OM-256 476 Page 1

SECTION 1 −WELDING HELMET SAFETY PRECAUTIONS −

READ BEFORE USING

helmet 2012−02

Protect yourself and others from injury — read, follow, and save these important safety

precautions and operating instructions.

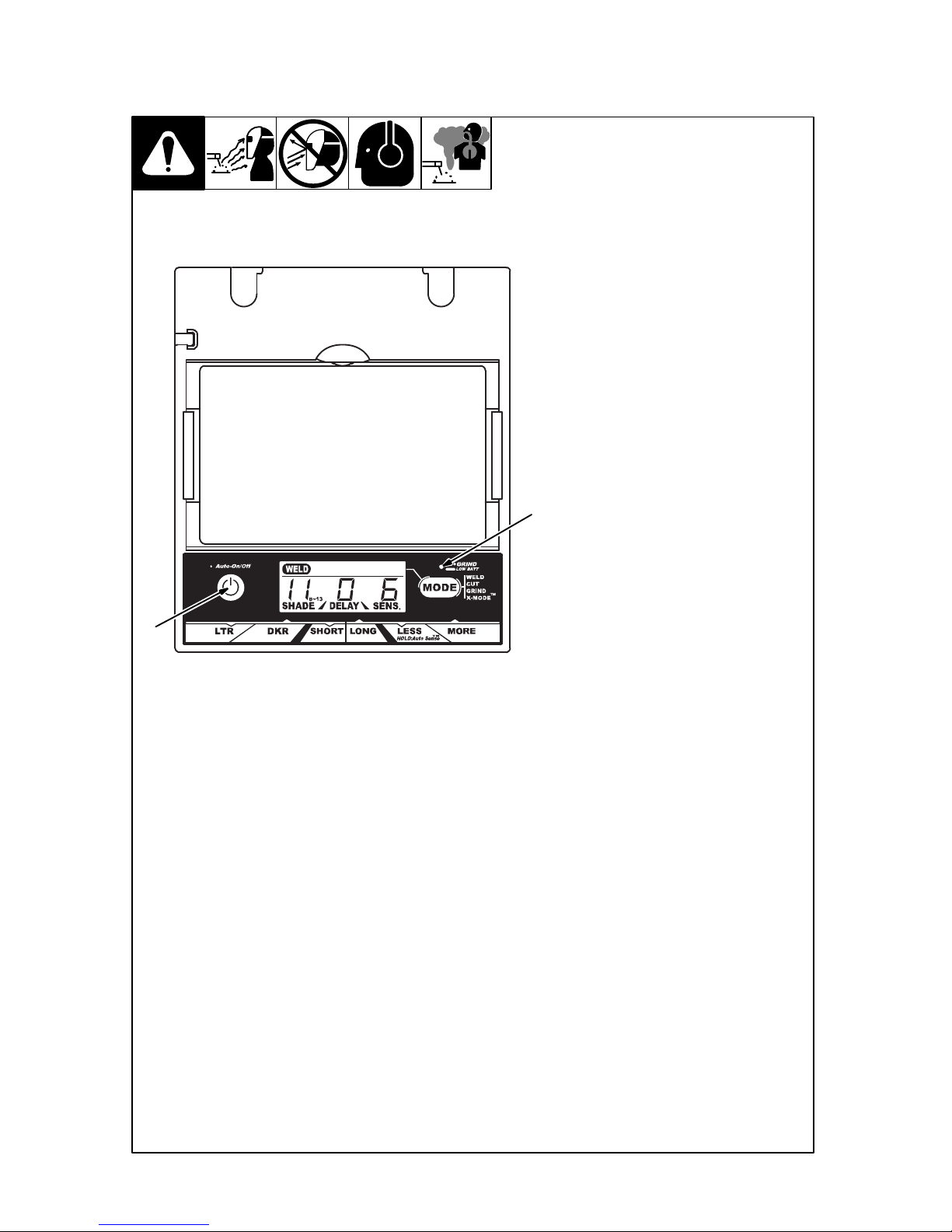

1-1. Symbol Usage

This group of symbols means Warning! Watch

Out! ELECTRIC SHOCK, MOVING PARTS,

and HOT PARTS hazards. Consult symbols

and related instructions below for necessary

actions to avoid the hazards.

Indicates special instructions.

DANGER! −Indicates a hazardous

situation which, if not avoided, will

result in death or serious injury. The

possible hazards are shown in the

adjoining symbols or explained in

the text.

Indicates a hazardous situation

which, if not avoided, could result in

death or serious injury. The possible

hazards are shown in the adjoining

symbols or explained in the text.

NOTICE −Indicates statements not related to

personal injury.

1-2. Arc Welding Hazards

Only qualified persons should install, operate, maintain, and repair this unit.

Arc rays from the welding process produce intense visible and invisible (ultraviolet

and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Wear a welding helmet fitted with a proper shade of filter to protect your face and eyes when

welding or watching (see ANSI Z49.1 and Z87.1 listed in Safety Standards). Refer to Lens

Shade Selection table in Section 1-4.

Wear approved safety glasses with side shields under your helmet.

Use protective screens or barriers to protect others from flash, glare, and sparks; warn

others not to watch the arc.

Wear protective clothing made from durable, flame-resistant material (leather, heavy cotton,

and wool) and foot protection.

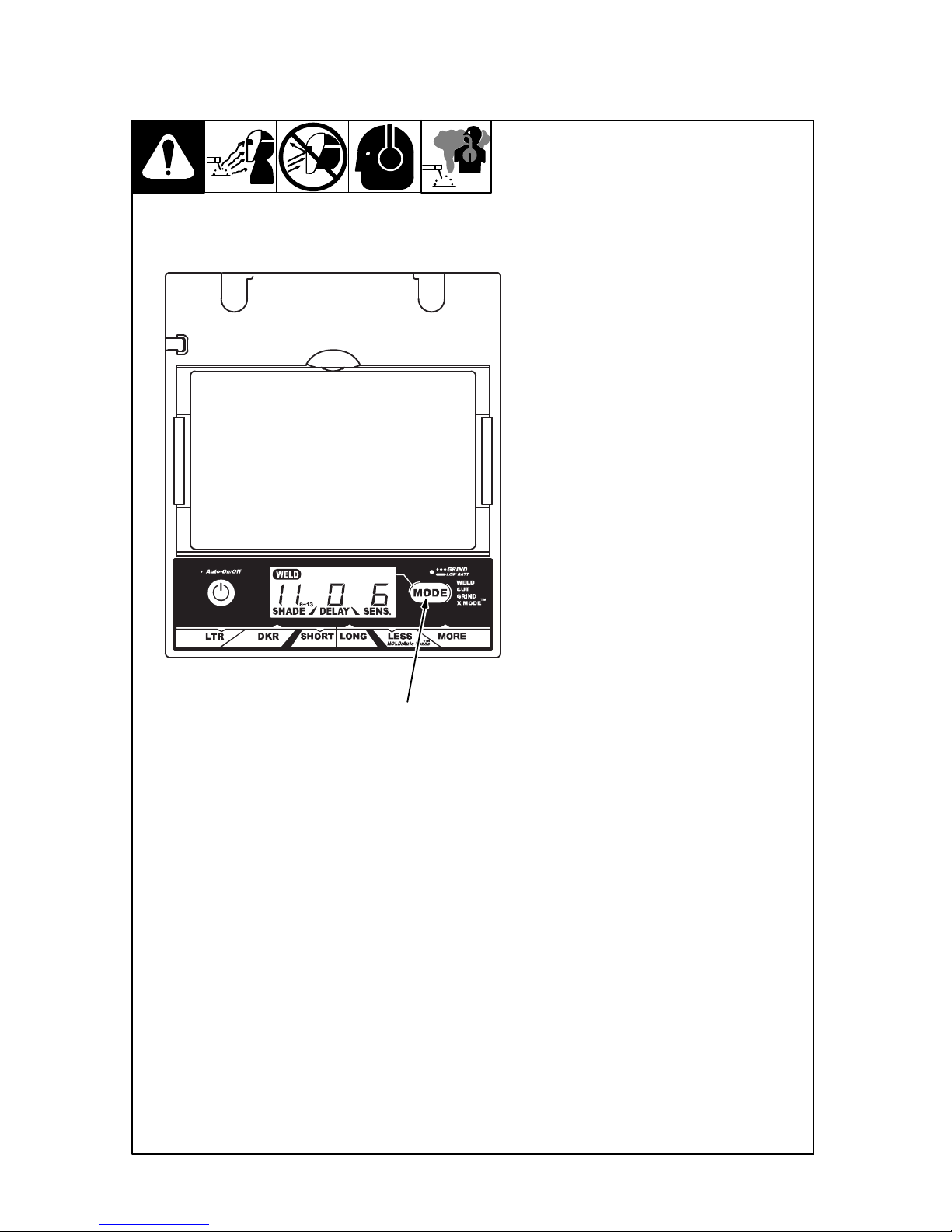

•Before welding, adjust the auto-darkening lens sensitivity setting to meet the application.

•Stop welding immediately if the auto-darkening lens does not darken when the arc is struck.

See the Owner’s Manual for more information.

ARC RAYS can burn eyes and skin.

Arc rays from the welding process produce intense visible and invisible (ultraviolet

and infrared) rays that can burn eyes and skin. Sparks fly off from the weld.

Use impact resistant safety spectacles or goggles and ear protection at all times when using

this welding helmet.

Do not use this helmet while working with or around explosives or corrosive liquids.

Do not weld in the overhead position while using this helmet.

Inspect the auto-lens frequently. Immediately replace any scratched, cracked, or pitted cover

lenses or auto-lenses.

WELDING HELMETS do not provide unlimited eye, ear, and

face protection.