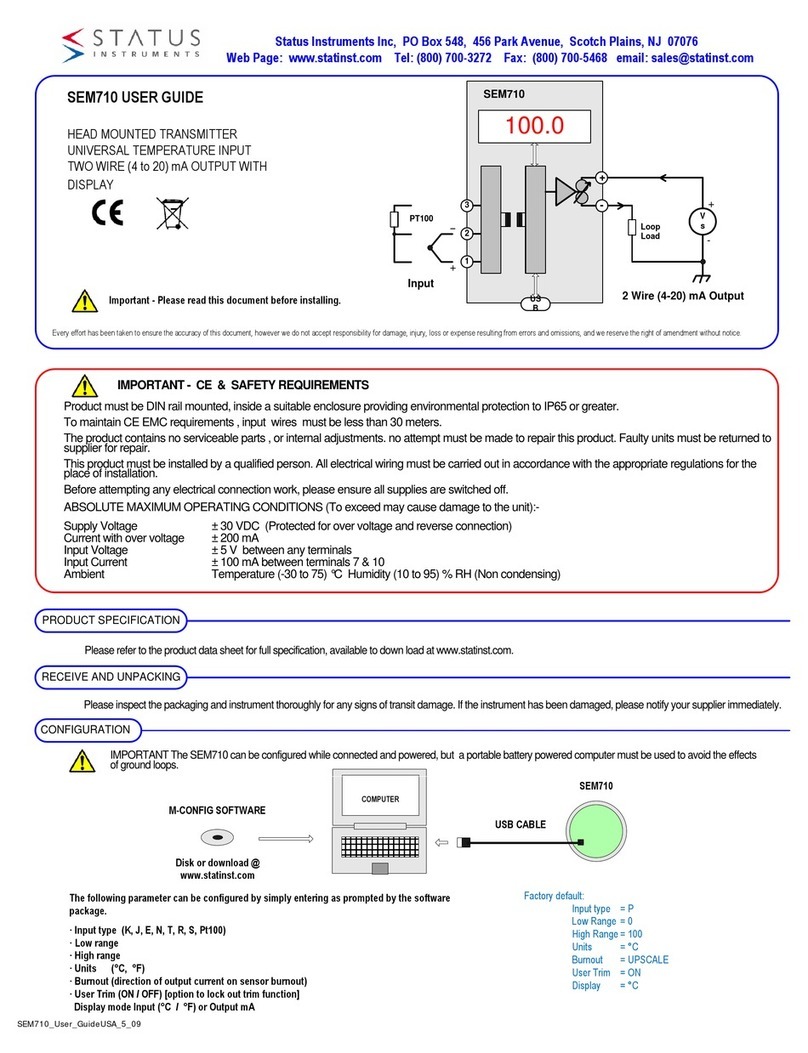

D2432-01-09 CN5171 SEM203TC User Guide

5.0 USER RANGING

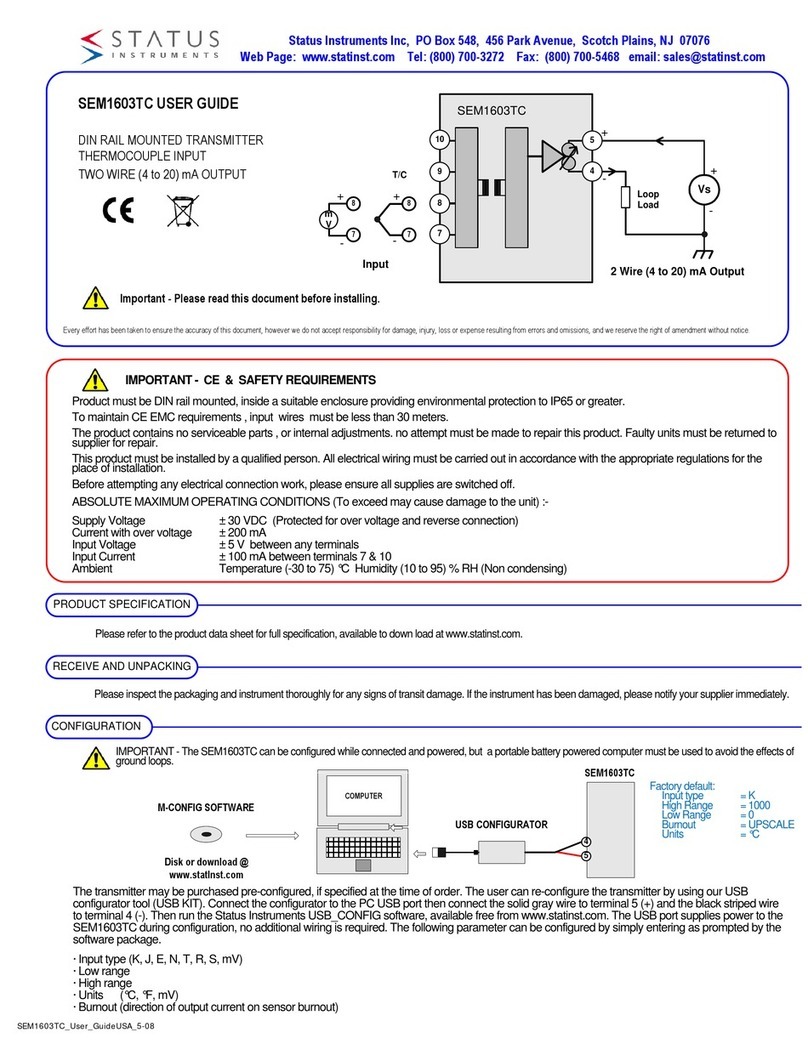

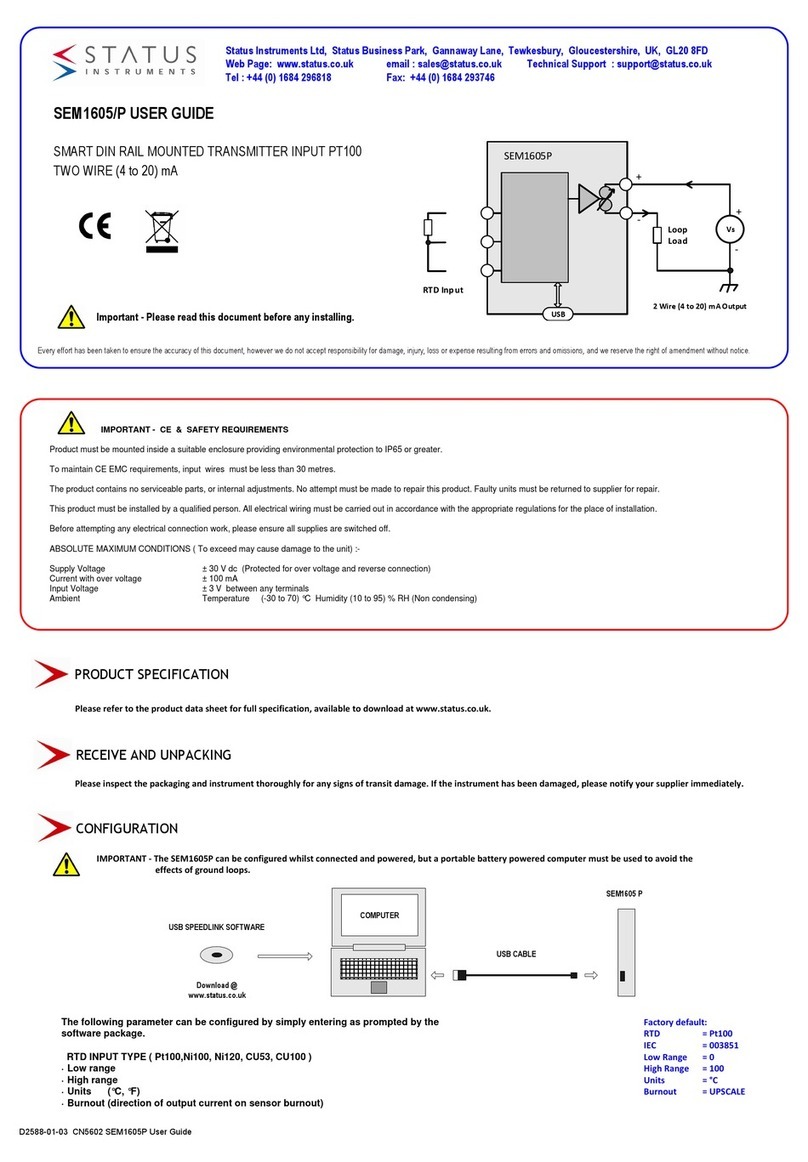

The transmitter may be purchased pre-configured, if specified at the time of order. User

ranging is provided to allow the temperature range of the transmitter to be set to a custom

range. This configuration level cannot change the input type, If the input type or other

parameters require change, then please refer to the advances configuration section. To confirm

the present input type set on the transmitter is correct for your application, count the number of

flashes of the range “R” LED at power up then refer to the chart in section 6 “Menu 1” to

establish the type set.

The push button is located under the slot in the key hole label, the slot located next to the

menu “M” LED.To press the button use a 3 mm screw driver (flat blade), inserted into the slot

and locate resistance of button key. The button has a slight click action.

It may be worth noting at this stage the advance user configuration provides the user with the

option of selecting fixed ranges, this may be a more attractive option if a suitable range is

available, as no calibration equipment will be required.

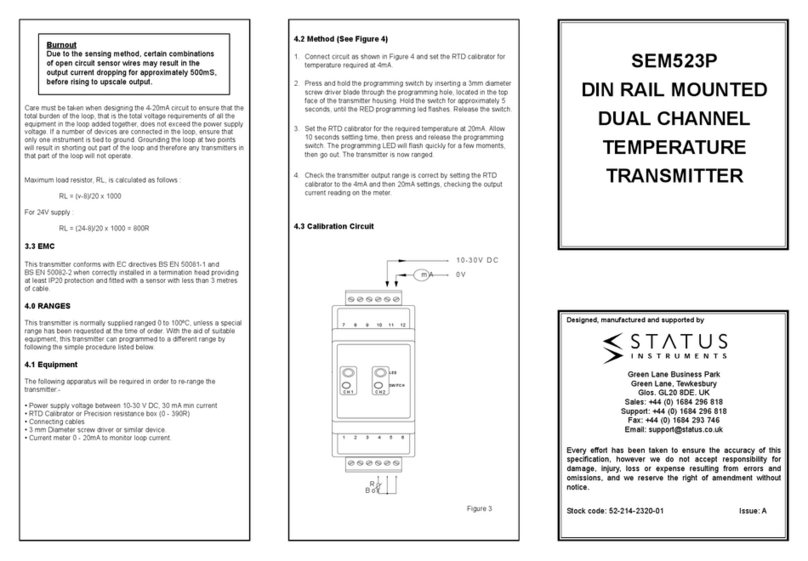

Configuration will require the following tools and equipment :-

•DC Supply (12 to 30) V @ 30 mA

•Thermocouple calibrator

•Thermocouple compensating wire

•Screw driver flat blade 3mm wide

To re-range the temperature scale follow the following instructions:-

•Connect thermocouple calibrator to SEM203TC input terminals using correct

thermocouple compensation wire. Observe polarity.

•Connect the output terminals to the DC supply, observe polarity.

•Turn DC supply on.

•Set calibrator to the required low scale temperature. Note Range “R” LED if on

indicates input connection error or input out of range, please check input.

•Allow 1 minute warm up period.

•To “enter” ranging, press and keep pressed the push button until Range “R” LED

flashes at a slow rate, then release button

•.The “R” LED will flash at a slow rate for a approximately one second during which

period the low scale range is stored. Once the store is complete the “R” LED will flash

at a medium rate indicating the transmitter is ready to store the high range setting.

•Set the calibrator to the required high range temperature and allow ten seconds.

•Press button to store high range setting, the “R” LED will flicker for one second before

the transmitter returns to normal operation. The transmitter is now re-ranged.

The above procedure also applies to mV input, but please ensure only copper wire is used for

connection to mV calibrator.

6.0 ADVANCED USER CONFIGURATION

The advanced user configuration option is based on five menus, each menu

Sets a different parameter:-

Menu 1 Selects one of eight input types.

Menu 2 Selects either custom user range or one of seven fixed range

Menu 3 Selects the output direct on sensor burnout

Menu 4 Provide User trim at 4mA and 20 mA.

Menu 5 Reset to factory default setting

The advance configuration menus are navigated using the push button, menu “M” LED and

range “R” LED, The push button is located underneath the slot in the key hole label, located

just below the “M” LED. To press the button use a 3 mm screw driver (flat blade) inserted into

the slot. The button has a slight click action.

Three commands are used to navigate menus, performed by clicking the button as follows:-

•Advance Single button press or click

•Escape or change direction Double press or click within 0.5 seconds

•Enter Press and hold button > two seconds

When a menu is selected the “M” LED will flash a burst of 1 to 5 flashes, the number of

flashes represents the menu number.

Note the range “R “ LED will only operate when a selected menu has been entered, then the

“R” LED uses a series of flashes or toggle flash rates to indicate the state or stage of the open

menu.

Navigating the menus (Read all of this section before attempting configuration)

To access the advanced user menus press and hold down button during SEM203TC power up.

The advance user menus will now be enabled and remain enabled until transmitter power is

removed. Note the “USER RANGING ” level will not be active at this stage, the push button will

now serve to navigate “advance user menus” as follows:-

•To “enter” menus press and hold button for > 2 seconds. The “M” LED will then starts

to flash, rate one flash per burst (indicating menu 1).

•To “advance” to the next menu use single button press, the “M” LED will advance to

two flashes per burst, indicating menu 2 is selected. Repeated single presses will

advance menu, once menu 5 is reached, the next press will returns to menu 1, for a

repeat cycle around the menus.

•To “escape” from menus back to normal operation use a double click of the button or

remove transmitter power. Note menus have no timeout escape and therefore will

remain selected indefinitely.

•To “enter” a selected menus press and hold button for two seconds, at which stage the

“R” LED will start to flash between bursts of the “M” LED, indicating the state of the

opened menu.

MENUS (First Select the required menu and open as described above.)

Menu 1 Input type

•On Entry “M” LED single flash every burst (menu 1), followed by a burst of between 1

to 8 “R” LED flashes, flash count represents the input type as listed below. Timeout is

10 seconds so be sure to act quickly if the type needs changing.

“R “ LED flashes

Input Type

1 Type K

2 Type J

3 Type E

4 Type N

5 Type T

6 Type R

7 Type S

8 mV

•Single button press to “advance” to the next input type, when type 8 is reached the

next “advance” will cycle back to type 1. To ensure valid indication of input menu,

allow one to two burst cycle after ”advance”, before counting the “R” LED flashes.

•Once the desired type is selected, allow 10 seconds with no button action, the

transmitter will then store the selected input type, (indicated by flicker of “R” LED)

before return back to normal operation.

Menu 2 Fixed ranges

•On “Entry” the “M” LED flashes twice every burst (menu2), followed by a “R” LED

flashes between 1 to 8 , flash count represents the range selected as described below.

Timeout is 10 seconds so be quick to act.

•Range 1 is allocated for the user custom push button set range. When a new custom

range (see USER RANGING) is entered, the range selected will automatically return to

1.

Range “R”

LED

flashes

Inputs

K,J,E, & N

(°C)

Input

T

(°C)

Inputs

R, & S

(°C)

Input mV

mV

1 User Ranged

2 0 to 1000 0 to 400 800 to 1760 0 to 70

3 0 to 1200 0 to 250 800 to 1600 0 to 5

4 0 to 600 0 to 200 800 to 1400 0 to 10

5 0 to 500 0 to 150 1000 to 1760 0 to 20

6 0 to 250 0 to 100 1000 to 1600 0 to 25

7 0 to 100 0 to 50 1000 to 1400 0 to 50

8 -100 to 100 -100 to 150 0 to 1600 -10 to 10

•Single button press to “advance” to the next range, once range 8 is reached, the next

“advance” will cycle range back to 1. To ensure valid indication of range menu, allow

one to two burst cycle after ”advance”, before counting flashes.

•Once the desired range is selected allow for 10 seconds with no button action, the

transmitter will then store new range (indicated by flicker of “R” LED) before returning

to normal operation.

Menu 3 Burnout Selection

•On “Entry” - “M” LED, three flash every burst (menu 3), followed by a “R” LED toggle

flash, either at a slow rate (every second) or a faster medium rate. Be quick to act as

timeout is 10 seconds.

•Slow rate indicated low scale burnout , fast rate indicates upscale burnout.

•To “advance ” to the the other burnout direction press button.

•To store new setting allow 10 seconds with no button action, the burn out selsction

menu will then timeout, store new setting, (indicated by a flicker of the “R” LED),

before returning back to normal operation.

Menu 4 User trim

This menu allows the user to trim the output current at zero and span, (similar function

to trim potentiometers) and is very useful for trimming out sensor errors.

The input of the transmitter must be connected to either a calibrator or a temperature

sensor held at a known temperature. The (4 to 20) mA loop current will also need to be

monitored with a current meter. This menu has extended timeout of 20 seconds.

•The trim action will only operate within certain output current bands, the zero will be

trimmed when the out current is between (3.8 to 6.0) mA, and the span will be trimmed

when the output current is between (18.0 to 21.5) mA.

•On “Entry” - “M” LED, four flash every burst (menu 4), followed by a “R” LED toggle

flash, either at a slow rate (every second) or a faster medium rate.

•Slow rate indicates trim direct down, whilst fast rate indicate trim direction up.

•To “change direction” the trim direction double click button.

•To trim, single press button to “advance” current by 2 uA, or press and hold button to

auto advance, after two seconds the trim will adjust automatically at a rate of 3 uA per

second until the button is released. Note after approximately 20 seconds of continuous

button press, the auto trim rate will speed up to a rate of 10 uA per second.

•To store new setting allow 20 seconds with no button action, the User Trim menu will

then timeout and store any new setting(s), (indicated by a flicker of the “R” LED),

before returning back to normal operation.

Menu 5 Set factory default

•On “Entry” - “M” LED, five flashes every burst (menu 5), followed by “R” LED toggle

flash at a slow rate (every second).

•To set factory default and zero any user trim, press button. Default setting will then be

loaded and stored into the transmitter, indicated by a flicker of the “R” LED. The

transmitter will then return to normal operation.

•To avoid any action, allow 10 seconds with no button action, Set factory default menu

will then timeout, without storing any default configuration. The transmitter will then

return to normal operation.