Miki Pulley Starflex ALS Series User manual

TRS-ALS-002-01/MD-000067150A

-1-

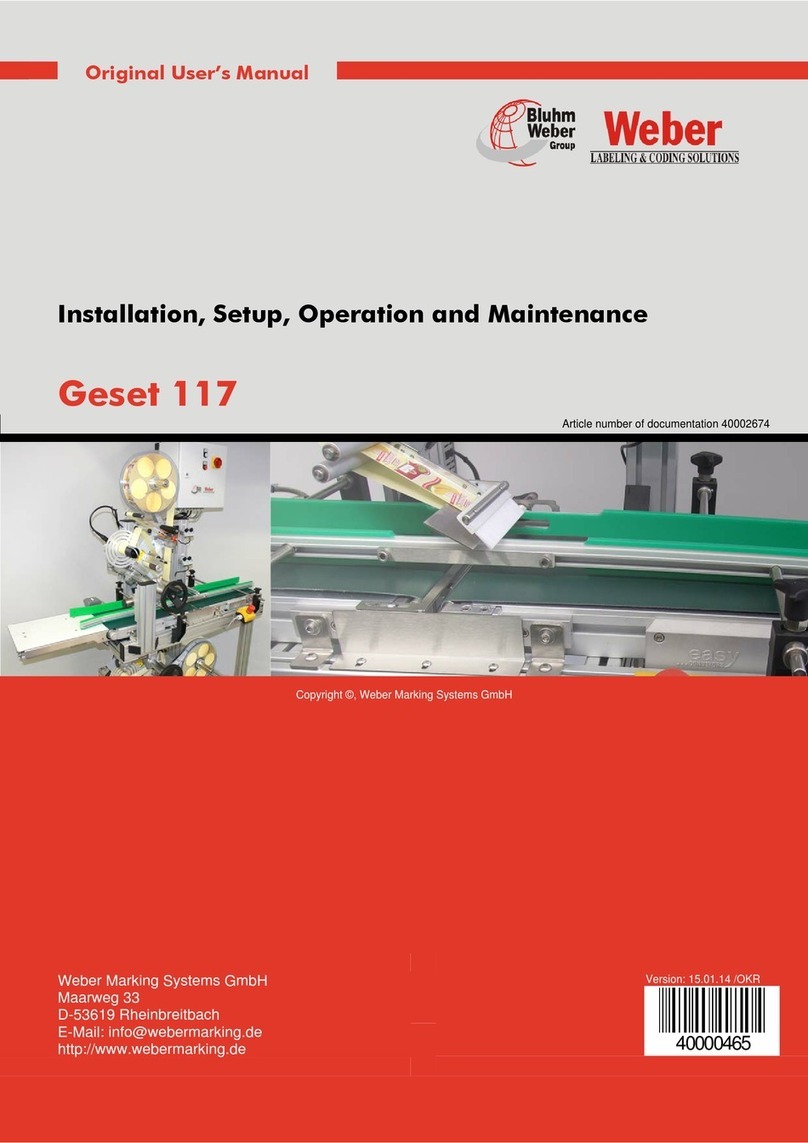

Miki Pulley Starflex Coupling

ALS –Y / R / B Model

Operation Manual

1. Safety Precautions

1-1 Precaution against mechanical hazards . . . . . . . . . . . . . . . . . . . . . . . . . P. 2

1-2 Precaution for safe assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 3

1-3 Precaution for safe operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 3 - 4

1-4 Precaution for safe maintenance and service . . . . . . . . . . . . . . . . . . . . . P. 4

1-5 Precaution for safe disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 5

2. Product Information

2-1 Unpacking the product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 5

2-2 Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 5

2-3 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 5

3. Installation Procedures

3-1 Handling Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 6

3-2 Operating environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 6

3-3 Installation procedures Key/Set Screw style hubs . . . . . . . . . . . . . . . . P. 6 - 7

3-3 Tightening torque for set screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 6

3-3 Standard specifications for the Key/set screw style hubs . . . . . . . . . . . P. 7

3-4 Installation procedures Clamp style hubs . . . . . . . . . . . . . . . . . . . . . . . P. 8 - 9

3-4 Tightening torque for clamp bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P. 8

3-4 Standard specifications for the Clamp style hubs . . . . . . . . . . . . . . . . . . P. 8 - 9

3-4 Standard bore diameter and bore diameter by limited allowable torque P. 9

Please read this Instruction Manual carefully before

using the Miki Pulley Starflex Coupling.

Forward this manual to the end-user for safe operation of coupling.

-2-

1. Safety Precautions

Read the operation manual and technical documents carefully before using this product. Failure to comply with

these instructions could result in serious injury or damage to equipment.

Safety precautions, in this manual, are labeled as "DANGER" or "CAUTION."

Before using this product in a device or machine where failure or malfunction can lead to a direct threat to life or

health (for example: nuclear power equipment, aerospace equipment, medical devices, transportation devices,

and safety devices) prior consideration must be given from Miki Pulley. Contact our authorized sales

representative.

This document must be given to the end user and should be kept for future reference. This manual’s contents

must always be observed to protect the user and others from danger, and preventing property damage when using

this product.

1-1 Precautions against mechanical hazards

Use safety shields or guards.

Contacting a moving part will cause injury. Use safety shields or guards to prevent

hazards. Provide a safety mechanism that halts the operation immediately when a safety

shield or guard is open.

Never use the product in a hazardous atmosphere that can cause ignition or

explosion.

Never use the product in an atmosphere of oil or flammable gas that can cause

ignition or explosion.

Provide a safety mechanism.

In the event of a product breakdown, the driven part can be completely separated

from the driving part. To prevent hazards, a safety mechanism should be in place.

DANGER:

Use safety guards

Danger of ignition

DANGER:

CAUTION:

Fields with this label may pose an imminent danger that could lead to

serious or even fatal injury, or other major incidents.

Fields with this label may cause personal injury or property damage if the

caution is not observed.

DANGER:

DANGER:

Mandatory

-3-

1-2 Precautions for safe assembly

Be sure to tighten all bolts and screws.

Improperly tightened bolts or screws can lead to product damage or impaired product

performance. Tighten the bolts and screws to our specified tightening torque.

Never turn on the machine during installation. Lock Out –Tag Out.

When installing the product, make sure that the main power of the machine is turned

off and can not be accidently turned on. If the driving part moves unexpectedly, personal

injury could result.

Do not exceed maximum permissible misalignment.

Attach the product to a machine within our specified "maximum permissible

misalignment." Failure to comply may cause injury, breakdown or machine damage.

Use Miki Pulley specified bolts and screws only.

Use Miki Pulley specified bolts and screws only. Failure to comply may cause injury,

breakdown or machine damage.

1-3 Precautions for safe operation

Do not exceed maximum RPM of unit.

Operating the product above the maximum speed can lead to product failure, damage

or an adverse influence on the machine. Observe the maximum speed.

Never touch the product while in operation.

Since the product contains rotating parts, touching the operating product will cause

injury. Never touch the product while in operation.

Prohibited

Prohibited

Prohibited

DANGER:

Mandatory

Never touch

DANGER:

Mandatory

CAUTION:

CAUTION:

DANGER:

DANGER:

-4-

Never use the product above the permissible torque.

Operating the product above the permissible torque can lead to product failure,

damage or an adverse influence on the machine. Never use the product above the

permissible torque.

If abnormal noises or vibrations occur, shut down the product immediately. Lock

Out -Tag Out Machine.

Unusual noises or vibrations may be a sign of abnormalities in the machine or product.

Problems left unsolved can damage the machine. Stop the operation immediately and

check the machine and product.

Never use the product in an environment that may have an adverse affect on the

product.

Use the product in a controlled environment. Do not expose to chemical sprays, strong

corrosives, extreme high or low temperatures. Failure to comply may cause injury,

breakdown or machine damage.

Never use the product with joint slippage. Fasten to shaft according to specified

tightening torques.

Slippage at the joint can generate heat during operation, damaging the product and

an adverse affect on the machine. Never use the product with joint slippage. Failure to

comply may cause injury, breakdown or machine damage.

1-4 Precautions for safe maintenance and service

Lock Out - Tag Out before beginning maintenance on machine.

Before starting any maintenance or service, be sure to turn off the main power to the

machine. Lock out -Tag Out machine to prevent accidents. Failure to comply may cause

injury.

Never disassemble the product.

Do not attempt to disassemble the product shipped as a complete assembly.

Unauthorized disassembly work can cause injury or damage the product.

Prohibited

CAUTION:

Prohibited

CAUTION:

Prohibited

Prohibited

Never disassemble

CAUTION:

DANGER:

Mandatory

CAUTION:

CAUTION:

-5-

1-5 Precautions for safe disposal

Keep away from infants and children.

To protect the environment, recycle where available.

2. Product Information

2-1 Unpacking the product

Carefully inspect the coupling upon receipt for damages during transit.

2-2 Structure

Key/set screw style hubs Clamp style hubs

[Figure 1] [Figure 2]

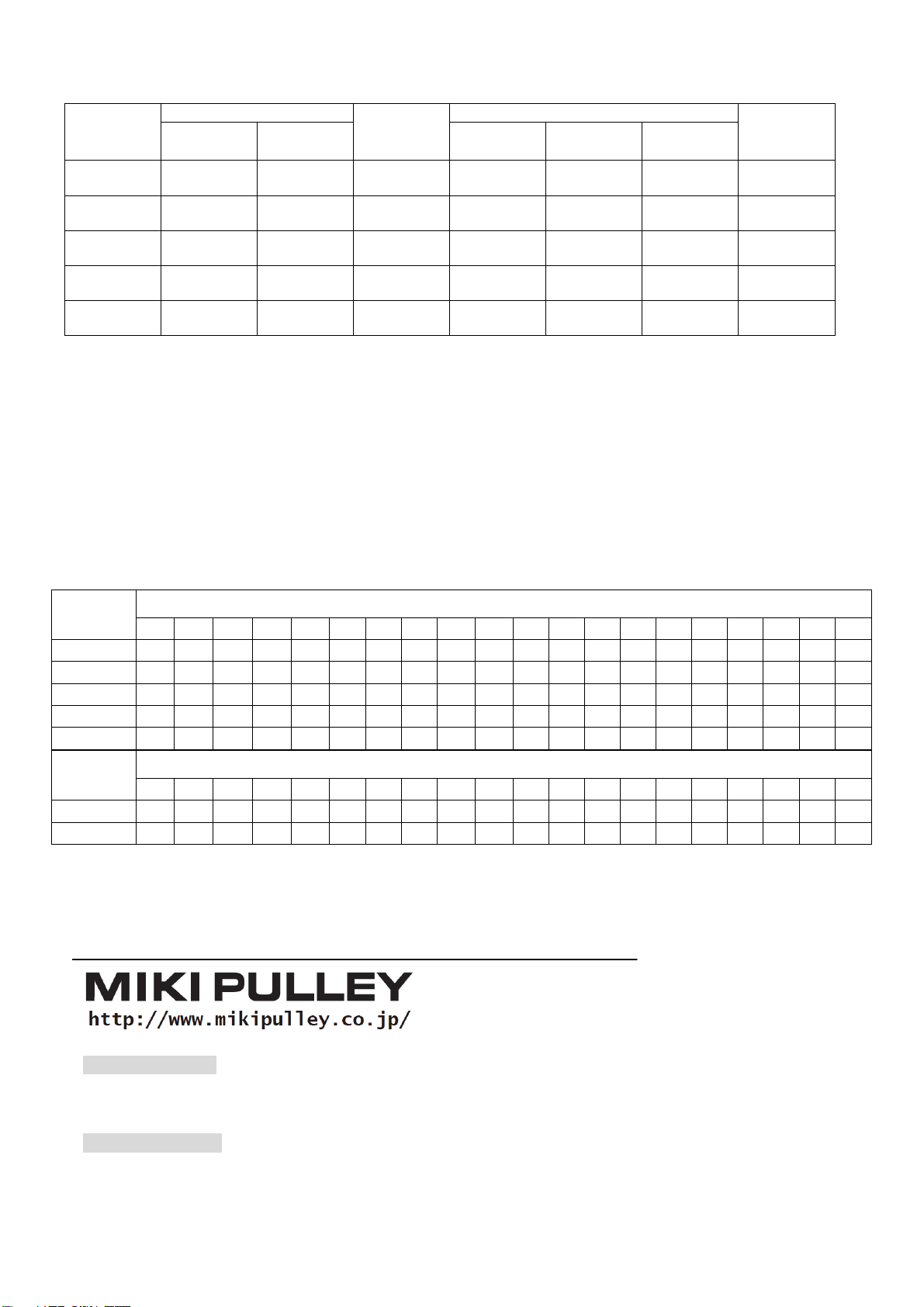

2-3 Dimensions Table 1

Model

ALS-014

ALS-020

ALS-030

ALS-040

ALS-055

ALS-065

ALS-080

ALS-095

ALS-105

L [mm]

22

30

35

66

78

90

114

126

140

L1,L2[mm]

7

10

11

25

30

35

45

50

56

Key/set screw style Clamp style

[Figure 3] [Figure 4]

DANGER:

CAUTION:

If there are any problems please contact the company where you purchased the product.

Hub

Element

Set screw

Element

Clamp hub

Clamp bolt

-6-

3. Installation Procedures

3-1 Handling Precautions

■ In transporting, handle the product carefully to avoid damaging the product.

■ Never handle the product in a way that excessive force is applied to the parts.

3-2 Operating environment

■ Do not use the product in a hot, humid, or dusty environments.

■ Do not use the product beyond the specified operating ambient temperature range. (-30℃to +80℃)

■ Do not use the product where it is exposed to corrosive gas, oil, or chemicals.

■ Do not use the product outdoors. The product is not corrosion resistant.

■ Do not use the product in highly dynamic applications such as high speed reversing.

3-3 Installation procedures

[Figure 5]

Key/set screw style

■ Before installing, make sure the main power switch to the equipment is in the off position to avoid operating the

motor by mistake and to ensure safety. Lock out –Tag Out procedures should be followed.

■ Remove the dust, dirt, and oil accumulated on the target shaft and coupling bores.

■ Install hub on shaft so that engagement is equal to dimensions L1and L2shown in Section 2-3, Table 1 and

figures 3 and 4.

■Be sure to use a torque wrench to tighten the set screws. Tighten to the set screw tightening torque indicated

below:

Tightening torque for set screws Table 2

Set Screw Size

M3

M4

M5

M6

M8

M10

Tightening torque [Nm]

0.7

1.7

3.6

6.0

14.5

28.0

Property Class 12.9

Black anodized

■To achieve maximum performance; align the shafts according to tables for set screw and clamp style hubs. The

misalignments shown are maximum values. Closer alignment at the time of initial installation is recommended

to maximize coupling life.

■Check the alignment at two points about 90 degrees away by applying a straight edge to the outer diameter

of the main body. The life of the element is significantly affected by the centering accuracy.

Parallel Angular Axial

-7-

Standard specifications for Key/set screw style hubs Table 3

Model

(Yellow)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-014-Y

1.2

2.4

34100

0.10

1

+0.6

0

0.007

ALS-020-Y

3

6

23800

0.15

1

+0.8

0

0.018

ALS-030-Y

7.5

15

15900

0.15

1

+1.0

0

0.047

ALS-040-Y

10

20

11900

0.10

1

+1.2

0

0.15

ALS-055-Y

35

70

8700

0.15

1

+1.4

0

0.35

ALS-065-Y

95

190

7400

0.15

1

+1.5

0

0.51

ALS-080-Y

190

325

6000

0.15

1

+1.8

0

1.01

ALS-095-Y

265

530

5000

0.15

1

+2.0

-0.5

1.5

ALS-105-Y

310

620

4500

0.20

1

+2.0

-0.9

2.1

Table 4

Model

(Red)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-014-R

2

4

34100

0.10

1

+0.6

0

0.007

ALS-020-R

5

10

23800

0.10

1

+0.8

0

0.018

ALS-030-R

12.5

25

15900

0.10

1

+1.0

0

0.047

ALS-040-R

17

34

11900

0.10

1

+1.2

0

0.15

ALS-055-R

60

120

8700

0.10

1

+1.4

0

0.35

ALS-065-R

160

320

7400

0.10

1

+1.5

0

0.51

ALS-080-R

325

650

6000

0.10

1

+1.8

0

1.01

ALS-095-R

450

900

5000

0.10

1

+2.0

-0.5

1.5

ALS-105-R

525

1050

4500

0.15

1

+2.0

-0.9

2.1

Table 5

Model

(Blue)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-030-B

12.5

25

15900

0.17

1

+1.0

-0.2

0.047

ALS-040-B

17

34

11900

0.20

1

+1.0

-0.5

0.15

ALS-055-B

60

120

8700

0.22

1

+1.4

-0.2

0.35

ALS-065-B

160

320

7400

0.25

1

+1.5

-0.6

0.51

ALS-080-B

325

650

6000

0.28

1

+1.8

-0.9

1.01

ALS-095-B

450

900

5000

0.32

1

+2.0

-0.5

1.5

ALS-105-B

525

1050

4500

0.36

1

+2.0

-0.09

2.1

Weights are at maximum bore diameter

Coupling specifications subject to change without notice

-8-

3.4 Installation procedures Clamp style hubs

■ The recommended dimensional tolerance of the target shaft is h7. (However, for a shaft diameter of φ35mm,

the tolerance is .)

■ Do not tighten the clamp bolt before inserting the shaft.

■ Wipe the rust, dust, oil and grease off the attachment shaft. Do not use clamp bolt with any oil or grease.

Molybdenum disulfide or extreme-pressure additives must be completely removed; as such additives

dramatically change the coefficient of friction.

■ Use only Miki Pulley clamp bolts.

■ After mounting the coupling, be sure to attach the safety shields or guards. Touching the coupling while it is

operating may result in an injury.

■ Be sure to use a torque wrench to tighten the clamp bolts. Tighten to the clamp bolt tightening torque indicated

in the table below:

Tightening torque for clamp bolts

Table 6

Model

ALS-014

ALS-020

ALS-030

ALS-040

ALS-055

ALS-065

ALS-080

Clamp bolt size

M2×6

M2. 5×8

M3×12

M5×16

M6×20

M8×25

M8×25

Tightening torque [Nm]

0.4

1.0

1.5

7.0

14.0

30.0

30.0

Property Class 12.9

Black anodized

Standard specifications for Clamp style hubs Table 7

Model

(Yellow)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-014-Y

1.2

2.4

10000

0.10

1

+0.6

0

0.007

ALS-020-Y

3

6

10000

0.15

1

+0.8

0

0.019

ALS-030-Y

7.5

15

10000

0.15

1

+1.0

0

0.045

ALS-040-Y

10

20

10000

0.10

1

+1.2

0

0.16

ALS-055-Y

35

70

7000

0.15

1

+1.4

0

0.34

ALS-065-Y

95

190

5900

0.15

1

+1.5

0

0.54

ALS-080-Y

190

325

4800

0.15

1

+1.8

0

1.00

Table 8

Model

(Red)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-014-R

2

4

10000

0.10

1

+0.6

0

0.007

ALS-020-R

5

10

10000

0.10

1

+0.8

0

0.019

ALS-030-R

12.5

25

10000

0.10

1

+1.0

0

0.045

ALS-040-R

17

34

10000

0.10

1

+1.2

0

0.16

ALS-055-R

60

120

7000

0.10

1

+1.4

0

0.34

ALS-065-R

160

320

5900

0.10

1

+1.5

0

0.54

ALS-080-R

325

650

4800

0.10

1

+1.8

0

1.00

+0.010

-0.025

-9-

Table 9

Model

(Blue)

Torque

Maximum

Speed

[min-1]

Misalignment

Nominal

[Nm]

Maximum

[Nm]

Parallel

[mm]

Angular

[°]

Axial

[mm]

Weight

[kg]

ALS-030-B

12.5

25

10000

0.17

1

+1.0

-0.2

0.043

ALS-040-B

17

34

10000

0.20

1

+1.2

-0.5

0.16

ALS-055-B

60

120

7000

0.22

1

+1.4

-0.2

0.34

ALS-065-B

160

320

5900

0.25

1

+1.5

-0.6

0.54

ALS-080-B

325

650

4800

0.28

1

+1.8

-0.9

1.00

Weights are at maximum bore diameter

Coupling specifications subject to change without notice

■ Torque values are limited in bore diameter. Review torque values by check the alignment at two points about 90

degrees away by applying a straight edge to the outer diameter of the main body. The life of the element is

significantly affected by the centering accuracy.

■ The specifications for special (non-catalog standard) models may differ from those given in the above table.

Check the specifications on the delivery specification sheet.

Standard bore diameter and bore diameter by limited allowable torque (Clamp style) Table 10

Model

Standard bore diameter [mm] and bore diameter by limited allowable torque [Nm]

3

4

5

6

6.35

7

8

10

11

12

14

15

16

18

19

20

22

24

25

28

ALS-014

0.31

0.42

0.54

0.65

ALS-020

1.2

1.6

2.1

2.2

2.6

3.0

ALS-030

2.0

2.2

3.4

4.7

5.4

6.0

7.4

ALS-040

8

16

23

31

34

34

34

ALS-055

38

41

48

51

54

61

67

71

80

Model

Standard bore diameter [mm] and bore diameter by limited allowable torque [Nm]

14

15

16

18

19

20

22

24

25

28

30

35

38

40

42

45

48

50

55

60

ALS-065

61

68

75

79

89

96

114

ALS-080

108

121

151

194

■ The bore diameters with values are available as standard bore diameters.

■ The allowable torque for the coupling is limited because of the clamp screw strength and bore size limitations.

Contact by email

Please contact us using the inquiry form and be aware that support for inquiries received on Saturdays,

Sundays, holidays, New Year's, and summer business holidays will be provided on the next business day.

Contact by phone

Japanese/English

Miki Pulley International Business Department

TEL +81-46-257-5109

This manual suits for next models

25

Table of contents

Other Miki Pulley Industrial Equipment manuals