4

5 Processing according to ISO 17664

5.1 Processing at the locaon of use

WARNING

Risk of infection due to non-sterile instruments

→ Always wear gloves.

Process the instrument within one hour aer each treatment in order to prevent piling.

Immediately remove any debris of cement, blood or composite.

Ensure a dry transport of the instrument to the place of processing.

Do not put the instrument in any kind of soluon.

5.2 Cleaning

WARNING

Dysfunctions due to cleanings in an ultrasonic bath

→ Only clean the instrument as described below.

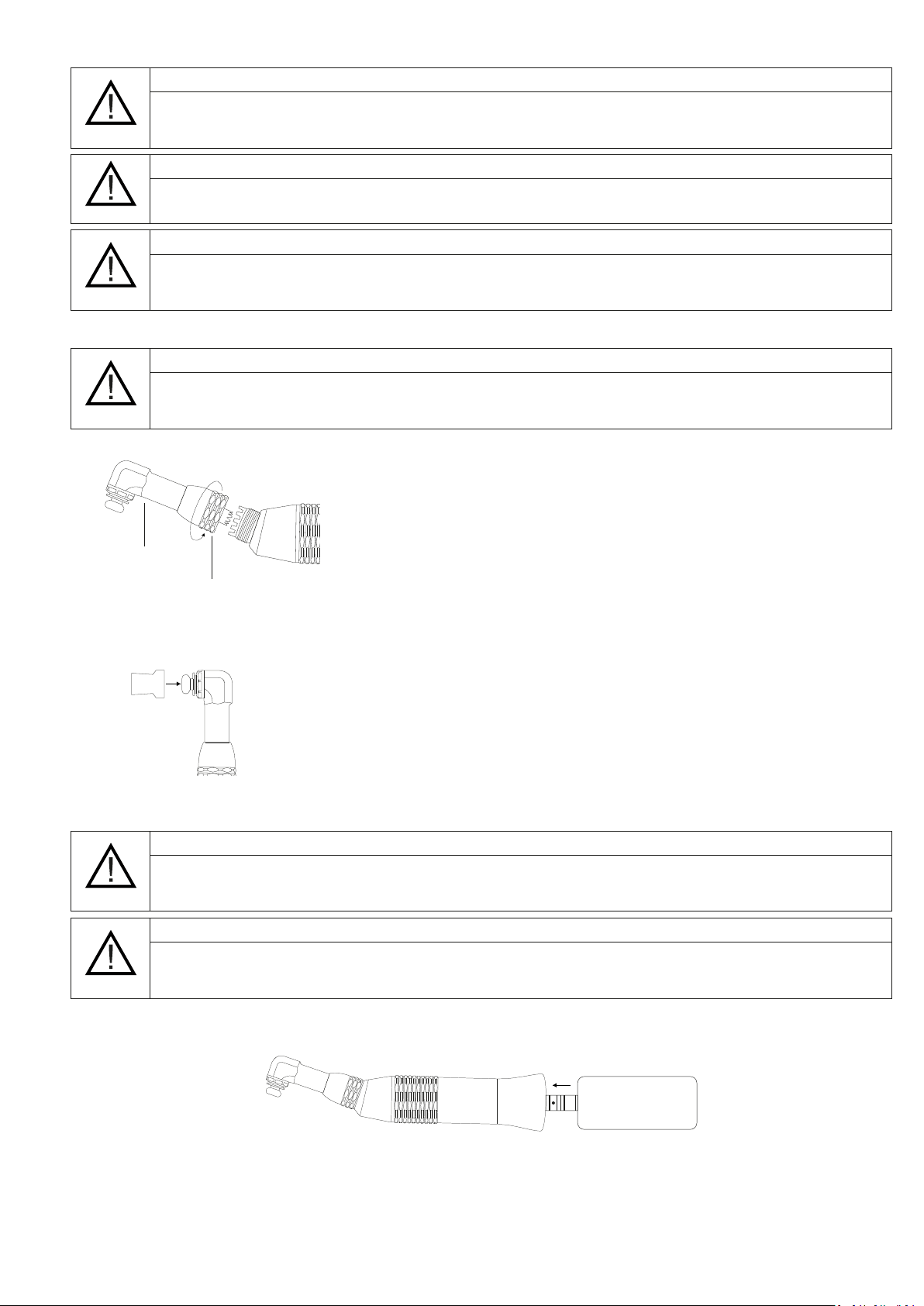

5.2.1 Manual pre-cleaning

CAUTION

Risk of infection due to multiple uses of dental brushes

→ To prevent cross infections always use a new dental brush for each instrument.

CAUTION

Insufficient cleaning of the surface and the water- and air pipes

→ In order to ensure a successful cleaning a thorough manual pre-cleaning, even with the small brush, must be done.

Tools:

- Drinkable water 30 °C ± 5 °C (86 °F ± 10 °F)

- Brush or so tooth brush

- Dental brush

- 50 ml syringe without cannula

To pre-clean the instrument place it under running water and carefully brush debris completely o the surface by using one of the tools menoned

above.

To pre-clean the spindle, please insert the enclosed dental brush in the spindle opening. Carefully loosen/remove any residue and debris by

circular moons with the brush.

Repeat the process several mes and each me clean the dental brush with water.

To pre-clean the water- and air pipes place the syringe at the lower end of the handpiece and rinse the cavies at least 5 mes.

5.3 Disinfecon

CAUTION

The use of disinfecng baths and/or of chlorinated disinfectants may lead to defects and dysfuncons of the instrument.

→ Only clean and disinfect the instrument in a thermal disinfector.

5.3.1 Manual disinfecon of the surface

Only use disinfectants whose microbiological eecveness is ensured by the manufacturer (e.g. VAH/DGHM-regis-traon and CE-mark).

Concerning the material compability, only disinfectants free of aldehyde and based on alcohol may be used.

Apply the disinfectant to a cloth and wipe the instrument clean.

Consider the reacng me that is set by the manufacturer of the disinfectant.

Follow the manual for the disinfectant.

5.3.2 Mechanical cleaning and disinfecon of the interior and the exterior

MK-dent recommends thermal disinfectors that fulll the EN ISO 15883-1 requirements and are approved by the manufacturer for the

straight- and contra angle, as well as for high speed handpieces. The cleaning should be carried out at a minimum of 55°C (131°F) and for

at least 5 minutes, the disinfecon at a minimum of 90°C (194°F) and for at least 5 minutes (for an A0-value > 3,000). For the cleaning a

mild alkaline cleaning agent with a pH of 9 to 11 is recommended, like e.g. Neodisher® MediClean Forte. For the validaon of the process

see chapter 6.2 Validaon of the processing.

For the internal cleaning the adaptors specied by the manufacturer must be used.

Repeat the process, if visible contaminaons sll exist aer the treatment in a thermal disinfector.

Before use the instrument must be dry and free of residues.

To prevent any kind of impairments of the instrument, make sure aer every cycle that the instrument is dry on the inside and the outside.

Directly aerwards use the MK-dent Premium Service Oil to lubricate the instrument.