OM-244997 Page 2

SECTION 2 −CONSIGNES DE SÉCURITÉ −LIRE AVANT

UTILISATION

weld table_2018-01_fre

Pour écarter les risques de blessure pour vous−même et pour autrui — lire, appliquer et ranger en lieu sûr ces consignes relatives

aux précautions de sécurité et au mode opératoire.

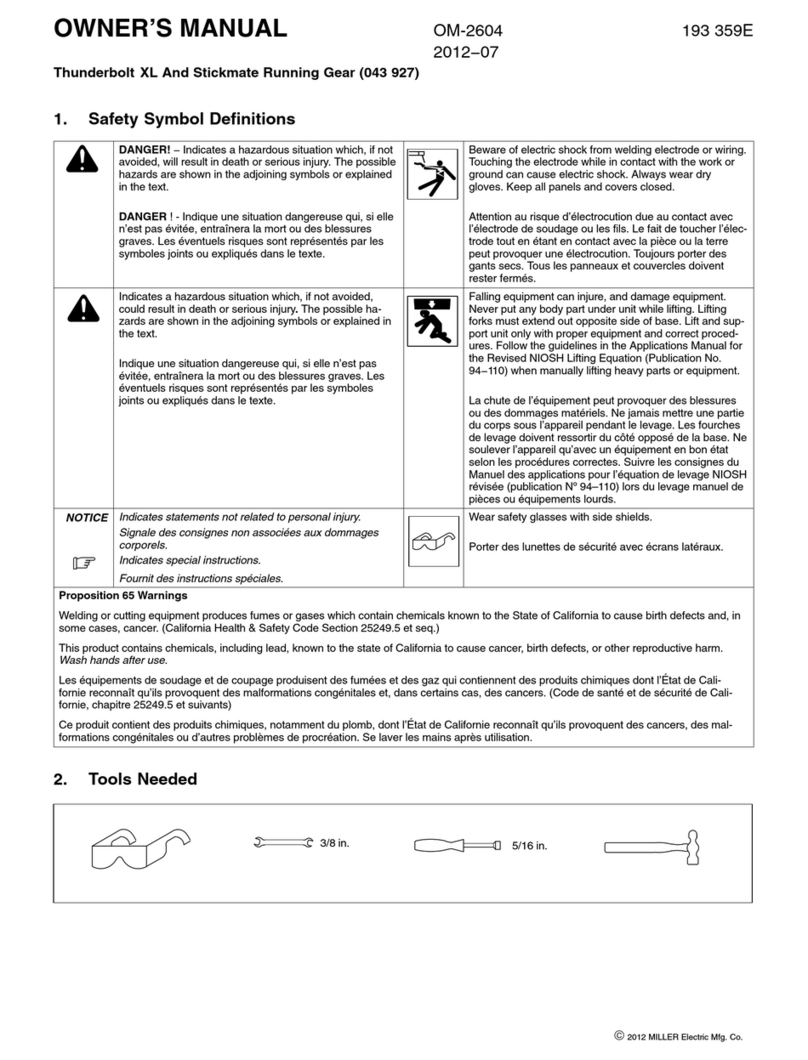

2-1. Symboles utilisés

DANGER! −Indique une situation dangereuse qui si on

l’évite pas peut donner la mort ou des blessures graves.

Les dangers possibles sont montrés par les symboles

joints ou sont expliqués dans le texte.

Indique une situation dangereuse qui si on l’évite pas

peut donner la mort ou des blessures graves. Les dan-

gers possibles sont montrés par les symboles joints ou

sont expliqués dans le texte.

AVIS −Indique des déclarations pas en relation avec des blessures

personnelles.

.Indique des instructions spécifiques.

Ce groupe de symboles veut dire Avertissement! Attention! DANGER

DE CHOC ELECTRIQUE, PIECES EN MOUVEMENT, et PIECES

CHAUDES. Consulter les symboles et les instructions ci-dessous y

afférant pour les actions nécessaires afin d’éviter le danger.

2-2. Dangers liés à la table de soudure

L’installation, l’utilisation, l’entretien et les réparations ne

doivent être confiés qu’à des personnes qualifiées. Une

personne qualifiée est définie comme celle qui, par la

possession

d’un diplôme reconnu, d’un certificat ou d’un

statut professionnel, ou qui, par une connaissance, une for-

mation et une expérience approfondies, a démontré avec

succès sa capacité à résoudre les problèmes liés à la tâche,

le travail ou le projet et a reçu une formation en sécurité afin

de reconnaître et d’éviter les risques inhérents.

LIRE LES INSTRUCTIONS.

DLire et appliquer les instructions sur les

étiquettes

et le Mode d’emploi avant l’instal-

lation, l’utilisation ou l’entretien de l’appareil.

Lire les informations de sécurité au début du

manuel et dans chaque section.

DN’utiliser que les pièces de rechange recommandées par le

constructeur.

DEffectuer l’installation, l’entretien et toute intervention selon les

manuels d’utilisateurs, les normes nationales, provinciales et de

l’industrie,

ainsi que les codes municipaux.

DNe pas réparer. modifier ou démonter la table de soudure ou l’utiliser

avec des pièces ou accessoires non fournis par le fabricant. Utiliser

uniquement des composants approuvés par le fabricant.

DS’assurer que toute la quincaillerie est bien serrée.

DNe pas utiliser la table de soudure avant d’être certain qu’elle est

bien montée et qu’elle fonctionne correctement.

DAvant chaque utilisation, inspecter la table de soudure pour

déceler tout signe de dommage et s’assurer qu’elle est bien

installée et maintenue correctement.

UNE DÉCHARGE ÉLECTRIQUE peut

entraîner la mort.

Le contact d’organes électriques sous tension peut

provoquer des accidents mortels ou des brûlures

graves.

DUn appareil mal installé ou mal raccordé à la terre est dangereux.

Installer, mettre à la terre et utiliser correctement cet appareil,

conformément

à son manuel d’utilisation et aux codes nationaux,

provinciaux et municipaux. Lire également la norme Z49.1 de

l’American National Standard Institute (ANSI), Safety in Welding,

Cutting, and Allied Processes, (Règles de sécurité en soudage,

coupage et procédés connexes) de l’American Welding Society

(www.aws.org).

Risque D’INCENDIE OU D’EXPLOSION.

DNe pas placer l’appareil sur, au-dessus ou

à proximité de surfaces inflammables.

DNe pas installer l’appareil à proximité de pro-

duits inflammables.

DUtiliser uniquement la table de soudure pour ce dont elle est

conçue. Ne pas utiliser la table de soudure pour des tâches qui

ne sont pas liées à la soudure, comme la peinture, la coupe du

bois ou toute autre activité qui pourrait produire des matières in-

flammables.

DAvant chaque utilisation, vider les débris du plateau collecteur

dans un contenant à l’épreuve des flammes.

LA CHUTE DE L’ÉQUIPEMENT peut

provoquer des blessures.

DNe pas dépasser les limites de poids de la

table de soudure, des tiroirs ou des étagères (se

reporter à la fiche technique). Distribuer le poids

de manière uniforme sur la table de soudure, dans les tiroirs et sur les

étagères. Ne pas utiliser la table de soudure, le plateau, les tiroirs ou

les étagères pour soutenir de l’équipement lourd.

DUtilisez les procédures correctes et des équipements d’une ca-

pacité appropriée pour soulever et supporter l’appareil.

DEn utilisant des fourches de levage pour déplacer l’unité, s’assu-

rer que les fourches sont suffisamment longues pour dépasser

du côté opposé de l’appareil.

DNe pas utiliser d’équipement motorisé pour tirer l’unité.

DNe pas déplacer ou installer la table de soudure à un endroit où

elle pourrait se renverser. Installer la table de soudure sur une

surface ferme et de niveau, loin des matières inflammables.

Verrouiller les roues pour maintenir la table en position.

DSuivre les consignes du Manuel des applications pour l’équation

de levage NIOSH révisée (Publication Nº94–110) lors du levage

manuellede pièces ou équipements lourds.

2-3. Proposition californienne 65 Avertissements

AVERTISSEMENT : cancer et troubles de la reproduction −www.P65W

arnings.ca.gov

.

2-4. Principales normes de sécurité

Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1,

is available as a free download from the American Welding Society at

http://www.aws.org or purchased from Global Engineering Documents

(phone: 1-877-413-5184, website: www

.global.ihs.com).

Applications Manual for the Revised NIOSH Lifting Equation, The Na-

tional Institute for Occupational Safety and Health (NIOSH), 1600

Clifton Rd, Atlanta, GA 30329-4027 (phone: 1-800-232-4636, website:

www.cdc.gov/NIOSH).