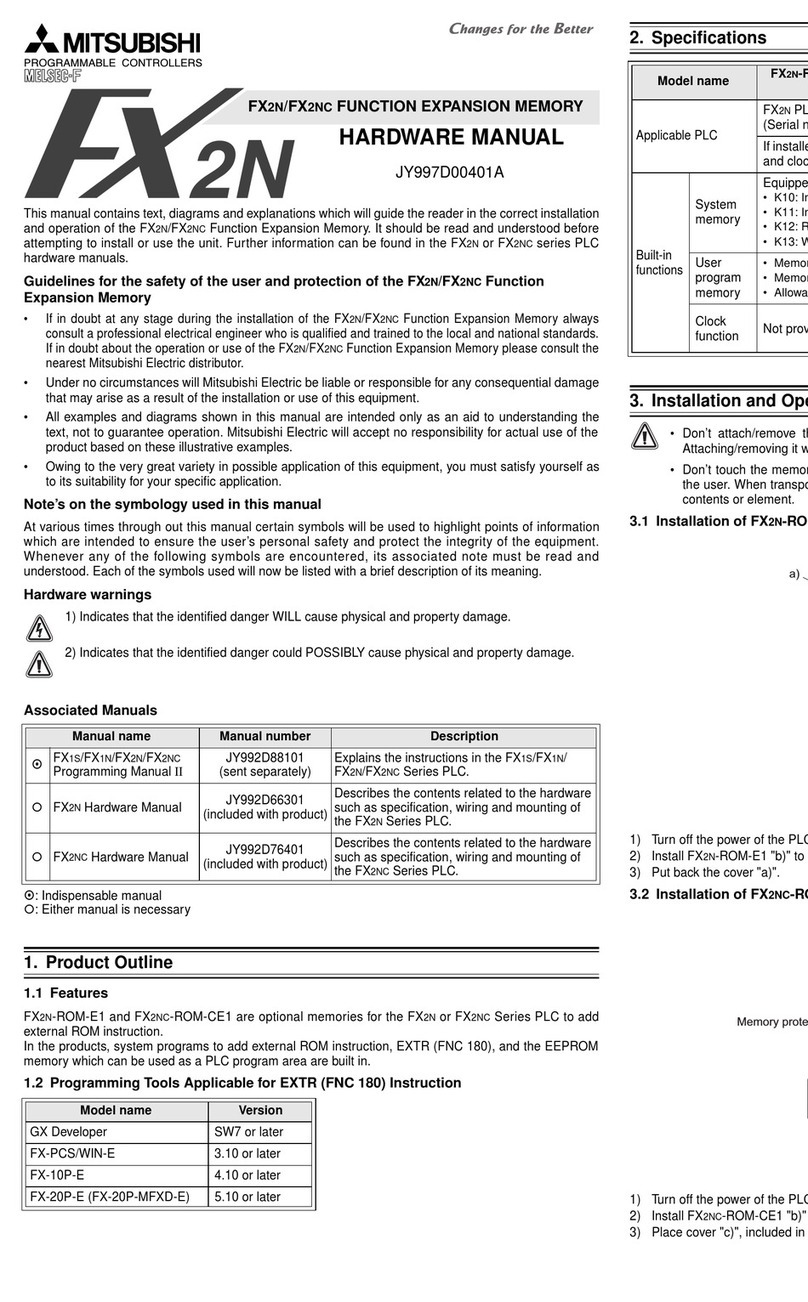

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any

patent licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving

industrial property rights which may occur as a result of using the contents noted in this manual.

HEAD OFFICE

HIMEJI WORKS

: TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

: 840, CHIYODA CHO, HIMEJI, JAPAN

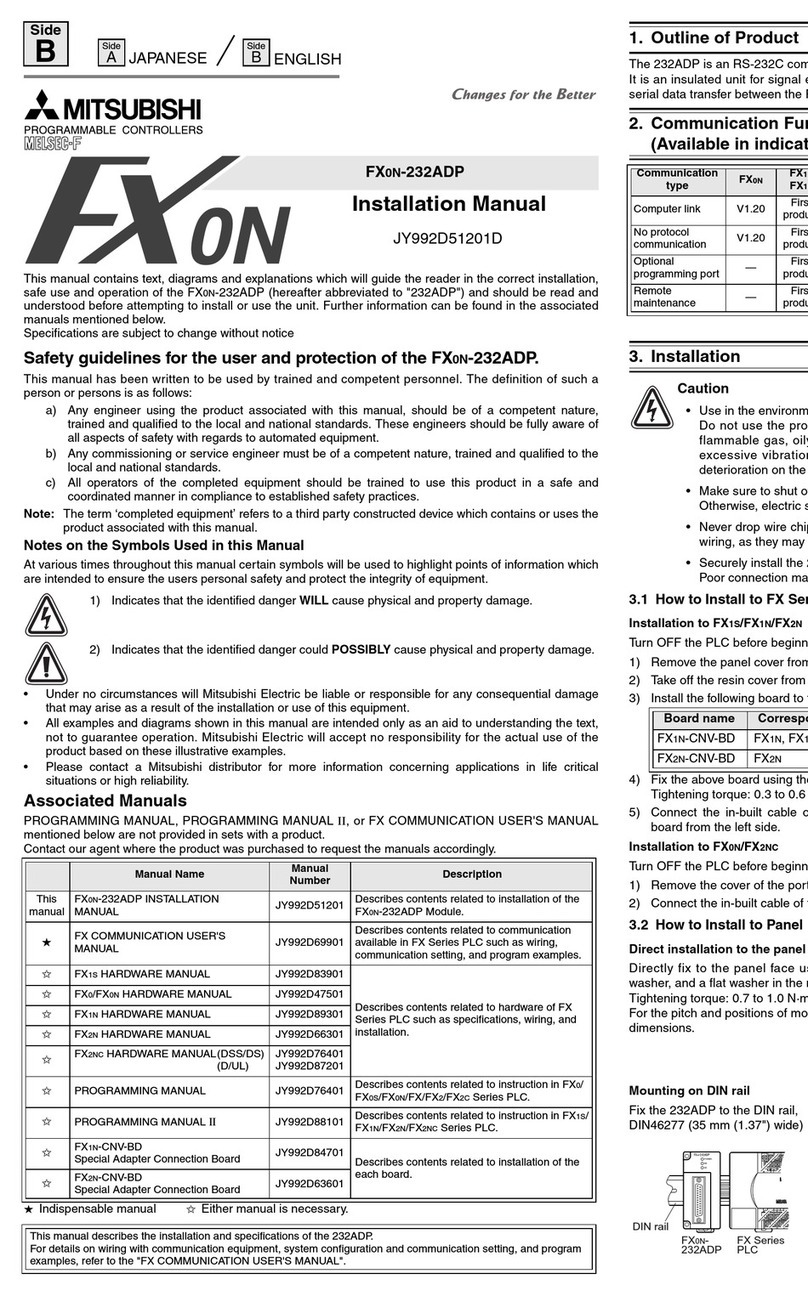

Side

A

Side

BJAPANESE ENGLISH

Side

B

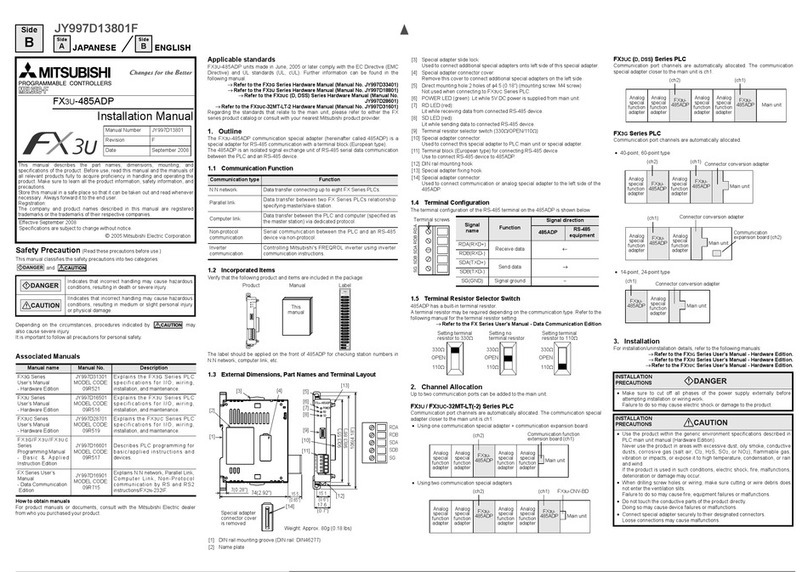

FX1N-485-BD RS-485 COMMUNICATION BOARD

USER’S GUIDE

JY992D84201C

This manual only describes the specifications for RS-485 Communication Board FX1N-485-BD.

For complete operation, wiring, mounting and programming instructions please refer to the FX1S, FX1N

HARDWARE MANUAL and PROGRAMMING MANUAL.

These manuals should be read and understood before attempting to install or use the unit.

Associated Manuals

1. Outline of Product

The RS-485 communication board FX1N-485-BD (hereafter referred to as "485BD") is connected to the

FX1S/FX1N Series PLC basic unit, and available for the applications described below.

Only one function expansion board can be connected to one PLC basic unit. Accordingly, the 485BD cannot

be used together with the FX1N-422-BD or the FX1N-232-BD.

1.1 Features

1) No protocol communication.

The 485BD transfers the data using the RS instruction between a bar code reader, personal computer

or printer.

As the 485BD is not equipped with buffer memory, it sends and receives the data using data registers

specified by the RS instruction.

For the RS instruction and the communication setting, refer to the FX Series User's Manual - Data

Communication Edition.

2) Computer link by dedicated protocol.

The 485BD transfers the data when a personal computer directly specifies devices of the PLC.

For the dedicated protocol and the communication setting, refer to the FX Series User's Manual - Data

Communication Edition.

3) Parallel link.

The 485BD transfers automatically auxiliary relays and data registers when two FX1S Series PLC’s or

two FX1N Series PLC’s are connected on a one-to-one basis.

For the setting procedure and program examples, refer to the FX Series User's Manual - Data Commu-

nication Edition.

4) N:N network.

The 485BD transfers automatically up to 64 auxiliary relays and 8 data registers when up to eight FX1S/

FX1N Series PLC units are connected. For the setting procedure and program examples, refer to the

FX Series User's Manual - Data Communication Edition.

Manual name Manual No. Description

FX1S Series

Hardware Manual JY992D83901 Describes contents related to hardware of FX1S Series PLC such

as specifications, wiring and installation.

FX1N Series

Hardware Manual JY992D88201 Describes contents related to hardware of FX1N Series PLC such

as specifications, wiring and installation.

FX Programming

Manual II JY992D88101 Describes instructions in FX1S/FX1N/FX2N/FX2NC Series.

FX Series User's

Manual - Data

Communication

Edition

JY997D16901

Describes contents related to communication available in FX

Series PLC such as wiring, communication setting and program

examples. (Make sure to read this manual.)

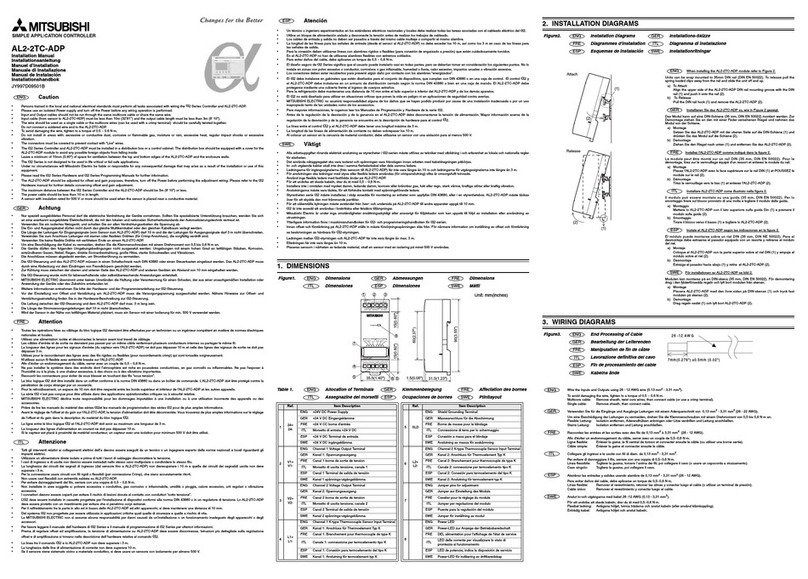

1.2 Outside dimensions and name of each part

1.3 System configuration

For the system configuration, refer to the FX Series User's Manual - Data Communication Edition offered

separately.

2. Installation

2.1 Installation procedure

Make sure to turn off the power before installing the 485BD.

A) Communication board 485BD (function expansion board)

B) Connector for optional equipment

C) M3 screw to fix board (2 pieces) (offered as accessories of board)

D) Top cover for board (offered as an accessory of board)

E) M3 screw to fix top cover (offered as an accessory of board)

Note: Do not remove this screw of FX1S.

• Plug the communication board A) in to the connector B).

• Fix the board to the basic unit with two M3 screws C). (Tightening

torque: 0.3 to 0.6 Nxm)

• Remove the top cover of the basic unit, and attach the top cover for

board D) instead.

During attachment, remove D)’ with a nipper, etc. so that the connector of the board is exposed.

• Fix the top cover with the M3 screw E). (Tightening torque: 0.3 to 0.6 Nxm)

• When the FX1N-5DM is used also, refer to the Hardware manual offered with the FX1S/FX1N Series

PLC main unit.

• Only one function expansion board is available for one FX1S/FX1N Series PLC basic unit. Never stack

up two or more function expansion boards. (Even if they are stacked up, they do not function at all.)

• The 485BD can be used with the FX1N-EEPROM-8L only for program transfer.

(The FX1N-EEPROM-8L cannnot be connected continuously.)

SDBRDA SDARDB SG

38.5 (1.52)

43 (1.69)

SD

➀➁➅

➂

RD

➃➄

➀

Unit: mm (inches)

Accessories: Top cover for board 1

Terminal resistor 330Ω2

Terminal resistor 110Ω1

M3 screw to mount board 2

M3 screw to fix top cover 1

Station No. label for link

➀Mounting hole (2-φ3.5)

➁Connector for PLC

➂Terminal block for RS-485 equipment

The top face of this terminal box is higher than the top face of the

PLC panel cover by approximately 7 mm.

➃SD LED: Flickers at high speed during send.

➄RD LED: Flickers at high speed during receive.

➅Connector for display module FX1N-5DM or memory cassette

FX1N-EEPROM-8L

3. Specifications

3.1 Environmental specifications

The environmental specifications are equivalent to those of the PLC main unit. (Refer to the manual of the

PLC main unit.)

3.2 Power supply specifications

5V DC, 60 mA is supplied as the power from the PLC.

3.3 Performance specifications

Transmission standard In conformance to RS-485 and RS-422

Maximum transmission

distance 50m (164ft) maximum

Communication type No protocol communication, Computer link (dedicated protocol),

parallel link, N:N network

Communication method Half duplex, bi-directional

Communication

procedure

No protocol communication, Computer link (dedicated protocol 1,

dedicated protocol 4), parallel link, N:N network

Transmission speed

(baud rate)

No protocol communication, Computer link (dedicated protocol): 300 to

19200 bps

Parallel link: 19200(bps)

N:N network: 38400(bps)

Insulation None

Guidelines for the safety of the user and protection of the RS-485

Communication Board FX1N-485-BD

• This manual has been written to be used by trained and competent personnel. This is defined

by the European directives for machinery, low voltage and EMC.

• If in doubt at any stage during the installation of the RS-485 Communication Board FX1N-485-

BD always consult a professional electrical engineer who is qualified and trained to the local

and national standards. If in doubt about the operation or use of the RS-485 Communication

Board FX1N-485-BD please consult the nearest Mitsubishi Electric distributor.

• Under no circumstances will Mitsubishi Electric be liable or responsible for any consequential

damage that may arise as a result of the installation or use of this equipment.

• All examples and diagrams shown in this manual are intended only as an aid to understanding

the text, not to guarantee operation. Mitsubishi Electric will accept no responsibility for actual

use of the product based on these illustrative examples.

• Owing to the very great variety in possible application of this equipment, you must satisfy

yourself as to its suitability for your specific application.

Manual number : JY992D84201

Manual revision : C

Date : AUGUST 2006

JY992D84201C

Effective Aug. 2006

Specifications are subject to

change without notice