Safety Precautions

(Read these precautions before using.)

(2)

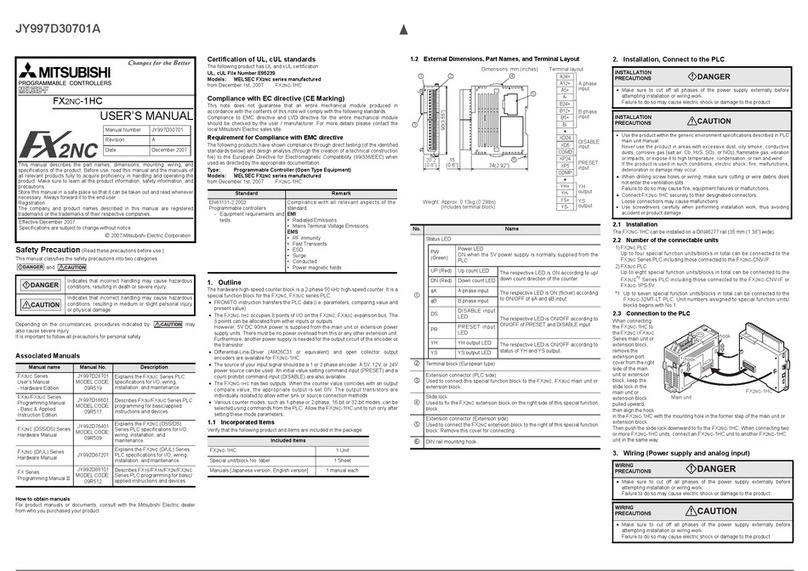

3. WIRING PRECAUTIONS

Reference

• Fit the extension cables, peripheral device connecting cables, input/output cables and battery connecting cable

securely to the designated connectors.

Contact failures may cause malfunctions.

• Use the product in the environment within the generic specifications described in section 3.1 of this manual.

Never use the product in areas with dust, oily smoke, conductive dusts, corrosive gas (salt air, Cl2, H2S, SO2or

NO2), flammable gas, vibration or impacts, or expose it to high temperature, condensation, or wind and rain.

If the product is used in such a place described, electrical shock, fire, malfunctions, damage, or deterioration may

be caused.

• Do not touch the conductive parts of the product directly, thus avoiding failure or malfunctions.

• Install the product securely using a DIN rail or mounting screws.

• Install the product on a flat surface.

If the mounting surface is rough, undue force will be applied to the PC board, thereby causing nonconformities.

• When drilling screw holes or wiring, cutting chips or wire chips should not enter ventilation slits. such an accident

may cause fire, failures or malfunctions.

• Be sure to remove the dust proof sheet from the PLC's ventilation port when the installation work is completed.

Failure to do so could cause fires, equipment failures, and malfunctions.

• Make sure to attach the terminal cover offered as an accessory to the product before turning on the power or

starting the operation after installation or wiring work.

Failure to do so may cause electric shock.

23

Reference

• Make sure to cut off all phases of the power supply externally before starting the installation or wiring work.

Failure to do so may cause electric shock. 25

Reference

• Connect the DC power supply wiring to the dedicated terminals described in this manual.

If an AC power supply is connected to a DC input/output terminal or DC power supply terminal, the PLC will be burnt

out.

• Perform class D grounding (grounding resistance: 100. or less) to the grounding terminal in the 20SSC-H with a

wire as thick as possible. Do not connect the grounding terminal at the same point as a heavy electrical system

(refer to subsection 5.2.2).

• Make sure to attach the terminal cover offered as an accessory to the product before turning on the power or

starting the operation after installation or wiring work.

Failure to do so may cause electric shock.

• Cables and wires for input to the 20SSC-H must be connected to their corresponding dedicated connectors as

described in this manual. For example, if you connect an AC power cable to a DC input connector, they will burn

out.

• Do not wire vacant terminals externally.

Doing so may damage the product.

• When drilling screw holes or wiring, cutting chips or wire chips should not enter ventilation slits. such an accident

may cause fire, failures or malfunctions.

• Properly perform wiring to the FX Series terminal blocks following the precautions below in order to prevent

electrical shock, short-circuit, breakage of wire, or damage to the product:

- The disposal size of the cable end should follow the dimensions described in this manual.

- Tightening torque should be between 0.5 to 0.8 N•m.

• Do not wire or bundle the SSCNET III cable with the main circuit cable, power cable and/or other such load carrying

cables other than those for the PLC. Separate these cables at least 100mm (3.94") from each other.

Noise and Surge induction interfere with the system operation.

• When pulling out SSCNET III cable from the connector, be sure to put the cap on SSCNET III connector.

If the SSCNET III end face is dirty, optical transmission is interrupted and it may cause malfunctions.

• Do not see directly the light generated from SSCNET III connector of servo amplifier or 20SSC-H.

When the light gets into the eyes, it causes discomformity in the eyes.

(The light source of SSCNET III corresponds to class1 defined in JISC6802 or IEC60825-1.)

• If SSCNET III cable is added a power such as a major shock, lateral pressure, haul, sudden bending or twist, its

inside distorts or breaks, and optical transmission will not be available.

SSCNET III cable should be given loose slack to avoid from becoming smaller than the minimum bend radius, and

it should not be twisted.

• Make sure to use SSCNET III cable within the range of operating temperature (refer to subsection 5.1.1) described

in this manual.

The optical cable and code part melts down if being left near the fire or high temperature. Therefore, do not make it

touched the part which becomes high temperature, such as radiator or regenerative brake option of servo amplifier,

or servomotor.

25