Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the

cause of Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi

products; damage, secondary damage, accident compensation caused by special

factors unpredictable by Mitsubishi; damages to products other than Mitsubishi

products; and to other duties.

For safe use

• This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

• This product has been manufactured under strict quality control. However when

installing the product where major accidents or losses could occur if the product

fails, install appropriate backup or failsafe functions in the system.

Country/Region Sates office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

Av. Rio Branco, 123-15 ,and S/1507,

Rio de Janeiro, RJ CEP 20040-005,

Brazil

Tel : +55-21-221-8343

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Her ts., AL10

8XB, UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo - Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel:+39-039-60531

Spain Mitsubishi Electric Europe B.V. Spanish

BranchCarretera de Rubi 76-80

08190 - Sant Cugat del Valles,

Barcelona, Spain

Tel:+34-935-653135

South Africa

Circuit Breaker Industries LTD.

Private Bag 2016, Isando 1600,

Johannesburg, South Africa

Tel : +27-11-928-2000

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-2887-8870

Specifications are subject to change without notice

HEAD OFFICE : MITSUBISHI DENKI BLDG MARUNOUTI TOKYO 100-8310 TELEX:J24532 CABLE MELCO TOKYO

HIMEJI WORKS : 840, CHIYODA CHO, HIMEJI, JAPAN

When exported from Japan, this manual does not require application to the Ministry of Economy,

Trade and Industry for service transaction permission.

Country/Region Sates office/Tel

China Ryoden International Shanghai Ltd.

3F Block5 Building Automation

Instrumentation Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6475-3228

Taiwan Setsuyo Enterprise Co., Ltd.

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 ALEXANDRA ROAD #05-01/02,

MITSUBISHI ELECTRIC BUILDING

SINGAPORE159943

Tel : +65-473-2480

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan BlockA Utara

No.1 Kav. No.11 KawasanIndustri/

PergudanganJakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Tel : +91-20-7128927

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

Side

A

Side

BJAPANESE ENGLISH

Side

B

●SAFETY PRECAUTIONS●

This manual describes the name of each part, outside dimensions and

specifications of the CC-Link/LT master block for Mitsubishi Programmable

Controller (PLC).

For the design and construction of the CC-Link/LT system, refer to the CC-

Link/LT Master Block Users Manual.

These ●SAFETY PRECAUTIONS●are classified into two categories:

"DANGER" and "CAUTION".

Depending on certain circumstances, procedures indicated by

may also be linked to serious ramifications.

It is important to follow the directions for usage.

[DESIGN PRECAUTIONS]

[INSTALLATION PRECAUTIONS]

Procedures which may lead to dangerous conditions or

cause death or serious injury if not carried out properly.

Procedures which may lead to dangerous conditions or

cause minor to medium injury, or physical damage, if

not carried out properly.

DANGER

CAUTION

CAUTION

• Construct an interlock circuit in the sequence program so that the

system works correctly using the communication information when an

error in the data link occurs.

If such an interlock circuit is not provided, accidents may be caused by

erroneous output or malfunction.

• When a remote I/O unit fails, inputs/outputs may randomly become ON

or OFF, therefore build an external monitoring circuit that will monitor any

input signals that could cause a serious accident.

Accident may be caused by erroneous output or malfunction.

• Use the master block without applying any force on the master block and

the flat cable dedicated to the CC-Link/LT.

Otherwise, such cables may break or fail.

• Shut down all phases of the power supply outside the master block, then

attach or remove the master block. If the power is not disconnected at all

phases an electric shock or serious damage to the product may occur.

DANGER

CAUTION

DANGER

• Use the master block in the environment described in this manual.

If the master block is used in an improper environment, then electrical

shock, fire, malfunction, product damage or product deterioration may

occur.

• Securely fix the master block with DIN rail or mounting screws. When

using mounting screws, securely tighten them within the specified torque

range.

If the screws are too loose, the module may detach from its installed

position, short circuit, or malfunction. If the screws are too tight, the

screws may be damaged, which may cause the module to detach from

its installed position or short circuit.

CAUTION

[WIRING PRECAUTIONS]

[STARTING AND MAINTENANCE PRECAUTIONS]

[DISPOSAL PRECAUTIONS]

●

●●

●Notification of CE marking●

●●

●

This notification does not guarantee that an entire mechanical module produced

in accordance with the contents of the notification comply with the following

standards. Compliance to EMC standards of the entire mechanical module

should be checked by the user / manufacturer.

Standards with which this product complies

Type : Programmable Controller (Open Type Equipment)

Models : Products manufactured from February 1st, 2003.

For more details please contact the local Mitsubishi Electric sales site.

- Notes For compliance to EMC regulation.

It is necessary to install the FX2N-64CL-M in a shielded metal control panel.

• Pay attention that foreign objects such as cuttings or wiring chips do not enter

the master block. It may cause fire, product failure or malfunction.

• During installation and wiring works, adhere dust-proof sheets supplied

together with the master block on the sides of the master block so that foreign

objects such as cutting chips and wiring chips do not enter the inside.

Otherwise, foreign objects may cause fire, failure or malfunction.

• Before operating the system, remove the dust-proof sheets so that heat can

be released. It may cause fire, product failure or malfunction.

CAUTION

• Shut down all power supplies, before starting the wiring work. If the power is

not disconnected from all sources an electric shock or serious product

damage may occur.

• CC-Link/LT network wiring uses the flat cable dedicated to the CC-Link/LT

specified by CC-Link Partner Association (CLPA), and perform wiring in

accordance with the specifications described in this manual.

If any cable other than the dedicated flat cable is used or if wiring is

performed in a method not conforming to the specifications, normal data

transmission cannot be assured.

• Do not bind the flat cable dedicated to CC-Link/LT together with major circuits

or power cables. Keep the dedicated flat cable away from major circuits and

power cables by 100 mm (3.93") or more.

It may cause malfunction due to noise interference.

• Accommodate the flat cable dedicated to CC-Link/LT inside a duct, or fix it

with clamps.

If the dedicated flat cable is loose or is pulled for movement or carelessness,

the master block and the dedicated flat cable may be damaged or

malfunction due to imperfect connection.

• Correctly wire the master block while confirming the rated voltage and

terminal arrangement of the master block. It may cause fire or product failure.

• Hold the connector area when disconnecting the flat cable dedicated to CC-

Link/LT from the master block.

If the cable area is pulled, the master block or the dedicated cable may be

damaged or malfunction.

• Do not touch the terminals when the power is ON. It may cause an electric

shock or malfunction.

• Make sure to shut down all phases of the power supply outside the master

block before starting cleaning. If all phases of the power supply are not shut

down, the master block may be seriously damaged or malfunction.

• Do not disassemble or modify the master block. Doing so may cause failure,

malfunction, injury, or fire.

• The case of the master block is made of resin. Do not drop or apply strong

impacts to the master block.

DANGER

CAUTION

DANGER

CAUTION

• When disposing of this product, treat it as industrial waste.

Electromagnetic Compatibility Standards

(EMC) Remark

EN61000-6-4:2001

Electromagnetic compatibility

-Generic standards - Emission standard for

Industrial environment

Following item is examined:

- Radiated Emissions

EN61131-2:1994 Programmable controllers

/A11: 1996 -Equipment requirements and

tests

/A12: 2000

Following items are examined:

- RF Immunity - Fast transients

- ESD

- Damped oscillatory wave

DANGER

Associated Manuals

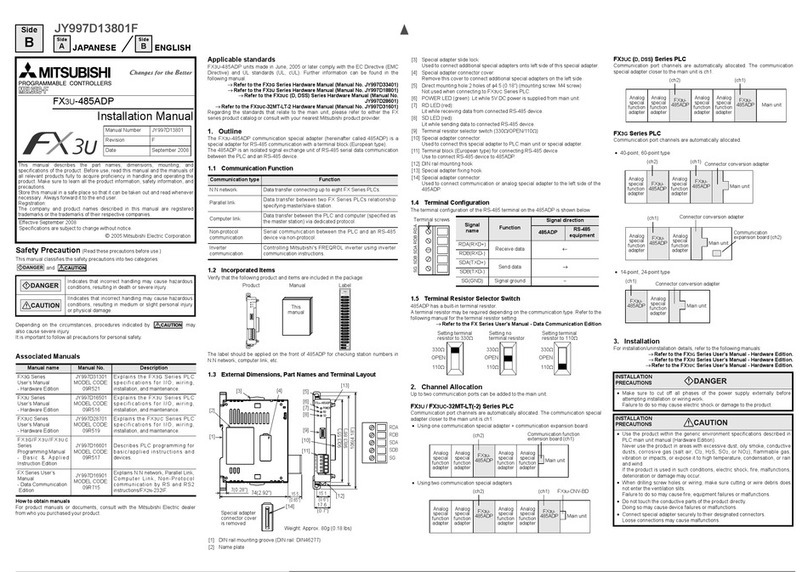

1. Product Outline

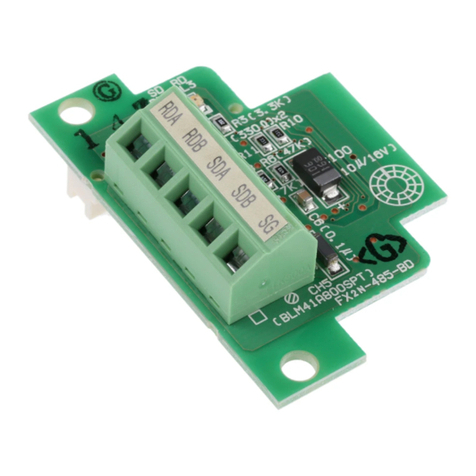

The CC-Link/LT master block FX2N-64CL-M can be connected to the FX Series

PLC.

By using this master block, the CC-Link/LT system can be constructed while

setting the FX Series PLC as the master station.

2. Part Name and Setting

Manual name Manual No. Description

CC-Link/LT Master

Block Model FX2N-

64CL-M User's Manual

(Detailed Volume)

(Japanese only)

JY997D06201

This manual contains the specifications,

wiring, handling, etc. of the CC-Link/LT

master block.

DIP switch for operation setting

Extension cable

connected to PLC

123456 8

OFFON

B RATE

16pts. 4pts.

ONLINE

-

TEST

-

3

2

1

4

5

6

8

--

CONFIG ONLINE

FX

2N

-64CL-M

--

O

N

Extension connector

connected to extension

block/unit or special

block/unit of the PLC

Connector for

CC-Link/LT interface

Hook for installation to DIN rail

2-φ4.5(0.18") mounting hole

(M4 mounting screw)

Status indicator LEDs

LINK

Name Description

Status indicator LEDs

POWER

<ONLINE mode/CONFIG mode/TEST mode>

Lit: Power is supplied

Extinguished: Power is not supplied

RUN

<ONLINE mode>

Lit: Master block is operating normally

Extinguished:Master block is abnormal

Power is interrupted

EEPROM read error (sum mismatch)

occurred

<CONFIG mode>

Lit: Master block is operating normally

Extinguished:Master block is abnormal

Power is interrupted

<TEST mode>

Lit: Master block is operating normally

Extinguished:Master block is abnormal

Power is interrupted

ERR.

<ONLINE mode>

Lit: Communication speed setting error occurred

EEPROM read error (sum mismatch) occurred

Flickering:Power supplied for communication is abnormal

DIP switch for operation setting was changed

during operation

Extinguished:Master block is operating normally

<CONFIG mode>

Lit: Communication speed setting error occurred

EEPROM write error occurred

Flickering:Power supplied for communication is abnormal

DIP switch for operation setting was changed

during operation

Extinguished:Master block is operating normally

<TEST mode>

Lit: Communication speed setting error occurred

Flickering:Power supplied for communication is abnormal

DIP switch for operation setting was changed

during operation

Extinguished:Master block is operating normally

• Factory default, all bits of the DIP switch are set OFF.

• The Test mode is selected when both the CONFIG and TEST mode are

set ON simultaneously.

• For each setting, the status at the time of power ON is valid.

(If a setting is changed after the power is ON, such a change is invalid.)

CONFIGMODE

• BFM #32 (20h) to #95 (5Fh) changed value while online will cause a

L ERR.

• No remote module attached during power ON will result in no L ERR.

• Remote module removed during operation will result in no L ERR.

Name Description

Status indicator LEDs

L RUN

<ONLINE mode/CONFIG mode>

Lit: Data link is being executed

Extinguished: Data link is stopped

<TEST mode>

Lit: Self-loop back Test was finished normally

Extinguished:Self-loop back Test was finished

abnormally

(Extinguished while the self-loop back

Test is being executed)

L ERR.

<ONLINE mode>

Lit: Use station number discrepancy

(when BFM#32(20h) to #95(5Fh) is edited, the

station numbers are checked.)

Outside-control-range station error occurred

Flickering: Stations are abnormal

Extinguished:Data link is being executed normally

<CONFIG mode>

Lit: Use station number discrepancy

(when BFM#32(20h) to #95(5Fh) is edited, the

station numbers are checked.)

Flickering: All stations are abnormal

Extinguished:Data link is being executed normally

<TEST mode>

Lit: Self-loop back Test was finished abnormally

Extinguished:Self-loop back Test was finished normally

(Extinguished while the self-loop back

Test is being executed)

SD <ONLINE mode/CONFIG mode/TEST mode>

Lit: Data is being sent

RD. <ONLINE mode/CONFIG mode/TEST mode>

Lit: Data is being received

Interface Connector to connect the flat cable dedicated to the CC-

Link/LT (24G/DB/DA/+24 V)

DIP switch for operation setting

1

B RATE

Communication speed setting

2

316pts/

4pts

Point mode setting

(Select the number of I/O points per station.)

OFF : 4-point mode (4 input points and 4 output points

in each station)

ON : 16-point mode (16 input points and 16 output

points in each station)

4-- Setting is disabled.

(Make sure that it is OFF during operation.)

5-- Setting is disabled.

(Make sure that it is OFF during operation.)

6CONFIG/

ONLINE

CONFIG mode

OFF : ONLINE mode (normal operation)

ON : CONFIG mode (The information on connected

stations is saved in the EEPROM.)

7TEST/

ONLINE

TEST mode

OFF : ONLINE mode (normal operation)

ON : TEST mode (Self-loop back Test)

8-- Setting is disabled.

(Make sure that it is OFF during operation.)

Communication speed SW1 SW2

156 kbps OFF OFF

625 kbps ON OFF

2.5 Mbps OFF ON

Setting disabled ON ON

3. Handling Cautions

The master block can be attached by way of DIN rail or attached directly

with screws.

The installation procedure in each case is described below.

Use the master block without applying any force on the cable.

3.1 Installation direction

• Do not install the master block on the floor surface, ceiling surface or in

the horizontal direction. If the master block is installed in such a way,

its temperature may rise.

Install the master block vertically on the wall surface as shown in the

figure below.

• Secure a space of 50 mm (1.96") or more between the master block and

other equipment or structure. Keep the master block off high voltage

cables, high voltage equipment and power equipment as much as

possible.

3.2 DIN rail installation

Align the upper DIN rail installation groove in the module with the DIN rail

1), and press the module in that status 2).

When removing the module, pull the hook for installation downwards 3),

then remove the module 4).

DIN rail mounting screw pitch

When installing the module to the DIN rail, tighten the mounting screws at

the pitch of 200 mm (7.87") or less.

3.3 Direct installation

Fix the master block on the panel surface by tightening M4 screws inserted

in two (upper and lower) mounting holes provided on the master block.

Install the module so that a clearance of 1 to 2mm (0.04" to 0.08") is

assured for each module.

4. Connection of External Equipment

Connect the master block to a remote I/O unit or power adapter using the

flat cable and the connector dedicated to CC-Link/LT.

• The connection order of the flat cable dedicated to CC-Link/LT has no

relevance to the station No.

• Make sure to lay out the master block on one side of the trunk line.

• In the CC-Link/LT system, terminating resistors should be connected to

both ends of the trunk line.

At this time, connect the terminating resistor on the master block side to a

position within 200 mm (7.87") from the master block.

• For the point of contact for the flat cable dedicated to CC-Link/LT, the

connector to connect the flat cable and terminating resistors, refer to the

homepage of the CC-Link Partner Association (CLPA) "http://www.cc-

link.org/".

Applicable DIN rail TH35-7.5Fe and TH35-7.5AI (conforming to JIS C2812)

1)

Installation Removal

2) 3)

4)

Applicable screw M4 height: 16mm(0.63") or more

(Tightening torque range: 78 to 108 N⋅

⋅⋅⋅cm)

5. Specifications

5.1 General specifications

5.2 Network wiring specifications

Item Specification

Operating

temperature 0 to 55°C (32 to 131°F)

Storage

temperature -20 to 70°C (-4 to 158°F)

Operating

humidity 35 to 85%RH (Dew condensation should not be allowed.)

Vibration

resistance

Conforming

to

EN68-2-6

Direct mounting

Number of

times of

sweep

Frequency

Acceleration Half amplitude

10 times in

each of X,

Y and Z

directions

(for 80

min)

10 to 57Hz

−0.075mm

57 to 150Hz

9.8m/s2−

DIN rail mounting

Frequency

Acceleration Half amplitude

10 to 57Hz

−0.035mm

57 to 150Hz

4.9m/s2−

Shock

resistance

In conformance to EN 68-2-27 (147 m/s2, working time: 11 ms,

half sine wave, three times in each of X, Y and Z directions)

Noise immunity By noise simulator of noise voltage = 1,000 Vp-p,

noise width = 1 µs, rising = 1 ns, cycle = 30 to 100 Hz

Dielectric

withstand

voltage

500V AC for 1 min In conformance to JEM-

1021

Between case and PLC

grounding terminal

Isolation

resistance 5 MΩor more by 500V DC megger

Operating

ambience

Should be free from corrosive gas, flammable gas and

conductive dusts. Do not use.

Grounding Grounding resistance 100Ωor less (Common grounding with

strong electrical systems.)

Item Specification Remarks

Communication

speed 2.5Mbps 625kbps 156kbps --

Distance between

stations No restriction --

Maximum number of

modules connected

in 1 drop line

8 units --

Maximum trunk

length

35m

(114' 9")

100m

(328' 1")

500m

(1640' 5")

Cable length between

terminating resistors

T-branch interval No restriction --

Maximum drop

length 4m(13' 1") 16m

(52' 5")

60m

(196' 10")

Cable length per

branch

Cumulative drop line

length

15m

(49' 2")

50m

(164' 0")

200m

(656' 2") Sum of all drop lines

Master station

Terminating

resistor

T branch

connection T-branch interval

Power

adapter Remote

I/O station

Remote

I/O station

Drop length

(including branch)

Remote

I/O station

Remote

I/O station

Remote

I/O station

Remote

I/O station

Distance between

stations

Terminating

resistor

Trunk length (branch line length not included)

Trunk line

Drop line

5.3 Performance specifications

*1 When connected to the FX1N Series PLC, up to two FX2N-64CL-M units can be

connected to each of the main unit and extension unit.

*2 FX2N-64CL-M draws 190mA from the 5V DC source.

The total 5V consumption of all special function blocks connected to a main unit

or extension unit must not exceed the 5V source capacity of the system.

(Refer to the Hardware manual of the Programmable controller)

Item Specification

Applicable PLC

FX1N/FX2N/FX2NC Series PLC

(FX2NC-CNV-IF is required when FX2NC

Series PLC is connected.)

Number of connectable master

blocks

FX1N Series : Up to 4 *1

FX2N Series : Up to 8 *2

FX2NC Series: Up to 3 *2

Applicable point mode 4-point mode and 16-point mode

(selectable by DIP switch)

Control specifications

4-point mode 16-point mode

Maximum number of link

points

Connected to FX1N Series PLC: 128 points

Connected to FX2N/FX2NC Series PLC: 256

points

(including I/O points in PLC in each case)

Number of link points per

station

( ) shows the number of link

points when composite I/O

module is used.

4 points (8 points) 16 points (32 points)

Link scan time

32 stations

2.5Mbps 0.7ms 1.0ms

625kbps 2.2ms 3.8ms

156kbps 8.0ms 14.1ms

64 stations

2.5Mbps 1.2ms 2.0ms

625kbps 4.3ms 7.4ms

156kbps 15.6ms 27.8ms

Communication specifications

Communication speed 2.5 Mbps, 625 kbps and 156 kbps

(selectable by DIP switch)

Protocol

BITR method

(Broadcastpolling +

Interval Timed Response)

Network topology T- b r a n c h

Error control method CRC

Number of connected stations 64 stations maximum

Remote station numbers 1 to 64

Master station connection

position Connected at end of trunk line

RAS function

Communication error detection, automatic

return to system, slave station

disconnection and internal loop back

diagnosis

Connection cable Dedicated flat cable (0.75 mm2x 4)

Number of occupied I/O points 8 points (fixed) +

Number of connected remote I/O points

Current consumption inside 5V DC

190 mA

(Supplied from PLC via extension

connector)

24V DC power

supply

Volt a ge 20.4V to 28.8V DC Supplied from power

adapter via

connector for CC-

Link/LT interface.

Current

consumption 25 mA

Initial current 35 mA

Mass (weight) 0.15 kg (0.33 lbs)

6. Outside Dimensions