MR330 Fiber Optic Position Sensor System

Page 3 of 62

Table of Contents

Revision History ..........................................................................................................................................2

1. Product Description.............................................................................................................................5

1.1 Position Sensor Background .......................................................................................... 5

1.2 Fiber Optic Position Sensor ............................................................................................ 5

1.3 Features........................................................................................................................... 6

2. Initial Preparation................................................................................................................................7

2.1 Unpacking and Inspection .............................................................................................. 7

2.2 Damage in Shipment ...................................................................................................... 7

2.3 Standard Contents.......................................................................................................... 7

3. Installation and Operation ..................................................................................................................8

3.1 Mounting the Sensor Unit............................................................................................... 8

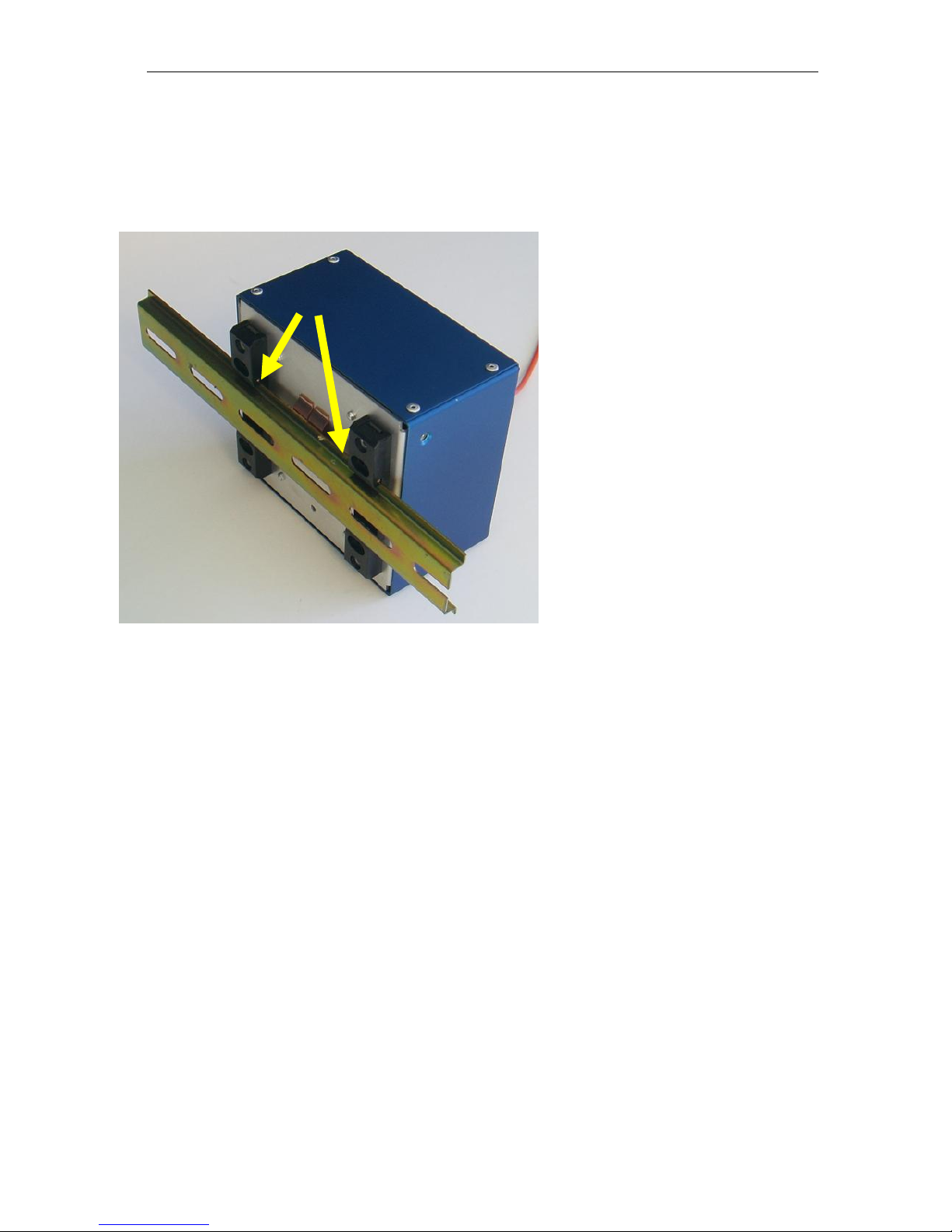

3.2 Mounting the Controller Unit .......................................................................................... 9

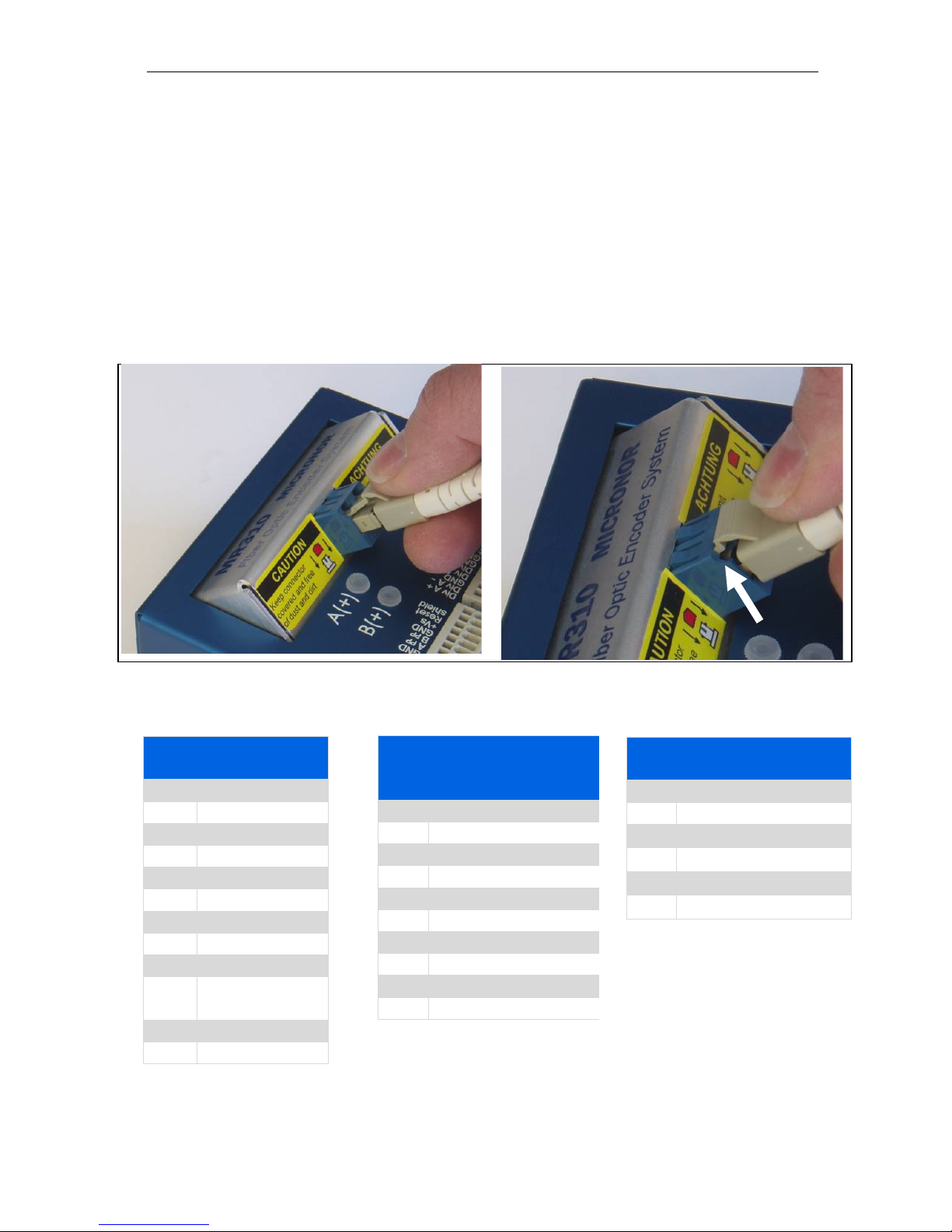

3.3 Connecting the Controller.............................................................................................10

3.4 System Start-Up without PC Computer ........................................................................13

3.5 Functional System Overview.........................................................................................14

3.6 Turn-Counter or Turn-Counter Size...............................................................................16

3.7 Multi-Turn Operation .....................................................................................................17

3.8 Battery Backup for Multi-Turn Operation.....................................................................18

3.9 SSI Interface ..................................................................................................................18

3.10 Voltage Output...............................................................................................................20

3.11 Isolated Current Output (4-20mA)................................................................................22

3.12 Digital Set Points...........................................................................................................23

4. Serial Communication – MODBUS.................................................................................................. 25

4.1 USB-Serial Emulator......................................................................................................25

4.2 Serial Interface Specification .......................................................................................26

4.3 Physical Connection for ModBus operation ................................................................26

4.4 Serial Bus Termination Resistor...................................................................................27

4.5 MODBUS Communications Protocol ............................................................................27

5. MR330 - Error Handling and Troubleshooting................................................................................ 34

5.1 Explanation of Status and Error Handling ...................................................................34

5.2 Explanation of Status and Error Indication..................................................................34

5.3 Reading the Error Counters..........................................................................................38

5.4 About Statistical Read Error Determination ................................................................38

5.5 Warranty Information ....................................................................................................40

6. Specifications................................................................................................................................... 41