Assembly and Operating Manual

Pneumatic Swivel Head type SRH

2 Date printed 30.09.11

Contents

1SAFETY.................................................................................................................................................4

1.1 SYMBOL KEY....................................................................................................................................4

1.2 APPROPRIATE USE...........................................................................................................................4

1.3 ENVIRONMENTAL AND OPERATING CONDITIONS .................................................................................4

1.4 SAFETY NOTES ................................................................................................................................5

2WARRANTY..........................................................................................................................................6

3SCOPE OF DELIVERY.........................................................................................................................6

4TECHNICAL DATA...............................................................................................................................6

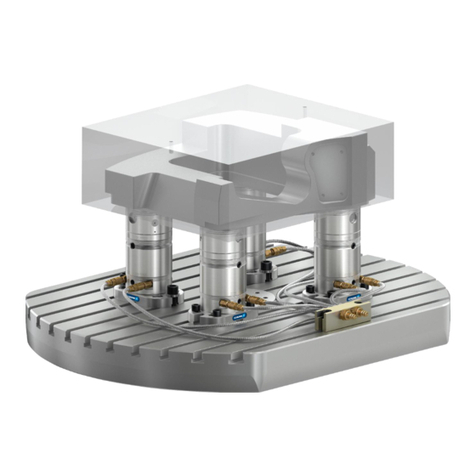

5ASSEMBLY AND INSTALLATION.......................................................................................................7

5.1 ASSEMBLY.......................................................................................................................................7

5.2 AIR CONNECTION/MEDIA CONNECTION...............................................................................................7

5.3 ADJUSTING THE END POSITIONS........................................................................................................8

5.4 FINE ADJUSTMENT OF SHOCK ABSORBER TRAVEL..............................................................................9

5.5 ASSEMBLING AND SETTING THE PROXIMITY SWITCHES .......................................................................9

5.5.1 MMS 22 magnetic switches (see data sheet)........................................................................9

5.5.2 Inductive proximity switches with M8 external thread..........................................................10

5.6 CABLE ASSIGNMENT.......................................................................................................................11

5.7 EDF PIN ASSIGNMENT FOR SRH ....................................................................................................11

6FUNCTION AND HANDLING .............................................................................................................12

7MAINTENANCE AND CARE...............................................................................................................12

7.1 SERVICING INTERVALS ...................................................................................................................12

7.2 NOTES ..........................................................................................................................................12

7.1 DISASSEMBLING THE ROTARY ACTUATOR........................................................................................13

7.2 REPLACING A SHOCK ABSORBER.....................................................................................................13

7.3 SHOCK ABSORBER USE AND INSTALLATION DIMENSIONS ..................................................................14

7.4 MEASURING INSTRUCTIONS............................................................................................................14

8ASSEMBLY DRAWINGS....................................................................................................................15

8.1 SRU ASSEMBLY DRAWINGS............................................................................................................15

8.2 SRH ASSEMBLY DRAWINGS............................................................................................................17

8.2.1 Exploded view for SRH 20-35..............................................................................................17

8.2.2 Exploded view for SRH 40-60..............................................................................................18

9BILLS OF MATERIALS ......................................................................................................................19

9.1 BILLS OF MATERIALS FOR SRH20...................................................................................................19

9.1.1 SRU bill of materials for SRH20...........................................................................................19

9.1.2 EDF bill of materials for SRH20...........................................................................................20

9.1.3 Bill of materials for SRH20...................................................................................................20

9.2 BILLS OF MATERIALS FOR SRH25...................................................................................................21

9.3 BILLS OF MATERIALS FOR SRH35...................................................................................................23

9.3.2 EDF bill of materials for SRH35...........................................................................................24

9.3.3 Bill of materials for SRH35...................................................................................................24

9.4 BILLS OF MATERIALS FOR SRH40...................................................................................................25

9.4.1 SRU bill of materials for SRH40...........................................................................................25

9.4.2 EDF bill of materials for SRH40...........................................................................................26

9.4.3 Bill of materials for SRH40...................................................................................................26

9.5 BILLS OF MATERIALS FOR SRH50...................................................................................................27

9.5.1 SRU bill of materials for SRH50...........................................................................................27