Absolute encoders – ESAV/ENAV series

www.micronor.com Specifications subject to change without notice, 98-0ENC-04-A, released 11/29/2023

Standard electronic, magnetic

multiturn, singleturn, analog

4. Programming

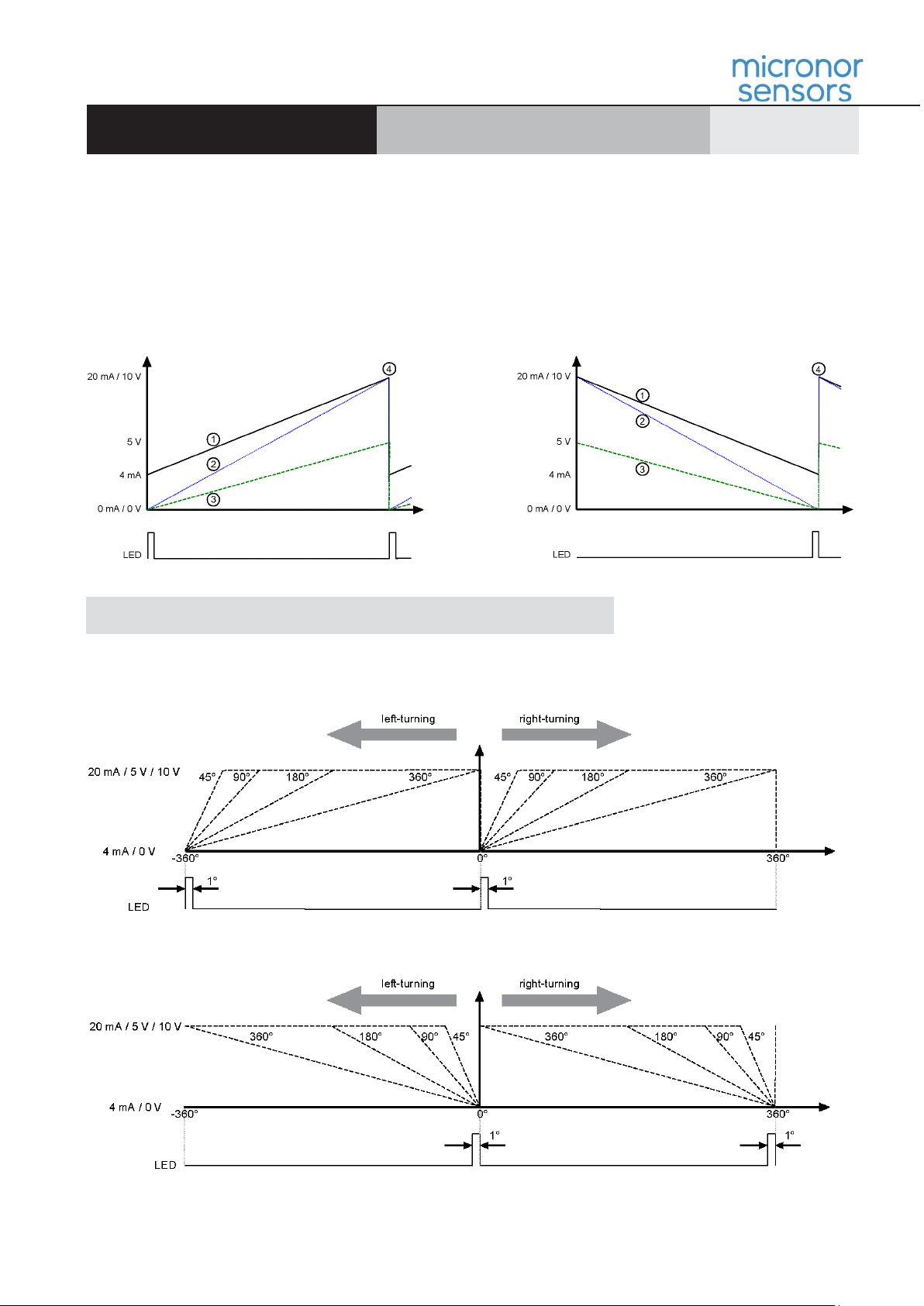

4.1 Scaling function (multiturn only)

Multiturn devices

The encoder is factory-set for a measuring range of 16 revolutions. Linear scaling is applied to the respective output signal.

The encoder is factory-set for a determined output range of 4 … 20 mA / 0 … 10 V / 0 … 5 V. It is scaled linearly over the desired measuring range.

The two scaling inputs SET 1 and SET 2 allow the user to set a measuring range himself. The desired measuring range must be > 22.5° and shall not exceed

65536 revolutions. To restore the default measuring range, apply + V to both SET inputs.

Important Notice:

•To trigger the scaling operation, apply the supply voltage + V to the corresponding scaling input at least 1 second.

•The scaling function is limited to 10,000 cycles. Beyond this limit, the error-free scaling of the output signal cannot be guaranteed.

•Actuate the SET inputs only once the shaft has stopped. Only this way will it be possible to take over properly the desired start and end position of the desired

signal scaling.

•If the inputs are not used, they should be connected to 0V (encoder ground GND), to prevent interferences.

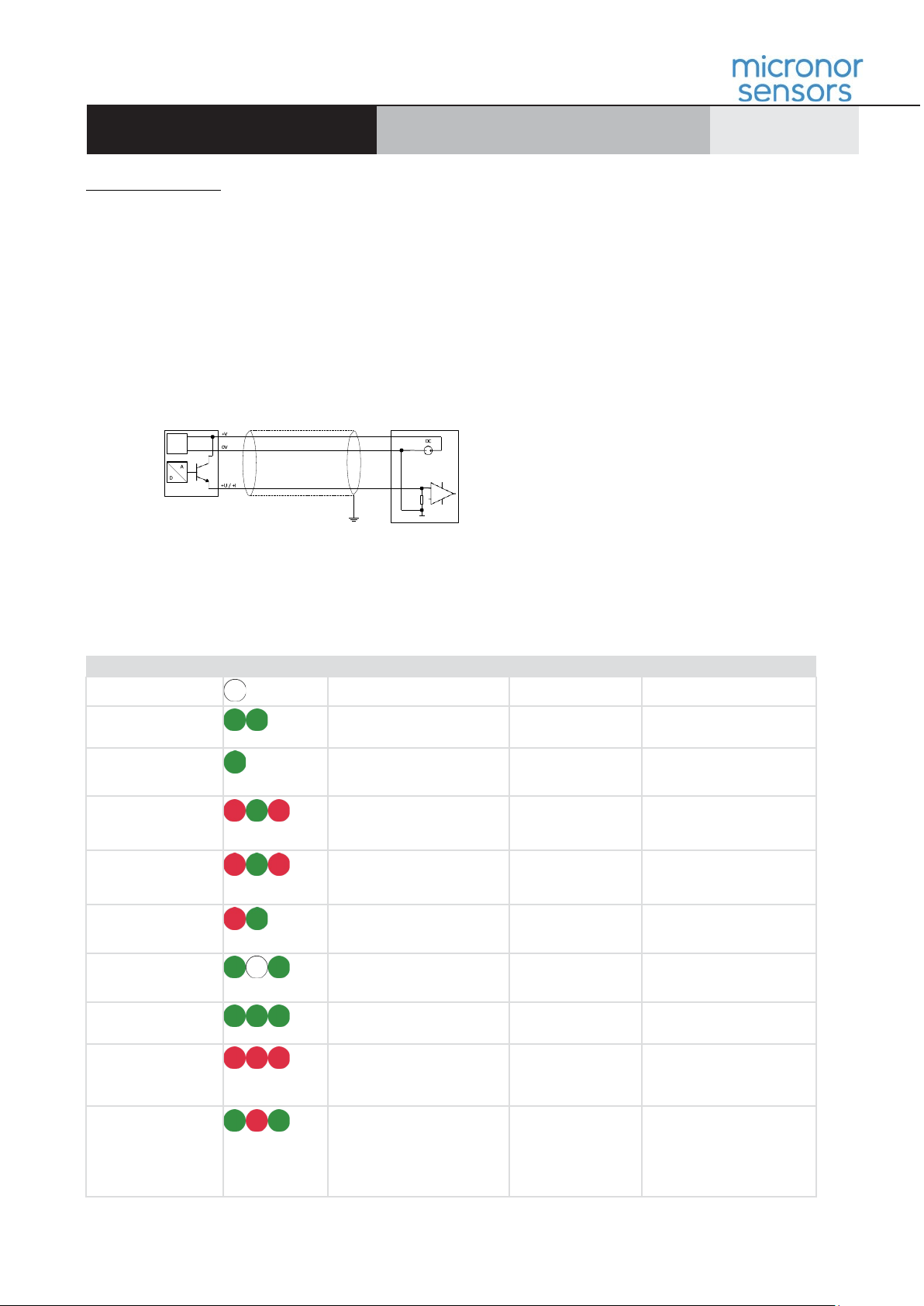

Scaling process for multiturn devices:

1) Turn the shaft to the desired start position.

2) Apply +V to input SET 1 for at least one second.

►The green LED flashes 1x

3) Turn the shaft to the desired end position.

4) Apply +V to input SET 2 for at least one second.

►The green LED flashes 3x. The new measuring range is active. The output signal jumps to the maximum value.

Resetting the scaled output signal for multiturn devices:

1) Make sure that the shaft stands still.

2) Apply +V to input SET 1 for at least one second.

►The green LED flashes 1x

3) Turn the shaft to the desired end position.

4) Apply +V to input SET 2 for at least one second.

►The green LED flashes 3x. The new measuring range is active. The output signal jumps to the maximum value.

If the inputs are not used, they must be connected to 0 V (encoder ground GND), to prevent in- terferences.

input SET 2 input Function

Setting the start position

Resetting to the default measuring range

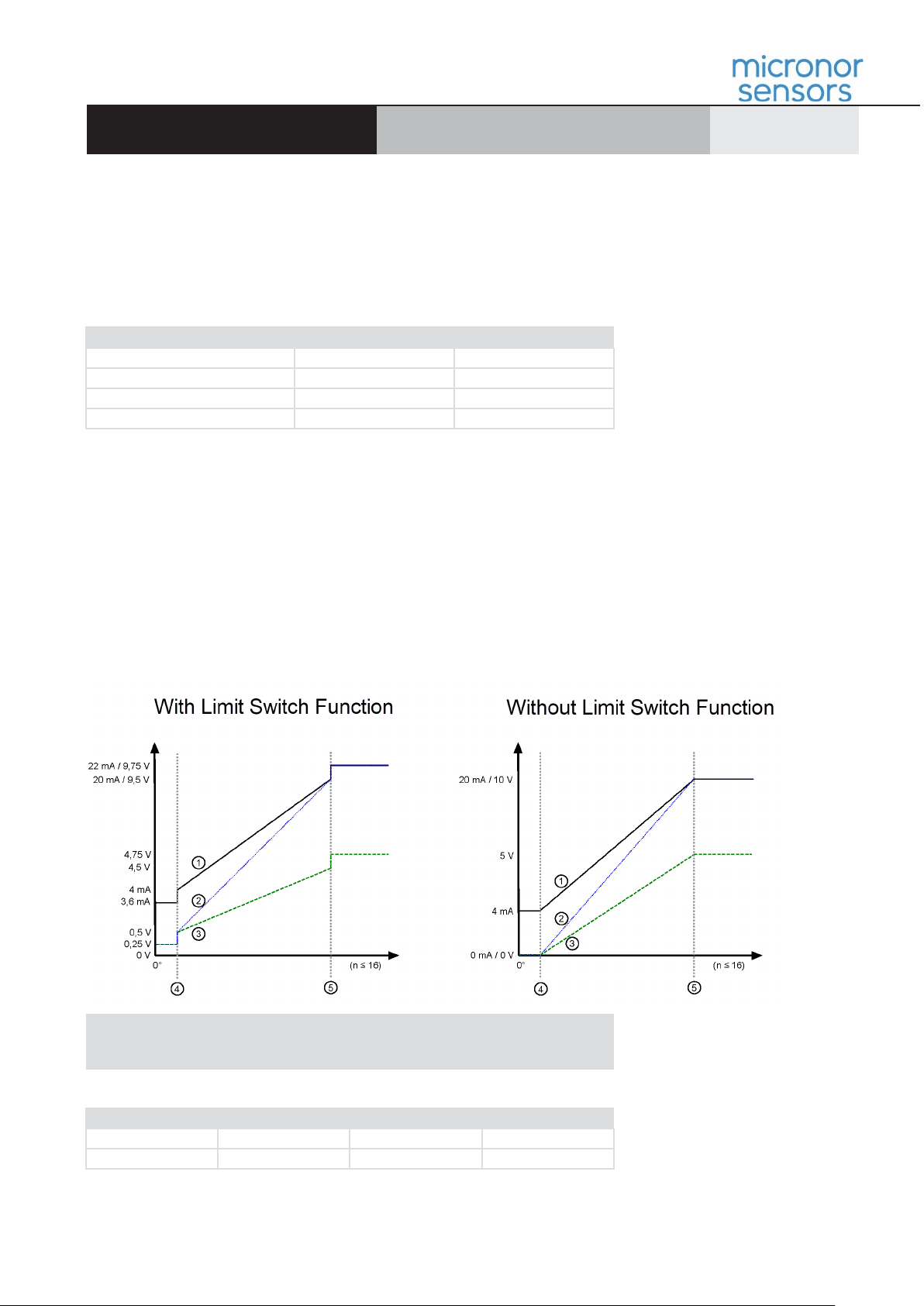

Singleturn devices

For singleturn devices, the measuring range cannot be scaled. It is factory-preset and displayed by the reference point display. However, the measuring range can be

shifted by the Zero set function.

Reference point display for singleturn devices:

With the factory-set "default" scaling, the LED displays the reference point of 0 ... 1°. The reference point display is no longer available if another measuring range is

scaled using the scaling inputs.

4.2 Zero Set Function (singleturn only)

With singleturn devices, the Zero set function allows shifting the measuring range. For this purpose, the current position is set to 0. The size of the measuring range

remains unchanged.

If this input is not used, it must be connected to 0V (encoder ground GND), to prevent interferences.

Zero set with singleturn devices:

1) Turn the shaft to the desired start position.

2) Apply +V to input SET 1 for at least one second.

►The green LED flashes 3x – green/red/green. The new measuring range is active