Remark :

1. Installation location of circuit breaker should be easy

to operation and shut off.

2. The circuit breaker shall have a contact separation in

all poles and provide full disconnection under

overvoltage category III condition in accordance

with the wiring rules.

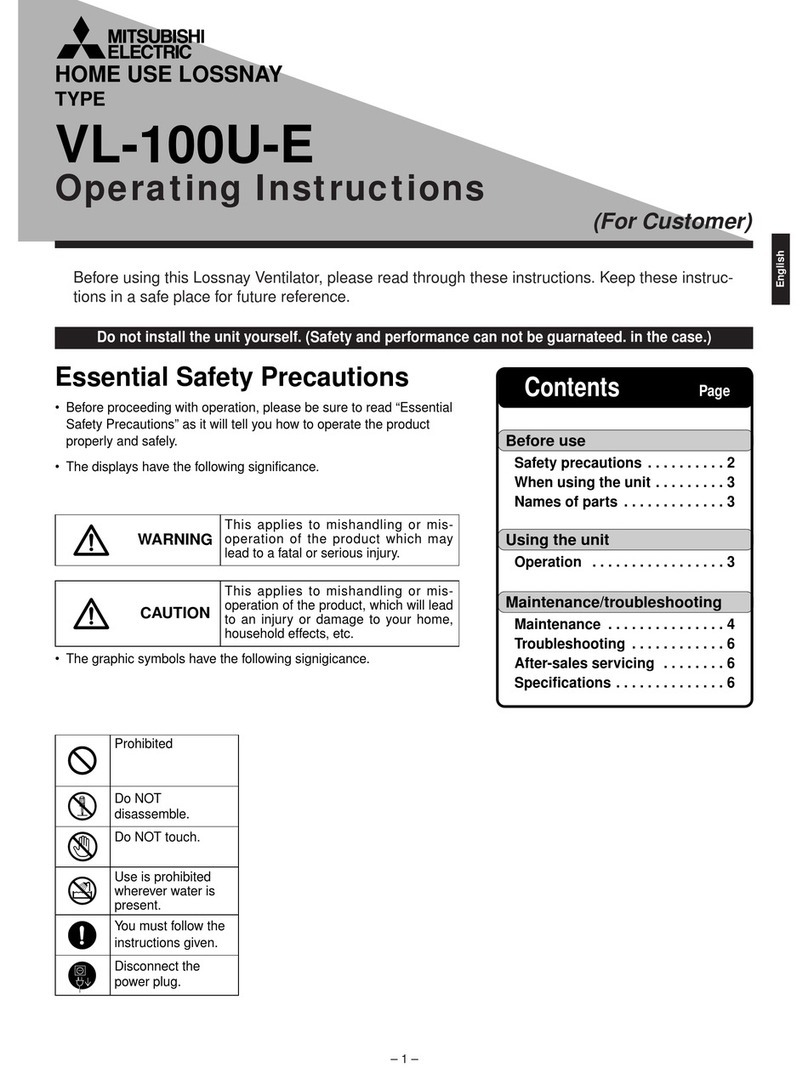

CAUTION

Pay attention to connect the wire,1 wire

from power supply especially common

wire connect with the “N(COM)” terminal.

SLIDE COVER

HOOK

WALL

SWITCH

*

Thermal

fuse

VENTILATOR MAIN UNIT

VVF

LEAD WIRE

1.6 mm or

2.0 mm

Figure.

Figure.

Figure.

Figure.

Continue

CONDUCTOR

STRIPPED WIRE

TERMINAL

TERMINAL

STRIPPED WIRE

TERMINAL

COVER

LEAD WIRE

LEAD WIRE

SCREW

SCREW

TERMINAL

COVER

CAUTION

GROUND

TERMINAL

GROUND

TERMINAL

Insert the tip of the flathead

screwdriver here.

Leadwire size for installation

To peel off lead wire 10 mm.

To pull wiring approx. 150 mm from the product.

To separate wiring from connecting board, then push

red button on connecting board and pull each wiring

with Screw Driver.

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

(1) Remove screw and unlock cover, weave VVF (Ø1.6, Ø2.0)

through rubber button until it can be completely passed.

(2) The product is used in high humidity area, the ground wiring

should be installed.

(3) To lock the cover and fix to screw.

General connector and electric line procedure

Lead wire connector method

Model :

Model :

(as Figure. )

as Figure.

1. Must use indoor wiring VVF cable Ø1.6 mm or Ø2.0 mm

2. In case of install ground wiring must install ground at least

1.0 mm and must install to Industrial Standard

Ground Rod by specialized technician.

22

2

Do not connect the ground wire to Gas duct, Water pipe

Lightning rod or Telephone line because may

occur electric shock.

CIRCUIT

BREAKER

*

WALL SWITCH is obtained from hardware store.

157