….. all like this marking texts in manual quickly jump, by CTRL+ left mouse button, to corresponding content

(cross reference).

In the Manual in „pdf“ format on these marking texts standard cursor changed to hand symbol ( ) . In this case only click to left

mouse button, (without CTRL), caused jump to corresponding content (cross reference).

(§NA) ……………….. parameters or features parking by this symbol are not available in this moment. As soon as will be available,

you can download and update new firmware for your controller –please watch information on our web.

In this manual are described general things about this line controllers. Exceptions for each type of model are described in separate

chapters or differences are highlights.

Separate chapters are devote to technical specifications and related things.

WARNING

With this device operated at higher voltages can be handled only

by persons knowledgeable - there is a danger of electric shock!

!

!

4 / 72 HBC-series V7 LV+MV

First steps

First, before you start run controller, we recommend read Basic Recommendations and make these steps:

solder (mounted) suitable connectors

select basic of driving type (car, boat, aircraft / PWM, constant rpm, constant torque).

This you make by program „Controller 2“

connect controller to motor and other parts

connect controller to driving (master) system, see more Basic controller connection

when you want use sensor motor, read first instruction here: Sensor motors and controllers

For first tests you can use controller with pre-defined average value of all parameters (type cells = Automat 78%) and Start with Automatic

throttle limits. Of course, optimal behaviors of the controller and your system you achieve only by correct (optimize) settings and tuning corre-

sponding parameters.

Parameter setting by program „Controller 2“ is very simple and intuitive and enable easy and transparent setting all controller features for op-

timal behavior. If you wish to enjoy all the possibilities of the controller, please refer to the whole manual.

When you set parameters, include throttle limits (= programed) or range of driving signal or driving voltage, you can start Start with pro-

gramed throttle limits.

Basic Recommendations

Shorten the cables between the battery and the controller as much as possible (however not under 5 cm, there is a possibility of un-

soldering wires from the controller) ! The higher the power and the "faster" the used motor, the more important is this requirement !

If you need to prolong the power conductors to batteries (distance between the controller and the batteries > 50 cm), it is neces-

sary to solder additional capacitor blocks (so more than capacitors used in the controller itself)!!! Additional capacitors must be the

same as used in controllers, i.e. „very low ESR“, 105°C.It is advantageous to use a block of capacitors 10X1G0.63 or 8X0G3.120, etc. Al-

so necessary used cables with correspond cross section !

Use only quality and well dimensioned connectors for connect battery to the controller ! Very suitable and very reliable connectors

are MP JET 5.0 –5.5 –6.0 mm, which are dimensioned for currents up to 200 –300A. MP JET connectors feature small transition re-

sistance, small dimensions and very firm connection (they do not come apart themselves as some other types do).

We recommend to put the socket on the “–“ wire (black wire) of the controller and the plug on the “+” wire (red wire). If you use for both

cables to the same connector (i.e. plug for example), the probability of polarity reversal (and thus destroy the controller) is very high.

Another good possibility is to use ring terminals and screwing to the controller.

!!! Warning, reversal of battery poles will reliably destroy the controller ! (The damage however, may not show immediately, but in some

later runs) !

If you use the connectors to the motor terminals, (marked „A“, „B“, „C“) apply to them the same criteria. If you choose the connectors,

on the controller side cables solder socket !

Insulate the connectors after soldering, e.g. using heat shrinking sleeve.

Never connect more cells (higher voltage) than is specified in technical data, you can damage controller.

We always recommend first connect the traction battery via the auxiliary connector with a serial resistor, see more „Sparking prevent when

connect higher voltage “

If you use for electronics feeding an external source (battery 14 up to 35V, etc.) must always be connected (turn-on) the battery first and is

disconnected (turn-off) last - see chapter „Connecting controller to the traction supply and turning on“.

Short circuit of motor wires together (when batteries are connected) or short cut of these wires to the feeding voltage (“+”or “–“

cables) results in damage or destroy of the controller !

Short circuit on the motor cables or feeding cables to any other wires (control signal, communication link, …) caused damaging of

the controller !

If the controller is powered by an AC adapter (mains power supply, not battery) should not even brake ! or off freewheel !!!

Freewheel must be set “without synchro”. If you need to brake when powered by an AC adaptermust be used the braking resis-

tors with appropriate management (control signal for braking resistors controlling provide controller yourself) !!! If you braking and the

controller is feeding from inverter, etc. without controlled braking resistors are very likely to destroy the controller !!!

Do not underestimate the quality of traction batteries, has a significant influence on the system behavior.

Do not SWITCH OFF controller or PLUG OFF BATTERY when motor RUN or when it is still turning –that may lead to damage or

destroy of the controller !!! This also applies to spontaneous disconnecting of the connector during operation, e.g. by vibra-

tions!!! This is why connectors should be chosen very carefully –see recommendation above.The only exception is a safety discon-

nection (Emergency disconnecting).

Be careful for using damaged motor or motor overloading, controller damaging is possible.

One controller can control only one motor.

It is necessary to cool the controller in operation with flowing air (or water for water coolers). Do not obstruct the access of cooling airflow

to the controller, e.g. by packing the controller in foam.

It is recommended to measure current drawn from battery with charged battery and full load (protection of the battery and controller).

Only clamp Ampermeters using is permitted (always for DC current, on the battery cables).

Never use Ampermeter inserted to the circuit (i.e. between battery and controller) –you can damage controller !

It is convenient to use measurements carried out by the controller during the drive and their display using PC. Please remember,

that even one additional cog on pinion of the motor significantly increase the drawn currents. With acceleration set faster, currents in the

start-up peak rise very fast, and that up to many times of the current in the steady state. It is necessary to do the measurement with the

hardest batteries, which you wish to use in the set. This will prevent possible problems with overloading the controller, motor and batteries.

Controllers designed for sensor motors can work also with sensorless motors –depend only on the correct parameter settings (motor type).

5 / 72 HBC-series V7 LV+MV

Technical data (valid for 25°C environment temperature)

Temperature of the environment: 0°C to 40°C Number of regulation steps: 2048 / full throttle range

Motor controlling: PWM: 8 up to 32 kHz Max. rpm for 2 poles motor: 250 000 rpm

Suitable for motors: without limits number of poles, motors of classical conception (rotor inside) and also for outrunners (rotor is on the outer

(sensors + sensorless) side), FreeAir, Hacker, Kontronik, Lehner, LRK, Mega, Model Motors, MP JET, MVVS, Neu, PJS, Plettenberg, etc.

Control signal: Positive pulses 1.5 0,8 ms, period 2.5 up to 30 ms / voltage 0 –3.3V / potentiometer / logic signal / data transfer

Feeding: from batteries: NiCd, NiMH, Li-Ion, Li-Pol, A123, acid (Pb) or others cells

from power supplies: in this case is not permit braking without braking resistors ! or switch-of freewheel !

Also is necessary set parameter P21 to „freewheel, no synchro“.

Weight is defined for basic modification, i.e ribbed heatsink + fans, WP, input voltage driving, without switch, without cables, srewed connectors

Low Voltage types:

HBC-series TMM®xxxxx-3 V 7.xx 18063-3 25063-3

Maximal continuous power: 11kW 15kW

Feeding voltage: 16 –63 V 16 –63 V

No. of feeding cells NiCd / NiMH: 20 –44 20 –44

No. of feeding cells Li-Ion / Li-Po:5 –15 5 –15

No. of feeding cells A123: 6 –17 6 –17

Max. continuous (nominal) current *):180 A 250 A

Max. short time current : **) 250 A 350 A

On-state FETs resistance for 25 °C (typ.): 2×0,8 m2×0,53 m

Basic dimensions [mm]: see picture see picture

Weight without power cables: 250 g 390 g

Power cables cross section: 6/6 or 10/10 mm2***) 10, 16 or 35 mm2

***) Note.: alternative also 16/16 mm2(to battery / to motor)

Medium Voltage types:

HBC-series TMM®xxxxx-3 V 7.xx 100120-3 140120-3

Maximal continuous power: 12 kW 16 kW

Feeding voltage: 16 –120 V 16 –120 V

No. of feeding cells NiCd / NiMH: 20 –83 20 –83

No. of feeding cells Li-Ion / Li-Po:5 –28 5 –28

No. of feeding cells A123: 6 –33 6 –33

Max. continuous (nominal) current *):100 A 140 A

Max. short time current: **) 140 A 200 A

On-state FETs resistance for 25 °C (typ.): 2×2,6 m2×1,75 m

Basic dimensions [mm]: see picture see picture

Weight without power cables: 250 g 390 g

Power cables cross section: 6/6 or 10/10 mm2 10 or 16 mm2

The appearance and the technical data may be changed without prior notice

Note: Higher power types HBC 50063-3 and HBC 280120-3 are described in separate manual.

Marking and Specification of the controllers HBC 18063-3, 25063-3, 100120-3 and 140120-3

TMM_AAAVVV-3 V7 HBC-series / specification of possibilities for ordering (ports, communication, connectors, …..)

Meaning of the specifications:

AAA –nominal current in Amperes

VVV –max. feeding voltage in Volts

Sample: TMM 50063-3-E V7 HBC

AAA = 140 max. continuous current 140A (nominal)

VVV = 120 max. feeding (traction) voltage 120V=

Switching DC/DC converter

Controllers can be supplied with an internal switching DC / DC converter for supply of related circuits or systems (eg, external display, etc.).

The voltage of this converter can be either +5 V or +12 V, max continuous current 1A, to 3A in pulses.

6 / 72 HBC-series V7 LV+MV

Currents specification

*) Maximal continuous current:

Maximal continuous current, without any time limits, is defined as current with full switching (100% motor PWM) with environment

temperature 25°C and with corresponding cooling (air flow, fan or water cooling).

Another important criterion is the phase currents in the full switch. Requested are practically identical (as relates to the current val-

ue) as the current from the battery. If the phase current is significantly higher than the current from the battery (engine overloaded,

poorly designed engine, etc.), the maximum continuous current be proportionally lower !!!

**) Maximal short time current:

Controller tolerates for a short period increased current The time during which the regulator can deliver this current depends on the

intensity of cooling. Adjustable current limit (parameter P19) is calculated from this current.

Recommendations: In case the controller is use with currents higher than ca 50% of the maximal values, we recommend intensive

cooling by air flow or use active cooling using fans or water cooling. This will not only prevent possible overheating

of the controller, but you will also gain higher efficiency of the drive unit (colder controller has lower losses than

warm one).

Technical specification of the inputs, outputs and other ports

Value Controller version: 18063-3 / 100120-3connector 25063-3 / 140120-3connector

Auxiliary feeding for control electronics: =14V 35V K1 =14V 35V K8/2, 3

Supported types of thermal sensors: thermistor NTC 10kΩ / Si diode / KTY 81-210 / KTY 84-151

Emergency disconnecting - Activation: -- +12V / 3mA K20/1

Safety traction ON / OFF: -- +12V / 3mA K3/1

Antispark relay control (open collector):-- max. 16V / 2A K3/3

Main contactor control (open collector):-- max. 16V / 4A K20/3

Control A - Voltage: 0 +3,3V (+5V, +10V) K2a 0 +3,3V (+5V, +10V) K2a

Potentiometer: 1kΩ ÷ 10 kΩ 1kΩ ÷ 10 kΩ

PWM 1/ log. signal (amplified):pulses +3V (+5V) / 0,1mA pulses +3V (+5V) / 0,1mA

PWM 1/ log. signal (only optocoupler):pulses +5 +12V / 3mA pulses +5 +12V / 3mA

Control B - Voltage: 0 až +3,3V (+5V, +10V) K2b 0 až +3,3V (+5V, +10V) K2b

Potentiometer: 1kΩ ÷10 kΩ 1kΩ ÷110 kΩ

PWM 2/ log. signal (amplified):pulses +3V (+5V) / 0,1mA pulses +3V (+5V) / 0,1mA

RS 232 TTL: +5V / 3mA K4 +5V / 3mA K15

CAN / RS 485: standard levels K3 standard levels K16

ICS-2: BL-1 0 / +3,3V K5 0 / +3,3V K18, K17

I2C bus: standard levels standard levels

Output +3,3V / +5V: max. 30mA max. 30mA

Fans driving (open collector):12V / 0,5A K6 12V / 0,5A K11

Braking resistors switch control: -- +12V / 10mA K21

Sensors - inputs: 0 +5V (+12V) K7 0 +5V (+12V) K13

Sensors feeding: 5V (12V) / 30mA K7 5V (12V) / 30mA K13

Note: on the request are possible realized inputs, outputs and insulate auxiliary feeding make for 24V.

time

Nominal (max. continuous) current

Starting current peak

Max. short time current

cca 140%

of nominal current

Up to 280% of nominal current

(depend on temperature, etc.)

100%

140%

~280%

7 / 72 HBC-series V7 LV+MV

Accessories and options, available combination of HBC controllers

Controllers have in basic version only basic equipment. Features and options can significantly affect by the controller additional

equipment specifications.

Equipment of the controllers in the basic version:

- potentiometer input control (voltage control, 0 up to +3.3V)

- supply the control electronics from external source (battery) +14V up to +35V)

- ICS-2 connector for setting parameters, reading data from the controller, monitoring, update firmware, connection of external modules

- air cooler

- power cables soldered to the motherboard power, length 20 cm, cross section according to parameter table

- closed design

- screw-type connectors

Accessories and options:

For concrete hardware specification (or a custom firmware) and for order a specific configuration of the controllers, please

use the "HBC_ordering_form.xls". Not all combinations are available simultaneously. For questions or inquiries, please con-

tact directly the MGM compro.

Controller type you can specify in the order according to your specific requirements

Switch: all controllers may be ordered with a switch (in a safe design - its damage or destroy does not affect the safety of flight

and the model / motor don´t stop working when switch component damaged

Heat sinks (coolers): outer ribbed heat sinks (coolers) are delivered in standard basic version

Fans: In case of insufficient cooling air flow can be ordered fans mounted to cooler - Active cooling (it is supplied as stand-

ard). Fans can also be ordered separately as a complete kit with screws, which can add the controller addi-

tionally - use different types of fans and bolts is not allowed !!!

Water cooling: version with water coolers is available for use in boats or in systems with higher demands for cooling intensity.

Capacitors axially: controllers 18063, 25063, 100120, 140120 can be ordered with a capacitor mounted axially - It is especially important

for models without a fan or water-cooled types.

Hydro version WP: water and humidity does not get on well with electronics. For significant increase of durability of the controller against

humidity and water, it is optionally possible to apply specialty protective cover (marked as WP). This however does

not mean that the controller with this protection is 100% durable during humidity and water and that it is not necessary

to protect it against these negative effects. The protection does not apply to salt water at all !

Hydro version WR: If you need high protection against water, moisture and dust, you can use controllers with WR modification. It is a

thick layer of special material on the PCB, more expensive solutions. The protection does not apply to salt water at

all!

Sensor motors: all types of controllers may be ordered suitable for sensor motors. These controllers may be connected to sensorless

motors as well as sensor motors. In this version is automatically available to the motor temperature measurement.

Battery temperature: controllers have add measuring of battery temperature

Each cell monitoring: all controllers have the option to measure each battery cell with an additional module BMM-16.

25063 controllers have the option of each battery cell to measure directly, without the module BMM-16.

Emergency disconnecting: controllers 25063, 140120, can be ordered with a safety disconnection. Can be combined with the

Auto-connect circuits for traction.

Automatic traction connection: controllers 25063, 140120, can be ordered with automatic traction connecting including antispark

access control circuit. This can be combined with a safety shutdown.

Control of braking resistors: All types can be ordered with a connector and power management circuits for braking resistor switch.

Communication: All types can be ordered with a communication interface RS 232 TTL, RS 485 or CAN. Communication lines can be

galvanic isolated.

Telemetry: All types can be ordered with options to connect Tx / Rx modules for telemetry (per channel RS-232 TTL).

Second ICS-2 connector: controllers 25063, 140120, can be ordered with the second ICS-2 connector for easy connection of external modules.

Type of controls: All types can be ordered with a control by voltage, PWM, potentiometer, data, logic and signal combinations. You can

also order two control channels (e.g. for a separate function brake / throttle).

Type of power connecting: controllers 18063, 25063, 100120, 14012 can be ordered with either a power-soldered wires or soldered MPJET 5.0

connectors on the PCB or screw eyes for wire insertion. Wires can be soldered to the board either vertically or axially

(parallel to the plate). Next possibility is using ring terminals with corresponding cable.

Connectors types: controllers 25063, 140120, can be ordered with different types of connectors on the control board.

The long data record: if necessary, the record can be extended with external module LBB_RT with micro SD card on the length of the order

of months. The module is also available in a version with real time. (§NA)

Cruise Control connection: for all types is available external module CCM1, with which the cruise control function is provided.

Auxiliary DC/DC converter: LV types (controllers up to 63V) can be ordered with an internal DC / DC converter supplying the auxiliary

+5 V or +12 V / 1 A

External display connecting: for all types is available an external display module can be connected either via CAN (preferred) or via the Rx / Tx

port.

External modules connecting: for all types of controllers can be connected external modules to an connector ICS-2

Customer changes: if you need non-standard features or behavior of the controller, it is possible to agree on a customer change - please

contact the MGM compro.

8 / 72 HBC-series V7 LV+MV

Available versions of HBC-series TMM xxxxx-3 V7 controllers and basic dimension

Height profile HBC 18063, 100120 i 25063, 140120 is the same

*) dimensions without Finger Guards; 5 mm with Finger Guards of the fan

HBC-series TMM 18063 V7, TMM 100120 V7,

with a fan, enclosed version, view from the

side with a fan (default dimensions)

**) for enclosed version this dimension 23 mm + 1.5 mm

(height of head of M3 screw)

HBC-series TMM 18063 V7, TMM 100120 V7, without fan, open version,

view from the side of the control board, filter capacitors axially:

(default dimensions)

9 / 72 HBC-series V7 LV+MV

Mounting:

Mounting of controllers is possible using either the 4 mounting holes in the corner of the main PCB or "on the edge" using two M3

screws in the cooler (red arrows) from both sides (M3 screws are needed).

If you use the holes in the main PCB, use spacer plate from non-conducting material (polyamide, xxxx etc). Choose the M3 screw head

such that it is not in contact with the surrounding copper areas on the board (that is up to Ø 6mm) or use an insulating pad.

If you use holes in the cooler, it does not matter which material is used as the coolers are insulated, they are not connected to any po-

tential.

If the system in which the controller is mounted vibrates, fasten it using suitable silent blocks.

HBC-series TMM 18063 V7, TMM 100120 V7,

side view on cooler without fan

(default dimensions)

HBC-series TMM 25063 V7, TMM 140120 V7,

view from side of cooler with fans

(default dimensions)

96 mm

63 mm

17.15

73.15

3.05

56.90

4 × mounting hole 3.5 mm

for M3 screws

60

40

100 mm

100 mm

3.94

92.20

92.96

3.56

4 × mounting hole 3.5 mm

for M3 screws

63

40

4 × mounting hole with M3 thread

4 × mounting hole with M3 thread

10 / 72 HBC-series V7 LV+MV

Basic types and modifications:

Power cables may also be connected to the motor and battery

using Ring Terminals 6/10, 6/16, 6/25 or 6/35 and M5 screws.

HBC 18063 V7 (HBC 100120) view from the

cooler side, with fan, "enclosed" version, power

conductors are soldered directly to the hole of the

power board (instead of MP JET 5.0 connectors)

connectors MP JET 5.0

HBC 18063 (HBC 100120) view from the cooler

side, without fan, "enclosed” version, power

conductors through MP JET 5.0 connectors

HBC 25063 V7 (HBC 140120) view from side of

cooler, with fans, "open" version”, power connectors

MP JET 5.0

HBC 25063 V7 (HBC 140120) from view of the con-

trol board, "open" version, power conductors are sol-

dered directly to the holes in the power board (instead

of MP JET 5.0 connectors)

HBC 18063 V7 (HBC 100120) view from the con-

trol board side, "enclosed" version, power conduc-

tors soldered directly to the holes in the power

board (instead of MP JET 5.0 connectors)

11 / 72 HBC-series V7 LV+MV

Water cooling for HBC 25063 and 18063 (140120 and 100120):

HBC 25063, 140120 V7 view from the water cooler side,

Power cables is mounted with ring terminals 6/35

(for cables 35mm2), filtering capacitors axially

HBC 25063, 140120 V7 view from the water cooler

side, power cables is mounted with ring terminals 6/16

(for cables 16mm2), filtering capacitors radially

HBC 18063, HBC 100120 V7 view from the

water cooler side, Power cables soldered 16 /

10 mm2, filtering capacitors radially

12 / 72 HBC-series V7 LV+MV

Basic description of the controllers

Controller HBC-series TMM 25063 V7 / 140120 V7: (view from the uncovered control board)

+BATT.

–BATT.

Phase A

Phase C

Phase B

+Antispark

Control board

Power board PWR-250A

4x mounting hole Ø3.5 mm

13 / 72 HBC-series V7 LV+MV

K18

K17

Indication of the

condition, 4× LED

K5

K4

K11

FAN +12V

FAN –

Fans

Mot. Temp.

GND

+5V / +10V

SENS_C

SENS_B

SENS_A

1

Motor

sensors

K13

EFRA compatible

+5V OUT

Mot. Temp.

SENS_C

SENS_B

SENS_A

K14B

Motor

sensors

1

K15

K16

J1

K12

1

Driving of the FET

GND

Braking

resistors

1

GND

AUX_4

AUX_3

K7

Auxiliary

inputs

SWITCH

GND

Switch

1

+12V OUT

PWR GND

Feeding of

ext. driver **)

1

1

+12V INP

PWR GND

+12V OUT

Auxiliary

feeding

ICS-2A

BL-1

SDA

SCL

+3.3V OUT

GND

+5V / TST

1

ICS-2B

1

+5V / TST

GND

+3.3V OUT

SCL

SDA

BL-1

Lipol cells

(Service

connectors)

GND

BAT. TEMP

1

Temperature

sensor of the

battery

CAN / RS 485

IN-OUT

INP_3 / Bline / CAN_H

GND

OUT_3 / Aline / CAN_L

1

1

RS 232 /

IN-OUT

-OPT / GND

OUT_4 / TX

-OPT / +5V EXT

DIR / INP_4 / RX

1

+10V

SENSE +

GND

Current

sensor 1

1

GND

INP_2

+3.3V output *)

DC/DC GND

DC/DC +3.3V

INP_1

Control B

Control A

1

1

-OPT_OUT / GND

PWROFF_OUT

-OPT_INP

PWROFF_INP

Emergency

disconnection

K3

K2B

K2A

Mot. Temp.

GND

SENS_C

SENS_B

SENS_A

+5V / +10V

K14A

Motor

sensors

Alternative connectors

1

K19

K20

K21

K10

K9

K8

1

IN-OUT_2

GND

IN-OUT_1

General

inputs /

outputs

Control of ex-

ternal drivers

FET / IGBT **)

Jumper or soldered

jumper

J1

SBC compatible

1

K6

GND

Jumper J1: connection of terminating imped-

ance of a CAN / RS 485 bus

(jumper or soldered jumper)

1

Cell 1 –

Cell 1 +

Cell 7 +

Cell 8 +

Cell 15 +

…………

K5

K4

1

GND

BAT. TEMP

…………

Cell 17 +

Cell 16 +

Battery service connector connection details:

Battery Tempera-

ture sensor

Battery

cells

Battery

cells

Marking

„CN-B15“

Summary of possible inputs / outputs

Controller connection (control board CN-B15):

(all possibilities and combinations)

*) only for potentiometer feeding

**) use only for connection with external power boards, e.g. controller HBC 40063 etc.

Notice 2: Connectors not needed for a particular specification (from customer) are not assembled

Notice 3: For details on possible versions of control including possibilities on input and output

connections see „Details of control of HBC xxxx V7 controllers“

Notice 4: connectors K2, K3, K6 –K11 and K13 –K21 can be screwed types (on picture), or types

For K4, K5 and K12 connectors are not available alternative types.

Phoenix Contact

pitch 3.5 mm

14 / 72 HBC-series V7 LV+MV

Connector description of driving board CN-B15:

Switch K10: switch is connected in a safety manner (turned on = switch is disconnected)

Connector K2A (primary control inputs):

Pin 1: +DC/DC converter output voltage of the or input +5V for isolated PWM 1 or output +3.3V (potentiometer 2 feed)

Pin 2: INP_1 control input digital, PWM 1, (also possible isolated) or Analog potentiometer 2, driving voltage 2

Pin 3: DC/DC converter GND (power ground for DC/DC converter system) or isolated ground for optically isolated driving PWM 1

Connector K2B (primary control input):

Pin 1: +3.3V output (supply of potentiometer 1)

Pin 2: INP_2 control input Analog, potentiometer 1, driving voltage 1 or input digital or PWM 2

Pin 3: GND signal ground

Connector K3 (general inputs / output):

Pin 1: IN-OUT-2, input / output open collector, 24V / 100mA (1A) / resp. output TTL (3.3V)

Pin 2: GND

Pin 3: IN-OUT-1, input / output open collector, 24V / 100mA (1A) / resp. output TTL (3.3V)

Connector K4, K5: Service connector for Lipol cells

K5: K4:

Pin 1: battery temperature sensor + ● Pin 1: cell 8, + pole

Pin 2: battery temperature sensor GND ●Pin 2: cell 9, + pole

Pin 3: cell 1, minus pole ●Pin 3: cell 10, + pole

Pin 4: cell 1, + pole ●Pin 4: cell 11, + pole

Pin 5: cell 2, + pole ●Pin 5: cell 12, + pole

Pin 6: cell 3, + pole ●Pin 6: cell 13, + pole

Pin 7: cell 4, + pole ●Pin 7: cell 14, + pole

Pin 8: cell 5, + pole ●Pin 8: cell 15, + pole

Pin 9: cell 6, + pole ●Pin 9: cell 16, + pole

Pin 10: cell 7, + pole ●Pin 10: cell 17, + pole

Connector K6: Temperature sensor for Lipol cells (KTY 81-210) –only when isn´t integrated to K5

Pin 1: battery temperature sensor GND

Pin 2: battery temperature sensor +

Connector K7 (auxiliary analog inputs)

Pin 1: GND

Pin 2: AUX_4 (slow analog)

Pin 3: AUX_3 (slow analog)

Connector K8 (input for auxiliary supply):

Pin 1: output voltafge +12V

Pin 2: PWR GND (power ground)

Pin 3: auxiliary feeding for electronics +14V up to +35V

(only if no used traction voltage for supply electronics - but this is only possible for models up to 63V)

Connector K9 (output for supply of external FET / IGBT drivers)

Pin 1: PWR GND (power ground)

Pin 2: output +12V

Connector K11 (cooling fans 12V)

Pin 1: –fan 12V

Pin 2: + fan 12V

Connector K12 (connection of external FET / IGBT drivers):

Only for controllers with a different (external) power board (as HBC 300400-3 etc.) - this connector is not defiantly assembled !

Connector K13 (motor sensors): Either for classic sensors or an encoder

Pin 1: SENS_A

Pin 2: SENS_B

Pin 3: SENS_C

Pin 4: sensor feeding +5V resp. +10V

Pin 5: GND

Pin 6: Temperature sensor of motor (KTY 81-210, termistor NTC 10 kΩ, …)

Connector K14A (sensors): Alternative connector for connection of motor sensors, compatible with SBC / HSBC controller range

Connector K14B (sensors): Alternative connector for connection of motor sensors, compatible with EFRA recommendations

15 / 72 HBC-series V7 LV+MV

Connector K15 (auxiliary driving / communication port): RS 232 TTL can be also optically coupled

Pin 1: RX / rotation direction / INP_4 (or +optocoupler input)

Pin 2: GND

Pin 3: TX / OUT_4 (or +optocoupler output)

Pin 4: +5V external feed, if inner feeding is not used., common also for K16 (or “– optocoupler output”)

Connector K16 (CAN or RS 485 bus / general I/O ): CAN / RS 485 can be also optically coupled

Pin 1: CAN_L / line B for RS 485 / OUT_3

Pin 2: CAN_H / line A for RS 485 / INP_3

Pin 3: GND

Connector K17, K18 (ICS-2): communication with PC (module USBCOM 4), outer I2C bus, indication, ….

K17 K18

Pin 1: output +5V ●Pin 1: BL-1 signal

Pin 2: GND ●Pin 2: SDA

Pin 3: output +3.3V ●Pin 3: SCL

Pin 4: SCL ●Pin 4: output +3.3V

Pin 5: SDA ●Pin 5: GND

Pin 6: BL-1 signal ●Pin 6: output +5V

Connector K19 (current probe) –only for external FET / IGBT modules:

Pin 1: GND

Pin 2: SENSE +, input from current probe HALL 400 B / 600B (or compatible type)

Pin 3: +10V output, feeding for current probe HALL 400 B / 600B

Connector K20 (emergency disconnection):

Pin 1: PWROFF_INP, input of signal “disconnect battery” (or +optocoupler input)

Pin 2: -OPT_INP (–optocoupler input)

Pin 3: PWROFF_OUT, output „switch-off“ (or +optocoupler output)

Pin 4: GND / -OPT_OUT (–optocoupler output )

Connector K21 (braking resistors driving):

Pin 1: driving output for switching component (MOSFET) which switch-on braking resistors, value +3.3V or +10V

Pin 2: GND

Jumper J1: connection of terminating impedance of CAN or RS 485 bus.

(coupler or soldered jumper)

Closed pins = termination impedance for CAN or RS 485 connected

Open pins = termination impedance for CAN or RS 485 disconnected

16 / 72 HBC-series V7 LV+MV

Connection of the controller (control board DN-B15):

( applies to all variants and combinations)

Jumper J1: connection of terminating impedance of CAN bus or RS 485

(coupler or soldered jumper)

Notice 7: Connectors not needed for a particular specification (from customer) are not assembled

Notice 8: all connectors (or specified only) can be changed to 2.54 mm pin headers, by customer request

Notice 9: For details on possible versions of control including possibilities on input and output connections

see „Details of control of HBC xxxx V7 controllers“

*) only for potentiometer feeding

Controller HBC 18063 V7: (view from uncovered control)

+BATT.

–BATT.

Phase A

Phase C

Phase B

+Antispark

Control board DN-A5

Power board PWR-180A

4x mounting hole Ø3.5 mm

SWITCH GND

K1

1

1

1

1

1

1

Alternative connectors

K4

K3

K2B

K7A

K6

K5A

SWITCH

+12V INP

PWR GND

GND

TEMP BAT.

GND

INP_2 / OUT_2

+3.3V output *)

DC/DC GND

DC/DC +3.3V

INP_1

CAN_H / A / OUT_3

COM GND

CAN_L / B / INP_3

Minus / GND

TX / OUT_4

RX / INP_4

+5V EXT / EO

Indication of

conditions 4× LED

Alternative connector

1

+5V / BEC

GND

+3.3V OUT

SCL

SDA

TEMPO

FAN 12V +

FAN 12V –

CS-1

MOSI

MISO

SCK

TEMP MOT

GND

SENS_C

SENS_B

SENS_A

+5V / +10V

K5B

ICS-2B

Motor

sensors

SPI /

indication

fan

Auxiliary

feeding

switch

GND

AUX_4

AUX_3

Auxiliary

inputs

Jumper of terminating

impedance for CAN

and RS 485

J1

K8

1

+5V / BEC

TST

GND

+3.3V OUT

SCL

SDA

TEMPO

ICS-2A

1

SBCcompatible

TEMP MOT

GND

SENS_C

SENS_B

SENS_A

+5V / +10V

Motor

sensors

K7B

1

K7C

Temperature

sensor of the

baterry

control B

control A

Marking DN-B15“

K2A

4

EFRA compatible

+5V OUT

TEMP MOT

SENS_C

SENS_B

SENS_A

GND

Motor

sensors

1

CAN /

RS 485

IN-OUT

RS 232

IN-OUT

17 / 72 HBC-series V7 LV+MV

Connector description of driving board DN-B15:

Connector K1 (linked, associated):

Pin 1: SWITCH - connected in a safe way (turned on = switch is disconnected)

Pin 2: SWITCH - connected in a safe way (turned on = switch is disconnected)

Pin 3: auxiliary supply of +14V up to +35V, can be used when it is not possible to use the main (traction) supply for feeding the in-

ner circuits

Pin 4: PWR GND (power ground)

Pin 5: GND

Pin 6: Temperature sensor for Lipol cells (KTY 81-210) / or can be used as a generic analog input

Connector K2A (primary control input):

Pin 1: DC/DC converter GND (power ground for DC/DC converter system) or isolated ground for optically isolated driving PWM 1

Pin 2: INP_1 control input digital, PWM 1, (also possible isolated) or Analog potentiometer 2, driving voltage 2

Pin 3: + DC/DC converter output voltage of the or input +5V for isolated PWM 1 or output +3.3V (potentiometer 2 feed)

Connector K2B (primary control input):

Pin 4: GND signal ground

Pin 5: INP_2 control input Analog, potentiometer 1, driving voltage 1 or input digital or PWM 2

Pin 6: +3.3V output (supply of potentiometer 1)

Connector K3 (communication port CAN or RS 485 / general I/O): CAN / RS 485, can be isolated also

Pin 1: GND for communication port can be isolated

Pin 2: CAN_H or line A of RS 485 bus or output OUT_3 (logical, not power output)

Pin 3: CAN_L or line B of RS 485 bus or input INP_3 (logical)

Connector K4 (communication port / general I/O): RS232 TTL, can be also optically coupled

Pin 1: RX or input INP_4 (logical, or optocoupler input)

Pin 2: GND or minus pole of optocoupler input

Pin 3: TX or output OUT_4 (logical, or optocoupler output)

Pin 4: +5V external feed of COM ports, if inner feeding is not used (internal feeding for com port also can be isolated)

Connector K5A or K5B (ICS-2): communication with PC (module USBCOM 3x), outer I2C bus, indication, ….

(assembled is only one or the other)

Pin 1: BL-1 signal

Pin 2: SDA

Pin 3: SCL

Pin 4: output +3.3V

Pin 5: GND

Pin 6: output +5V

Connector K6 (cooling fan 12V and SPI):

(SPI port is available on if indication by LED is not used)

Pin 1: –fan 12V

Pin 2: + fan 12V

Pin 3: CS-1

Pin 4: MOSI

Pin 5: MISO

Pin 6: SCK

Connector K7A, K7B, K7C (motor sensors): Either for classic sensors or an encoder.

K7A, K7B K7C

Pin 1: SENS_A ● Pin 1: GND

Pin 2: SENS_B ● Pin 2: SENS_C

Pin 3: SENS_C ● Pin 3: SENS_B

Pin 4: sensor feeding +5V resp. +10V ● Pin 4: SENS_A

Pin 5: GND ● Pin 5: Temperature sensor of motor KTY 81-210

Pin 6: Temperature sensor of motor KTY 81-210 ● Pin 6: sensor feeding +5V resp. +10V

Connector K8 (auxiliary inputs):

(available only if BEC is not in the controller)

Pin 1: GND

Pin 2: AUX_4 auxiliary measuring input, e.g. for connection of altimeter etc.

Pin 3: AUX_3 auxiliary measuring input

Jumper J1: connection of terminating impedance of CAN or RS 485 bus.

(coupler or soldered jumper)

Closed pins = termination impedance for CAN or RS 485 connected

Open pins = termination impedance for CAN or RS 485 disconnected

18 / 72 HBC-series V7 LV+MV

Basic controller connection

Note 1: Both inputs INP_1 and INP_2 can be the same, both should be controlled by voltage or potentiometer, both can be

controlledby input PWM, etc.

Switching

element

FET driver

Power

connectors

Traction battery

(supply)

Power

connectors

or direct motor connection to the

controller (without power connectors)

GND

Sensor C

Sensor B

Sensor A

Connector for motor sensors

INP_1

GND

1 kΩ

GND

+3.3V

(GND)

Signal

source

-----------

Control

system

Potentiometer

or control voltage

control voltage

Input control PWM

(+5V)

GND

INP_2

Braking resistors

driving

Braking resistors

Auxiliary control

logic signals

Auxiliary output

signals

ICS-2 connector

GND

GND

(+5V)

(+5V)

+3.3V

SCL

SDA

BL_1 (Driving of the braking lights, indication, etc.)

ICS-2

I2C link,

communication with external modules,

communication with PC (USBCOM 4),

parameters settings, update firmware,..

feeding of ext. modules

Note 2: Not every type of controller has all the inputs,

outputs, and options

Note 3: Some inputs, outputs can be galvanic isolated

(as input PWM, CAN, RS-485, etc.)

GND

1 kΩ

GND

+3.3V

Potentiometer

or control voltage

control

voltage

INP_2

GND

1 kΩ

GND

+3.3V

Potentiometer

or control voltage

control

voltage

INP_1

Auxiliary battery

for feeding electronics

Control system

display, BMS, …

Data (controlling)

communication

(GND)

(+5V)

RS 485

CAN

GND

RS 485

CAN

Communication _2

Control system

display, ….

Data (controlling)

communication

(GND)

RS 232 TTL

GND

RS 232 TTL

Communication _1

TxD

RxD

TxD

RxD

Motor temperature

Sensors feeding

+14V 35V

Electronics feeding

GND

GND

switch V1

BATT

(GND)

A

B

C

Controller HBC- series

Power board

- motor driving

Control board

*)

*) controllers up to 63V (LV types) can be used traction voltage to feeding of the electronics - must be specified in the order

BLDC motor

with or without

sensors

+5V or +10V

19 / 72 HBC-series V7 LV+MV

Emergency disconnection circuit / posibility of automatic traction connecting

(this function is available only for controllers with driving board CN-B15, i.e. for HBC 25063-3, 140120-3)

Condition for applying is feeding of the control board by external voltage +14 V that is present even after disconnect-

ing the traction battery.

If your application requires the ability to disconnect the traction battery during operation (i.e. the engine is running) by security but-

ton, shock sensor, etc., you must use this connection. This function can also be activated in the setting of parameters (parameter P58).

The system also provides automatic connection sequence to traction voltage (switching relays and contactors then after turning the

switch CON), parameter P92. This feature can be used independently of the emergency disconnecting. This function is suitable if you

need to automatically control the inputs and antispark to traction and is not used BMS to ensure these functions.

Recommend connecting for HBC 25063 (140120):

*) The possibility of emergency disconnectio with using

BMS-2 system (output PO 1 of the BMS-2 unit).

In this case, it is necessary to cancel the jumper

K20/2 to K20/4.

To indicate turn-on the main power contactor

(= traction power supply connection) can be used

either bulb 12V / or 1 to 5W LED with

corresponding serial resistor.

Power

connectors

GND

Sensor C

Sensor B

Sensor A

Motor temperature

Sensors feeding

+14V 35V

Control electronics

feeding

GND

Traction battery

+

PSW1

Auxiliary battery

for electronics feeding

Fuse

relay

Emergency

button ED

PWROFF_INP

K20/1

K20/2

-OPT_INP

K3/3

K20/3

K8/2

K8/3

Indication

K20/4

GND

Service cable A

K4, K5

Service cable B

to „charging part“

of BMS

18 wires

Service

connector

for battery

OUT_1

PWROFF_OUT

Control board

CN_B15

5A

300 -1000A by

controller and load

Controller 25063 - HBC- series

BATT

phase A

Power board

- Motor driving

phase C

phase B

+Antispark

BATT

Internal

switch

GND

switch V1

K10/1

K10/2

K2a/3

K2a/2

INP_1

Safety Traction

connect / disconnect

(turn-on electronics)

*)

Internal switch

=

Internal

switch

BMS-2 MASTER

version 3.3 or higher

3

(GND)

2

Connector

„B“

PO 1

to K20/2

Internal

switch

contactor

switch CON

20 / 72 HBC-series V7 LV+MV

When is used additional capacitors for HBC 25063-3 (140120-3) controller, necessary using this connecting with

external antispark resistor.

*) The possibility of emergency disconnecting by using

BMS-2 system (output PO 1 of the BMS-2 unit).

In this case, it is necessary to cancel the jumper

K20/2 to K20/4.

To indicate turn-on the main power contactor

(= traction power supply connection) can be used

either bulb 12V / or 1 to 5W LED with

corresponding serial resistor.

(turn-on electronics)

Power

connectors

GND

Sensor C

Sensor B

Sensor A

Motor temperature

Sensors feeding

+14V 35V

Control electronics

feeding

GND

Traction battery

+

PSW1

Auxiliary battery

for electronics feeding

Fuse

relay

Emergency

button ED

PWROFF_INP

K20/1

K20/2

-OPT_INP

K3/3

K20/3

K8/2

K8/3

Indication

K20/4

GND

Service cable l A

K4, K5

Service cable B

to „charging part“

of BMS

18 wires

Service

connector

for battery

OUT_1

PWROFF_OUT

Control board

CN_B15

5A

300 -1000A by

controller and load

Controller 40063 - HBC- series

BATT

phase A

Power board

- Motor driving

phase C

phase B

+Antispark

BATT

GND

switch V1

K10/1

K10/2

Safety Traction

connect / disconnect

*)

External Antispark resistor

50Ω

Internal

switch

Internal

switch

(GND)

PO 1

Internal

switch

BMS-2 MASTER

version 3.3 or higher

3

2

Connector

„B“

to K20/2

contactor

K2a/3

K2a/2

INP_1

switch CON

This manual suits for next models

4

Table of contents

Other MGM Control System manuals

Popular Control System manuals by other brands

Rockwell Automation

Rockwell Automation MSR300 instruction manual

cinetto

cinetto Piano B-Moved Assembly instructions

MachMotion

MachMotion 2000 Series General installation manual

GO Systemelektronik

GO Systemelektronik BlueBox T4 manual

Ariston

Ariston Chafforeaux elco 3319130 Assembly and operation instructions

CYP

CYP CVW-9000W Operation manual