Mitsubishi MELSEC A1SCPUC24-R2 Instructions for use

Other Mitsubishi Controllers manuals

Mitsubishi

Mitsubishi CR800 Series User manual

Mitsubishi

Mitsubishi FX3G-4EX-BD User manual

Mitsubishi

Mitsubishi AL-232CAB User manual

Mitsubishi

Mitsubishi MELSEC Q Series User manual

Mitsubishi

Mitsubishi AJ65BT-R2 User manual

Mitsubishi

Mitsubishi QD75M1 User manual

Mitsubishi

Mitsubishi FX1N-14MR-ES/UL User manual

Mitsubishi

Mitsubishi MELDAS TRS50 User manual

Mitsubishi

Mitsubishi MELSEC-F FX-TRN-BEG-E User manual

Mitsubishi

Mitsubishi MELSEC-A User manual

Mitsubishi

Mitsubishi MELSEC iQ-R series User manual

Mitsubishi

Mitsubishi MELSEC-F FX-10DM-E User manual

Mitsubishi

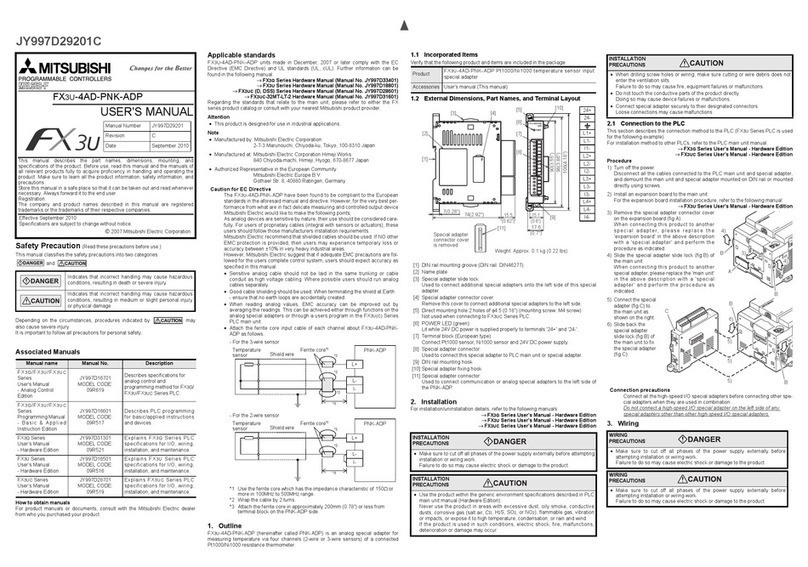

Mitsubishi FX3U-4AD-PNK-ADP User manual

Mitsubishi

Mitsubishi q64rd User manual

Mitsubishi

Mitsubishi MELSEC iQ-F series User manual

Mitsubishi

Mitsubishi MELSEC Q Series User manual

Mitsubishi

Mitsubishi MELSEC Q Series User manual

Mitsubishi

Mitsubishi FX0N-16NT User manual

Mitsubishi

Mitsubishi MELSEC-AnS Series User manual

Mitsubishi

Mitsubishi A1SJH User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions