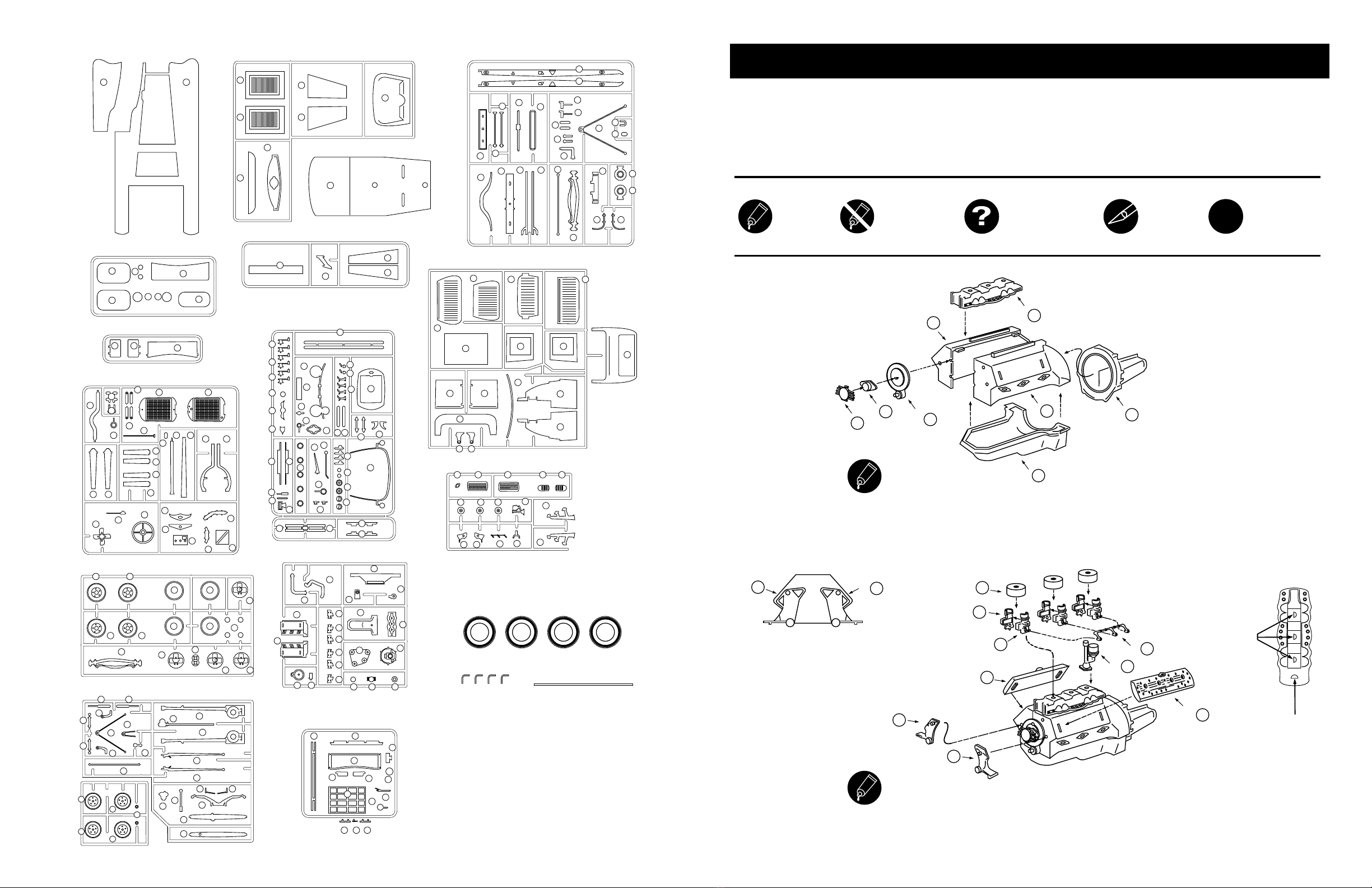

27

Cement dash to chassis, carefully threading the steering

linkage through hole in firewall and aligning it with the small

indentation on the lower dash. Cement part E(4) to dash,

wrapping around steering linkage. Cement steering wheel parts

as shown and cement to steering linkage.

27

J

14

J

13

J

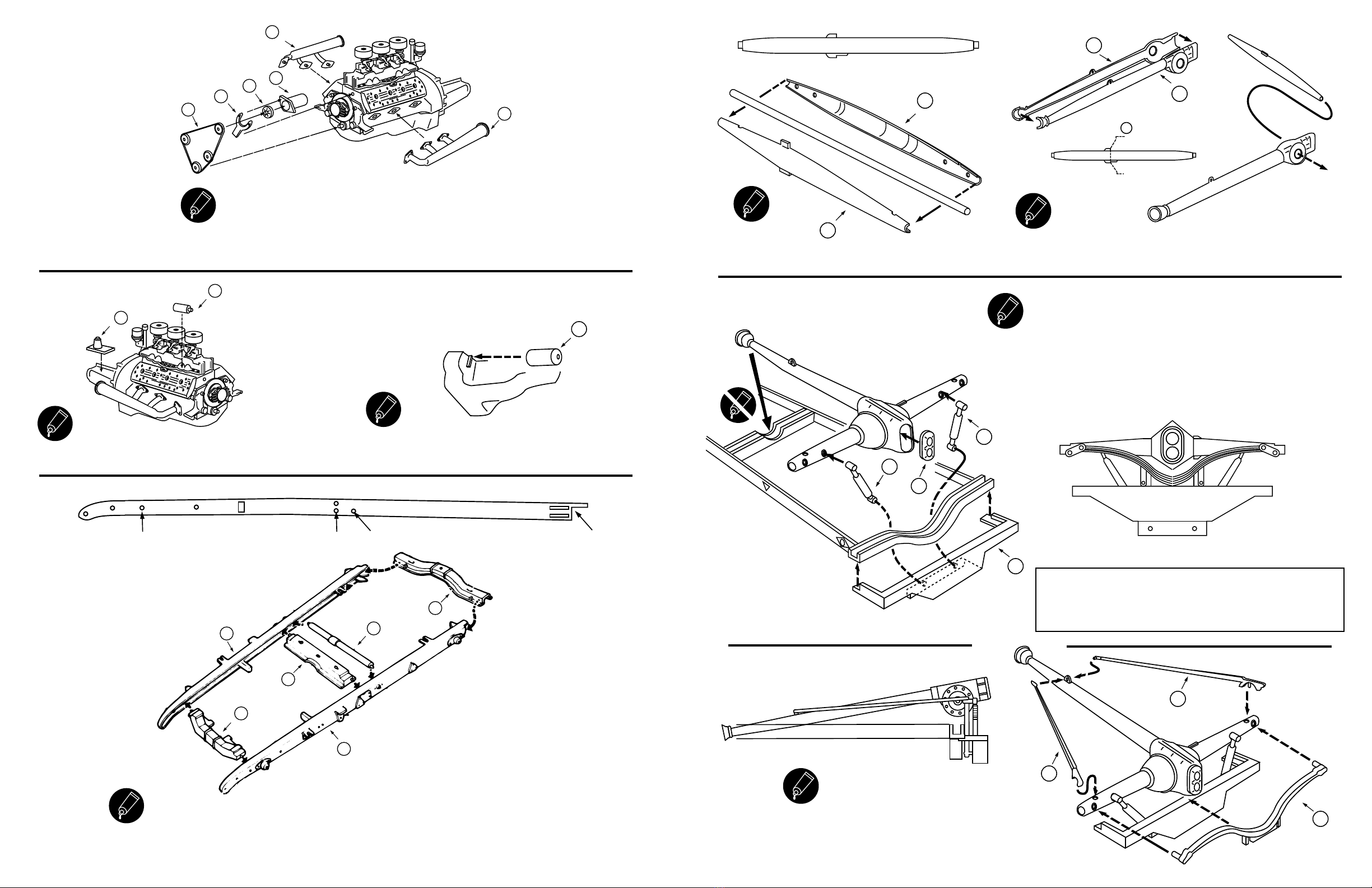

28

Assemble radiator a shown. Cement water hoses (62/24) to the engine. Glue

radiator in place on frame, the glue hoses to radiator. Cement tie rods (13/14)

in place as shown.

Fit parts into holes

as indicated

14

B

24

B

13

B

13

F

14

F

24

B

62

B

62

B

1

F

2

F

2

J

24

F

25

F

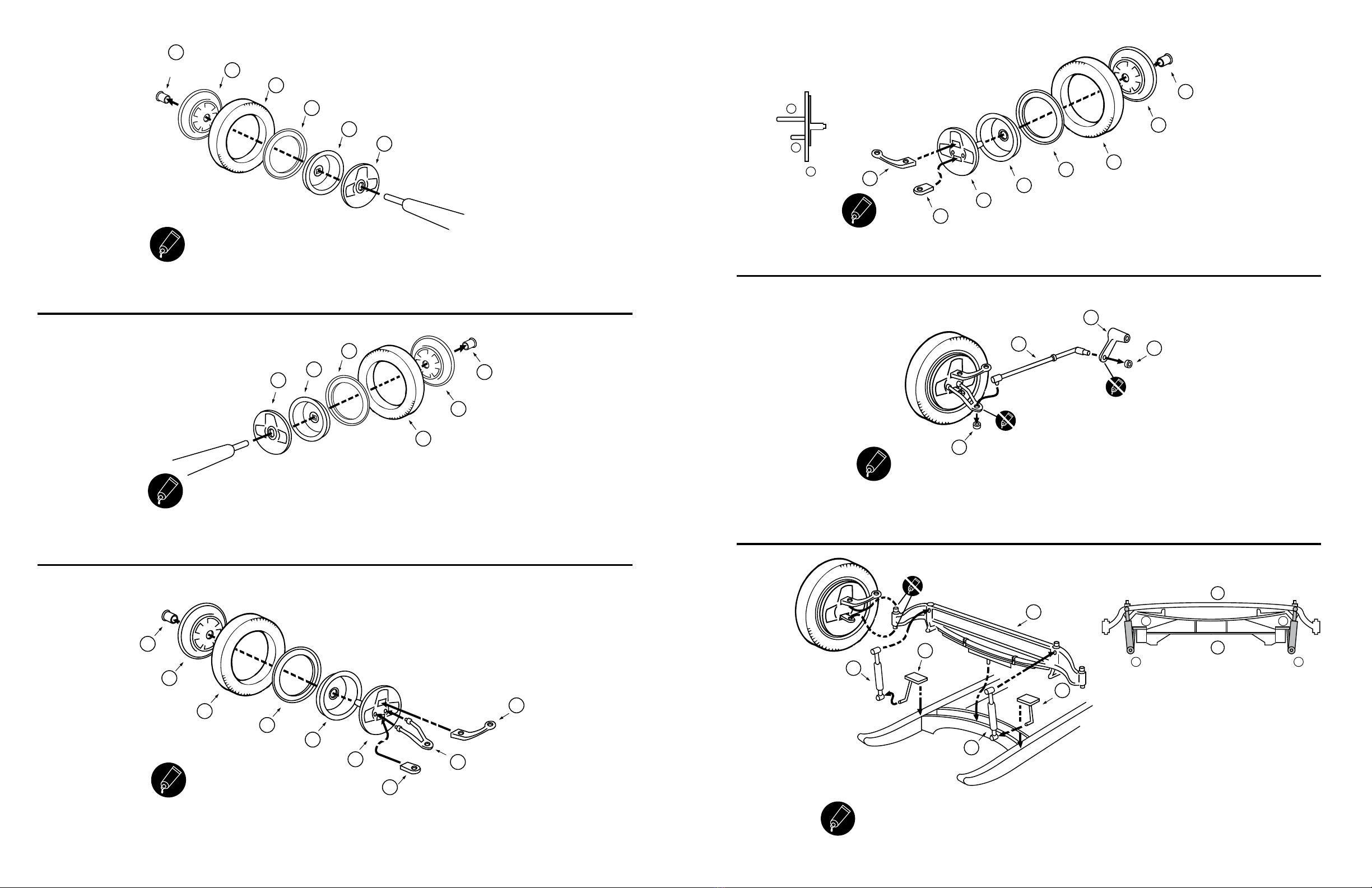

29

Assemble seat L (15) and L (2), then insert into body

shell L (16). Do not glue.

15

L

16

L

2

L

30

Cement sides L (7) and L (8) to body shell. Do not apply glue

to hinge points. Attach seat bottom L (3).

7

L

3

L

8

L

OPTIONAL STEP OPTIONAL STEP

4

E

31

Cement body shell to assembled chassis.

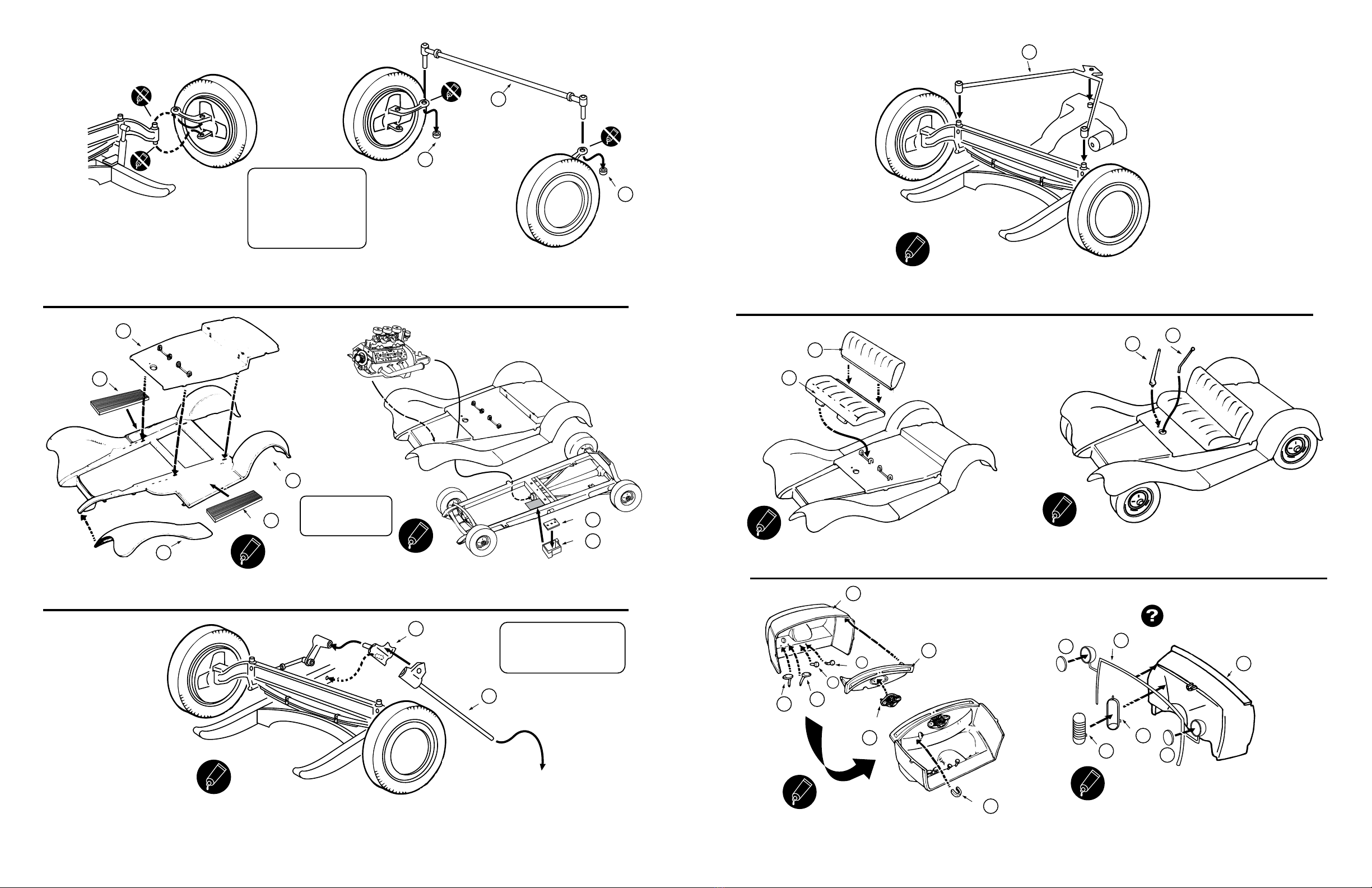

32

Cement door halves L (10,14) together. Cement hinge pin

to hinge E (9), then cement hinges E (8,9) to door.

33

Cement door halves L (9,13) together. Cement hinge pin

to hinge E (9), then cement hinges E (8,9) to door.

35

34

Fit (do not cement) hinges F5 to door hinges. Hold door

shut and in place with tape, then carefully cement hinges

F (5) to body.

Fit (do not cement) hinges F5 to door hinges. Hold door

shut and in place with tape, then carefully cement hinges

F (5) to body.

8

E

9

E

13

L

9

L

5

F

5

F

5

F

5

F

36

Glue part C(2) and C(3) together using a slow-setting cement.

Align assembly with radiator and firewall and glue in place.

3

C

2

C

9

E

8

E

14

L

10

L

Shorten one end of hinge pins to dimensions shown.

Glue into position as shown.

(Part is shown upside down).

End view

1/16"

(2mm)

2X

Steps

32/33

10 11