(2/n) LEN130391B

CONTENTS

General Description .................................................................................................................................3

Specification.............................................................................................................................................4

Configuration Conditions of CC-Link System..........................................................................................5

3.1 Remote net ver.2 mode, remote net addional mode........................................................................5

Programming............................................................................................................................................7

4.1 Programming Procedure...................................................................................................................7

Parameter Settings ..................................................................................................................................8

5.1 Procedure from Parameter Settings to Data Link Startup................................................................8

5.1.1 CPU ParameterArea and Master Module Parameter Memory.............................................8

5.1.2 Procedure for Parameter Settings to Data Link Startup with GX Developer ........................8

5.2 Example of Parameter Settings with GX Developer (Remote net ver.2 mode)..............................9

5.2.1 Master Station Network Parameter Settings.........................................................................9

Communication Between the Master Station and ME96.......................................................................13

6.1 Communication Guideline...............................................................................................................13

6.2 Initial Communication .....................................................................................................................14

6.3 Error Communication......................................................................................................................14

6.4 Normal Communication..................................................................................................................15

6.4.1 Monitoring by Pattern...........................................................................................................15

6.4.2 Monitoring by Command(1H)...............................................................................................16

6.4.3 Setting by Command(2H)....................................................................................................17

Remote I/O and Remote Register .........................................................................................................18

7.1 Remote Input RX, Remote Output RY............................................................................................ 18

7.1.1 Remote input RX..................................................................................................................18

7.1.2 Remote Output RY...............................................................................................................20

7.2 Remote Register (RWr, RWw)........................................................................................................ 22

7.2.1 When Monitoring by Pattern................................................................................................25

7.2.2 When Monitoring by Command(1H)....................................................................................28

7.2.3 When Setting by Command(2H)..........................................................................................42

7.2.4 Data format of Monitoring by Command(1H) and Setting by Command(2H).....................45

7.2.5 Multiplying factor..................................................................................................................56

7.2.6 About Error Occurrence.......................................................................................................57

Abbreviations and Special Terms...........................................................................................................58

Program Example ..................................................................................................................................59

9.1 Program Content.............................................................................................................................59

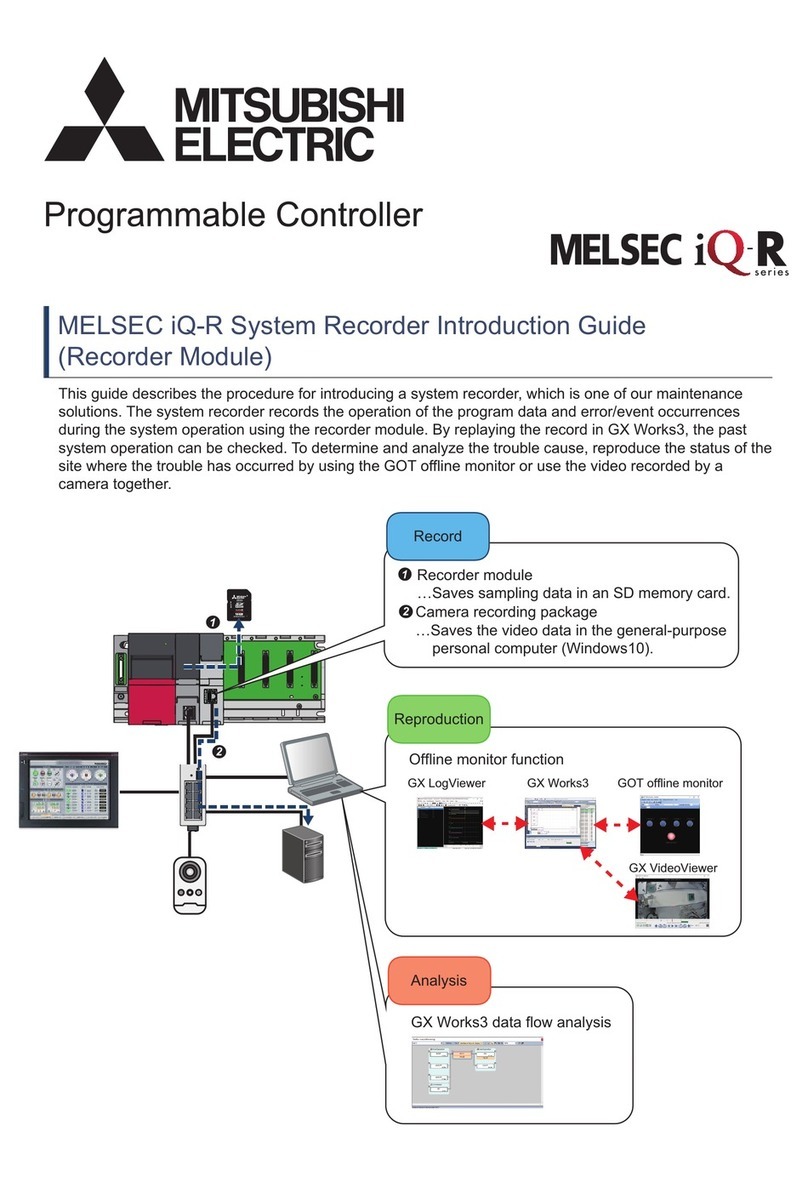

9.2 System Configuration .....................................................................................................................59

9.3 Parameter Settings.........................................................................................................................60

9.3.1 Network Parameter Settings and Auto Refresh Parameter Settings ..................................60

9.3.2 Operational Settings............................................................................................................61

9.3.3 Station Information Settings.................................................................................................61

9.4 Device Allocation.............................................................................................................................62

9.5 Program Example...........................................................................................................................64

Test Mode...............................................................................................................................................69

10.1 ME96SSH/SSR/SSHA/SSRA/SSHB/SSRB-MB ............................................................................ 69