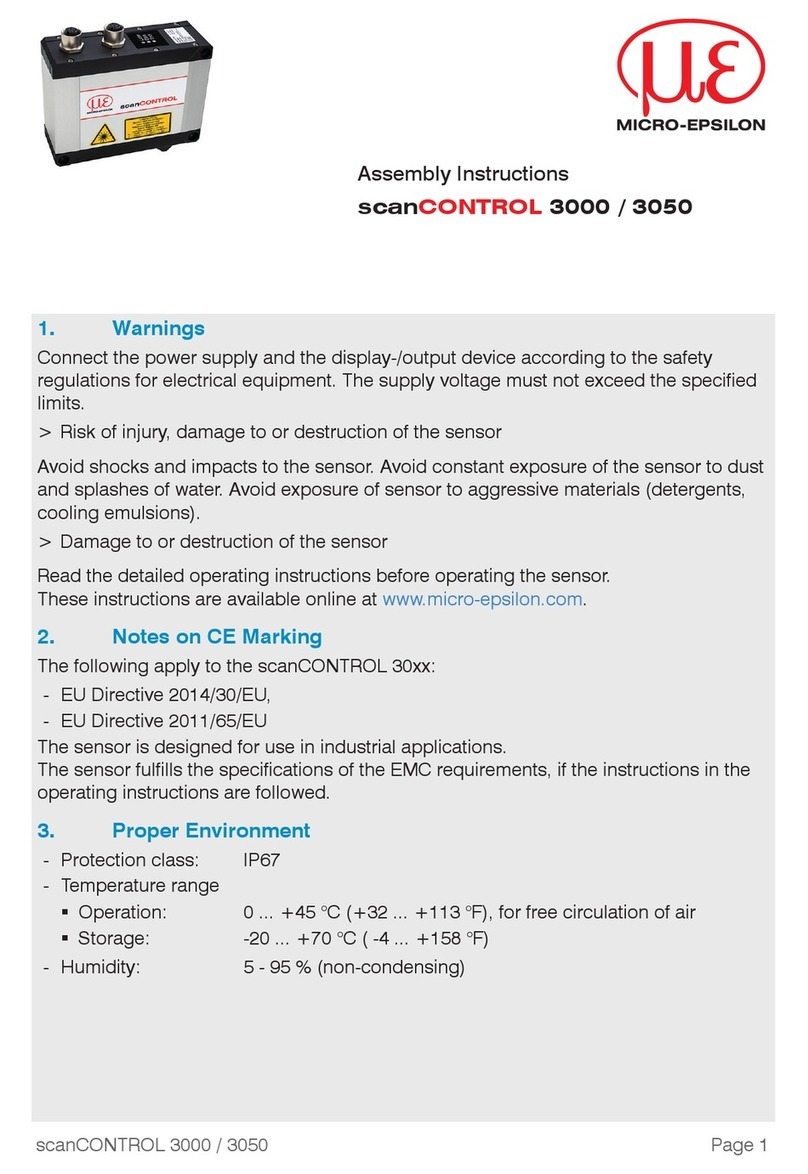

Trigger, Encoder, Mode Switching

The switching inputs of the multifunction port can either be used for encoder input, for

trigger input or for loading previously stored user modes.

The signal levels are switchable for all switching inputs between LLL (low-voltage-,

TTL logic) and HLL (high-voltage-, HTL logic):

- LLL level: Low 0 V … 0.8 V, high 2.4 V … 5 V, internal pull-up 10 kΩ to 5 V

- HLL level: Low 0 V … 3 V, high 11 V … 24 V (permitted to 30 V), internal pull-up 10

kΩ to 24 V

- Pulse duration: ≥ 5 µs

Multifunction Port

Designation Sensor con-

nector pin

Cable color

PC2600/2900-x

Notes

+Ub 9 red + 11 V - 30 V DC (rated value

24 V); max. 500 mA

GND 2 blue 0 V

+Laser on/off 3 white optional

-Laser on/off 1 brown

RS422 12 red-blue RS422, input respectively output

/RS422 11 gray-pink

In1 6 yellow Digital Input 1

GND-In1 4 green Ground In 1

In2 5 pink Digital Input 2

GND-In2 8 gray Ground In 2

In3 10 violet Digital Input 3

GND-In3 7 black Ground In 3

Shield Housing black No galvanic connection to GND

23

4

5

6

7

8

9

1

10

11

12-pin screw connector, view on solder pin side

GND: galvanically isolated from 1, 2, 3, RS422, Laser on/

off

Laser on/off: Input galvanically isolated from GND,

IN1…3, RS422

IN1, IN2, IN3, RS422: Inputs galvanically isolated from

GND and Laser on/off

External Laser Switching

The sensors of the scanCONTROL 26xx/SI, scanCONTROL 29xx/SI series offer this

function.

Use a serial key switch inside the control circuit to switch off the laser.

You will find details for the wiring in the instruction manual, Chap. 5.2.6.