Mimaki Europe B.V.

Textile and Apparel Products

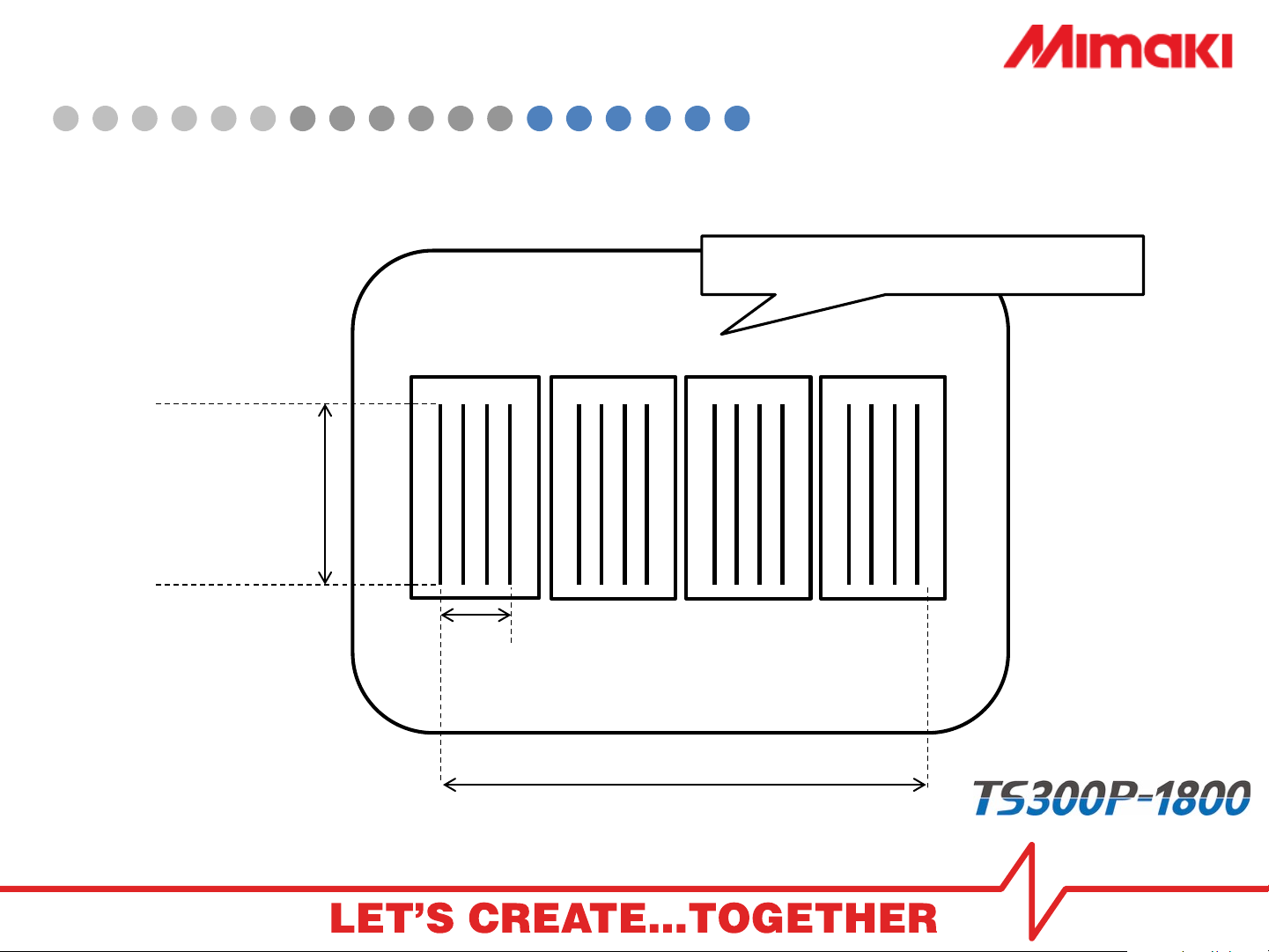

Configuration

5

Works with: PS,EPS,TIFF,BMP,JPEG, etc.

Minimum recommended PC configuration

CPU: Core i5 3.5GHz

Memory: 8GB

HDD: 500GB

I/F : USB2.0, 4 ports or more

ODD: DVD-ROM

Network: 1000BASE-T

Compatible OS : Windows Vista(32/64bit)

Windows 7(32/64bit)

Windows 8(32/64bit)

Windows 10(32/64bit)

Monitor: 1366x768

Standard configuration

&

Options:

•TxLink3 Standard/Professional

•RasterLink 6

•Additional pinch rollers

•Anti-static sheet

USB 2.0, 5m cable is recommended

or

Ethernet 1000BASE-T CAT6*

Output / Status

Inks:

•Dye sublimation ink “Sb410”

•Ink colors: BLT,MT,YT,KT,LBT,LMT,LKT,FPT,FYT

•Supply: 2L ink pack

*Use a network CAT6 cable

Connection via a relaying router is not supported. When using a switch, use a 1000BASE-T supported version.

Lite

Including:

•Heater unit 1800

•TxLink3 Lite

•Tension bar