4

Table of Contents

Warranty................................................................................................................................................................................................3

Table of Contents ................................................................................................................................................................................4

Installation...................................................................................................................................................................................... 5-12

Component Parts and Assembly Hardware............................................................................................................................................... 5

Required Tools ...................................................................................................................................................................................................... 6

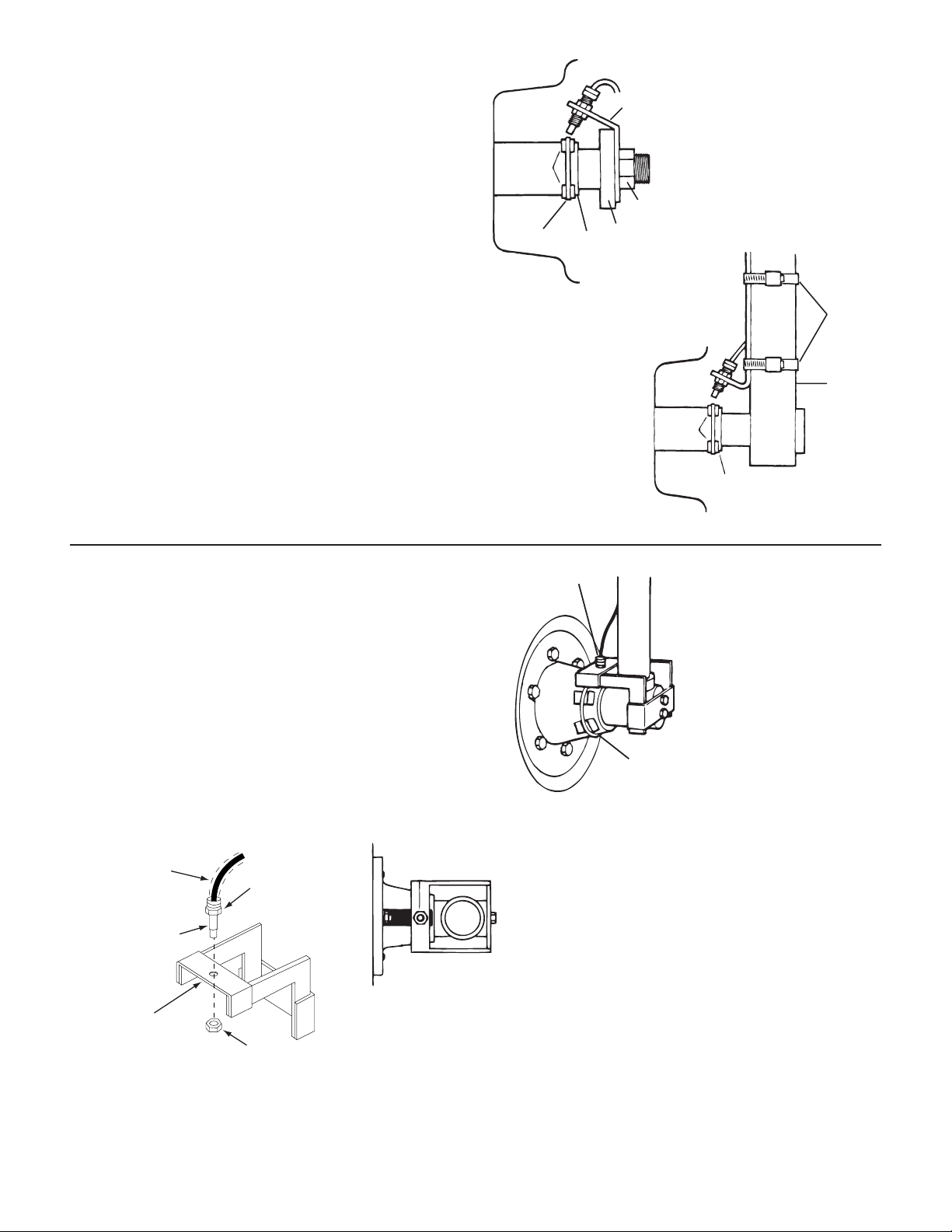

Mounting the Display Console ....................................................................................................................................................................... 6

Electrical Installation........................................................................................................................................................................................... 7

Speed Sensor Installation............................................................................................................................................................................7-11

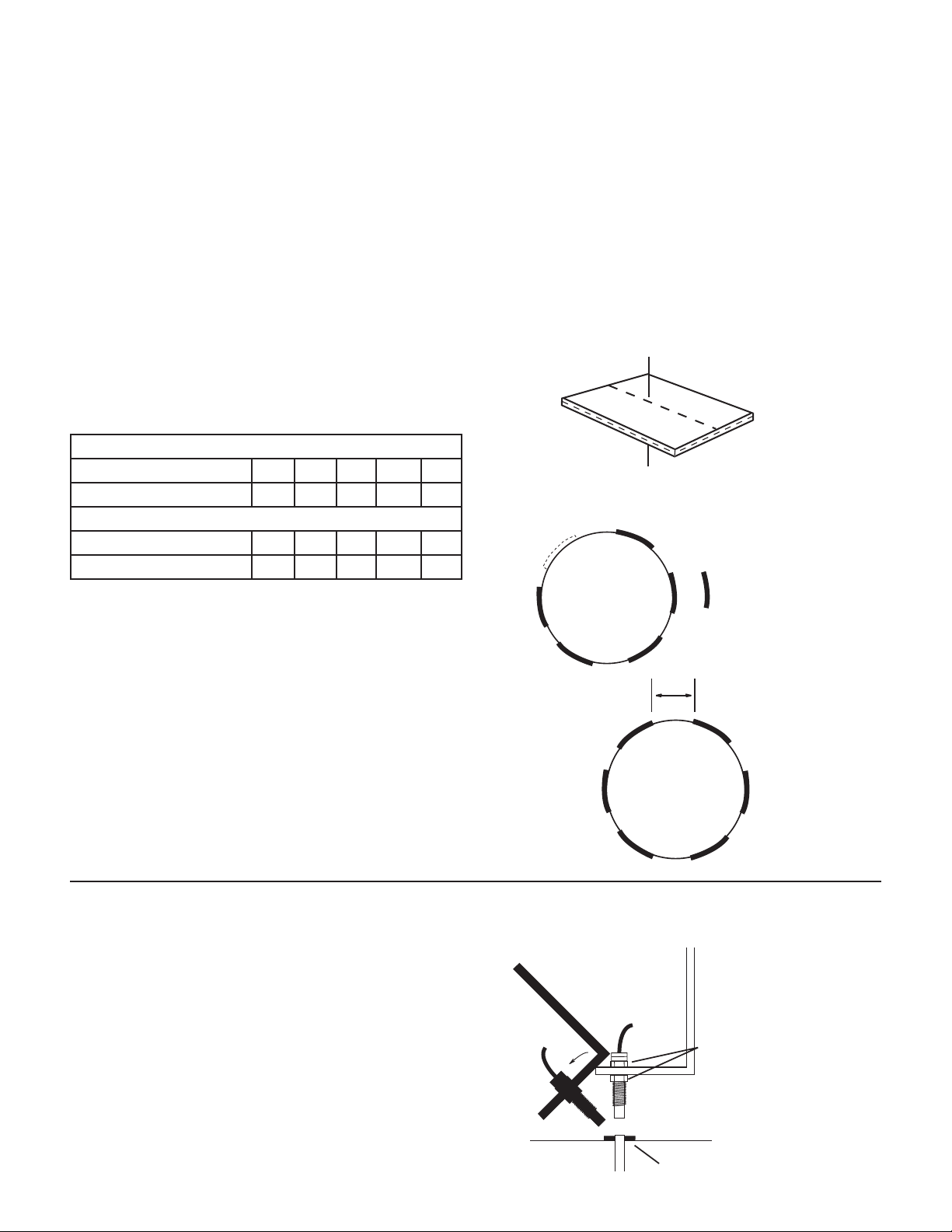

Magnets........................................................................................................................................................................................................... 8

Attaching Magnets to Hub....................................................................................................................................................................... 8

ATV Wheels .................................................................................................................................................................................................... 9

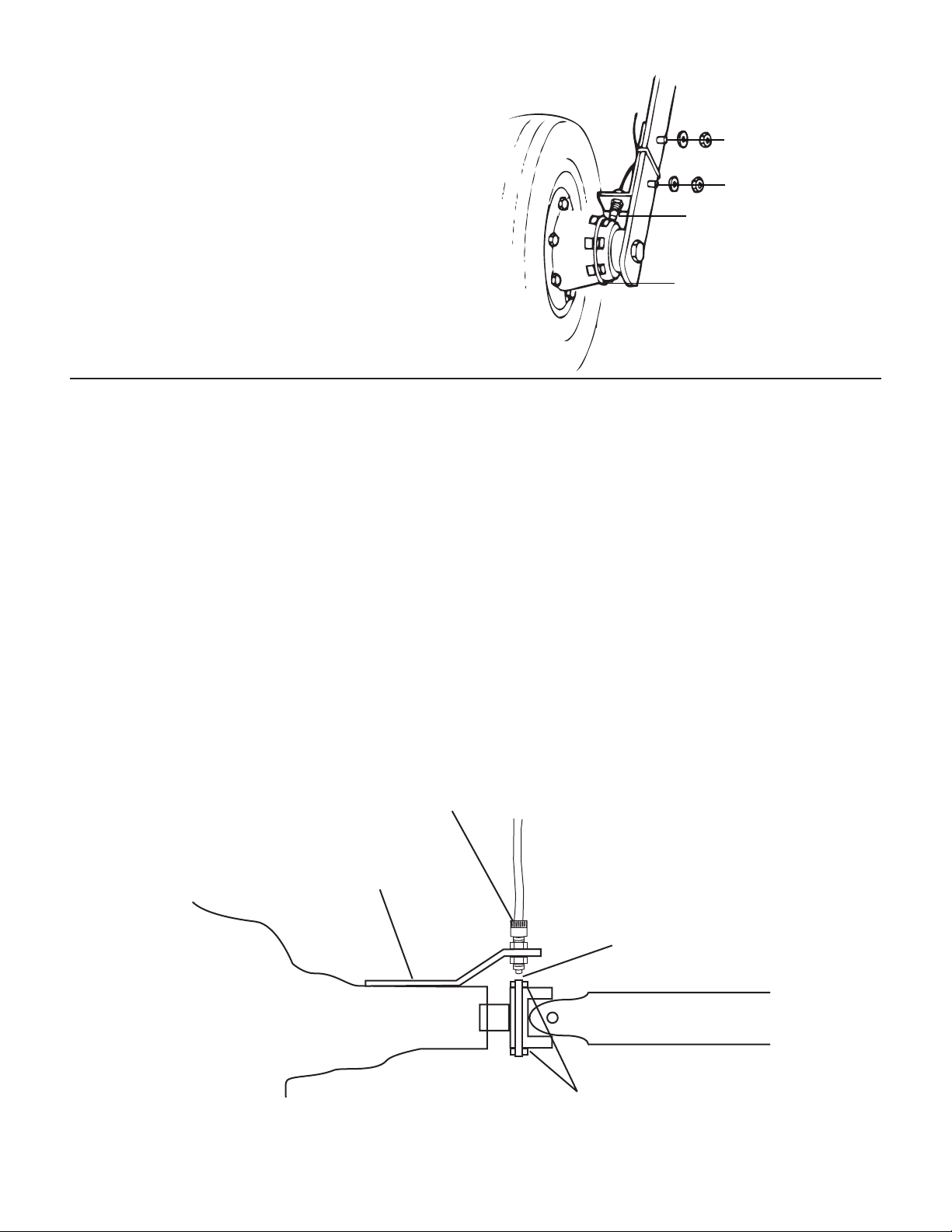

Front Tractor Wheels.................................................................................................................................................................................. 9

Implement Wheels ....................................................................................................................................................................................10

Optional Drive Shaft Mount...................................................................................................................................................................10

Optional Gas Engine RPM Sensor Installation.........................................................................................................................................11

Optional Tach/Shaft Sensor Installation....................................................................................................................................................11

Speed Sensor Options......................................................................................................................................................................................12

Care and Maintenance .....................................................................................................................................................................12

Console Functions.............................................................................................................................................................................13

Calibration ....................................................................................................................................................................................14-15

Field Calibration - Speed and Distance ...................................................................................................................................................14

Optional Distance Calibration .......................................................................................................................................................................14

RPM Calibration ..................................................................................................................................................................................................15

Operation......................................................................................................................................................................................15-16

Measuring Speed ...............................................................................................................................................................................................15

Measuring Distance...........................................................................................................................................................................................15

Measuring Hours ................................................................................................................................................................................................15

Measuring RPM...................................................................................................................................................................................................15

Resetting System Counters ............................................................................................................................................................................15

Optional Features .............................................................................................................................................................................................16

Over-Speed Alarm Instructions ............................................................................................................................................................16

Troubleshooting..........................................................................................................................................................................17-18

Console Appears Dead.....................................................................................................................................................................................17

Speed is Always Zero or Erratic.....................................................................................................................................................................17

Console is Erratic in Operation......................................................................................................................................................................17

Checking Individual Components ...............................................................................................................................................................18

Console..........................................................................................................................................................................................................18

Harness ..........................................................................................................................................................................................................18

Power .............................................................................................................................................................................................................18

Accessory Power ........................................................................................................................................................................................18

Magnetic Hall-effect Sensor...................................................................................................................................................................18

Console Input..............................................................................................................................................................................................18

Speed Input .................................................................................................................................................................................................18

RPM/Tach Input..........................................................................................................................................................................................18

Appendices...................................................................................................................................................................................19-22

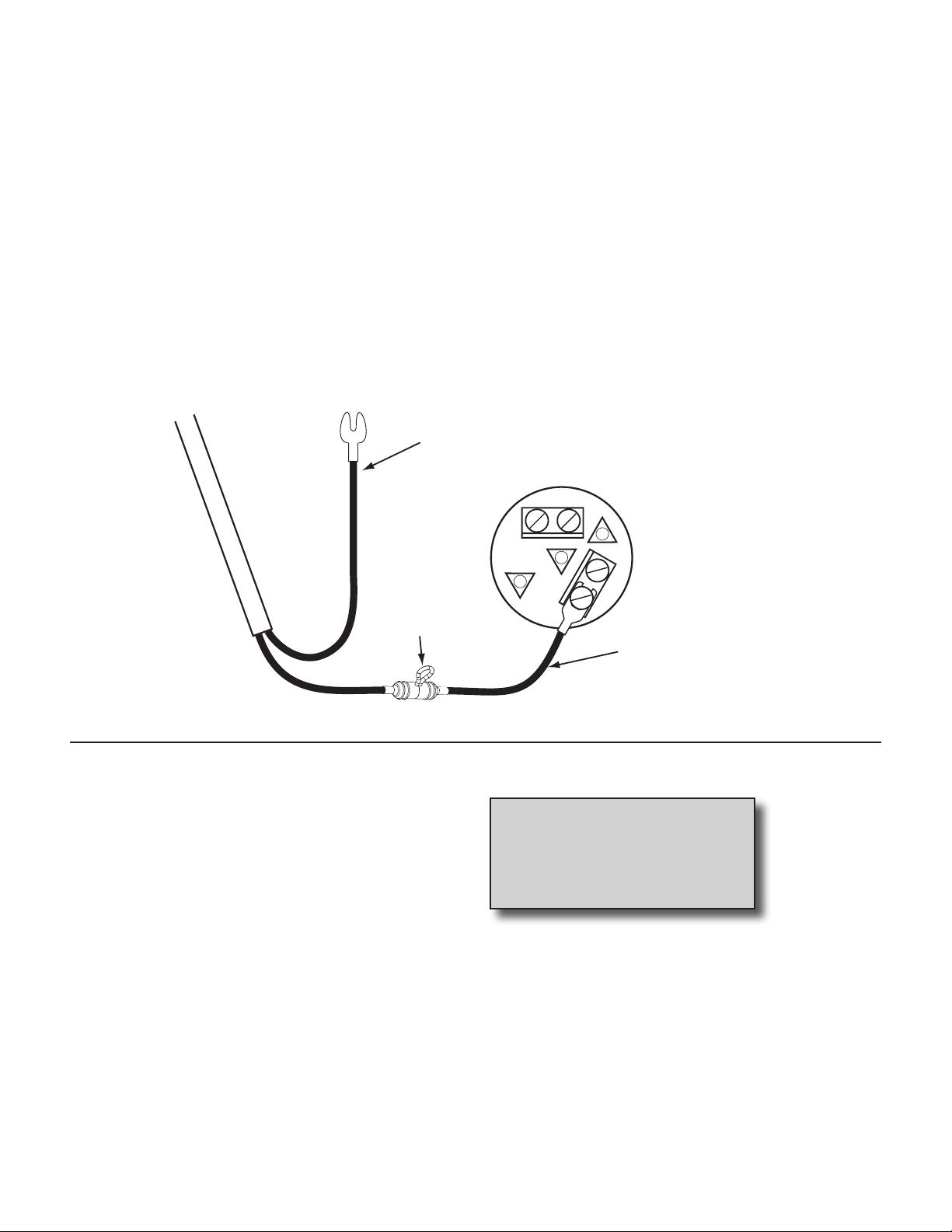

Appendix A: Radar “Y” Cables .....................................................................................................................................................................20

Appendix B: Conversion Tables..................................................................................................................................................................21

Appendix C: Parts List.....................................................................................................................................................................................22