© Copyright MINOS DIS TICARET LIMITED SIRKETI., 2017. All rights reserved. Reprinting, even of sections, only possible with the approval of

MINOS DIS TICARET LIMITED SIRKETI. Document No: T-DYKM 1,5-2.2018_I.O.M./ Tarih: 09.07.2018

This warranty provided by Minos Agricultural Machinery does not cover any faults caused by

any abnormal or unintended use of the meter.

We declare:

● that during the warranty period, the product will operate flawlessly, if you use it in

accordance with its purpose and the enclosed instructions;

● that upon your request, we will repair any defect of the machine if you inform us of it

during the warranty period. The warranty takes effect from the date of purchase of the

product, evident from the certified warranty certificate and the receipt.

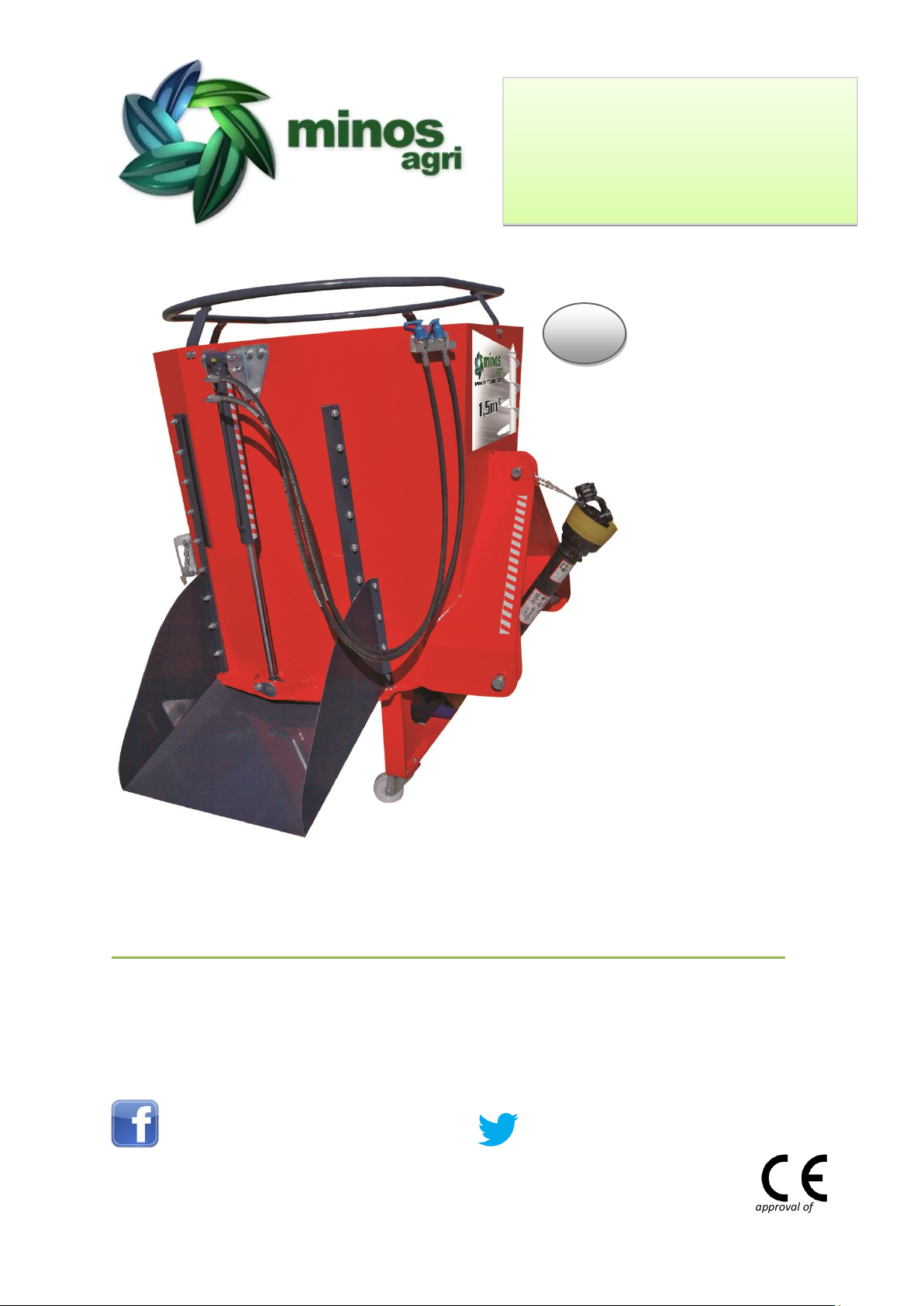

● The machine is designed to bring various animal feed into a homogenous mixture and to

distribute this mixture to the animals.

The warranty becomes invalid due to:

● failure to comply with the enclosed instructions;

● damage and faults caused by improper use;

● usage of an unsuitable PTO shaft;

● negligent handling of the product, overloading which leads to the fracture of any parts;

● interference with the product by an unauthorised person;

● damage caused by mechanical shock due to the fault of the buyer or a third person;

● damage caused by flooding, fire, lightning;

● damage and faults caused during transport, shipment, loading and unloading;

● damage and faults caused by fire, lightning, flood and earthquake (natural disasters),

inappropriate environment and accidents;

● faults caused by installation or connection of the meter not in compliance with the

installation and operating manual;

The warranty will be valid only for the period stated on the reverse side of this certificate

and the faults at the product, and no other right or damages under any reason whatsoever

can be claimed. In the events that the warranty certificate is destroyed or defaced, that the

serial number on the product is removed or destroyed, the warranty certificate will become

null and void. Any warranty certificate not bearing the seal and authorised signature of the

seller and the date of sale will not be valid.

MINOS is liable for damages it caused by intentional and deliberate damages, not for minor

negligence. Besides, it will not be liable for the results, including but not limited to the

interruption of business activities or loss from profit due to this reason, or any loss caused as

a result of the failure of a duty due to the breakdown of the product.

If there is any defect in the product, the defective product shall be sent to MINOS with risks

and expenses on customer’s account. The defects of the product will be removed by MINOS

by replacing a new one or repairing the same.

CAUTIONS ABOUT THE WARRANTY