colorCONTROL MFA-7/-14/-21/-28

Contents

1. Safety ........................................................................................................................................ 5

1.1 Symbols Used ................................................................................................................................................. 5

1.2 Warnings.......................................................................................................................................................... 5

1.3 Notes on CE Marking ...................................................................................................................................... 5

1.4 Intended Use ................................................................................................................................................... 6

1.5 Proper Environment......................................................................................................................................... 6

2. Functional Principle, Technical Data ....................................................................................... 7

2.1 Short Description............................................................................................................................................. 7

2.2 Measuring Principle ......................................................................................................................................... 7

2.3 Functions ........................................................................................................................................................ 7

2.4 Display Element .............................................................................................................................................. 7

2.5 Technical Data ................................................................................................................................................. 8

2.5.1 Technical Data for Controller ......................................................................................................... 8

2.5.2 Technical Data for MFS Sensors .................................................................................................... 9

3. Delivery .................................................................................................................................. 10

3.1 Unpacking/Included in Delivery .................................................................................................................... 10

3.2 Storage .......................................................................................................................................................... 10

4. Installation and Assembly...................................................................................................... 11

4.1 Installation and Mounting .............................................................................................................................. 11

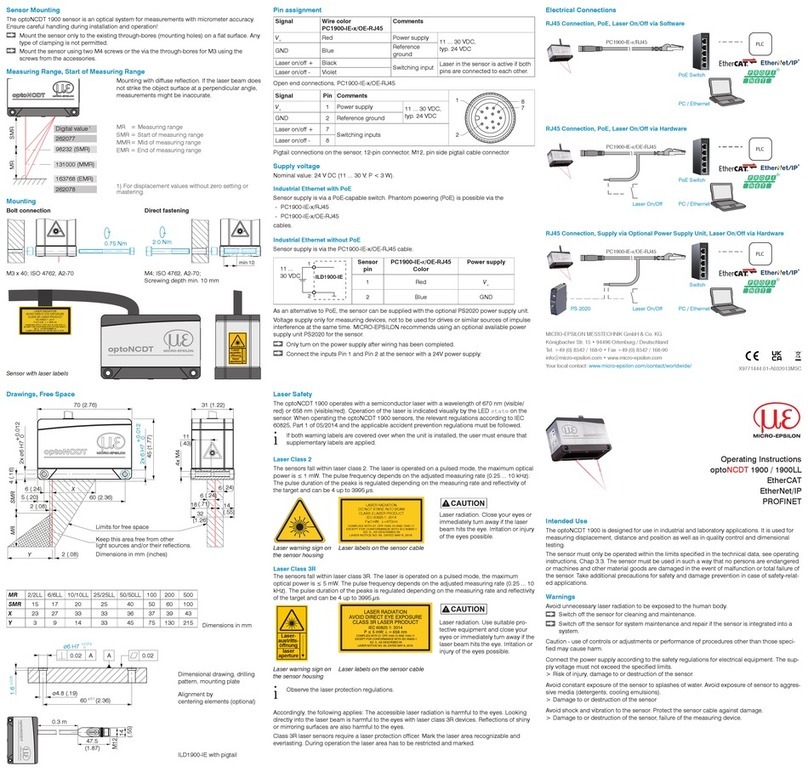

4.2 Mounting the MFS Receiver Sensor.............................................................................................................. 12

4.3 Status LED ..................................................................................................................................................... 12

4.4 Electrical Connections Controller.................................................................................................................. 13

4.4.1 Connection Options ..................................................................................................................... 13

4.4.2 Pin Assignment............................................................................................................................. 13

4.4.3 Supply Voltage ............................................................................................................................. 14

4.4.4 Data Transmission for RS422, RS232 or USB ............................................................................ 14

4.4.5 RS422 (with IF2001/USB Converter)............................................................................................ 15

5. Operation ................................................................................................................................ 16

5.1 Initial Operation ............................................................................................................................................. 16

5.2 Operation using sensorTOOL ....................................................................................................................... 16

5.2.1 Controller Search ......................................................................................................................... 16

5.3 System Parameterization via sensorTOOL (Settings Menu)......................................................................... 17

5.3.1 Modulation Setup ......................................................................................................................... 17

5.3.2 Configuration................................................................................................................................ 18

5.3.2.1 Configuration/Measurement ..................................................................................... 18

5.3.2.2 Global Settings.......................................................................................................... 19

5.3.2.3 Channel Overview..................................................................................................... 20

5.4 Measurement Menu....................................................................................................................................... 21

5.4.1 Data Acquisition............................................................................................................................ 21

5.4.2 Signal Processing......................................................................................................................... 22

5.4.3 Data Acquisition Table.................................................................................................................. 23

5.4.4 Recording and Saving Measurement Data.................................................................................. 23

5.5 Single Value Menu......................................................................................................................................... 24

5.6 Color Display Menu ....................................................................................................................................... 25

5.7 Info Menu ....................................................................................................................................................... 26

5.7.1 Reset to Factory Settings ............................................................................................................. 26

5.7.2 Export / Import Settings .............................................................................................................. 26

5.7.3 Disconnecting............................................................................................................................... 27

6. Serial Interface (RS422, RS232 and USB) ............................................................................ 27

7. Cleaning.................................................................................................................................. 28

8. Software Support with MEDAQLib ........................................................................................ 28

9. Disclaimer............................................................................................................................... 28

10. Service, Repair ....................................................................................................................... 29

11. Decommissioning, Disposal.................................................................................................. 29