Miki Pulley COUPLINGS User manual

COUPLINGS

Flexible Couplings and Hub-shaft Connections

'09.06-0-SO-COUP2(e)-001A

COUPLINGS Flexible Couplings and Hub-shaft Connections

461 Imai-Minami-cho, Nakahara-Ku, Kawasaki-City, Kanagawa, Japan

4

High-reliability

Metal Plate Spring

Format Realizing

Its Best Shape

Through Finite

Element Analysis

SERVO FLEX is an ultrahigh-rigidity flexible coupling derived from Miki Pulley's unique development capability.

It has gained high reliability by its layered plate spring format as its best shape, which is rigid in the

torsional direction and flexible in the bending asymmetrical and axial directions.

SERVO FLEX is also available in a variety of models to cover a wide range of fields and purposes, and this full

selection contributes to the higher precision and efficiency of instruments.

S E R V O F L E X

5

6

F L E X I B L E C O U P L I N G SS E R V O F L E X

High-reliability Metal Plate Spring Format

When jointing a shaft to another shaft, it is extremely difficult to precisely center these two shafts.

It is even more difficult to maintain the centering due to problems such as shaft deflection and shaft thermal expansion as a result

of operating machine equipment, support block distortion after long hours of use, abrasion of the bearing, and for other reasons.

The role of flexible couplings is not only simply to joint the driving shaft and driven shaft but also to resolve the above problems by

selecting appropriate flexible couplings suitable for each purpose.

An optimal design using the advanced finite element method (FEM) is applied for the plate spring shape and

strength design of each model, which are important for the performance of the couplings, and thorough

model analysis is performed by 3D-CAD.

Optimal Design by 3D-CAD and FEM

BENDING RADIALTORQUE THRUST

SFS-SS SFC-SA2 SFC-DA2

0

20,000

15,000

10,000

5,000

Pin bush

Types of coupling

Oldham Cross-slit Heli-cal

Torsional rigidity [N·m/rad]

Ultrahigh-rigidity Metal Plate Spring Flexible Couplings

A layered metal plate spring is adopted for the power transmission part of SERVO FLEX, enabling ideal performance

of the flexible coupling, which is rigid in the torsional direction and flexible in the bending asymmetrical and axial

directions.

7

F L E X I B L E C O U P L I N G S

The stainless-steel plate spring reduces thermal conduction from a servo motor to the driven shaft, which also reduces variations in

accuracy caused by thermal expansion.

80

70

60

50

40

30

20

10

00 15 30 45 60 75 90 105 120 135 150 165 180

A

B

C

Time [min]

Temperature [°C]

ABC

Heat Rejection

Backlash

Pseudo backlash

No Backlash

Elastic (metal) coupling

Metal plate spring: SERVOFLEX

Elastic (rubber and resin) coupling

Rubber, resin compression and resin

plate spring, etc

Corrected coupling

Oldham, pin bush, etc.

The power transmission of SERVO FLEX is performed entirely by a friction lock, enabling no backlash, accurate shaft rotation, and

ultraprecision control operation.

No Backlash

8

Full Selection

òSuperbly strong high-strength aluminum alloy adopted

òLow inertia achieved by the shaft diameter interlock-type hub outer diameter

òNo hazardous substances used, RoHS Directive compliant

òHigh-rigidity single element

òHigh-flexibility double element

òTaper shaft-compatible adapter

òClamp mounting only with one bolt

SFC MODEL

òWide selection

òHigh-rigidity single element

òHigh-flexibility double element

òFloating shaft suitable for long shaft intervals

òTaper shaft-compatible hub

òSelectable from finished-assembly products and parts-delivered products

òShaft bore design freely made from a pilot bore and a simple, strong friction lock

F U L L L I N E U PS E R V O F L E X

SFS MODEL

9

òSFM for the machine tool main shaft, SFF for the feed shaft

òThe main shaft-compatible type allows a maximum rotation speed of 20000 min–1.

òHigh-precision mounting by using an excellent centering mechanism

òIrregularity removed to the extent possible and wind roar lowered during high-speed rotation

òHigh-rigidity single element

òHigh-flexibility double element

òUltrahigh torque transmission of 8000 N·m

òUnique plate spring shape in order to equally combine high torque transmission and flexibility

òHigh-rigidity single element

òHigh-flexibility floating shaft

òShaft bore design freely made from a pilot bore

F U L L L I N E U P

SFF·SFM MODEL

SFH MODEL

10

Two types of couplings, either a rigid type with one element or a flexible type

with two elements using a spacer, can be selected.

The clamp method, an easy and exact installation method with no backlash,

is adopted for the shaft installation method.

Moreover, it is compatible with the taper shaft by using an adapter.

It also complies with the EU Restriction of Hazardous Substances Directive,

“RoHS Directive” that prohibits six hazardous substances

such as mercury, lead, and others.

SERVO FLEX: A Wide Selection of Metal Plate Spring

Couplings Made of High-power Aluminum Alloy

SFC MODEL

High Rigidity, High Flexibility

An ideal-shaped plate spring, designed based on thorough analysis using the advanced finite element

method (FEM) is applied for the element.

Two types of couplings, either a high-rigidity type with one element or a high-flexibility type with two

elements using a spacer, can be selected.

BENDING RADIALTORQUE THRUST

PLATE SPRING OF IDEAL FORM

SERVO FLEX

SFC

11

SFC MODEL

A Wide Range of Installation Methods

òBy adoption of the clamp method, installation is

easy and exact.

òThe servo motor taper shaft can be optionally

supported.

SERVO FLEX

SFC

SFC MODEL

High-strength aluminum alloy hub SFC

Clamp lock

+ Taper shaft compatible

SFC-£SA2-£B-£B

SFC-£DA2-£B-£B

High-rigidity single element SFC-£SA2-£B-£BC

High-flexibility double element SFC-£DA2-£B-£BC

High-rigidity single element

High-flexibility double element

12

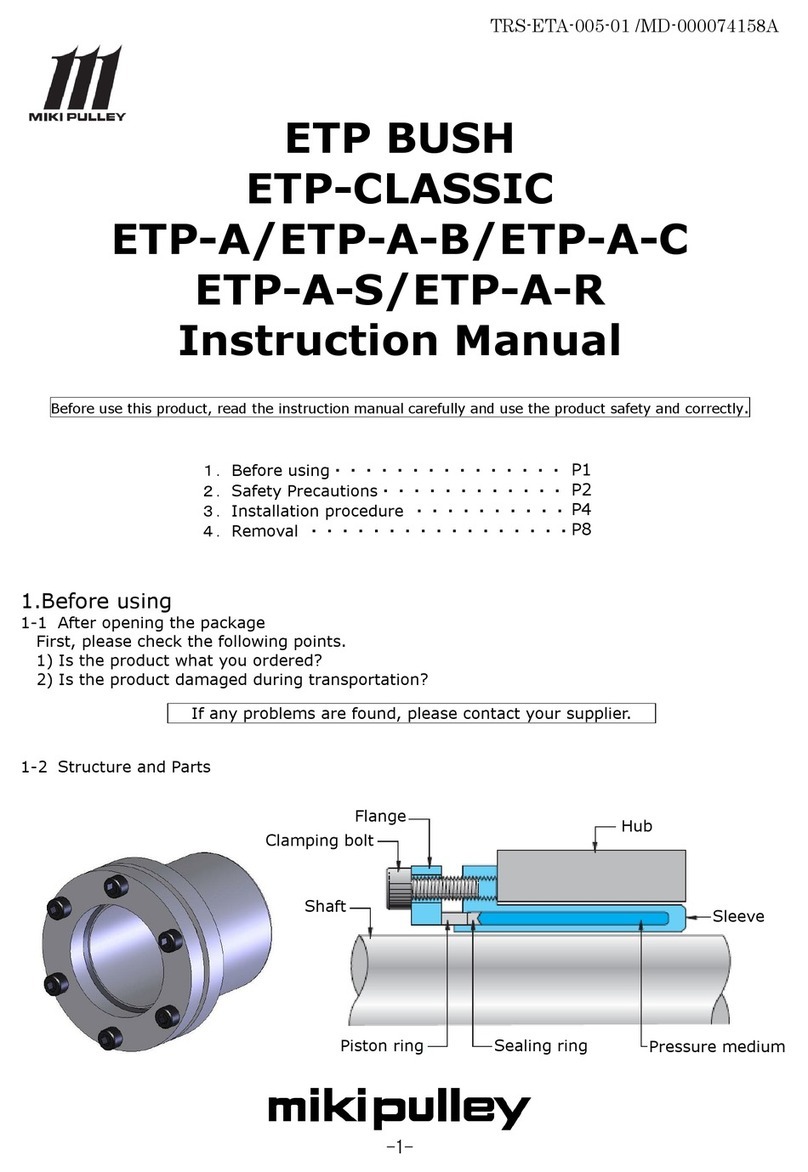

¢Structure and Material

Clamp bolt material: SCM435

Surface treatment: Solid lubricant film treatment

Element material: Plate spring SUS304

Collar SUS304*1

Bolt material: SCM435

Surface treatment: Trivalent chromate treatment*2

Clamp hub material: High-strength aluminum alloy

Surface treatment: Anodic coating film treatment

Clamp bolt material: SCM435

Surface treatment: Solid lubricant film treatment

Element material: Plate spring SUS304

Collar SUS304*1

SFC-SA2 SFC-DA2

Clamp bolt material: SCM435

Surface treatment: Solid lubricant film treatment

Element material: Plate spring SUS304

Collar SUS304

Clamp hub material: High-strength

aluminum alloy

Surface treatment: Anodic coating film treatment

SFC-SA2/DA-BC

Clamp hub material:

High-strength aluminum alloy

Surface treatment:

Anodic coating film treatment

Bolt material: SCM435

Surface treatment: Trivalent chromate treatment

Taper adapter material: Equivalent of S45C

Surface treatment: Black oxide finish

Bolt material: SCM435

Surface treatment: Trivalent chromate treatment *2

Spacer material: High-strength aluminum alloy

Surface treatment: Anodic coating film treatment

* The collar material of the items marked with *1 is S45C from size #080 to size #100,

using trivalent chromium for the surface treatment.

* The bolt surface treatment of the items marked with *2 is antirust coating from size #080

to size #100.

SERVO FLEX

SFC

¢Wide Range of Installation Methods

The clamp method is adopted for the method of mounting on the shaft, so it is

easy to finish only by tightening the right and left sides.

Power transmission is performed entirely by a friction lock. There is no backlash.

A specialized jig is used for assembling couplings, so high-precision concentricity

is ensured.

It is also compatible with the servo motor taper shaft by installing a taper adapter.

13

Taper adapter option

SFC MODEL

The outer diameter of the clamp hub is designed so the outer diameter dimension interlocks with the bore

diameter that customers adopt. By using a small bore diameter to shrink the outer diameter, it is possible to

keep the inertia to the minimum required. One of three pattern shapes is determined automatically according

to the combination of bore diameters to be adopted.

¢Ultralow Inertia

TYPE A TYPE B TYPE C

SERVO FLEX

SFC

14

SERVO FLEX

SFC

K

A1

L

SLF C

L

SLF C

L

SLF C

A2

M

M

M

N

N

D

D

d1

D

d2

d1

d2

d2

d1

TYPE A TYPE B TYPE C

¢Specification

SFC-SA2

¢Dimensions

Model

Permissible

tourque

[N·m]

Max. permissible misalignment

Max. rotation

speed

[min

–1

]

Torsional

stiffness

[N·m/rad]

Radial

displacement

[N/mm]

Shape

TYPE

Moment of inertia

[kg·m2]

Mass

[kg]

Price

Parallel offset

[mm]

Angular

misalignment

[ ˚ ]

Axial

displacement

[mm]

SFC-005SA2 0.6 0.02 0.5 ±0.05 10000 500 140 C 0.25×10–6 0.007 –

SFC-010SA2 1.0 0.02 1 ±0.1 10000 1400 140 C 0.58×10–6 0.011 –

SFC-020SA2 2.0 0.02 1 ±0.15 10000 3700 64 C 2.36×10–6 0.025 –

SFC-030SA2 5.0 0.02 1 ±0.2 10000 8000 64

A 4.00×10–6 0.033 –

B 6.06×10–6 0.041 –

C 8.12×10–6 0.049 –

SFC-035SA2 8.0 0.02 1 ±0.25 10000 18000 112 C 18.43×10–6 0.084 –

SFC-040SA2 10 0.02 1 ±0.3 10000 20000 80

A 16.42×10–6 0.076 –

B 22.98×10–6 0.090 –

C 29.53×10–6 0.105 –

SFC-050SA2 25 0.02 1 ±0.4 10000 32000 48

A 54.88×10–6 0.156 –

B 77.10×10–6 0.185 –

C 99.33×10–6 0.214 –

SFC-060SA2 60 0.02 1 ±0.45 10000 70000 76.4

A 143.7×10–6 0.279 –

B 206.1×10–6 0.337 –

C 268.5×10–6 0.396 –

SFC-080SA2 100 0.02 1 ±0.55 10000 140000 128 C 709.3×10–6 0.727 –

SFC-090SA2 180 0.02 1 ±0.65 10000 100000 108 C 1227×10–6 0.959 –

SFC-100SA2 250 0.02 1 ±0.74 10000 120000 111 C 1858×10–6 1.181 –

* The indicated values in the moment of inertia and mass are measured with the maximum bore diameter.

* The torsional stiffness indicates the actual measurement value of element.

Model

d1*1d2*1

D N L LF S A1 A2 C K M

Tightening

torque

[N·m]

Shape

TYPE

CAD

file No.

Min. Max. Min. Max.

SFC-005SA2 4 6 4 6 16 – 16.7 7.85 1.0 – 4.8 2.5 6.5 2-M2 0.4 to 0.5 C C005S2B1

SFC-010SA2 4 8 4 8 19 – 19.35 9.15 1.05 – 5.8*23.15 8.5 2-M2.5*31.0 to 1.1*3C C010S2B1

SFC-020SA2 5 10 5 10 26 – 23.15 10.75 1.65 – 9.5 3.3 10.6 2-M2.5 1.0 to 1.1 C C020S2B1

SFC-030SA2

5 10 5 10

34 21.6 27.3 12.4 2.5

8 –

3.75 14.5 2-M3 1.5 to 1.9

A C030S2B1

5 10 Over10 14 8 12.5 B C030S2B2

Over 10 14 Over10 14 – – 12.5 C C030S2B3

SFC-035SA2 8 16 8 16 39 – 34.0 15.5 3.0 – 14.0 4.5 17 2-M4 3.4 to 4.1 C C035S2B1

SFC-040SA2

8 15 8 15

44 29.6 34.0 15.5 3.0

11 –

4.5 19.5 2-M4 3.4 to 4.1

A C040S2B1

8 15 Over 15 19 11 17.0 B C040S2B2

Over 15 19 Over 15 19 – – 17.0 C C040S2B3

SFC-050SA2

10 19 10 19

56 38 43.4 20.5 2.4

14.5 –

6 26 2-M5 7.0 to 8.5

A C050S2B1

10 19 Over 19 25 14.5 22.0 B C050S2B2

Over 19 25 Over 19 25 – – 22.0 C C050S2B3

SFC-060SA2

12 24 12 24

68 46 53.6 25.2 3.2

17.5 –

7.75 31 2-M6 14 to 15

A C060S2B1

12 24 Over 24 30 17.5 26.5 B C060S2B2

Over 24 30 Over 24 30 — – 26.5 C C060S2B3

SFC-080SA2 20 35 20 35 82 – 68 30 8 – 28 9 38 2-M8 27 to 30 C C080S2B1

SFC-090SA2 25 40 25 40 94 – 68.3 30 8.3 – 34 9 42 2-M8 27 to 30 C C090S2B1

SFC-100SA2 35 45 35 45 104 – 69.8 30 9.8 – 39 9 48 2-M8 27 to 30 C C100S2B1

Unit [mm]

SFC MODEL

CAD CAD

* *1 The torque permitted could be limited depending on the bore diameter. Refer to the “Standard bore diameter” on page15.

* *2 indicates the value when d1 or d2 is ø4 to ø7. It will be 0.6 if d1 or d2 is ø8.

* *3 indicates the value when d1 or d2 is ø4 to ø7. It will be M2 if d1 or d2 is ø8. The tightening torque of M2 is 0.4 to 0.5N·m.

* The dimensional tolerance of the target shaft is h7. However, for a shaft diameter of ø35, the tolerance is . Contact us for tolerances other than h7.

+0.010

- 0.025

15

T h e l a t e s t C A D d a ta c a n b e d ow n l o a d e d fr o m o u r we b s i t e . h t t p : // w w w. m i k i p u l l e y. c o . j p / The CAD mark indicates that CAD data is available by CD-ROM.

The CAD file No. represents the file name in the CD-ROM.

CAD CAD

SERVO FLEX

SFC

¢Standard bore diameter

Model Standard bore diameter d1·d2 [mm]

4 5 6 6.35 7 8 9 9.525 10 11 12 14 15 16 17 18 19 20 22 24 25 28 30 32 35 38 40 42 45

SFC-005SA2 ò ò ò

SFC-010SA2 ò ò ò ò ò ò

SFC-020SA2 1.2 ò ò ò ò ò ò ò

SFC-030SA2 2.8 3.4 ò ò ò ò ò ò ò ò ò

SFC-035SA2 òò ò òòòòòò

SFC-040SA2 9ò ò òòòòòòòòò

SFC-050SA2 22 òòòòòòòòòòòò

SFC-060SA2 51 òòòòòòòòòòòò

SFC-080SA2 òòòòòòòò

SFC-090SA2 òòòòòòò

SFC-100SA2 òòòòò

* The bore diameters with value or marked òare supported as standard bore diameter.

* The permissible torque of small bore diameter indicated in the column with value is limited by the shaft locking mechanism. The value indicates its operating torque [N·m].

* For bore diameters other than those above, processing cost is added to the standard price.

¢Optional: Taper shaft compatible

Model

Moment of inertia [kg·m2] Mass [kg]

Price

Shape TYPE

B

Shape TYPE

C

Shape TYPE

B

Shape TYPE

C

SFC-050SA2-

£

B-11BC

81.52×10–6 103.7×10–6 0.237 0.266 –

SFC-050SA2-

£

B-14BC

87.34×10–6 109.6×10–6 0.268 0.297 –

SFC-050SA2-

£

B-16BC

94.16×10–6 116.4×10–6 0.306 0.335 –

SFC-060SA2-

£

B-16BC

225.3×10–6 287.8×10–6 0.469 0.528 –

¢Specification SFC-£SA2-£B-£BC

Model CAD file No.

Shape TYPE

B

Shape TYPE C

SFC-050SA2-£B-11BC C050S2C1 C050S2C2

SFC-050SA2-£B-14BC C050S2C3 C050S2C4

SFC-050SA2-£B-16BC C050S2C5 C050S2C6

SFC-060SA2-£B-16BC C060S2C1 C060S2C2

¢Dimensions

A1

TYPE C

TYPE B

Taper 1/10

0

+0.030

W

A2

0

+0.3

T

WA

M

C

LA

LF

L

LC

D

dA

DA

Model W T WA LA dA DA L D LC LF C A1 A2 M

SFC-050SA2-£B-11BC 4 12.2 18 16 17 22 48.4

56 43.4 20.5 6 14.5 22 2-M5

-£B-14BC 4 15.1 24 19 22 28 53.4

-£B-16BC 5 17.3 24 29 26 30 63.4

SFC-060SA2-£B-16BC 5 17.3 24 29 26 30 69.6 68 53.6 25.2 7.75 17.5 26.5 2-M6

SFC-£SA2-£B-£BC

CAD CAD

Unit [mm]

* The shape type is either TYPE B or TYPE C.

Bore diameter: d1-d2

B: Clamp hub

BC: Taper adapter

Type: SA2

Single element, aluminum hub

Size

SFC - 040 - SA2 - 14 B - 15 B

Ordering Information

16

SERVO FLEX

SFC

¢Specification

Model

Permissible

torque

[N·m]

Max. permissible misalignment Max.

rotation

speed

[min–1]

Torsional

stiffness

[N·m/rad]

Radial

displacement

[N/mm]

Shape

TYPE

Moment of

inertia

[kg·m2]

Mass

[kg]

Price

Parallel offset

[mm]

Angular

misalignment

[ ˚ ]

Axial

displacement

[mm]

SFC-005DA2 0.6 0.05

0.5 (one side)

±0.1 10000 250 70 C 0.36×10–6 0.010 –

SFC-010DA2 1.0 0.11

1 (one side)

±0.2 10000 700 70 C 0.79×10–6 0.015 –

SFC-020DA2 2.0 0.15

1 (one side)

±0.33 10000 1850 32 C 3.40×10–6 0.035 –

SFC-030DA2 5.0 0.18 1

(one side) ±0.4 10000 4000 32

A 7.33×10–6 0.053 –

B 9.39×10–6 0.061 –

C 11.45×10–6 0.069 –

SFC-035DA2 8.0 0.24

1 (one side)

±0.5 10000 9000 56 C 26.78×10–6 0.123 –

SFC-040DA2 10 0.24 1

(one side) ±0.6 10000 10000 40

A 29.49×10–6 0.122 –

B 36.05×10–6 0.136 –

C 42.61×10–6 0.151 –

SFC-050DA2 25 0.28 1

(one side) ±0.8 10000 16000 24

A 96.94×10–6 0.246 –

B 119.2×10–6 0.275 –

C 141.4×10–6 0.304 –

SFC-060DA2 60 0.34 1

(one side) ±0.9 10000 35000 38.2

A 252.4×10–6 0.440 –

B 314.8×10–6 0.498 –

C 377.3×10–6 0.556 –

SFC-080DA2 100 0.52

1 (one side)

±1.10 10000 70000 64 C 1034×10–6 1.051 –

SFC-090DA2 180 0.52

1 (one side)

±1.30 10000 50000 54 C 1776×10–6 1.373 –

SFC-100DA2 250 0.52

1 (one side)

±1.48 10000 60000 55.5 C 2704×10–6 1.707 –

* The indicated values in the moment of inertia and mass are measured with the maximum bore diameter.

* The torsional stiffness indicates the actual measurement value of element.

Model

d1*1d2*1

D N L LF LP S A1 A2 C d3 K M

Tightening

torque

[N·m]

Shape

TYPE CAD file No.

Min. Max. Min. Max.

SFC-005DA2 4 6 4 6 16 – 23.2 7.85 5.5 1.0 – 4.8 2.5 6.5 6.5 2-M2 0.4 to 0.5 C C005D2B1

SFC-010DA2 4 8 4 8 19 – 25.9 9.15 5.5 1.05 – 5.8*23.15 8.5 8.5 2-M2.5*31.0 to 1.1*3C C010D2B1

SFC-020DA2 5 10 5 10 26 – 32.3 10.75 7.5 1.65 – 9.5 3.3 10.6 10.6 2-M2.5 1.0 to 1.1 C C020D2B1

SFC-030DA2

5 10 5 10

34 21.6 37.8 12.4 8 2.5

8 –

3.75 15 14.5 2-M3 1.5 to 1.9

A C030D2B1

5 10 Over 10 14 8 12.5 B C030D2B2

Over 10 14 Over 10 14 – – 12.5 C C030D2B3

SFC-035DA2 8 16 8 16 39 – 48 15.5 11 3 – 14.0 4.5 17 17 2-M4 3.4 to 4.1 C C035D2B1

SFC-040DA2

8 15 8 15

44 29.6 48 15.5 11 3

11 –

4.5 20 19.5 2-M4 3.4 to 4.1

A C040D2B1

8 15 Over 15 19 11 17.0 B C040D2B2

Over 15 19 Over 15 19 – – 17.0 C C040D2B3

SFC-050DA2

10 19 10 19

56 38 59.8 20.5 14 2.4

14.5 –

6 26 26 2-M5 7.0 to 8.5

A C050D2B1

10 19 Over 19 25 14.5 22.0 B C050D2B2

Over 19 25 Over 19 25 – – 22.0 C C050D2B3

SFC-060DA2

12 24 12 24

68 46 73.3 25.2 16.5 3.2

17.5 –

7.75 31 31 2-M6 14 to 15

A C060D2B1

12 24 Over 24 30 17.5 26.5 B C060D2B2

Over 24 30 Over 24 30 – – 26.5 C C060D2B3

SFC-080DA2 20 35 20 35 82 – 98 30 22 8 – 28 9 40 38 2-M8 27 to 30 C C080D2B1

SFC-090DA2 25 40 25 40 94 – 98.6 30 22 8.3 – 34 9 47 42 2-M8 27 to 30 C C090D2B1

SFC-100DA2 35 45 35 45 104 – 101.6 30 22 9.8 – 39 9 50 48 2-M8 27 to 30 C C100D2B1

Unit [mm]

¢Dimensions

L

S

LP LF C

L

S

LP LF C

L

S

LP LF C

MMM

d3

d3

d3

K

A1

A2

N

N

D

d1

d1

D

d2

d1

d2

D

d2

TYPE A TYPE B TYPE C

SFC-DA2

SFC MODEL

CAD CAD

* *1 Permissible torque could be limited depending on the bore diameter. Refer to the “Standard bore diameter” on page 17.

* *2 indicates the value when d1 or d2 is ø4 to ø7. It will be 6.0 if d1 or d2 is ø8.

* *3 indicates the value when d1 or d2 is ø4 to ø7. It will be M2 if d1 or d2 is ø8. The tightening torque of M2 is 0.4 to 0.5N·m.

* The dimensional tolerance of the target shaft is h7. However, for a shaft diameter of ø35, the tolerance is . Contact us for tolerances other than h7.

+0.010

- 0.025

17

T h e l a t e s t C A D d a ta c a n b e d ow n l o a d e d fr o m o u r we b s i t e . h t t p : // w w w. m i k i p u l l e y. c o . j p / The CAD mark indicates that CAD data is available by CD-ROM.

The CAD file No. represents the file name in the CD-ROM.

CAD CAD

SERVO FLEX

SFC

Model Standard bore diameter d1·d2 [mm]

4 5 6 6.35 7 8 9 9.525 10 11 12 14 15 16 17 18 19 20 22 24 25 28 30 32 35 38 40 42 45

SFC-005DA2 ò ò ò

SFC-010DA2 ò ò ò ò ò ò

SFC-020DA2 1.2 ò ò ò ò ò ò ò

SFC-030DA2 2.8 3.4 ò ò ò ò ò ò ò ò ò

SFC-035DA2 ò ò ò ò ò ò ò ò ò

SFC-040DA2 9ò ò òòòòòòòòò

SFC-050DA2 22 òòòòòòòòòòòò

SFC-060DA2 51 òòòòòòòòòòòò

SFC-080DA2 òòòòòòòò

SFC-090DA2 òòòòòòò

SFC-100DA2 òòòòò

* The bore diameters with value or marked òare supported as standard bore diameter.

* The permissible torque of small bore diameter indicated in the column with value is limited by the shaft locking mechanism. The value indicates its operating torque [N·m].

* For bore diameters other than those above, processing cost is added to the standard price.

¢Standard bore diameter

Type: DA2

Double element, aluminum hub

Size

SFC - 040 - DA2 - 14 B - 15 B

Bore diameter: d1-d2

B: Clamp hub

BC: Taper adapter

Ordering Information

¢Optional: Taper shaft compatible

Model

Moment of inertia [kg·m2] Mass [kg]

Price

Shape TYPE

B

Shape TYPE

C

Shape TYPE

B

Shape TYPE

C

SFC-050DA2-

£

B-11BC

123.6×10–6 145.8×10–6 0.327 0.356 –

SFC-050DA2-

£

B-14BC

129.4×10–6 151.6×10–6 0.358 0.386 –

SFC-050DA2-

£

B-16BC

136.2×10–6 158.4×10–6 0.396 0.424 –

SFC-060DA2-

£

B-16BC

334.1×10–6 396.5×10–6 0.630 0.688 –

¢Specification SFC-£DA2-£B-£BC

Model CAD file No.

Shape TYPE B Shape TYPE C

SFC-050DA2-£B-11BC C050D2C1 C050D2C2

SFC-050DA2-£B-14BC C050D2C3 C050D2C4

SFC-050DA2-£B-16BC C050D2C5 C050D2C6

SFC-060DA2-£B-16BC C060D2C1 C060D2C2

¢Dimensions

A1

LA

LC

L

LF

Taper 1/10

A2

WA

C

TYPE C

TYPE B

0

+0.030

W

0

+0.3

T

M

D

dA

DA

Model W T WA LA dA DA L D LC LF C A1 A2 M

SFC-050DA2-£B-11BC 4 12.2 18 16 17 22 64.8

56 59.8 20.5 6 14.5 22 2-M5

-£B-14BC 4 15.1 24 19 22 28 69.8

-£B-16BC 5 17.3 24 29 26 30 79.8

SFC-060DA2-£B-16BC 5 17.3 24 29 26 30 89.3 68 73.3 25.2 7.75 17.5 26.5 2-M6

* The shape type is either TYPE B or TYPE C.

SFC-£DA2-£B-£BC

CAD CAD

Unit [mm]

18

SERVO FLEX

SFC

¢Spring characteristics

030SA2

020SA2

005SA2

080SA2 090SA2

100SA2

060SA2

035SA2

050SA2050SA2

040SA2040SA2

035DA2

010DA2

020DA2

005DA2

080DA2 090DA2

100DA2

060DA2

050DA2050DA2

010SA2

040DA2040DA2

030DA2

0

00.5 1.0 1.5 2.0

60

50

40

30

20

10

90

80

70

0 0.5 1.0 1.5 2.0

0

60

50

40

30

20

10

90

80

70

Displacement [mm]

Displacement [mm]

Load [N]Load [N]

030SA2

020SA2

005SA2

080SA2 090SA2

100SA2

060SA2

035SA2

050SA2050SA2

040SA2040SA2

035DA2

010DA2

020DA2

005DA2

080DA2 090DA2

100DA2

060DA2

050DA2050DA2

010SA2

040DA2040DA2

030DA2

0

00.5 1.0 1.5 2.0

60

50

40

30

20

10

90

80

70

0 0.5 1.0 1.5 2.0

0

60

50

40

30

20

10

90

80

70

Displacement [mm]

Displacement [mm]

Load [N]Load [N]

035DA2

010DA2

020DA2

005DA2

080DA2

090DA2

100DA2

060DA2

050DA2050DA2

040DA2040DA2

0 0.1 0.2 0.3 0.4 0.5 0.6

0

300

250

200

150

100

50

350

Parallel offset [mm]

Load [N]

Design Check Items

SFC MODEL

òAxial Load and Displacement Amount

SFC-£SA2

òAxial Load and Displacement Amount

SFC-£DA2

òParallel Offset Direction Load and

Displacement Amount

SFC-£DA2

19

T h e l a t e s t C A D d a ta c a n b e d ow n l o a d e d fr o m o u r we b s i t e . h t t p : // w w w. m i k i p u l l e y. c o . j p / The CAD mark indicates that CAD data is available by CD-ROM.

The CAD file No. represents the file name in the CD-ROM.

CAD CAD

SERVO FLEX

SFC

¢Selection procedure

Servo motor specification Compatible coupling specification

Rated output

[kW]

Rated revolution

[min–1]

Rated torque

[N·m]

Max. torque

[N·m]

Shaft dia.

[mm]

Single element Double element Max. bore

dia. [mm]

Model (SFC-£SA2) Model (SFC-£DA2)

0.05 3000 0.16 0.48 8 010SA2 010DA2 8

0.1 3000 0.32 0.95 8 020SA2 020DA2 10

0.2 3000 0.64 1.90 14 030SA2 030DA2 14

0.4 3000 1.30 3.80 14 035SA2 035DA2 16

0.5 2000 2.39 7.16 24 050SA2 050DA2 25

0.5 3000 1.59 4.77 24 050SA2 050DA2 25

0.75 2000 3.58 10.7 22 050SA2 050DA2 25

0.75 3000 2.40 7.20 19 040SA2 040DA2 19

0.85 1000 8.12 24.4 24 060SA2 060DA2 30

1 2000 4.78 14.4 24 050SA2 050DA2 25

1 3000 3.18 9.55 24 050SA2 050DA2 25

1.2 1000 11.5 34.4 35 080SA2 080DA2 35

1.5 2000 7.16 21.6 28 060SA2 060DA2 30

1.5 3000 4.78 14.3 24 050SA2 050DA2 25

2 2000 9.55 28.5 35 080SA2 080DA2 35

2 3000 6.37 15.9 24 050SA2 050DA2 25

3 1000 28.60 85.9 35 090SA2 090DA2 35

3.5 2000 16.70 50.1 35 080SA2 080DA2 35

3.5 3000 11.10 27.9 28 060SA2 060DA2 30

5 2000 23.90 71.6 35 080SA2 080DA2 35

5 3000 15.90 39.7 28 060SA2 060DA2 30

7 2000 33.40 100 35 090SA2 090DA2 35

¢Simplified selection

Td = Ta × K (see below)

(1) Calculate torque Ta applied to the coupling based on the

motor output P and coupling operating rotation speed n.

Ta [N·m] = 9550 × P [kW]

n [min−1]

Load character

Constant

Fluctuations: Slight

Fluctuations: Medium

Fluctuations: Large

1.0 1.25 1.75 2.25

In servo motor drive, multiply the service factor K=1.2 to 1.5

by the maximum torque of servo motor Ts.

Td = Ts × (1.2 to 1.5)

Tn ≥Td

(2) Calculate corrected torque Td applied to the coupling after

deciding the service factor K based on load conditions.

(5) Confirm if the required shaft diameter does not exceed the

maximum bore diameter of the selected size.

(3) Select a coupling size with permissible torque Tn that

becomes equal or greater than the corrected torque Td.

(4) Depending on the bore diameters, the coupling permissible

torque may be limited. Refer to the “Specification” and

“Standard bore diameter”.

The table indicates suitable sizes based on the rated output, rated torque and maximum torque of general-purpose servo motors. Since

torque characteristics of servo motors differ depending on the manufacturer, select the coupling size after confirming the specification of the

manufacturer.

For machines whose load torques periodically fluctuate

drastically, contact us.

20

SERVO FLEX

SFC

Size LF dimension [mm]

005 7.85

010 9.15

020 10.75

030 12.4

035 15.5

040 15.5

050 20.5

060 25.2

080 30

090 30

100 30

¢Feed-screw systems

¢How to evaluate the eigenfrequency of

feed-screw system

¢Mounting

Motor

Feed

screw

Bearing

Table

Coupling

J1 J2

Rotative direction

Axial direction

LF

LF

(1) Oscillation phenomena of servo motors

If the eigenfrequency of the entire feed-screw system is under

400 to 500Hz, oscillation may occur depending on the gain

adjustment of the servo motor.

The problems can be avoided by raising the eigenfrequency

of the mechanical system or adjusting the tuning function (filter

function) of the servo motor.

(1) Select the coupling according to the normal operating torque

and maximum torque of the servo motor/stepping motor.

Nf: Eigenfrequency of the entire feed-screw system [Hz]

k: Torsional stiffness of the coupling and feed screw [N·m/rad]

J1: Moment of inertia of the driving side

J2: Moment of inertia of the driven side

The concentricity of the right and left bore diameters is ensured

by adjusting with an specialized jig. However, the assembly

accuracy may be disturbed if a strong impact is given to the

product. Please handle it with care.

(1) Confirm the clamping bolts are loosened. Remove the rust,

dust and oil content on the inside diameter surface of the

shaft and coupling. (Wipe off the oil content completely with a

waste cloth, etc.)

(4) Make sure that the insertion length of the coupling into the

shaft is kept in the position so that the target shaft is in

contact with the entire length of the flange (LF dimension) as

illustrated below.

(2) Resonance caused by stepping motors

Resonance can occur within a certain speed range due

to the pulsation frequency of the stepping motor and the

eigenfrequency of the entire system. Resonance can be

avoided by not applying the resonant rotation speed, or by

reviewing the eigenfrequency in the design phase.

Cont act us for unclear p oints concerning oscill ation

phenomena of servo motors.

Contact us for unclear points concerning resonance of

stepping motors.

(2) In the following feed-screw system, evaluate the entire

eigenfrequency: Nf from the torsional stiffness: kof the

coupling and feed screw, the moment of inertia: J1 of the

driving side and the moment of inertia: J2 of the driven side.

(3) Confirm the two clamping bolts are loosened and the coupling

is movable to the axial and rotative directions.

If it does not move smoothly, adjust centering of both shafts

again.

If the concentricity can not be confirmed with the method

described above, confirm the mounting accuracy by other

measures.

(2) Insert the coupling into the shaft. At this time, do not apply

more than necessary force such as compression or pulling to

the element part of the coupling.

After the coupling is mounted into the motor, do not apply

excessive compression when inserting the coupling into the

mating shaft.

Design Check Items

SFC MODEL

21

T h e l a t e s t C A D d a ta c a n b e d ow n l o a d e d fr o m o u r we b s i t e . h t t p : // w w w. m i k i p u l l e y. c o . j p / The CAD mark indicates that CAD data is available by CD-ROM.

The CAD file No. represents the file name in the CD-ROM.

CAD CAD

SERVO FLEX

SFC

Size Clamp bolt Tightening torque [N·m]

005 M2 (0.4 to 0.5)

010 M2 (0.4 to 0.5)

010 M2.5 (1.0 to 1.1)

020 M2.5 (1.0 to 1.1)

030 M3 (1.5 to 1.9)

035 M4 (3.4 to 4.1)

040 M4 (3.4 to 4.1)

050 M5 (7.0 to 8.5)

060 M6 (14 to 15)

080 M8 (27 to 30)

090 M8 (27 to 30)

100 M8 (27 to 30)

* If the bore diameter is ø8, size 010 will be M2.

* For the above tightening torque, solid lubricant film treatment is applied to the bolt

and the torque coefficient is 0.18.

* The value of the tightening torque is between the minimum and the maximum values.

The bolts should be tightened by the tightening torque within this range.

(5) As a principle, the target shaft is a circular shaft. However, if

shafts other than a circular shaft have to be used for a certain

reason, be careful with the shaft installation position as

illustrated below. (Note that key slot, D-cut, etc. must not be

processed on the filling side of the ¢part.)

Certain shaft installation positioning may result in damage

to the coupling itself and lowering of shaft-retaining force. It

is recommended to use a circular shaft for fully satisfactory

coupling performance.

(6) After checking that no force such as compression, tension,

etc. is applied to the axial direction, the shaft is retained so

that the whole length of the clamp hub is in contact with both

shafts, and two clamp bolts are tightened at an appropriate

torque value.

To tighten the clamp bolts, a calibrated torque wrench is used

within the range of the clamp bolt-tightening torque as shown

in the table below.

òSolid lubricant film treatment is applied to the clamp bolt,

so make sure that Miki Pulley’s specified clamp bolt is used

and no coatings such as oil, etc. are applied. If any coating is

applied to the surface, the clamp bolt, the coupling itself, and

other parts might be damaged due to excessive shaft force.

òExample of Good Mounting

òExample of Bad Mounting

¢

Coupling bore diameter surface

treatment

For the SERVO FLEX SFC model, depending on the process,

although there are two types of parts, one with bore diameter

surface treatment such as additional processing and key slot

processing and the other without surface treatment, there is no

problem in terms of performance of the couplings. Contact us

for advice regarding whether bore diameter surface treatment

should be used according to the customers’ conditions of use.

22

Three types of couplings, either a high-rigidity type with one element, a high-flexibility type with two elements using a

spacer, or a floating shaft with configurable spacer length can be selected.

A variety of methods are available for mounting on a shaft such as a friction lock compatible with a large diameter, a high-

precision friction lock, a taper shaft-compatible method, and others.

The pilot bore item has also been standardized, enabling methods such as the key/set screw method, shrink fit-compatible

method, and others.

SERVO FLEX: A Wide Selection of Metal Plate Spring

Couplings Made of Steel

SFS MODEL

High Rigidity, High Flexibility

An ideal-shaped plate spring, designed based

on thorough analysis using the advanced

finite element method (FEM), is applied for the

element.

Three types of couplings, either a high-rigidity

type with one element, a high-flexibility type

with two elements using a spacer, or a floating

shaft with configurable spacer length can be

selected.

BENDING RADIAL

TORQUE THRUST

PLATE SPRING OF IDEAL FORM

SERVO FLEX

SFS

Other Miki Pulley Industrial Equipment manuals