Table of Contents

1. Safety Instruction.......................................................................... 1

1.1 Electrocution ...............................................................................................1

1.2 Grounding....................................................................................................1

1.3 Power Source...............................................................................................1

1.4 Connecting the Tester Table to the High Voltage Output Terminal.............2

1.5 Warm-up......................................................................................................2

1.6 External control unit ....................................................................................2

1.7 Machine failure............................................................................................2

1.8 Ending the test.............................................................................................2

1.9 Installation, storage .....................................................................................3

1.10 Emergency treatment...................................................................................3

2General Summary ......................................................................... 4

2.1 Package and Accessories .............................................................................4

2.2 Front Panel................................................................................................... 5

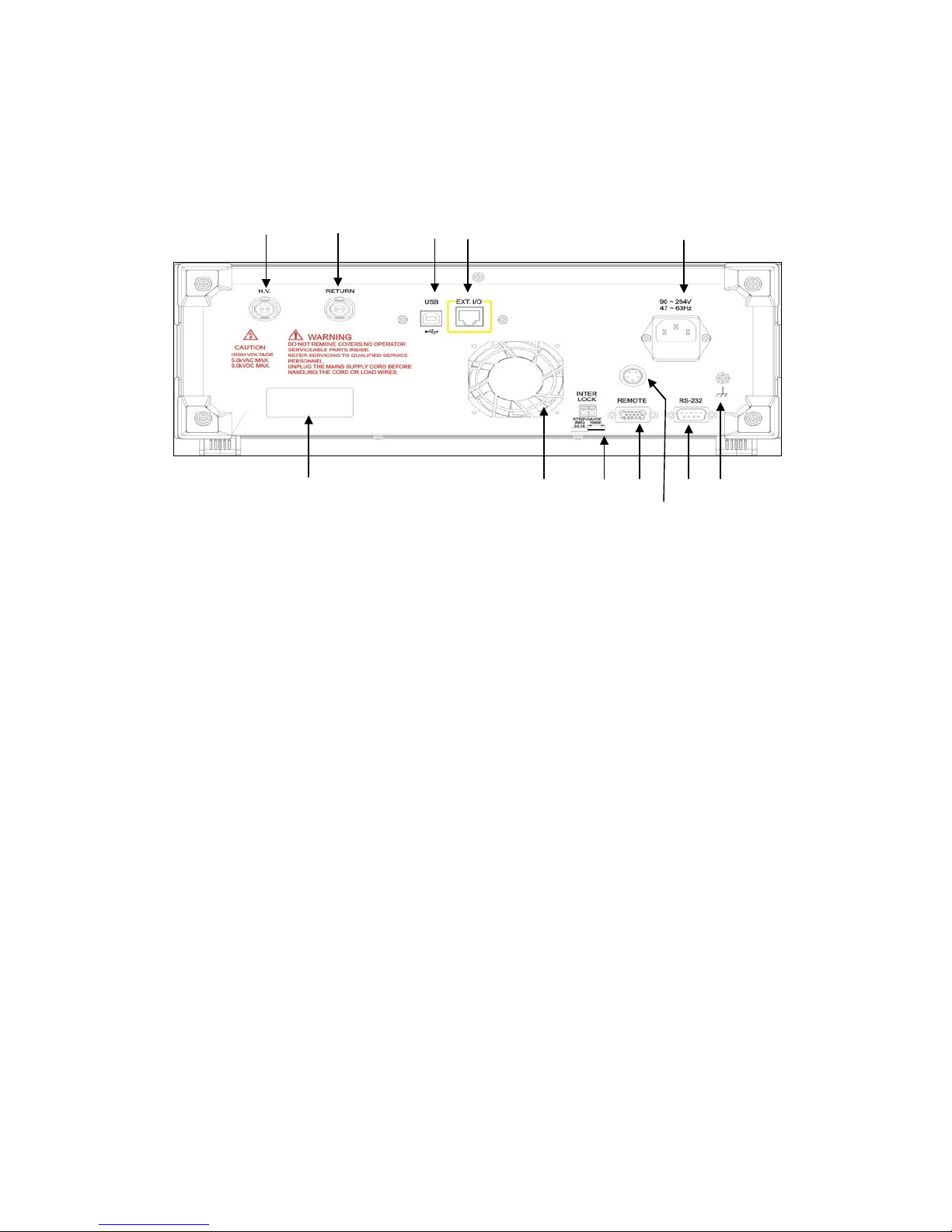

2.3 Rear Panel....................................................................................................6

3Basic operation ............................................................................. 7

3.1 Function block diagram................................................................................7

3.2 Standby screen.............................................................................................8

3.3 System settings (SYSTEM) ..........................................................................10

3.4 Function (FUNC).........................................................................................12

3.5 Specification setup 1 (SETUP) ....................................................................14

3.6 Specification setup 2 (SETUP) ....................................................................16

3.7 File management (FILE)..............................................................................18

4Start testing ................................................................................ 21

4.1 Before testing .............................................................................................21

4.2 Testing in progress......................................................................................22

4.3 Ending a Test ..............................................................................................23

4.4 Release determination results ...................................................................24

5Remote control I/O (REMOTE) .................................................... 25

6RS-232/USB device...................................................................... 28

6.1 RS- 232 interface ........................................................................................28

6.2 Command format.......................................................................................28

6.3 Connector...................................................................................................28