MEES18K070

Hydro unit

4

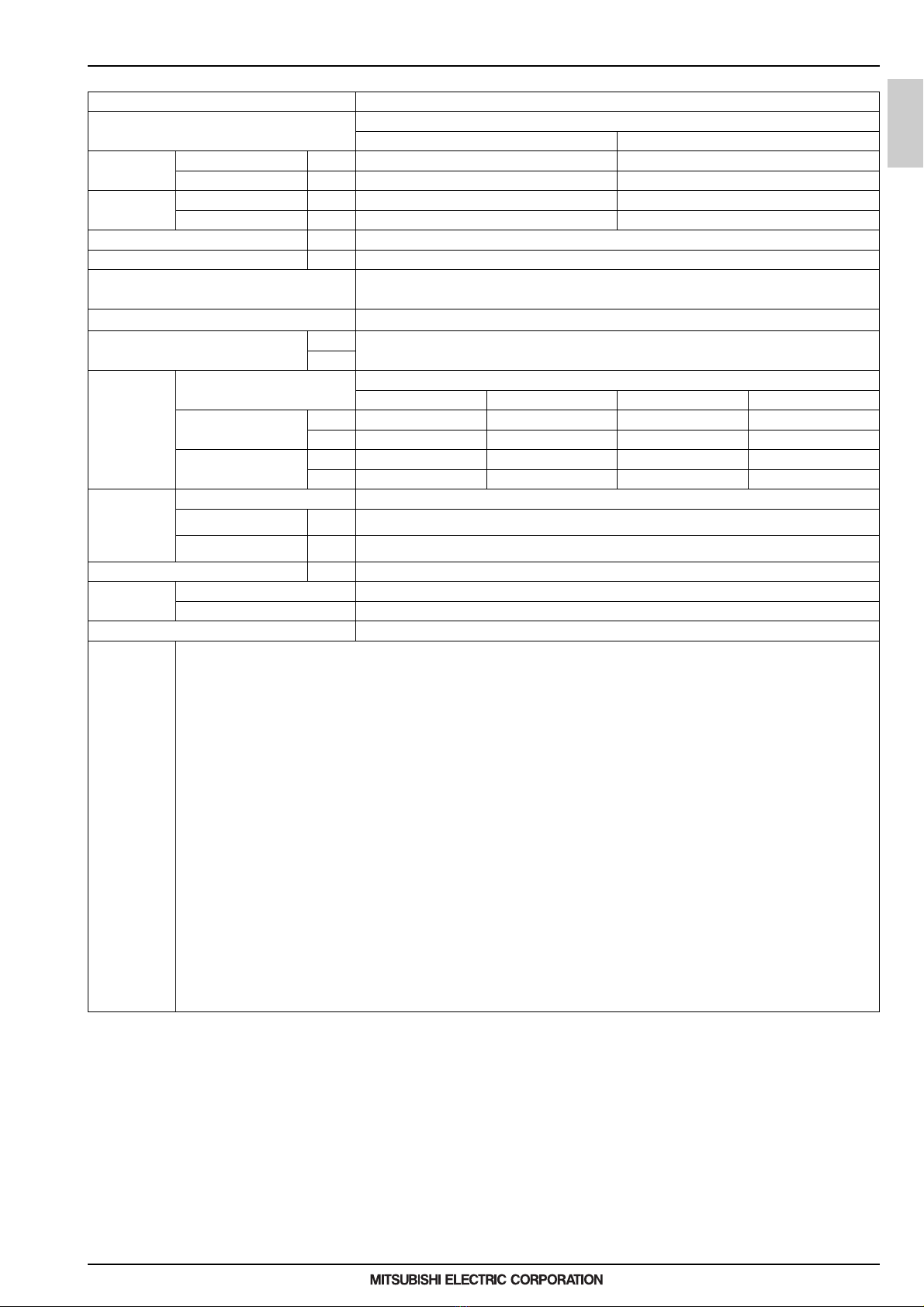

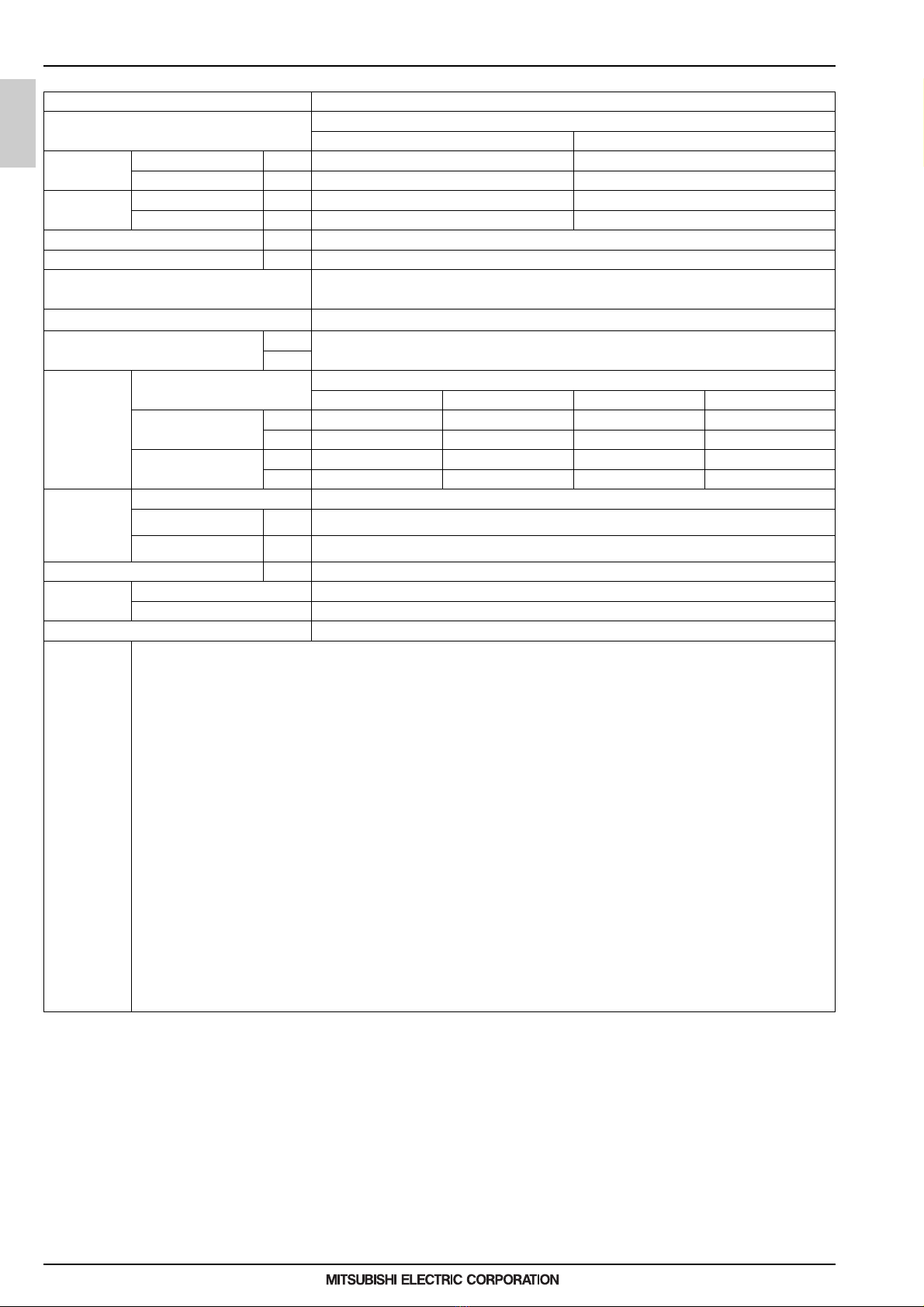

1. SPECIFICATIONS Hydro unit

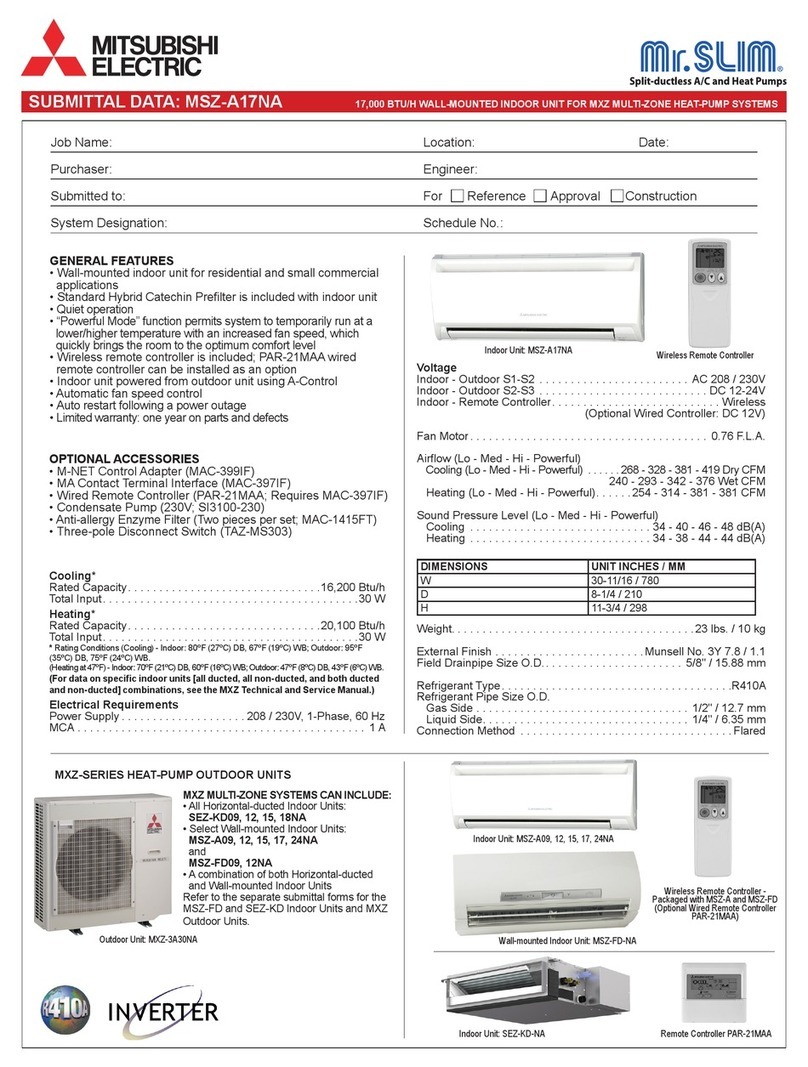

Model name CMH-WM500V-A

Power source 1-phase 220-230-240 V

50 Hz 60 Hz

Power input Cooling kW 1.06/1.06/1.06 1.06/1.06/1.06

(220/230/240) Heating kW 1.06/1.06/1.06 1.06/1.06/1.06

Current input Cooling A 5.47/5.23/5.02 5.47/5.23/5.02

(220/230/240) Heating A 5.47/5.23/5.02 5.47/5.23/5.02

Sound pressure level (measured in anechoice room) dB <A> 60

Applicable temperature range of installation site °C (D.B.) -5~52

External finish Pre-coated galvanized steel sheets

(Lower part drain pan: Pre-coated galvanized sheets + powder coating)

Connectable outdoor/heat source unit capacity (E)M400~500

External dimension H x W x D mm 660 x 920 x 740

in. 25-63/64 x 36-7/32 x 29-9/64

Refrigerant piping

diameter

To outdoor/heat source unit Connectable outdoor/heat source unit capacity

M400 M450/500 EM400 EM450/500

Liquid pipe mm (in.) 12.7 (1/2) 15.88 (5/8) 12.7 (1/2) 15.88 (5/8)

O.D. Brazed Brazed Brazed Brazed

Gas pipe mm (in.) 28.58 (1-1/8) 28.58 (1-1/8) 28.58 (1-1/8) 28.58 (1-1/8)

O.D. Brazed Brazed Brazed Brazed

Water piping

diameter

To Indoor unit

Inlet Pipe mm (in.)

I.D. 50 (2) housing joint

Outlet Pipe mm (in.)

I.D. 50 (2) housing joint

Net weight kg (lbs) 143 (316) [157 (347) with water]

Standard

attachment

Document –

Accessories Y-type strainer, Auto air vent valve, Joint, Elbow, Pipe

Optional parts Drain pan (PAC-SH01DP-E)

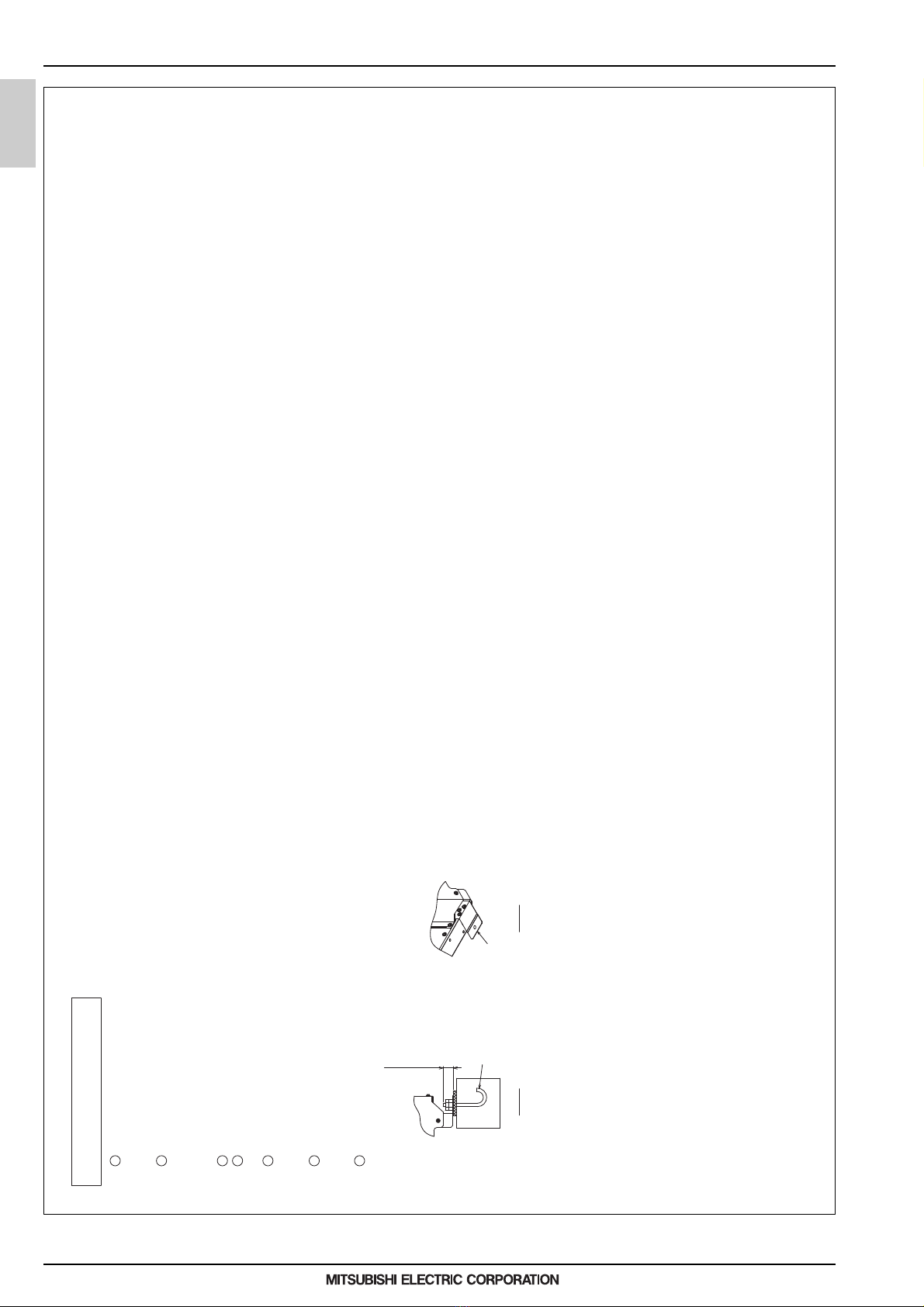

Note 1.Works not included:

Installation/foundation work, electrical connection work, duct work, insulation work, power source switch, and other items are not specified in this specifications.

2.The equipment is for R32 refrigerant.

3.Install this product in a location where noise (refrigerant noise) emitted by the unit will not disturb the neighbors.

(For use in quiet environments with low background noise, position the Hydro unit at least 5 m away from any indoor units.)

4.Please install the Hydro unit in a place where noise will not be an issue.

5.Please attach an expansion vessel (field supply).

6.Use copper, plastic, steel, or stainless steel pipes for the water circuit. Furthermore, when using copper pipe-work use a non-oxidative brazing method.

Oxidation of the pipe-work will reduce the pump life.

7.When brazing the pipes, be sure to braze, after covering a wet cloth to the insulation pipes of the units in order to prevent it from burning and shrinking by heat.

8.Please install an air purge valve where air will gather in the water circuit.

9.Please install a pressure reducing valve and a strainer on the water supply to the Hydro unit.

10.Please refer to the databook or the installation manual for the specified water quality.

11.Please always make water circulate or pull out the circulation water completely when not using it. *Please do not use it as a drinking water.

12.Please do not use ground water and well water.

13.When installing the Hydro unit in an environment which may drop below 0 °C, please add antifreeze to the circulating water.

(Refer to the data-book and the installation manual).

14.R32 is flammable, and certain restrictions apply to the installation of units.

When installing new units, moving the existing units, or changing the layout of the room,

ensure that installation restrictions are observed.

For detail, refer to the section in the Databook on installation restrictions.

15.Drain or condensation water will be discharged from hydro units during test run. If this will be a problem, install a separately sold drain pan.

16.Do not install the unit where it could be salt-damaged.

0000005070.BOOK 4 ページ 2018年11月15日 木曜日 午後6時41分