4

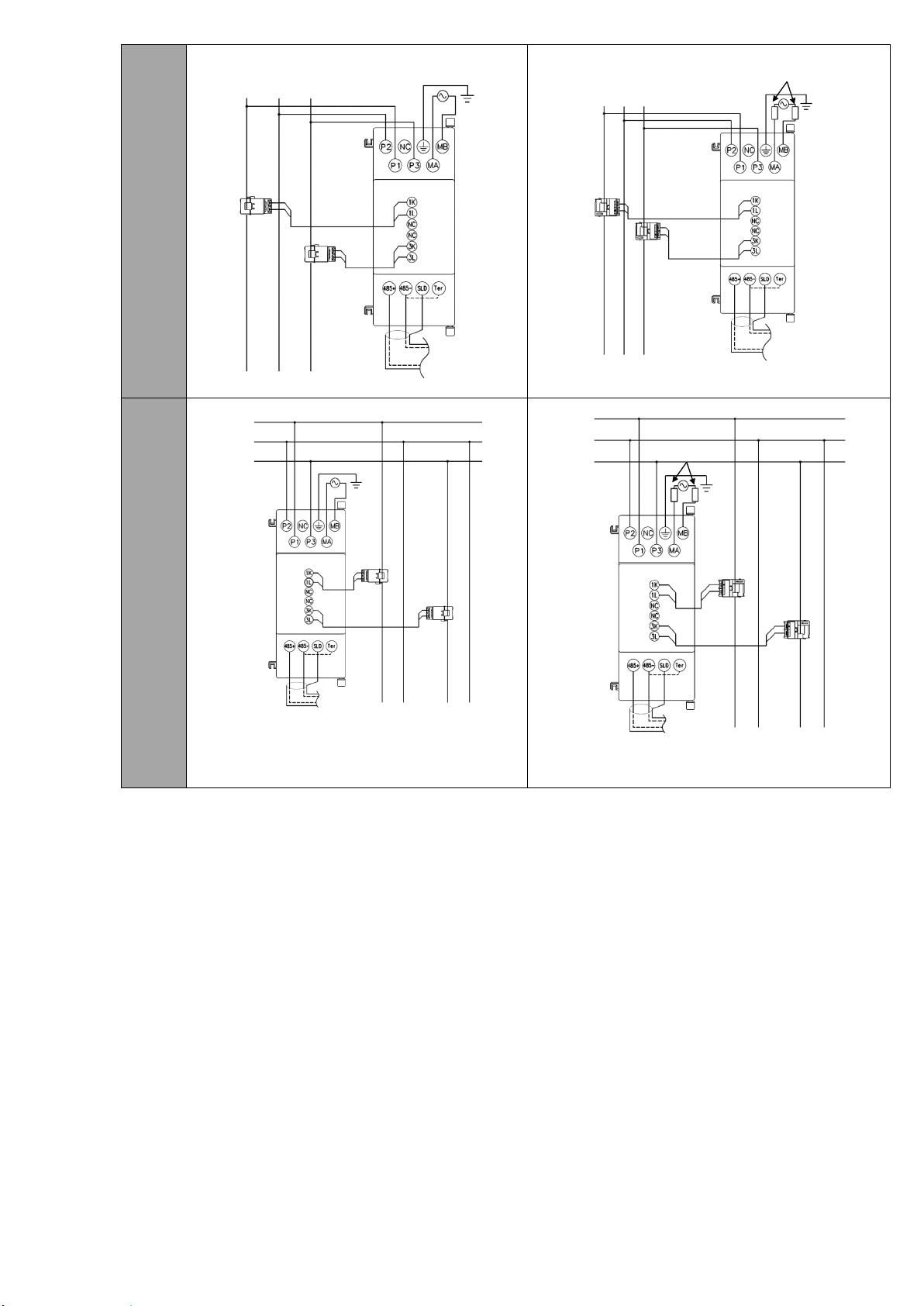

<Connection with the current sensor>

・When using this product, make sure to use it in combination with current sensor (EMU-CT**, EMU-CT**-A. EMU2-CT5

and EMU2-CT5-4W). This product cannot connect with the secondary side (5A) of current transformer. Please not to

exceed the rating of this product for input of current sensor. For further details, please refer to current sensor manual to

maintain the functionality and the accuracy of this product.

・The dedicated current sensor (EMU-CT**, EMU-CT**-A) is used only for low voltage circuit. It cannot be used for a high

voltage circuit. EMU2-CT5 and CT5-4W should be used with the secondary side (5A) of transformer transfixed. If it is

connected with a high-voltage circuit by mistake, it may cause a burnout of the device and a fire. It is critically dangerous.

For the allowable maximum voltage of current sensor, refer to “12. Option devices” in this manual.

・The dedicated current sensor has a polarity (directionality). Be careful about it when installing the unit.

・If the wires connected to this unit are strongly pulled off, it may cause a malfunction or a breakage to the unit or the wire.

<Connection of frame GND terminal>

・Do not exceed the specified voltage when doing an insulation resistance test and a commercial frequency withstand

voltage test.

・Frame FG terminal must be grounded according to the D-type ground.

・To prevent persons with little knowledge about electric equipment from electric shock, panel must be taken either

following measure.

Lock the panel so that only those who get an education about electric equipment and have sufficient knowledge can

unlock, or shut off power supply automatically by opening the panel.

Cover the dangerous part of this unit.

This unit cannot be used for deal and proof of electric energy measurement stipulated in the measurement law.

Before operating the product, check that active bare wire and so on does not exist around the product. If any bare wire exists,

stop the operation immediately, and take an appropriate action such as isolation protection.

In the event of a power outage during the setting by Display unit / Communication line, the Energy Measuring unit is not set

correctly. Please set again after power recovery.

Do not disassemble or modify this unit. It may cause failure, malfunction, injury or fire.

Use this unit within the ratings specified in this manual. If it is used outside the ratings, it may cause not only

malfunction or failure but also fire burnout.

The secondary side of the models EMU2-CT5, EMU-CT50, EMU-CT100, EMU-CT250,EMU-CT50-A, EMU-CT100-A,

EMU-CT250-A, EMU-CT400-A, EMU-CT600-A is equipped with the protective circuit against opening of secondary

terminals. Opening them during the wiring work causes no problems. However, for safety, please do not continuously

energize the module with the terminals open.

The current sensors dedicated to this unit EMU-CT400/600 resemble the split current transformer for general gauges

CW-5SL closely in appearance. However, characteristics are completely different. Be sure to connect the dedicated

current sensor. Connecting CW-5SL to this unit directly may cause failure of the device, a burnout or a fire.

Push the RESET switch with an appropriate force (1.6N). The addition of force than necessary, it may cause a

malfunction or failure of the Unit.

1.5 Maintenance Precautions

Use a soft dry cloth to clean off dirt of the unit surface. Do not let a chemical cloth remain on the surface for an extended period

of time nor wipe the surface with thinner or benzene.

Check for the following items to use this unit properly for long time.

(1) Daily maintenance

(a) No damage on this unit

(b) No abnormality with LCD indicators

(c) No abnormal noise, smell or heat

(2) Periodical maintenance (Once every 6 months to 1 year)

- No looseness with installation and wire connection

Caution

Do periodical maintenance under the electric outage condition. Failure to do so may cause

electric shock, failure of the unit or a fire. Tighten the terminal regularly to prevent a fire.

To store this unit, turn off the power and remove wires, and put it in a plastic bag.

For long-time storage, avoid the following places. Failure to follow the instruction may cause a failure and reduced life of the unit.

- Places the Ambient temperature exceeds the range -10 - +60°C.

- Places the average daily temperature exceeds 35°C.

- Places the Relative humidity exceeds the range 30-85% or places with dewfall.

- Vibration and impact exceed the specifications.

- Dust, corrosive gas, saline and oil smoke exist.

- Places metal fragments or conductive substances are flying.

- Place where metallic particles or inductive substances are dispersed

When disposing of this unit, treat it as industrial waste.