3

System

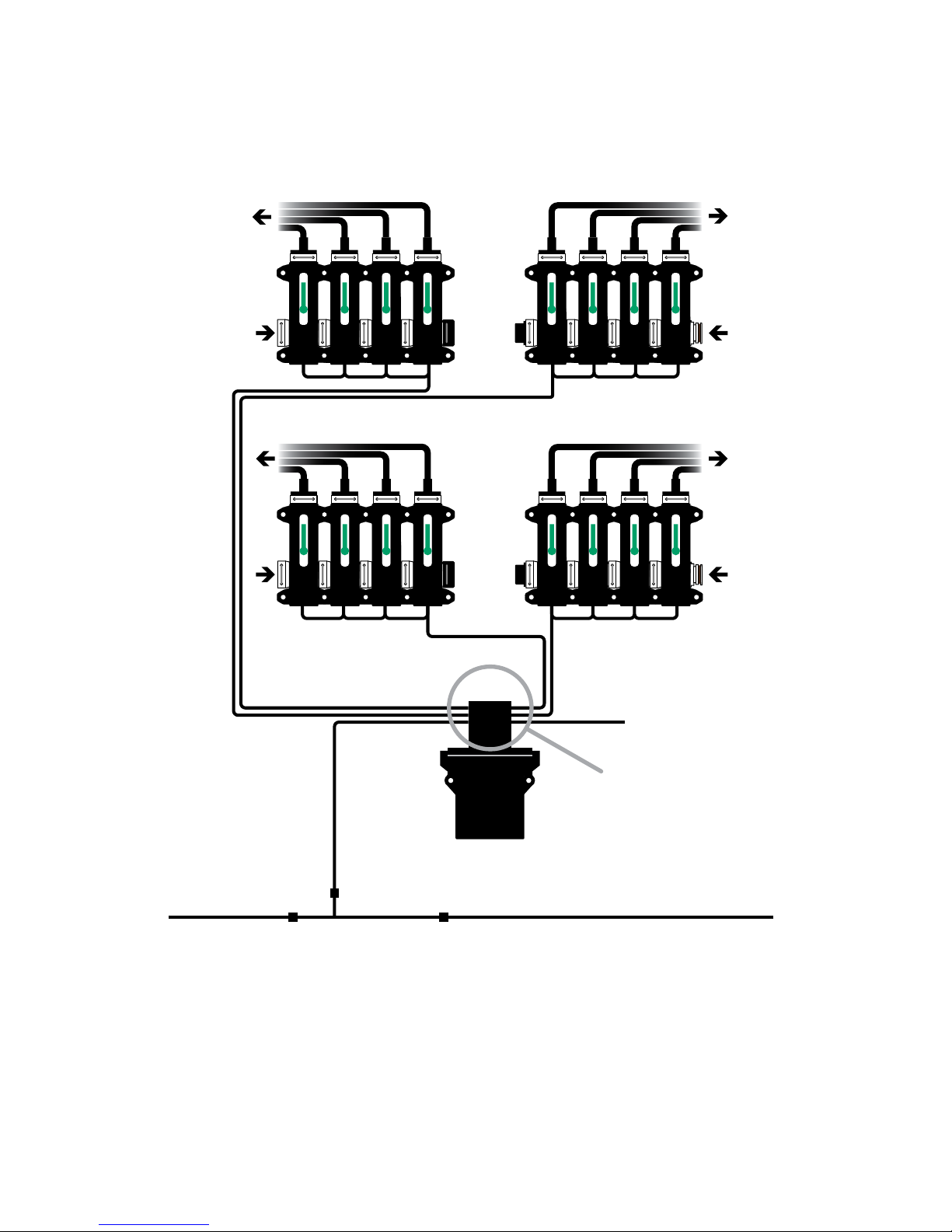

The SafeGuard™ ISOmod uses an existing virtual terminal

(VT) in the cab to display liquid blockage information

and control settings. On-screen messages and simple

icon buttons on the virtual terminal access all monitoring

functions. View real-time status of individual and total

sensors arranged into dual networks and independent left

and right sensor banks. Data communication is based on

ISOBUS - ISO 11783 standards.

ISOmod™ Interface

This is the information processing unit of the SafeGuard™

ISOmod™ system - continuously scanning rows for

blockages and displaying information on the Virtual

Terminal screen. It provides the physical interface

between the liquid blockage sensors and the Virtual

Terminal. The wiring harness of the ISOmod connects to

the sensors and an available ISOBUS connection.

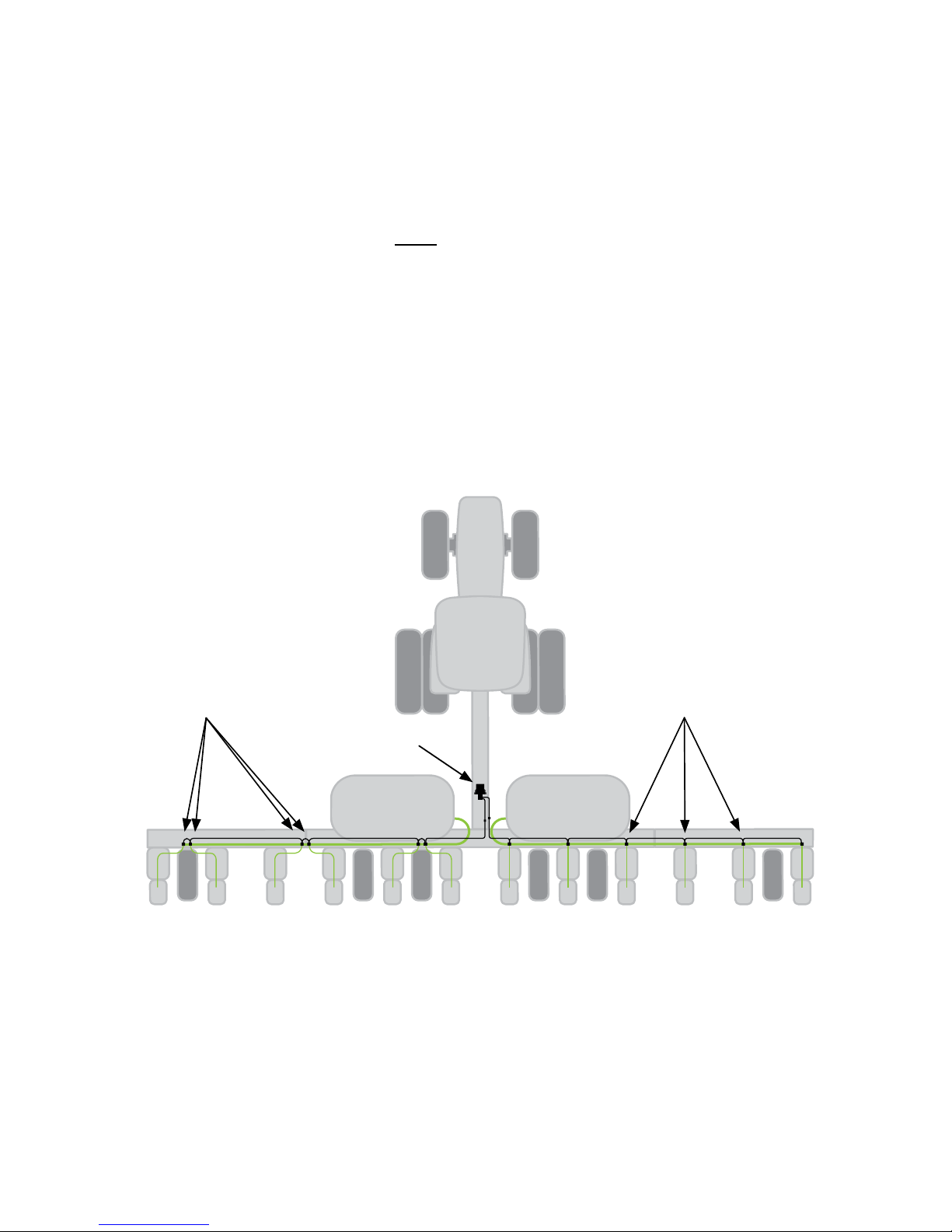

Sensor & Cartridges

The sensor assembly is a liquid flow chamber surrounded

by a blockage detection shroud. Its physical character-

istics are similar to visual flow monitor devices. The flow

openings accommodate plug (male) and cap (female)

fittings. (See page 21) The sensors may be mated with

other sensor assemblies or used individually. The chamber

contains a detection cartridge which rises with flow. A

fumigant-ready version of the sensor is also available.

Cartridges are available in a variety of weights to

accommodate a wide variety of liquid densities, and also

to provide partial blockage monitoring.

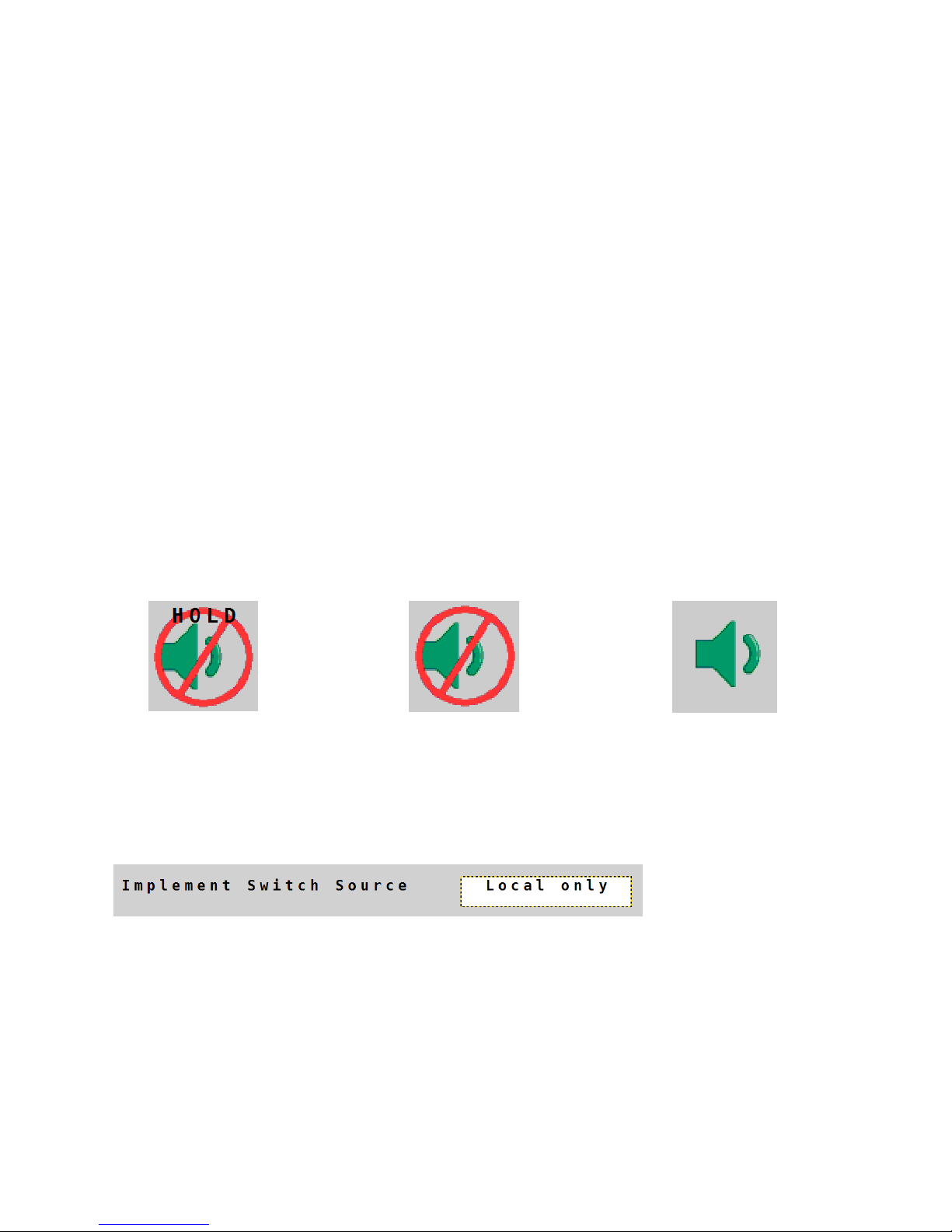

Implement Switch (optional)

The ISOmod wiring harness also has a Run/Hold con-

nection for an optional Implement Switch. This circuit

silences the audible alarm and also enables the review

of recorded screen information. (See page 11)

Micro-Trak makes an Implement Switch (P/N 18541)

with an integral magnetic mount designed to easily

connect to the ISOmod wiring harness.

Overview

Sensor

Implement Switch

ISOmod™

Interface