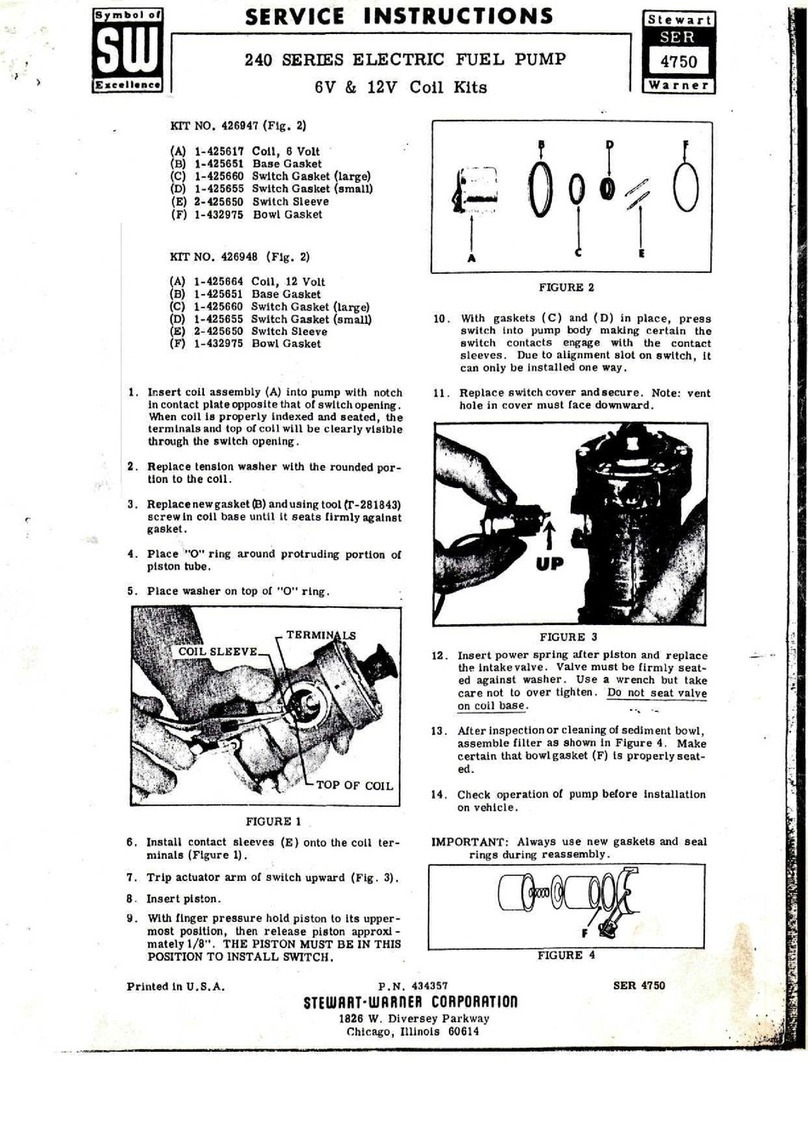

PR036484w REV 07/20 3 of 7

Product Labeling Symbols

YWARNING Direction of Pressure Control

(Valves)

ON (Power) Hot Surface

OFF (Power) Protective Conductor Terminal

How to Use the Chemical Duty

Vacuum/Pressure Pump

The Vacuum/Pressure Pump is shipped ready for

use. See the Specifications section for required

operating conditions.

CAUTION: The pump is rated for indoor use only.

CAUTION: Be sure available power matches

unit requirements. A grounded three-conductor

AC electrical source is required. Units are available for

115 V~ 60 Hz, 100 V~ 50/60 Hz, or 230 V~ 50 Hz.

See the Specifications section for details of electrical

supply options available.

1. Unpack the unit and retain all packing material until

you verify proper product operation.

2. The unit rests on four vibration isolator pads. Place

the unit on a suitable surface, such as a bench,

desk, or table. Be sure not to block the ventilation

holes located on the motor housing.

3. Select appropriately-sized tubing, according to your

application. Use approximately 1⁄4in. I.D. tubing to

withstand the anticipated pressure or vacuum.

CAUTION: During vacuum filtration, use the

supplied Millex®-FA50 hydrophobic vent filter,

to prevent excessive amounts of liquids or mist

from entering the pump (Figure 1). For maximum

protection, use a vacuum-flask water trap

(Figure 2).

4. Prepare the necessary equipment or filter holder and

connect the tubing to the equipment. Do not connect

the tubing to the pump.

5. Plug the power cord into an appropriate

electrical source.

CAUTION: Do not turn the pump on with

equipment or filter holder already attached.

If the pump is inadvertently turned on with the

tubing fully connected and it does not run, turn

off the pump and disconnect the tubing. Restart

the pump and then reconnect the tubing. If the

pump’s thermal overload switch automatically

shuts off the motor, disconnect the tubing and

allow the pump to cool for at least 10 minutes

before restarting. Reconnect the tubing only after

the pump is operating.

6. Turn on the pump, using the toggle switch located

on the front of the pump.

7. Connect the tubing from the filter holder or other

equipment to the pump and begin your procedure.

8. If using the pump for vacuum: Adjust the

vacuum by closing the pressure regulator

and opening the vacuum regulator fully

(counterclockwise). Slowly tighten down (clockwise)

the vacuum regulator until you obtain the desired

vacuum reading on the vacuum gauge.

If using the pump for pressure: Adjust the

pressure by turning the vacuum regulator down

fully and opening the pressure fully (turn counter

clockwise). Slowly tighten down (turn clockwise)

the pressure regulator until you obtain the desired

pressure reading on the pressure gauge.

9. Turn off the pump when you are finished.Disconnect

the tubing first from the pump and then from the

filter holder or other equipment.

Maintenance

Under normal operating conditions, and using

proper handling procedures, the chemical duty

vacuum/pressure pump should provide many hours

of trouble-free operation.

Dry vacuum/pressure pumps are 100% oil-free.The

pump employs a non-lube piston and cylinder. No

maintenance is necessary for the bearings.

All bearings are sealed and permanently lubricated.

Lubrication should not be attempted. The units are

built for continuous duty operation with quietness

and durability.

CAUTION: Do not lubricate any of the parts with oil,

grease or petroleum products. Do not clean with acids,

caustics, or chlorinated solvents. Do not replace the

connecting rod or motor bearings.

Disconnect the pump from power before

performing any maintenance.