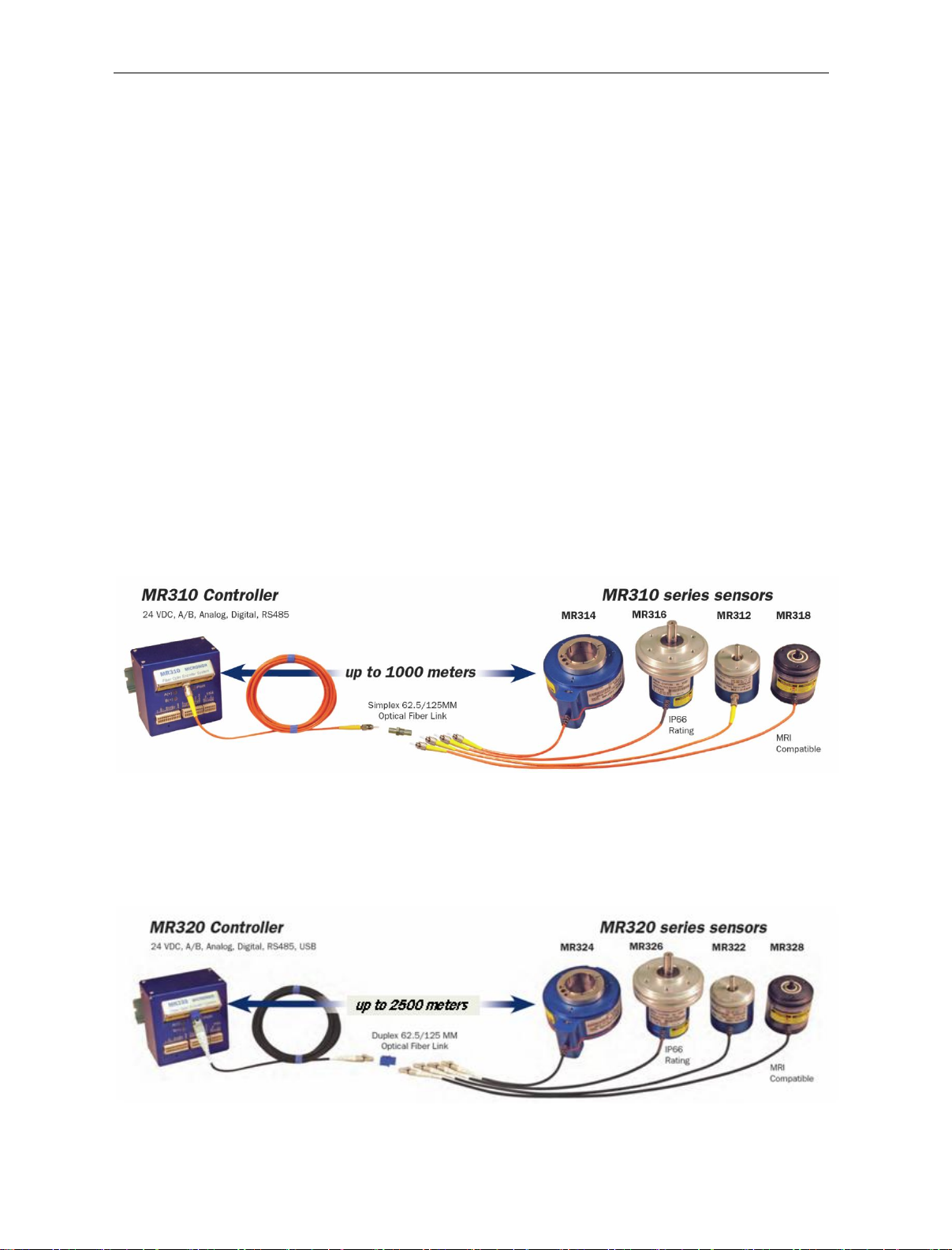

MICRONOR INC. MR310/MR320 Series ZapFREE® Encoder System

Page 5 of 94

6.2.1 Serial Interface Specification ................................................................46

6.2.2 Communications Protocol .....................................................................46

6.2.3 The Block Check Character <BCC>.......................................................48

6.3 Configuration Commands and Parameters ................................................48

6.3.1 Configuration Commands (Registers 10-19) .......................................50

6.3.2 User Commands (Registers 20-2A) ......................................................51

6.3.3 Diagnostic Commands (Registers 30-39) ............................................53

6.4 Communications/Programming Example ..................................................53

6.5 Detailed Description of Each Function.........................................................55

6.5.1 Counter (Register 20).............................................................................55

6.5.2 Divider (Register 21) ..............................................................................55

6.5.3 RPM (Register 22) ..................................................................................56

6.5.4 Voltage Mode (Register 23)...................................................................56

6.5.5 Voltage Scale (Register 24) ...................................................................58

6.5.6 Voltage Filter (Register 25)....................................................................59

6.5.7 Current Mode (Register 26) ...................................................................60

6.5.8 Current Scale (Register 27) ...................................................................64

6.5.9 Current Filter (Register 28)....................................................................64

6.5.10 Counter Reset (Register 29) ..............................................................65

6.5.11 Counter Multiplier (Register 2A)........................................................66

6.5.12 Encoder Direction (Register 2B) ........................................................67

6.5.13 Hardware Reset Value (Register 2C).................................................68

6.5.14 Reset On Count/Homing (Register 2D) ...........................................69

6.5.15 Saving Parameters in EEPROM (Register 13)..................................70

7. Maintenance and Service ...................................................................................71

7.3 Encoder Will Not Produce Quadrature Signals............................................71

7.1.1 LED’s Do Light Up ...................................................................................71

7.1.2 LED’s Do NOT Light Up ...........................................................................71

7.2 Serial Interface...............................................................................................72

7.2.1 Testing The Interface Cable ...................................................................72

7.3 Fiber Optic Connector Cleaning ....................................................................73

7.3.1 WET Cleaning Method............................................................................74

7.3.2 DRY Cleaning Method - Micronor MR321 DRY Cleaning Kit ..............74

7.4 Troubleshooting .............................................................................................75

7.4.1 Verify MR310 Operation using ZAPPYSoftware ..............................75

7.4.2 Verify Visual Continuity of Fiber Optic Cable Link................................76

7.4.3 Verify Optical Output Power of MR310 Module...................................77

7.4.4 Verify Loss Condition of the Optical Cable Link ...................................77

7.4.5 Built-In System Analysis of Complete Fiber Optic Encoder System and Link

78

7.5 Blinking Error Codes ......................................................................................80

8. Reference Drawings ............................................................................................81