4

Table of Contents

Micro-Trak Warranty ............................................................................................................................................................................. 3

Table of Contents ..................................................................................................................................................................................4

Introduction ...........................................................................................................................................................................................5

Component Parts, Assembly Hardware & Optional Equipment .............................................................................................. 6-7

FlowTrak II System Overview ............................................................................................................................................................. 8

FlowTrak II Wiring Overview ............................................................................................................................................................... 9

Installation ......................................................................................................................................................................................10-16

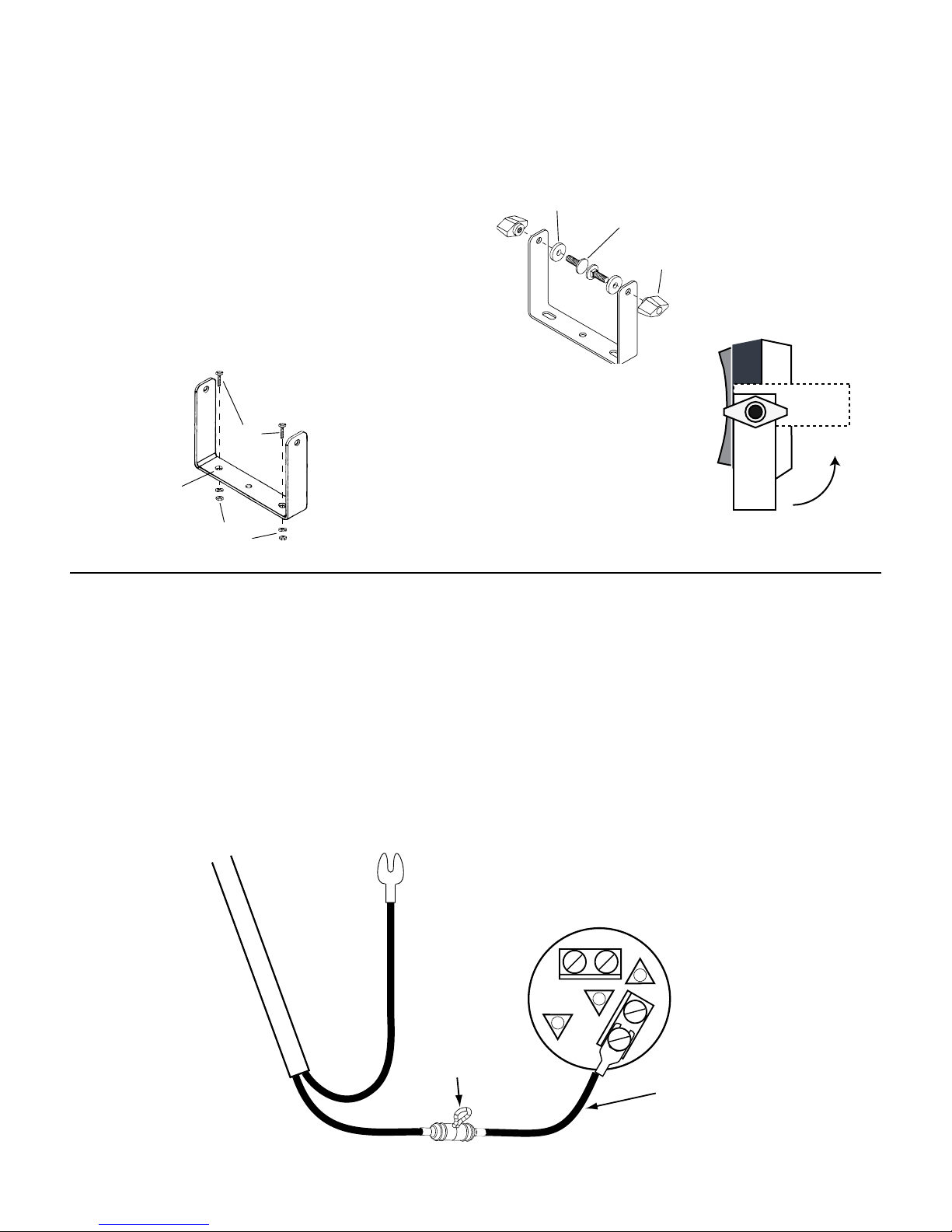

Mounting the Display Console ........................................................................................................................................................................10

Electrical Installation ...........................................................................................................................................................................................10

Speed Sensor Installation ............................................................................................................................................................................11-12

Magnets ...........................................................................................................................................................................................................11

Attaching Speed Sensor ............................................................................................................................................................................12

Connecting the Speed Sensor Cable ....................................................................................................................................................12

Speed Sensor Options................................................................................................................................................................................12

Mounting and Plumbing Flowmeter ............................................................................................................................................................ 13

Installing Flow Sensor Cable ............................................................................................................................................................................13

Remote Run/Hold .................................................................................................................................................................................................14

Connecting the Control Output ......................................................................................................................................................................15

Manual Pressure Relief Valve ...........................................................................................................................................................................16

Range Adjust Valve ..............................................................................................................................................................................................16

Care and Maintenance .......................................................................................................................................................................................16

FlowTrak II Console Functions .................................................................................................................................................................................17

Calibration .................................................................................................................................................................................................................18-24

English/Metric Selection .................................................................................................................................................................................... 18

Entering Calibration Values .............................................................................................................................................................................. 19

Speed Cal for Radar or GPS ...............................................................................................................................................................................20

Factory-loaded Calibration Values .................................................................................................................................................................20

Determining Speed Calibration ...................................................................................................................................................................... 21

Drive Shaft Speed Sensor Calibration ...........................................................................................................................................................21

Fine Tuning Speed/Distance Cal Value ..................................................................................................................................................22-23

Entering Target Test Speed ..............................................................................................................................................................................23

Exiting Calibration ................................................................................................................................................................................................23

Fine Tuning Flowmeter Calibration Value ..................................................................................................................................................24

Special Calibration ........................................................................................................................................................................................................ 25

Cal Parameters .......................................................................................................................................................................................................25

Factory Settings ....................................................................................................................................................................................................25

Operation - “Sprayer Monitor” Mode and “Batch” Mode ........................................................................................................................26-29

Console Switches and Buttons ........................................................................................................................................................................26

Data Description .............................................................................................................................................................................................26-27

Resetting System Counters ...............................................................................................................................................................................28

Clearing Counters .................................................................................................................................................................................................29

Troubleshooting ......................................................................................................................................................................................................30-34

Message/Warnings...............................................................................................................................................................................................30

General ..................................................................................................................................................................................................................... 31

Checking Individual Components ..................................................................................................................................................................32

Console Inputs .......................................................................................................................................................................................................33

Plumbing Troubleshooting Chart ..................................................................................................................................................................34

Plumbing Guidelines ...................................................................................................................................................................................................35

Pump Inlet, Agitation, Flowmeter, Pump ....................................................................................................................................................35

Valve Purpose and Adjustments .....................................................................................................................................................................35

Throttle Valve ................................................................................................................................................................................................ 36

Appendices ................................................................................................................................................................................................................36-42

Appendix A: Optional Speed Sensor Mounting Installation .........................................................................................................37-38

Appendix B: Flowmeter Assembly ................................................................................................................................................................39

Appendix C: Radar “Y” Cables .........................................................................................................................................................................40

Appendix D: Conversion Chart .......................................................................................................................................................................41

Appendix E: Replacement Parts List .............................................................................................................................................................42