Contents

1. Introduction ...............................................................................................................................................3

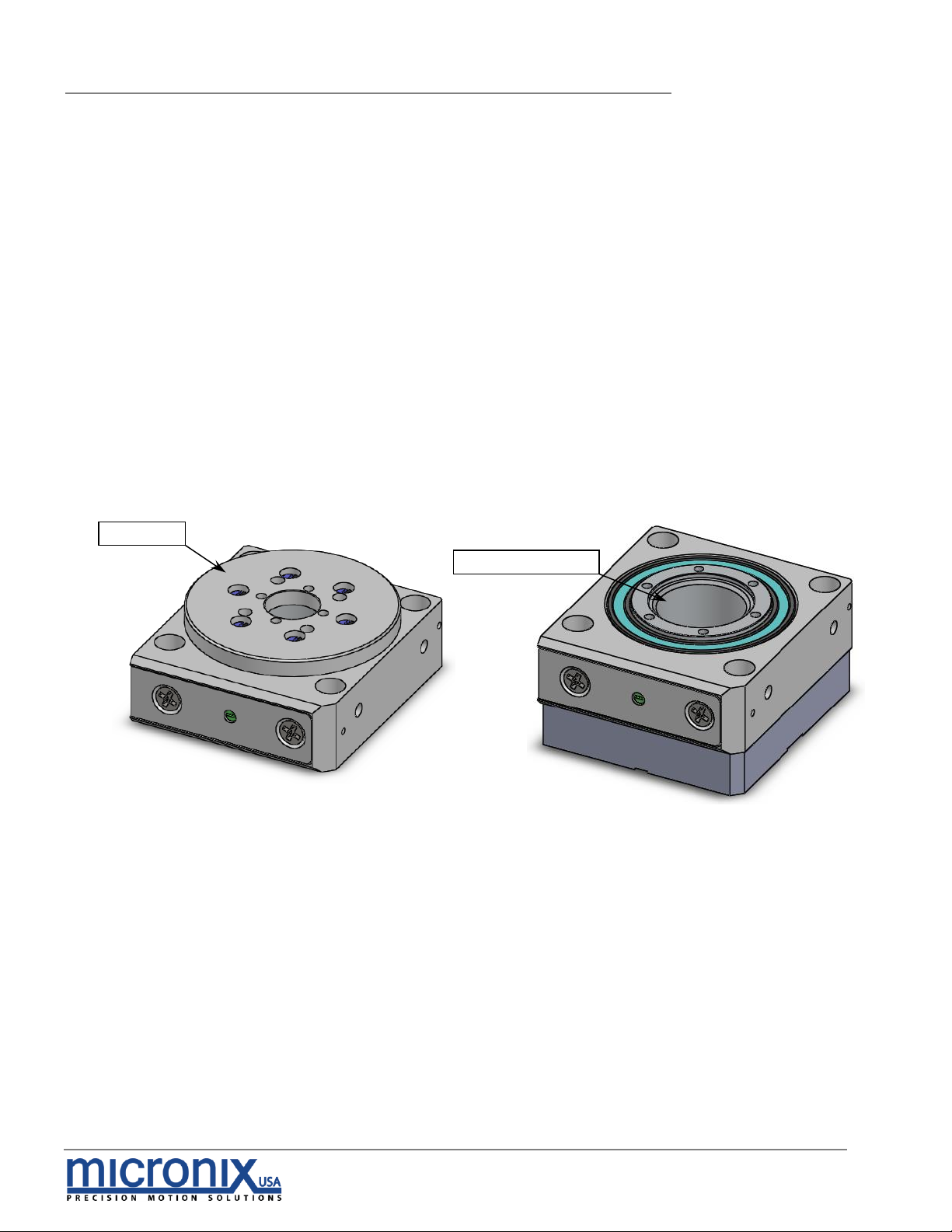

1.1 Product Description ...............................................................................................................................3

1.2 Recommended Controllers ..................................................................................................................4

1.3 Technical Data .......................................................................................................................................4

1.4 Load Characteristics..............................................................................................................................4

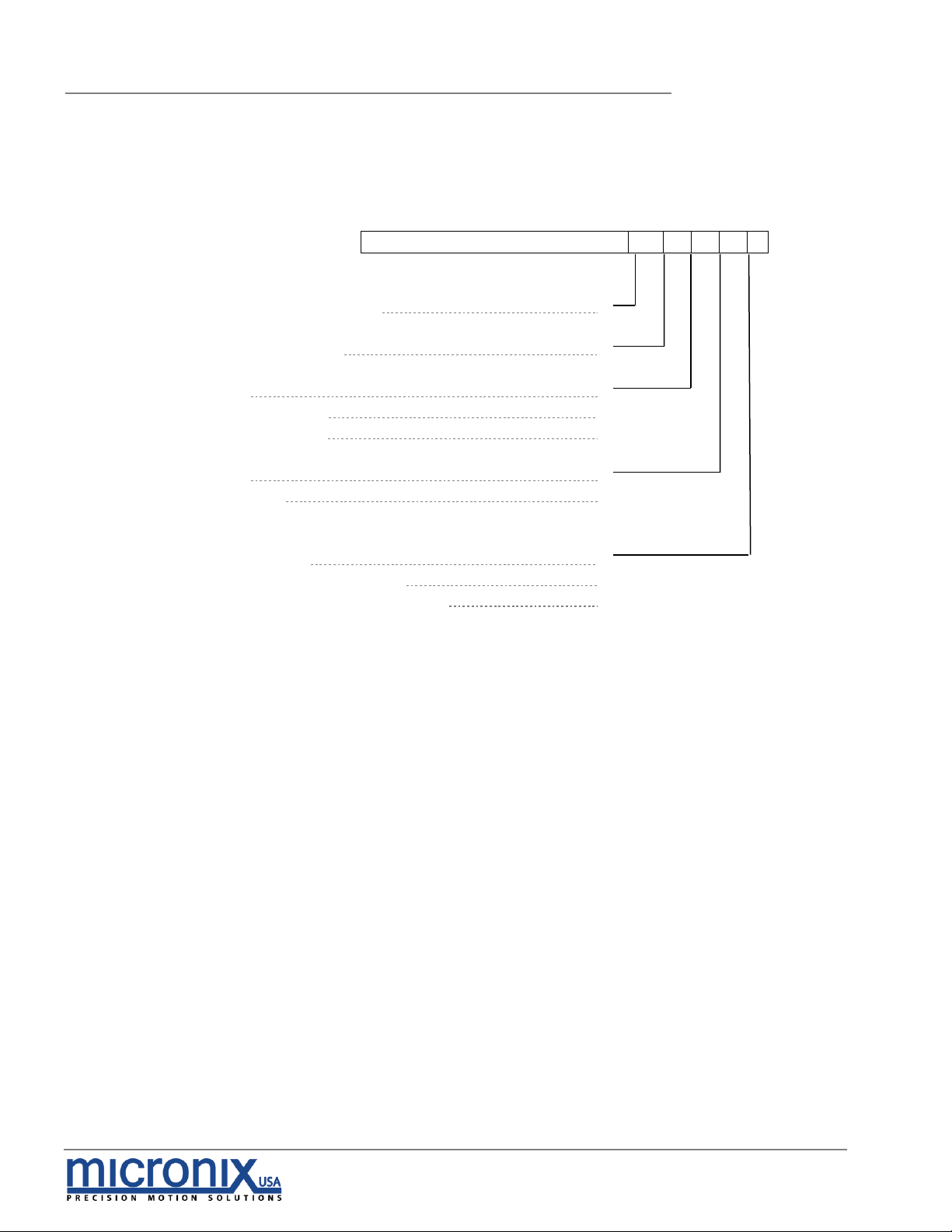

2. Model Configurations ...............................................................................................................................5

2.1 PR-32 Order Numbers.............................................................................................................................5

3. Preparing to Install the PR-32 ...................................................................................................................6

3.1 Installation Preparation..........................................................................................................................6

3.2 Package Contents .................................................................................................................................6

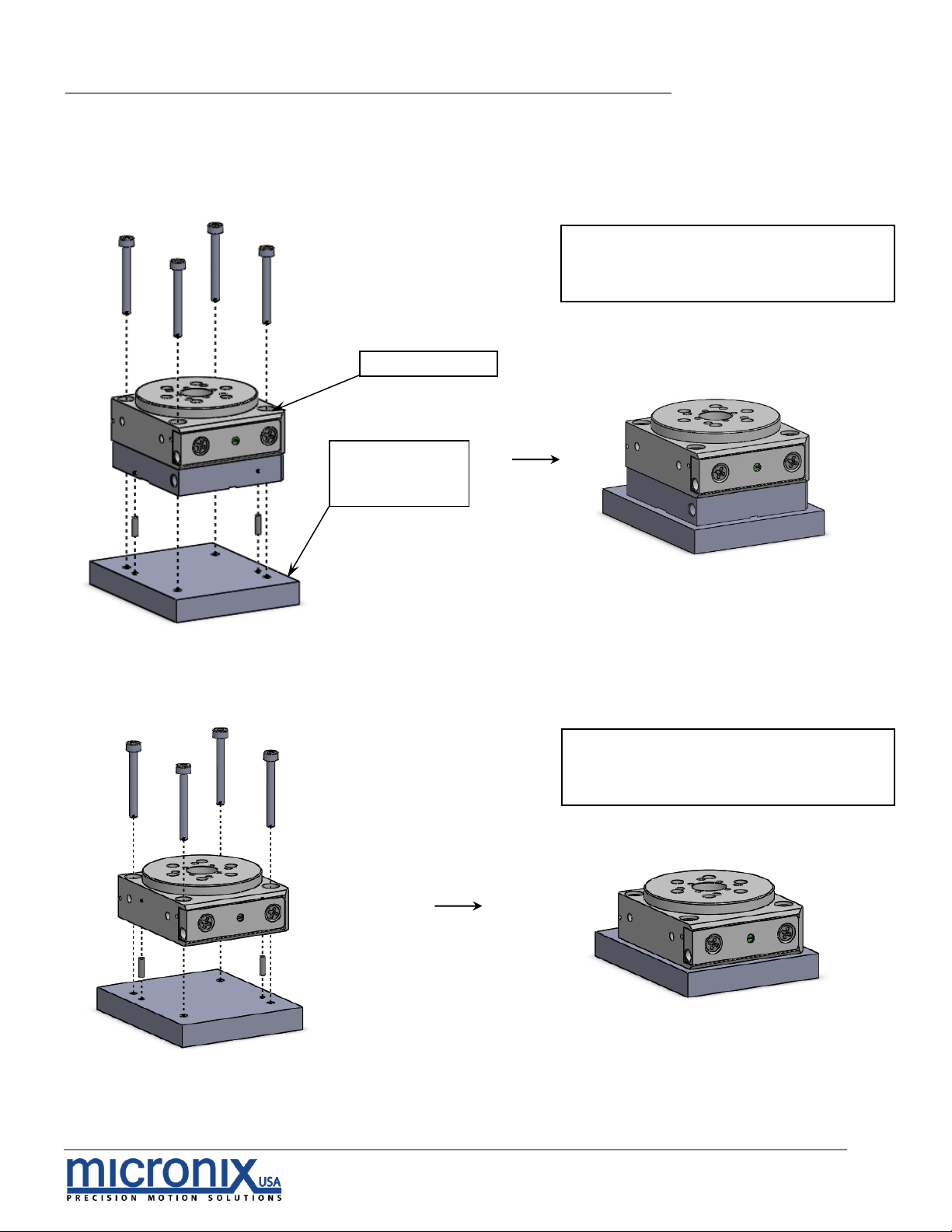

4. Installing the PR-32....................................................................................................................................6

4.1 PR-32 Installation.....................................................................................................................................7

4.1.1 General Mounting...........................................................................................................................7

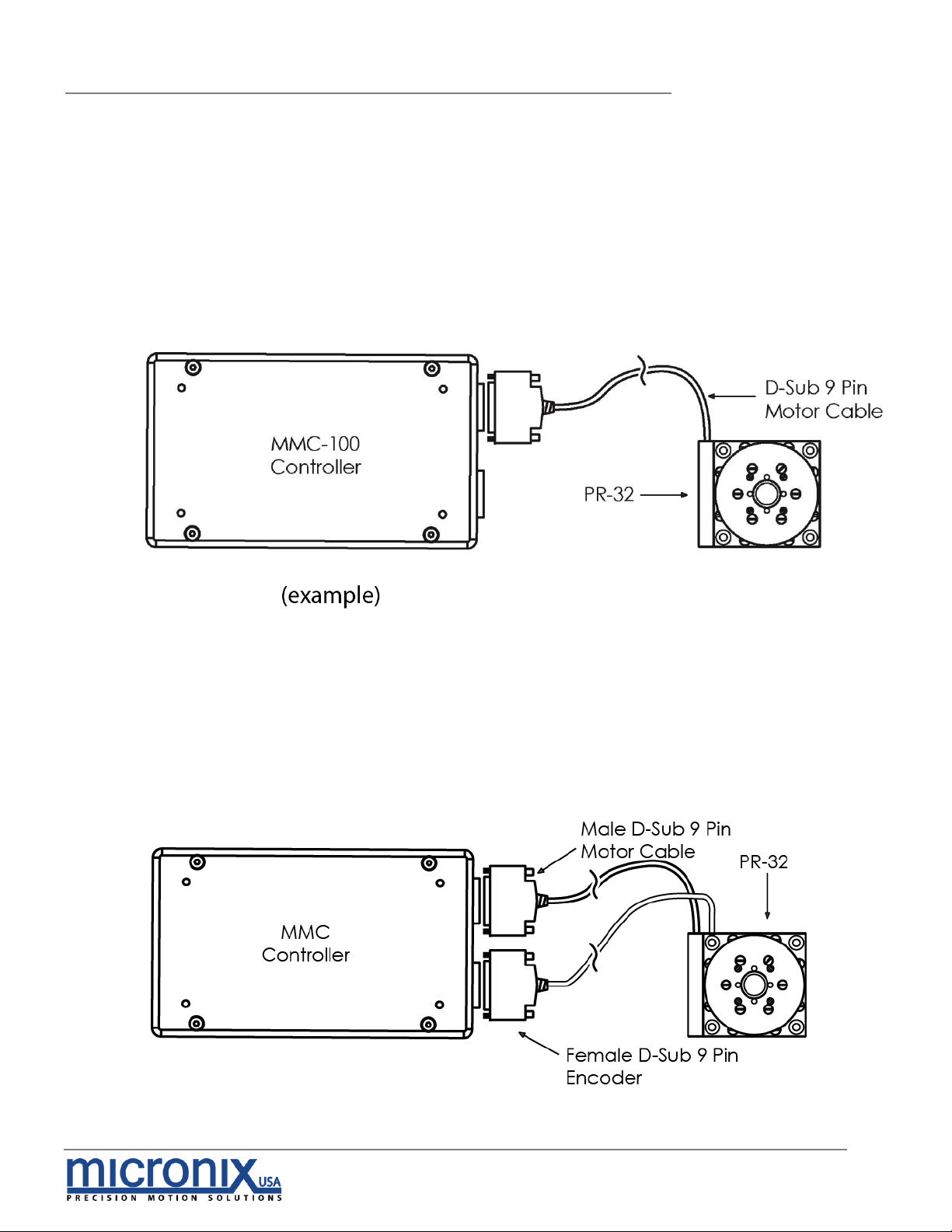

5. Connecting the PR-32...............................................................................................................................8

5.1 Atmospheric Environments ...................................................................................................................8

5.1.1 Open Loop Installation & Wiring Diagram...................................................................................8

5.1.2 Closed Loop/Encoder Installation & Wiring Diagram ................................................................8

5.1.3 Wiring Diagram for Atmospheric System with Analog Encoder ...............................................8

5.2 Vacuum Environments...........................................................................................................................9

5.2.1 Handling and Preparation .............................................................................................................9

5.2.2 Open loop Installation & Wiring Diagram....................................................................................9

5.2.3 Closed Loop/Encoder Installation & Wiring Diagram ................................................................9

6. Technical Specifications ........................................................................................................................10

6.1 Dimensions.............................................................................................................................................10

7. Stacking Configurations .........................................................................................................................11

7.1 Configuration Examples (Additional configurations available upon request)............................11

8. Supplementary Information ...................................................................................................................11

8.1 Units and Conventions.........................................................................................................................11

8.2 Maintenance ........................................................................................................................................11

A. Appendix.................................................................................................................................................12

A.1 Electrical Connections.........................................................................................................................12

A.1.1 DB-9 Male Motor Connector .......................................................................................................12

A.1.2 Encoder Pinout ..............................................................................................................................12

A.2 Phase Piezo Motor Wiring Diagram....................................................................................................12

A.3 Open Loop Vacuum Wiring Diagram ...............................................................................................13

A.3.1 Straight Through 9-Pin Feed Through..........................................................................................13