Avoid Noise Problems

Check and follow the local regulations for sound levels and hours of operation for garden machinery.

In general, operate Multi-Tools between 8 am and 5 pm on week days and 9 am to 5 pm at weekends.

Avoid using the Multi-Tool late at night and/or early in the morning.

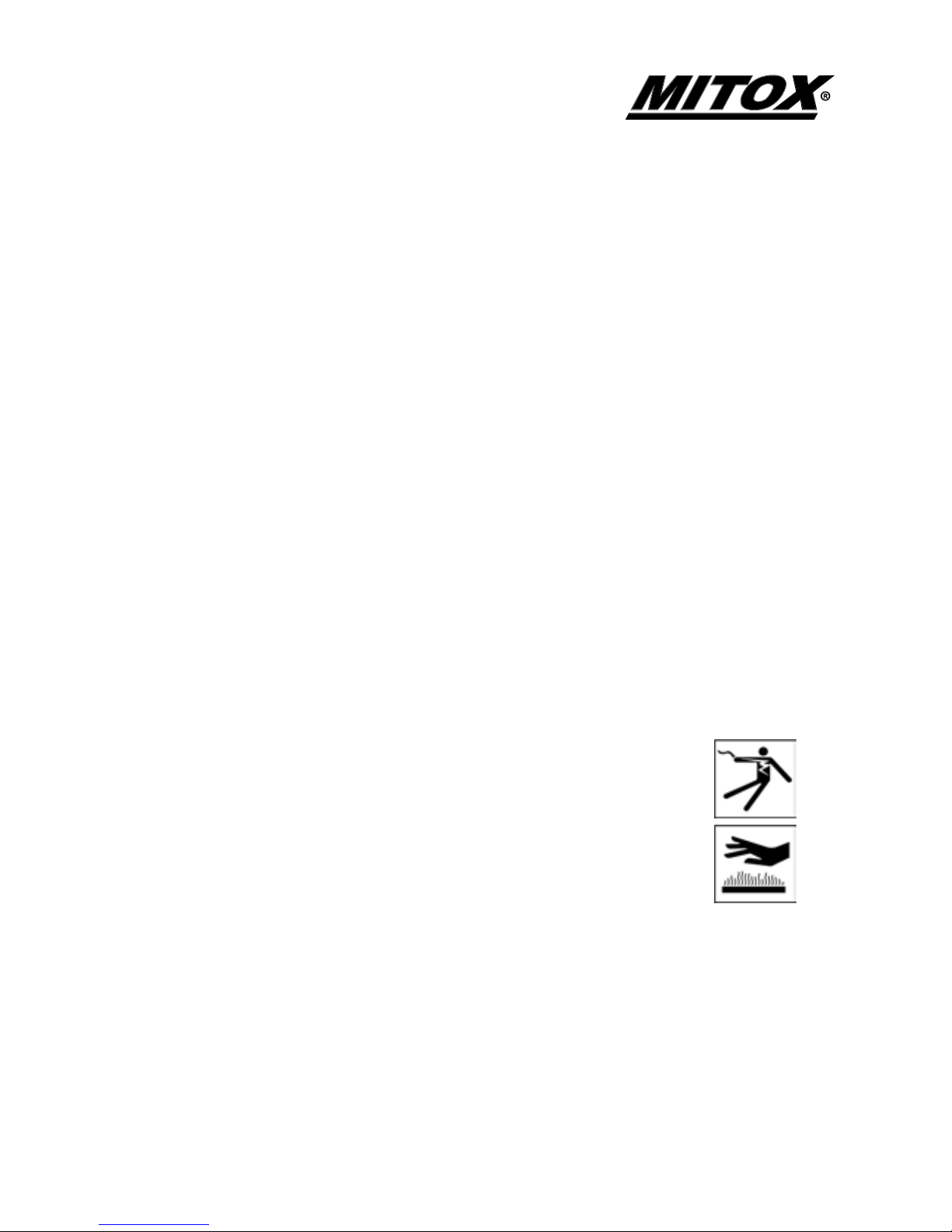

Safety when using the Multi-Tool

When using the Multi-Tool, grip the handles rmly with both hands, place your feet slightly apart so your

weight is distributed evenly across both legs, and always maintain a steady even posture while working. Do

not use on ladders or if the ground surface is slippery or uneven. Never attempt to cut directly overhead or

with one hand.

• Maintain full engine speed when cutting.

• Never allow other persons to come within the work area as doing so

might expose them to danger.

• Keep work area clear of all persons, particularly small children and pets.

Injury may result from ying debris.

• If grass or other objects get caught in the Multi-Tool during operation,

always stop the engine before removing the object.

• Never touch the spark plug or plug HT cable while the engine is in operation,

doing so may result in an electrical shock.

• Never touch the exhaust, spark plug, or any metallic parts while the engine

is in operation or immediately after shutting down the engine. These parts

reach high temperatures during operation and doing so could result in serious burns.

• When you nish cutting in one location and wish to continue work in another area, stop the

engine and t the blade safety guards.

• Always remove fuel from the fuel tank before transportation to prevent fuel spillage.

• Never leave the Multi-Tool exposed to direct sunlight as this can heat the fuel tank and may cause

a discharge of fuel, and ood the engine.

• Be careful not to hit the nylon cutting head against stones or the ground.