Turning on the Laser

The measuring laser on the sensor is switched on via a software command or a switching input. This allows to switch off the sensor for maintenance purposes or similar. Response time: after the laser

is switched on, the sensor needs depending on the measuring rate five cycles to send correct measured data.

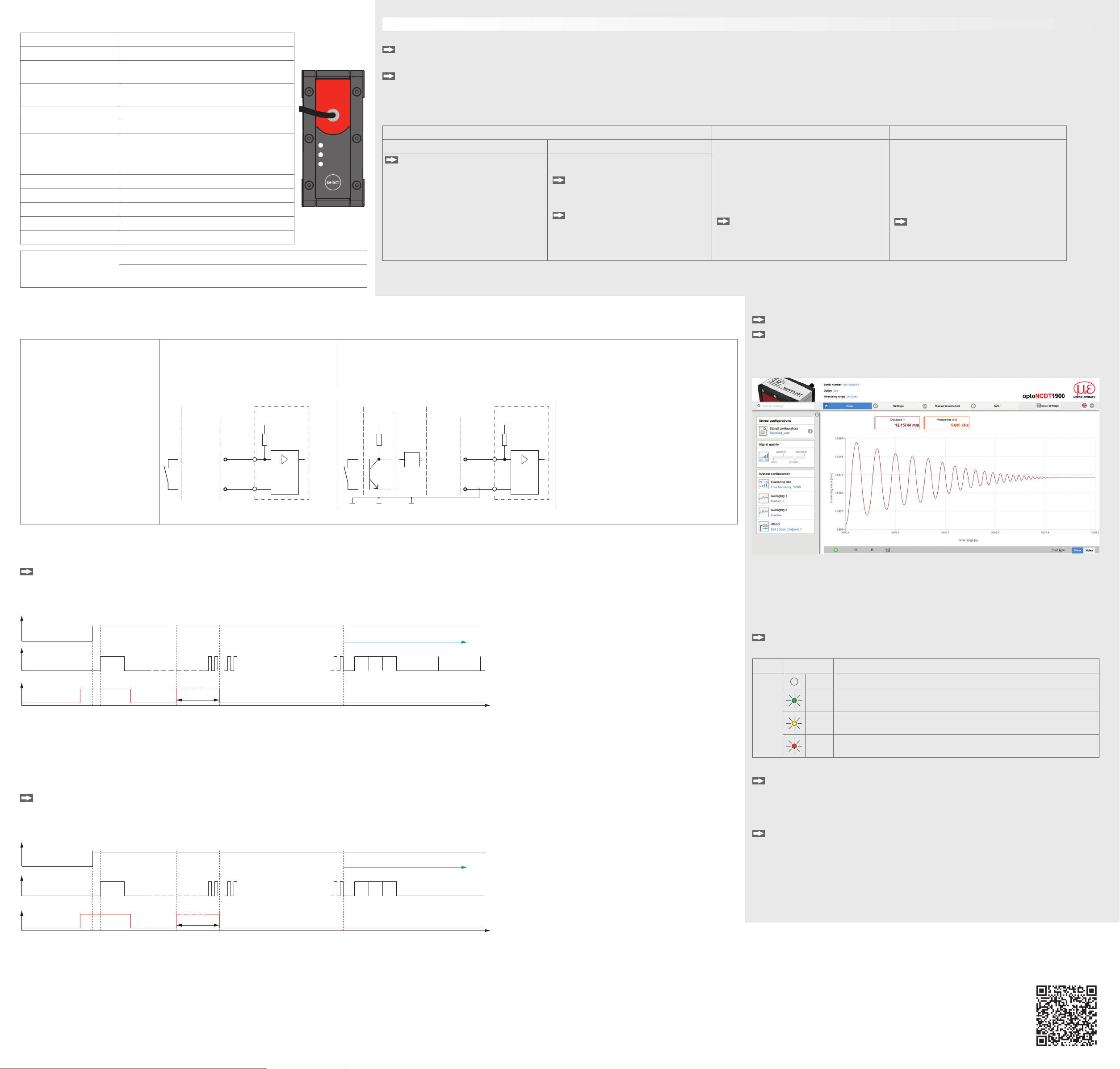

Laser on/off via software,

Supply with PoE

The measuring laser on the sensor is

activated via a software command.

Laser on/off via hardware,

Supply with PoE

The measuring laser on the sensor is activated

via a switch or similar.

Laser on/off via hardware,

Supply without PoE

A switching transistor with open collector (for example in an optocoupler), a relay contact or a digital TTL or

HTL signal are suitable for switching.

Activation using the

PC1900-IE-x/OE-RJ45 cable is pos-

sible.

Activation using the PC1900-IE-x/OE-RJ45 cable is possible.

PC1900-IE-x/OE-RJ45

7

Violet 8

ILD1900-IE

Black

VH

PC1900-IE-x/OE-RJ45

7

1

Violet 8

Type 1 ILD1900-IE

Type 2 Type 3

Black

V+

10k

VH

The inputs are not electrically separated.

24 V logic (HTL): Low level ≤ 3 V;

High level ≥ 8 V (max 30 V)

internal pull-up resistor, an open input is detected

as High.

Max. switching frequency 10 Hz

The ground of the logic circuit must be galvani-

cally connected to "Laser on/off -".

No external resistance is required for current limitation. For permanent "Laser on", connect the black and violet wires.

Switch between EtherCAT Operation and Ethernet Setup Mode

The sensor starts in the last stored operating mode. It is factory set to EtherCAT. Access via Ethernet is possible in the Ethernet setup mode.

Press and hold the Select button on the sensor before switching on the power supply on the sensor. Release the button again as soon as the State LED flashes yellow. Press the button again

for approx. 10 to 15 seconds until the State LED flashes red.

Within the time t2... t3, the red flashing with 8 Hz starts after 10 seconds. The key must be released again after 15 seconds at the latest. When the Select key is released at the latest at time t3, the

State LED starts to flash yellow at 8 Hz.

State LED

Firmware installation or

IE/Ethernet switch

Select key

Supply

voltage

red

yellow, appr. 8 Hzred, 8 Hzyellow flashing appr. 1 Hz yellow green yellow

t0t1t3

t2

10 ... 15 sec

t4

Ethernet Setup Mode

t0: Supply voltage is applied.

t1: The State LED starts flashing yellow, the Select button

can be released

t2: Within 15 sec. (t2 - t1), press Select button again and

hold for further 10 ... 15 sec. (t3 - t2)

t3... t4: Switches from EtherCAT to Ethernet setup mode, duration

max. 1 min.

t4: Sensor starts in Ethernet setup mode, the State LED

lights up briefly at intervals of approx. 1 sec.

Flowchart for starting a sensor in Ethernet setup mode

After completion of the firmware installation/switch, the sensor reboots at time t4.

Switch between Ethernet Setup Mode and EtherCAT

The sensor starts in the last stored operating mode. With the select button, you can set the sensor to the EtherCAT mode.

Press and hold the Select button on the sensor before switching on the power supply on the sensor. Release the button again as soon as the State LED flashes yellow. Press the button again

for approx. 10 to 15 seconds until the State LED flashes red.

Within the time t2... t3, the red flashing with 8 Hz starts after 10 seconds. The key must be released again after 15 seconds at the latest. When the Select key is released at the latest at time t3, the

State LED starts to flash yellow at 8 Hz.

State LED

Firmware installation or

Ethernet/IE switch

Select key

Supply

voltage

redyellow flashing appr. 1 Hz yellow green

t0t1t3

t2

10 ... 15 sec

t4

EtherCAT operation

yellow, appr. 8 Hzred, 8 Hz

t0: Supply voltage is applied

t1: The State LED starts flashing yellow, the Select but-

ton can be released

t2: Within 15 sec. (t2 - t1), press Select button again and

hold for further 10 ... 15 sec. (t3 - t2)

t3... t4: Switches from Ethernet setup mode to EtherCAT, dura-

tion max. 1 min.

t4: Sensor starts in EtherCAT operating mode.

Flowchart for starting a sensor in EtherCAT operation

After completion of the firmware installation/switch, the sensor reboots at time t4.

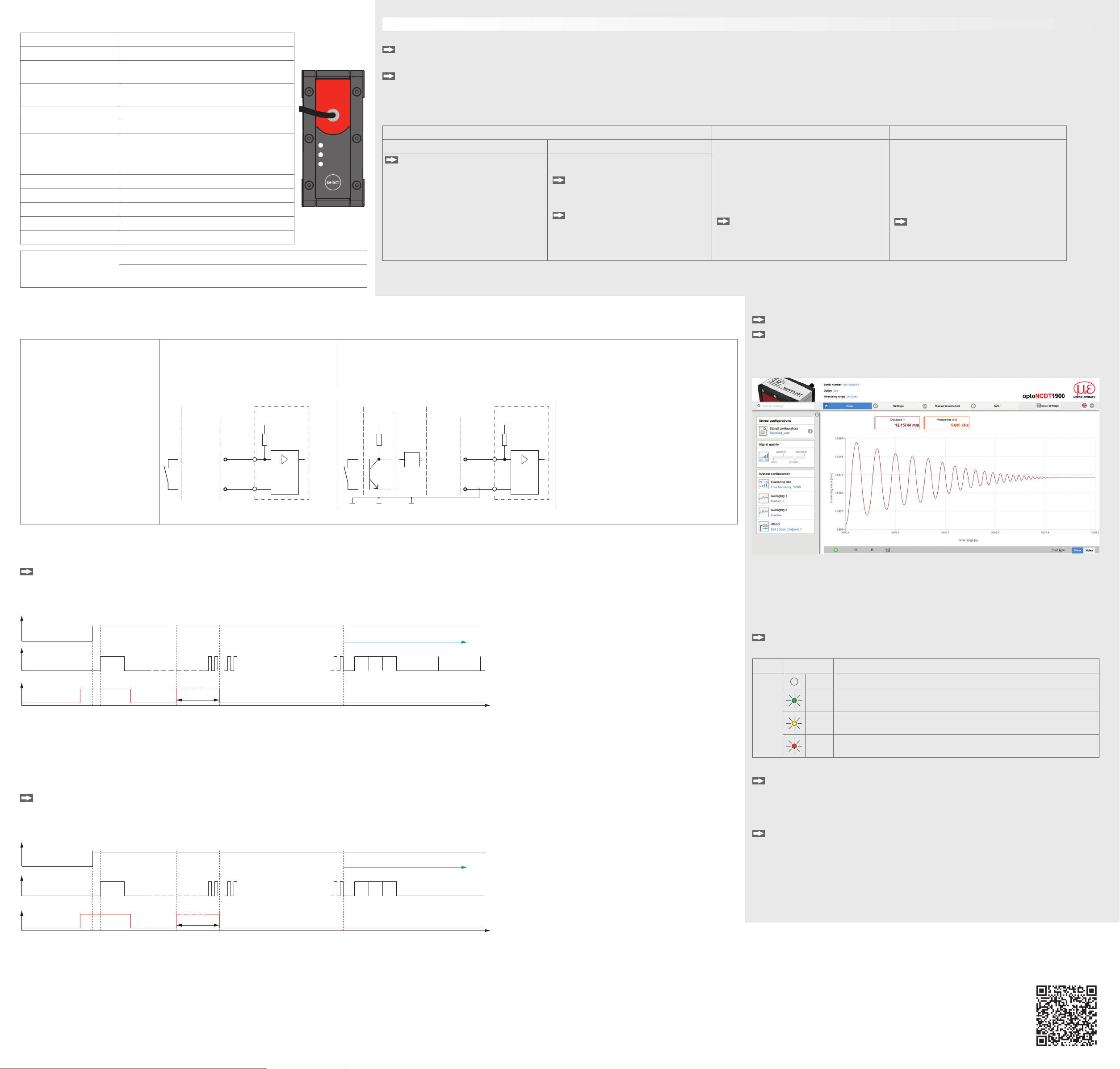

Access via Web Interface

Start your web browser.

Type the IP address of the sensor into the address bar.

Interactive web pages you can use to configure the sensor are now displayed in the web

browser. The web interface does not guarantee real-time measurements. The currently running

measurement can be controlled using the function buttons in the Chart type section.

In the top navigation bar, other functions (settings, measurement chart etc.) are available. The

appearance of the websites can change dependent of the functions. Each page contains dy-

namic parameter descriptions and tips on completing the web page.

After parameterization, store all settings permanently in a parameter set so that they are available

again the next time the sensor is switched on. To do this, use the Save settings button.

Positioning the Target

Position the target as centrally as possible within the measuring range.

The state LED on the sensor indicates the position of the target to the sensor.

LED Color Meaning

state

Off Laser beam is switched off.

Green Measuring object within the measuring range

Yellow Target is in the mid of measuring range.

Red No distance value available, e.g. target outside the measuring range, too

low reflection

Saving the Settings, Continuing Industrial Ethernet Operation

Go to Settings > System settings > Load & Save or click the Save settings

button.

The sensor now also saves the settings for use in Industrial Ethernet operation.

For sensors with operation mode EtherCAT:

Go to Settings > System settings > Boot mode. Select the entry Industrial

Ethernet.

The sensor disconnects from the browser and boots automatically with the Industrial Ethernet

firmware. The boot process can take up to one minute.

Alternatively, you can return to the Industrial Ethernet operation via the select button. Details

can be found in section Switch between Ethernet Setup Mode and EtherCAT.

Continue working in your PLC environment.

Control and Display Elements

State LED Meaning

state

RUN/SF/MS

ERR/BF/NS

Green Measuring object within the measuring range

Yellow Measuring object in the mid of the measuring

range

Red No distance value available, e.g. target outside

the measuring range, too low reflection

Yellow flashing, 1 Hz Bootloader

Yellow flashing, 8 Hz Installation active

State LED lights up

(green, yellow or red) and

briefly flashes yellow at

intervals of approx. 1 sec.

Ethernet setup mode

Off Laser switched off

LED RUN/SF/MS Meaning

depending on Industrial Ethernet operation (IE)

LED ERR/BF/NS Meaning

depending on Industrial Ethernet operation (IE)

Select button Meaning

- Switching operating mode (with EtherCAT only)

- Resetting to factory setting

Quick Guide

Structure of the Components

Mount the sensor and connect the components to one another.

Initial Operation

Connect the sensor to a power supply if PoE is not used.

Operation via Web Interface

The sensors start with the last stored operating mode. Standard is Industrial Ethernet (IE). A web server is implemented in the sensor; the web interface displays, among other things,

the current settings of the sensor. Operation is only possible while there is an Ethernet connection to the sensor.

EtherCAT EtherNet/IP Profinet

Ethernet setup mode Ethernet over EtherCAT (EoE) iAn ILD1900-IE with EtherNet/IP is deliv-

ered in DHCP mode without IP address.

A DHCP server is required, to assign

an temporary IP address to the sensor.

Subsequently, it is also possible to as-

sign a static IP address.

Assign an IP address to the sensor.

You can find an example of this in the appen-

dix of the operating instructions.

iAn ILD1900-IE with Profinet has no IP

address by default. The static IP address

and the device name are assigned

via DCP (Discovery and Configuration

Protocol). The IP address and the device

name can be assigned, e.g., via the TIA

Portal software.

Assign an IP address to the sensor.

You can find an example of this in the appen-

dix of the operating instructions.

Switch to the Ethernet setup mode.

Details can be found in section Switch

between Industrial Ethernet Oper-

ation and Ethernet Setup Mode.

The standard IP address is 169.254.168.150.

Note: As IP setting of the network card

to which the sensor is connected, we

recommend a static configuration with

169.254.168.1 as IP address and the subnet

mask 255.255.0.0.

Parallel to the EtherCAT operation you can

adjust the sensor.

Enable the EoE in your PLC software.

Virtual Ethernet Port is a name in

TwinCAT®.

Assign a MAC address and an IP

address to the slave.

You can find more information about the sensor in the operating instructions.

They are available online at:

https://www.micro-epsilon.com/displacement-position-sensors/laser-sensor/

optoNCDT_1900/?sLang=en

Proper Environment

- Protection class: IP67 (applies only when sensor cable is plugged in)

Lenses are excluded from the protection class. Contamination of the lenses causes impairment

or failure of the function.

- Temperature range - Humidity: 5 ... 95% (non-condensing)

Operation: 0 ... +50 °C - Ambient pressure: Atmospheric pressure

Storage: -20 ... +70 °C