MIKSTER MIKSTER

Controller setup

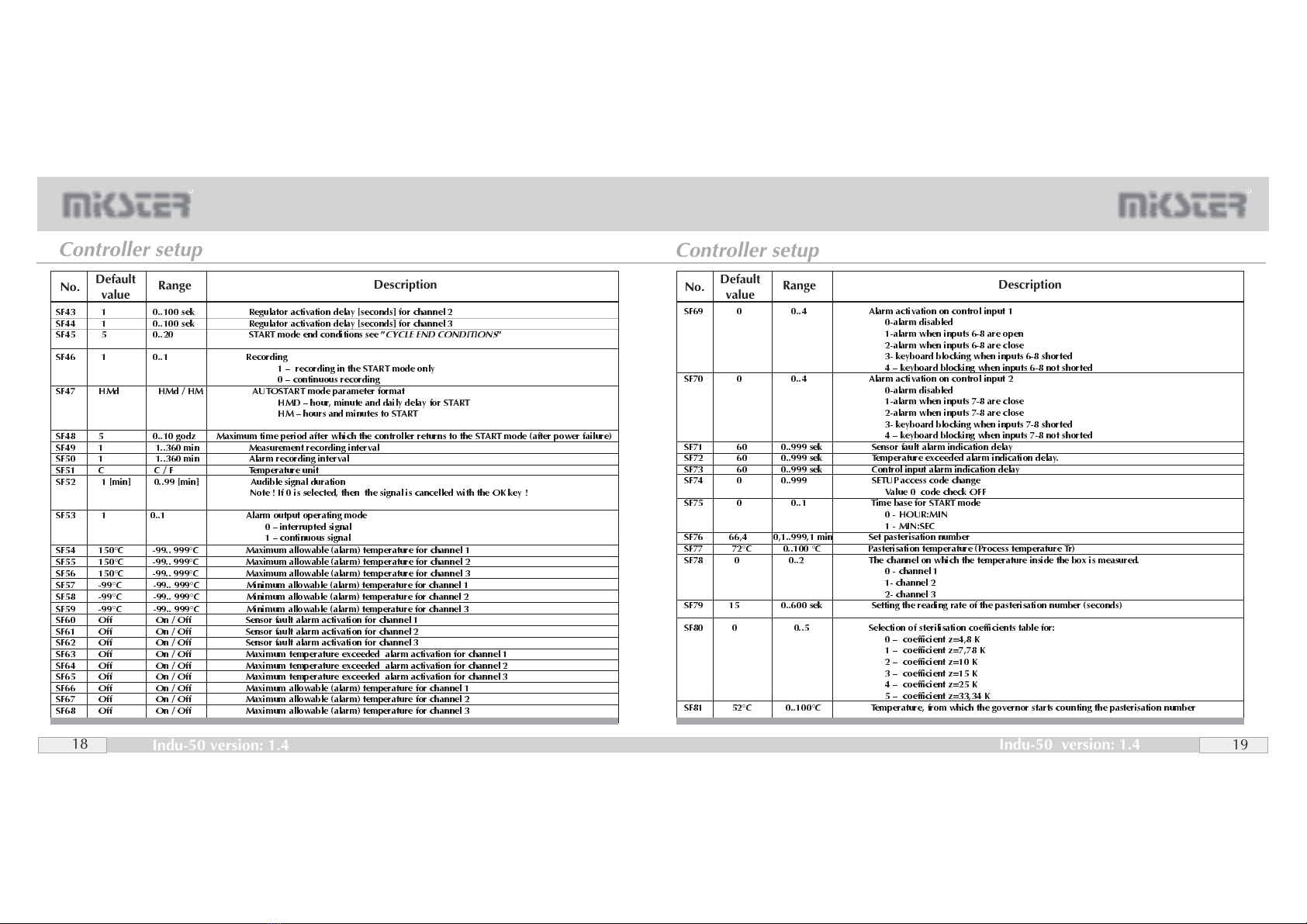

Controller setup

To get into the SETUP menu, press and hold down the key and then press the key. After

entering the access code you can change the controller parameters.

CONTROLLER SETUP

No. Description

Default

value Range

MODBUS network address

Baud rate

0 9600 ,1 19200, 2 38400,3 57600,4 115200

Channel 1 easuring input type

0 PT-500, 1 PT-100, 2 PT1000, 3 0..20 A*, 4 4..20 A*

5 ther ocouple s**, 6 ther ocouple b**, 7 ther ocouple r**, 8 ther ocouple t**

9 ther ocouple j**, 10 ther ocouple e**, 11 ther ocouple k**, 12 ther ocouple n**

* current input version, ** ther ocouple operation version

SF3 1 0..12 Measuring input type for channel 2

SF2 1 0..12

SF1 0 0..4

SF0 1 0..128

SF4 1 0..12 Measuring input type for channel 3

SF5 0 -99,0 .. 999 C Value corresponding to 0 A for channel 1 0..20 A input

°°

C

SF6 200 -99,0 .. 999 C Value corresponding to 20 A 1 0..20 A inputfor channel

°°

C

SF7 0 -99,0 .. 999 C Value corresponding to 0 A 2 0..20 A inputfor channel

°°

C

SF8 200 -99,0 .. 999 C Value corresponding to 20 A 2 0..20 A inputfor channel

°°

C

SF9 0 -99,0 .. 999 C Value corresponding to 0 A 3 0..20 A inputfor channel

°°

C

SF10 200 -99,0 .. 999 C Value corresponding to 20 A 3 0..20 A inputfor channel

°°

C

SF11 0 -99,0 .. 999 C Value corresponding to 4 A 1 4..20 A inputfor channel

°°

C

SF12 200 -99,0 .. 999 C Value corresponding to 20 A 1 4..20 A inputfor channel

°°

C

SF13 0 -99,0 .. 999 C Value corresponding to 4 A 2 4..20 A inputfor channel

°°

C

SF14 200 -99,0 .. 999 C Value corresponding to 20 A 2 4..20 A inputfor channel

°°

C

SF15 0 -99,0 .. 999 C Value corresponding to 4 A 3 4..20 A inputfor channel

°°

C

SF16 200 -99,0 .. 999 C Value corresponding to 20 A 3 4..20 A inputfor channel

°°

C

SF17 0,0 -20,0 .. 20,0 C Te perature readout adjust ent for channel 1

SF18 0,0 -20,0 .. 20,0 C Te perature readout adjust ent for channel 2

SF19 0,0 -20,0 .. 20,0 C Te perature readout adjust ent for channel 3

SF20 On On / Off Regulator operation in channel 1

OFF- always

ON- only in the START ode

SF21 On On / Off as above for channel 2

SF22 On On / Off as above for channel 3

SF23 -99 -99..400 C Mini u allowable setpoint for channel 1

SF24 150 -99..400 C Maxi u allowable setpoint for channel 1

SF25 -99 -99..400 C Mini u allowable setpoint for channel 2

SF26 150 400 Maxi u allowable setpoint for channel 2

SF27 - - -

SF28 - - -

SF29 0 0..3 Regulator type for channel 1

0 nor al hysteresis

1 reversed hysteresis

2 nor al hysteresis, setpoint ra ping algorith

3 PID regulator

SF30 0 0..3 Regulator type for channel 2

SF31 0 0..3 Regulator type for channel 3

°°

°°

°°

°°

°°

°°

°°

C

C

C

C

C

C

CC

SF32 1,0 C 0,0 .. 5,0 C Low hysteresis for channel 1

SF33 1,0 C 0,0 .. 5,0 C Low hysteresis for channel 2

SF34 1,0 C 0,0 .. 5,0 C Low hysteresis for channel 3

SF35 1,0 C 0,0 .. 5,0 C High hysteresis for channel 1

SF36 1,0 C 0,0 .. 5,0 C High hysteresis for channel 2

SF37 1,0 C 0,0 .. 5,0 C High hysteresis for channel 3

SF38 120 C -99..999 C Channel 3 te perature setpoint

SF39 20 C 0..200 C Regulator activation te perature (Tza) for channel 1

For setpoint ra ping algorith

SF40 20 C 0..200 C

SF41 20 C 0..200 C

SF42 1 0..100 sek Regulator activation delay [seconds] for channel 1

°°

°°

°°

°°

°°

°°

°°

°°

°°

°°

Regulator activation te perature (Tza) for channel 2

For setpoint ra ping algorith

Regulator activation te perature (Tza) for channel 3

For setpoint ra ping algorith

RR

-

EDIT

16 17

No. Description

Default

value Range

Indu-50 version: 1.4

Indu-50 version: 1.4