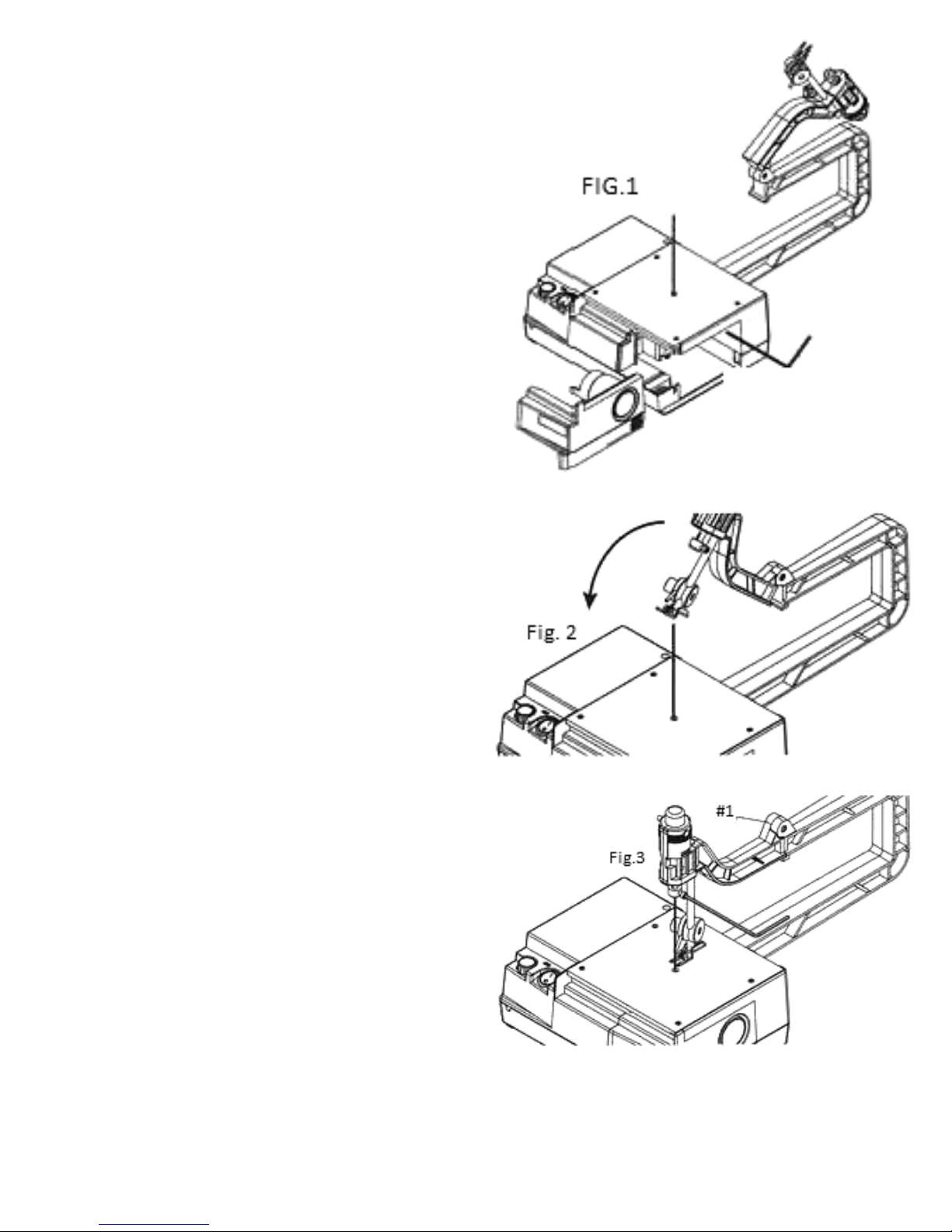

With the lower clamping ring in this position, you can set the

saw down on your table and begin installing your blade.

Loosen the Elbow nob one full turn and raise and lay the

head assembly backward. The lower clamping ring is visible

through the hole in the table top and the slit in the center of

it; here is where you will insert your blade. IMPO TANT:

For proper installation, the teeth of the blade must point

downward and at least 2 teeth should be below the top of the

table. With the premium blades provided, you can count on

4 to 6 teeth being below the table surface when fully inserted

into the slit of the lower clamping ring. Once oriented

correctly, slide the blank end of the blade into the slit until

you reach the bottom of the channel and the teeth are below

as explained above. Using the long end of the hex key,

tighten the set screw firmly with the blade straight up and

perpendicular to the table as shown in Fig.1.

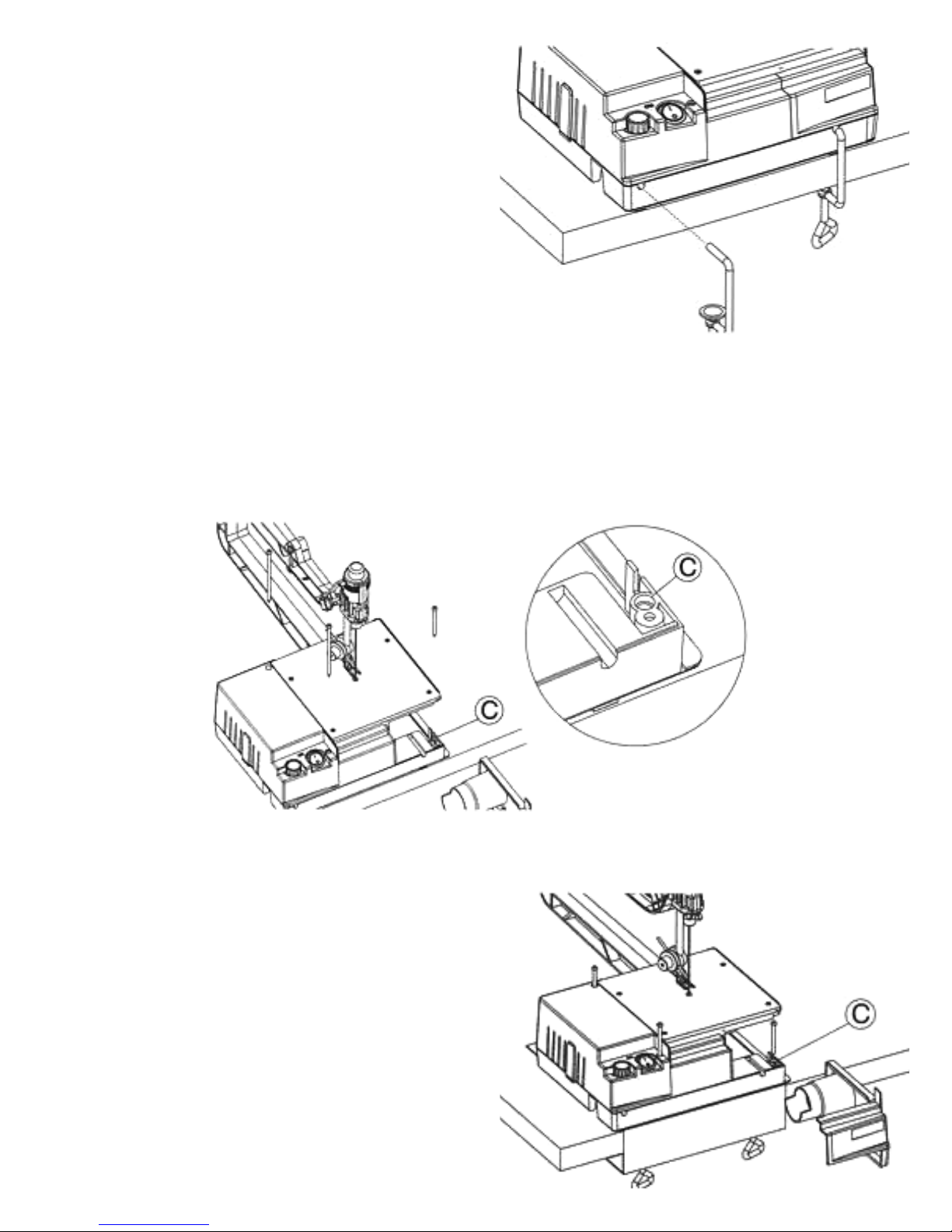

Now refer to Fig. 2. Before you swing the head assembly

forward, remove the Upper Clamping Ring (3). Using the hex

key, loosen the set screw enough so that the Ring slips off of

the upper shaft. Lay the ring on the machine table top for a

moment. Flip the head assembly forward slowly and before

the grooved roller contacts the upright blade, manually bend

the blade forward, allowing it to make room for the assembly

until the head assembly is back down completely. Tighten

the Elbow nob.

It is time to check the positioning of the black roller of the

foot. You want the back of the blade to be lightly in contact

within the groove of the roller. If adjustment is needed,

loosen the screw as described previously in section #2 and

slide it either away from or toward the blade.

A 7 mm hex wrench will work best, as you will not have to

raise the head assembly. Remember, the screw is upside

down to you and to loosen it you need to rotate it “clockwise”

in this position.

If all you have at this time is a phillips screw driver, you will

need to raise the head up, make your adjustment, and test

again by lowering the assembly onto the blade and keep

adjusting in this manner until it is where it needs to be. Each

time, you will need to secure the Elbow nob to check for

proper alignment.

Once adjusted, pull the top of the blade to the left or right of

the head and slip the Clamping Ring over and onto the

blade, allowing it to rest on the foot below.

There is a slit in the upper shaft. Manuever the blade into the

slit. Now, bring up the Clamping Ring, and with the set screw

to the right side, slide it fully up onto the shaft. The set screw

should line up with the indent on the shaft. Slightly secure

the set screw by hand with several turns until it stays in place.

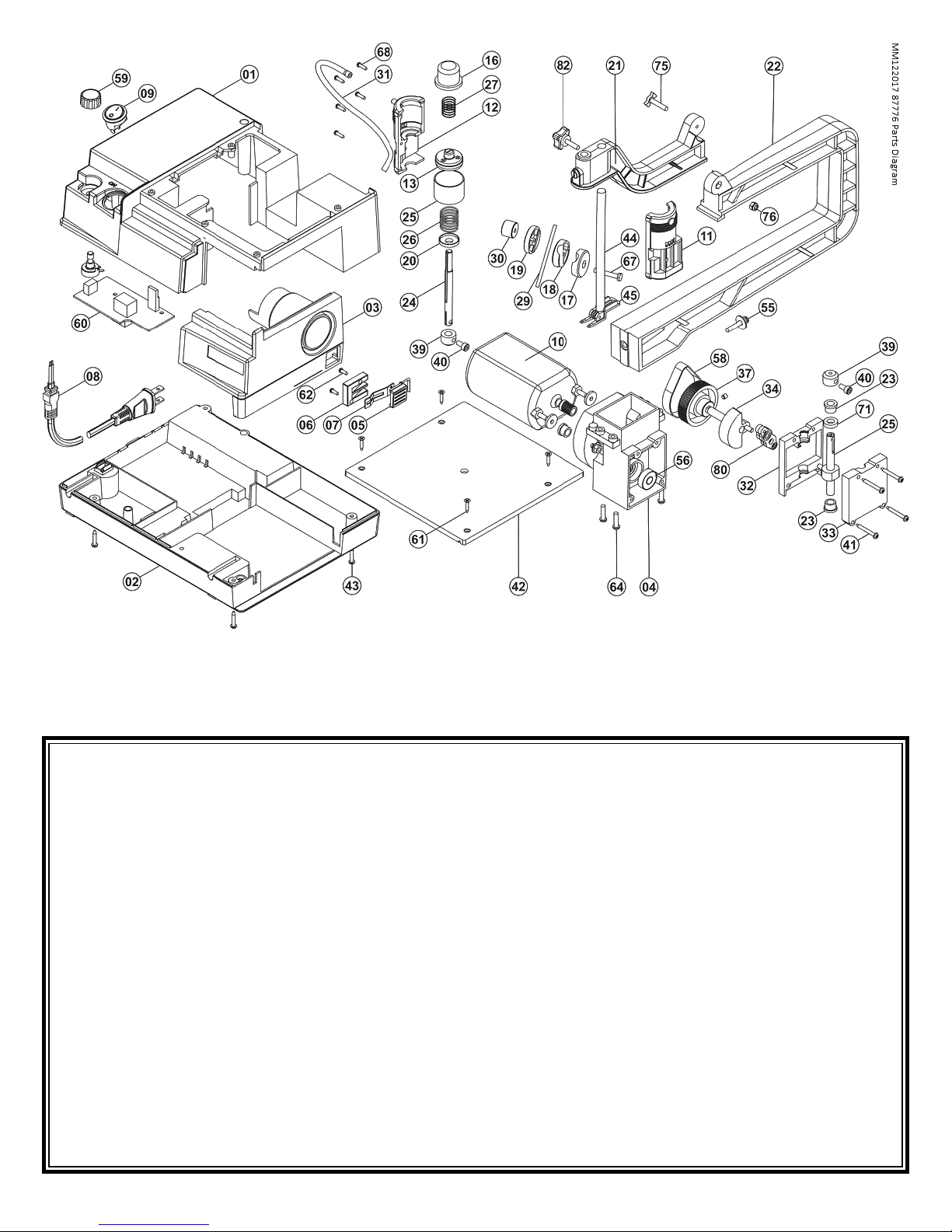

Installation is almost complete. With one hand, push down

on the top black cap of the Dust Blower Assembly (2). You

will feel the inner shaft going down and coming into

contact with the top of the blade. At this point, tighten the

side set screw fully, clamping the blade in place. Note: Do

not push down beyond the point of just “in contact” with the

blade and cause the blade to bow to the side. Nor, do you

leave a large gap of contact. Once you feel it properly in

contact, use your other hand and the Hex Wrench to tighten

the screw fully. Installation is complete. See Fig.3.

Now with all items tightened and tools put away, turn on your

saw. The blade should move in a reciprocating motion without

binding, bumping, bowing or straining. Run through the full

speed range. Place a small piece of paper in front of the

aluminum blower tube and check the airflow. Power the saw

down. The next step is to secure your saw to a bench.