© 2007 MidNite Solar Page 1

MNE-240 Series E-Panel Owner’s Manual

1.0 Introduction

The MNE-240 Series E-Panel enclosure from MidNite Solar provides the basic DC and AC over-

current protection and disconnects required for a NEC compliant renewable energy system. It is

specifically designed to accommodate inverters that provide 120/240VAC in a single unit. The

MNE-240 Series E-Panel can expand to grow as your needs arise and includes the following:

• Powder-coated steel chassis with knockouts to accommodate various install needs.

• Inverter mounts on a unique hinged door to keep a small system foot-print

• E-Panel mounting brackets are included to aid in one person installations

• Inverter battery breaker, inverters cables and snap in grommets included

• 500 amp/50 mV shunt included for battery monitoring systems

• Heavy duty 150 amp bus-bars for AC HOT, NEUTRAL, GROUND, BATT +/- and PV + included

• Dual 50 amp AC input disconnects for generator or utility (prewired)

• Dual 50 amp inverter AC Bypass Switch (prewired)

• Bracket included for mounting optional charge controller (Classic or MX60)

• Inverter, remote control and charge controller mounting hardware included

• One rectangular cut-out for mounting a North American GFCI style AC outlet

• Cut-outs for mounting up to six additional 13mm wide din-rail mount AC and DC breakers (for

circuits such as PV, wind, hydro or AC distribution)

• Conforms to UL508A 1st Edition and CSA C22.2 #14-M95 (Industrial Control Panel)

2.0 Features

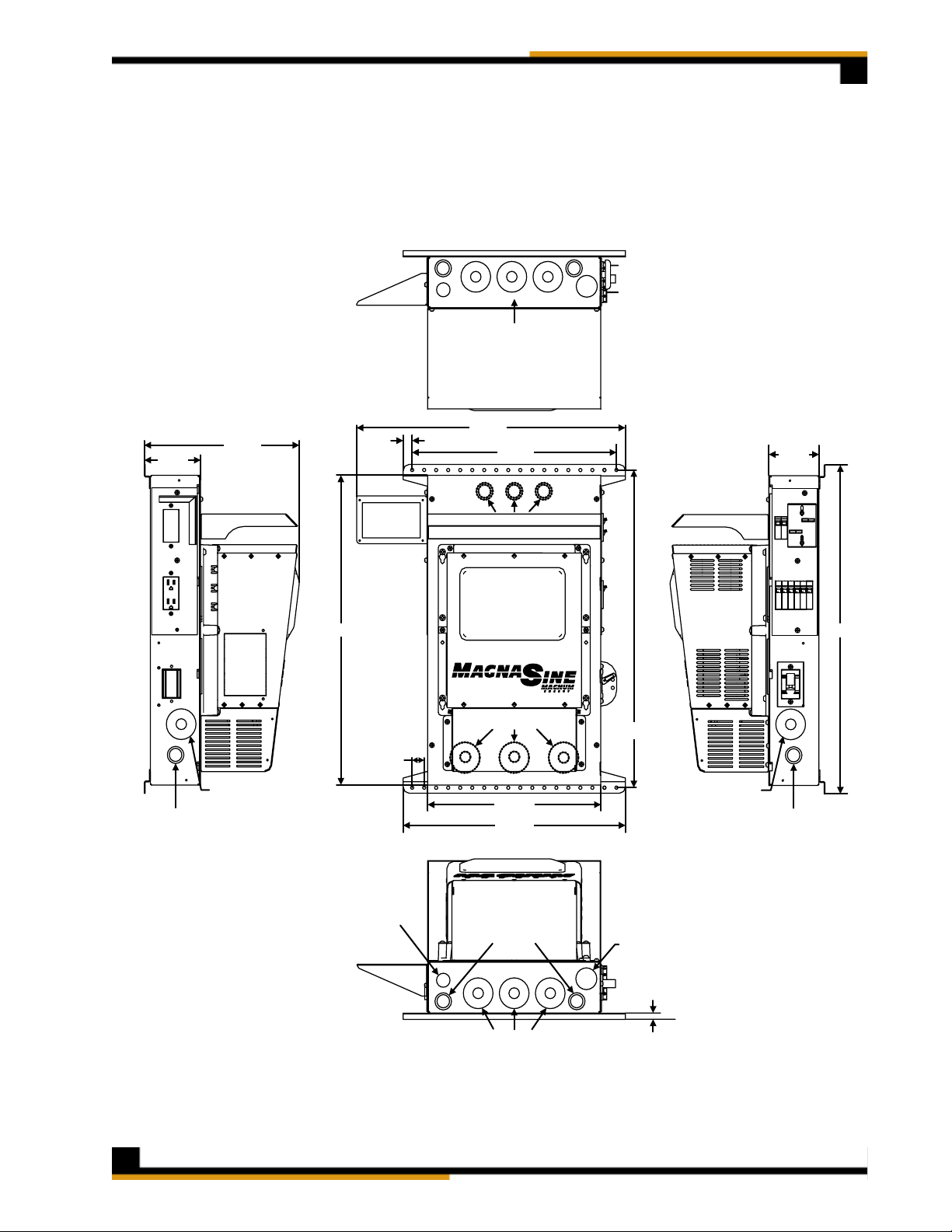

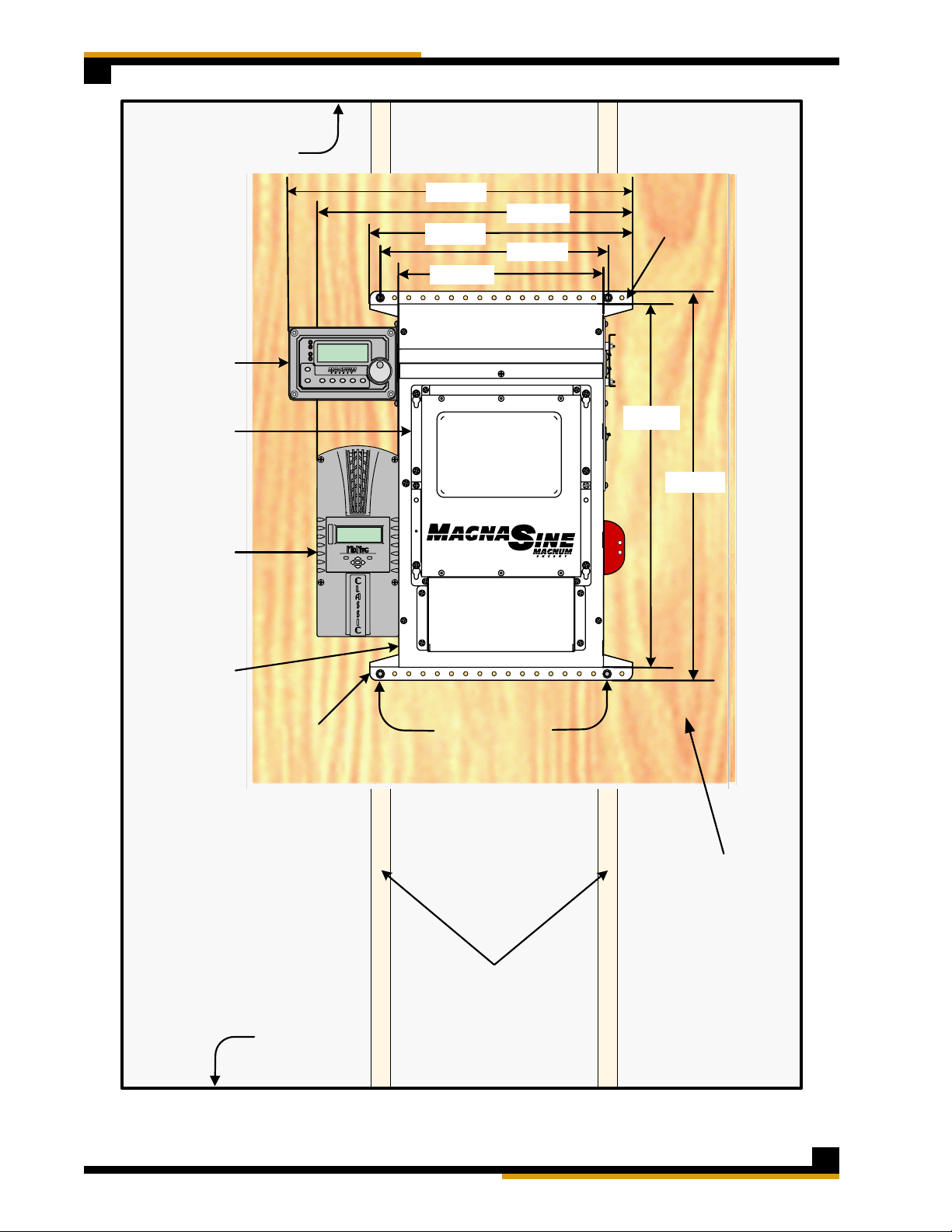

Refer to Figure 1 for the following information.

The MNE-240 Series E-Panel incorporates all the AC and DC wiring bus-bars and disconnects

required to connect the Magnum MS-AE Series inverter/charger system.

It also provides additional room to install additional equipment, such as the MidNite Classic Charge

controller (with accompanying solar array breakers/disconnects and battery temp sensors), the

Magnum Battery Monitor, a PV Ground Fault device, and AC branch breakers (that can be used

in lieu of an AC sub-panel to power the inverter’s AC loads). These additional breakers are

installed on a supplied Din-rail mounting bracket that has space for up to six 13mm sized AC or

DC breakers.

The E-Panel includes a DC Breaker used to disconnect the battery bank from the inverter as

required by the National Electric Code (NEC). This breaker is also used as an overcurrent device

to protect against extremely high currents that a battery is capable of producing if any short

circuits occur. A variety of DC Breaker options are available from MidNite Solar.

Next to the DC Breaker is a 500 amp/50 mV shunt with a DC negative bus-bar attached. The

shunt is provided so that a Battery Monitor, which is used to determine the battery bank’s state

of charge, may be easily connected without any rewiring. The DC negative bus-bar provides a DC

negative connection point for any DC loads or PV Panels in the installation.

Located on the right side of the E-Panel system is an AC input disconnect and an inverter bypass

switch. The AC disconnect is used to remove the incoming AC power to the inverter input. The

inverter bypass switch is provided to easily route the incoming AC power around the inverter and

directly to the AC loads in the system - without rewiring or losing power to the AC loads in the

system - in case the inverter needs to be removed.